Delivering effective Waste Minimisation - Wrap

Delivering effective Waste Minimisation - Wrap

Delivering effective Waste Minimisation - Wrap

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Delivering</strong> <strong>effective</strong> <strong>Waste</strong> <strong>Minimisation</strong> 03<br />

1.0 Introduction<br />

The construction industry is the UK’s largest<br />

consumer of natural resources, using over<br />

400 million tonnes of material per annum.<br />

It generates more than one-third of the UK’s<br />

waste arisings, of which only half is reused<br />

or recycled (primarily aggregates and metals).<br />

Over 60 million tonnes of construction sector<br />

waste is sent to landfill or similar disposal<br />

sites every year.<br />

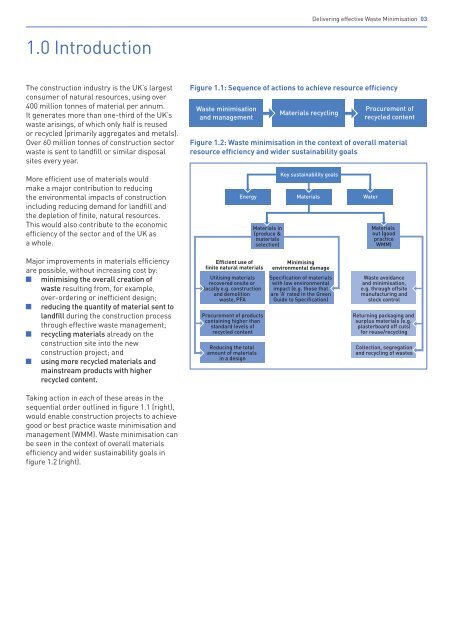

Figure 1.1: Sequence of actions to achieve resource efficiency<br />

<strong>Waste</strong> minimisation<br />

and management<br />

Materials recycling<br />

Procurement of<br />

recycled content<br />

Figure 1.2: <strong>Waste</strong> minimisation in the context of overall material<br />

resource efficiency and wider sustainability goals<br />

More efficient use of materials would<br />

make a major contribution to reducing<br />

the environmental impacts of construction<br />

including reducing demand for landfill and<br />

the depletion of finite, natural resources.<br />

This would also contribute to the economic<br />

efficiency of the sector and of the UK as<br />

a whole.<br />

Energy<br />

Materials in<br />

(produce &<br />

materials<br />

selection)<br />

Key sustainability goals<br />

Materials<br />

Water<br />

Materials<br />

out (good<br />

practice<br />

WMM)<br />

Major improvements in materials efficiency<br />

are possible, without increasing cost by:<br />

minimising the overall creation of<br />

waste resulting from, for example,<br />

over-ordering or inefficient design;<br />

reducing the quantity of material sent to<br />

landfill during the construction process<br />

through <strong>effective</strong> waste management;<br />

recycling materials already on the<br />

construction site into the new<br />

construction project; and<br />

using more recycled materials and<br />

mainstream products with higher<br />

recycled content.<br />

Efficient use of<br />

finite natural materials<br />

Utilising materials<br />

recovered onsite or<br />

locally e.g. construction<br />

and demolition<br />

waste, PFA<br />

Procurement of products<br />

containing higher than<br />

standard levels of<br />

recycled content<br />

Reducing the total<br />

amount of materials<br />

in a design<br />

Minimising<br />

environmental damage<br />

Specification of materials<br />

with low environmental<br />

impact (e.g. those that<br />

are ‘A’ rated in the Green<br />

Guide to Specification)<br />

<strong>Waste</strong> avoidance<br />

and minimisation,<br />

e.g. through offsite<br />

manufacturing and<br />

stock control<br />

Returning packaging and<br />

surplus materials (e.g.<br />

plasterboard off cuts)<br />

for reuse/recycling<br />

Collection, segregation<br />

and recycling of wastes<br />

Taking action in each of these areas in the<br />

sequential order outlined in figure 1.1 (right),<br />

would enable construction projects to achieve<br />

good or best practice waste minimisation and<br />

management (WMM). <strong>Waste</strong> minimisation can<br />

be seen in the context of overall materials<br />

efficiency and wider sustainability goals in<br />

figure 1.2 (right).