Guidelines for the Control of Legionella in Manufactured Water ...

Guidelines for the Control of Legionella in Manufactured Water ...

Guidelines for the Control of Legionella in Manufactured Water ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Guidel<strong>in</strong>es</strong><br />

<strong>for</strong> <strong>the</strong> <strong>Control</strong><br />

<strong>of</strong> <strong>Legionella</strong><br />

<strong>in</strong> <strong>Manufactured</strong> <strong>Water</strong> Systems<br />

<strong>in</strong> South Australia, 2008<br />

Revised 2013

<strong>Control</strong> <strong>of</strong> <strong>Legionella</strong> <strong>in</strong> <strong>Manufactured</strong> <strong>Water</strong> Systems <strong>in</strong> South Australia<br />

Prepared by:<br />

Health Protection Programs<br />

Public Health Services<br />

Public Health and Cl<strong>in</strong>ical Systems<br />

Department <strong>for</strong> Health and Age<strong>in</strong>g<br />

on <strong>the</strong> recommendation <strong>of</strong> <strong>the</strong> Chief Public Health Officer<br />

National Library <strong>of</strong> Australia Catalogu<strong>in</strong>g-<strong>in</strong>-Publication Entry<br />

Title:<br />

<strong>Guidel<strong>in</strong>es</strong> <strong>for</strong> <strong>the</strong> control <strong>of</strong> legionella <strong>in</strong><br />

manufactured water systems <strong>in</strong> South Australia / Health Protection Programs.<br />

Edition: Revised 2013<br />

ISBN:<br />

Subjects:<br />

9781742435169 (paperback)<br />

<strong>Legionella</strong> – South Australia – Prevention.<br />

Microbial contam<strong>in</strong>ation – South Australia – Prevention.<br />

<strong>Water</strong>borne <strong>in</strong>fection – South Australia – Prevention.<br />

<strong>Water</strong> – Pollution – Health aspects – South Australia – Prevention.<br />

O<strong>the</strong>r Authors/Contributors:<br />

South Australia. Department <strong>for</strong> Health and Age<strong>in</strong>g. Health Protection Programs<br />

Dewey Number: 614.59241

Foreword<br />

Foreword<br />

In a modern and highly mechanised world, water is used <strong>in</strong> a wide range <strong>of</strong> devices designed to improve standards <strong>of</strong><br />

liv<strong>in</strong>g. However, <strong>the</strong>se devices have to be correctly managed and ma<strong>in</strong>ta<strong>in</strong>ed to ensure that <strong>the</strong>y do not present risks<br />

to human health. There are many micro-organisms that can grow <strong>in</strong> water and, while most are harmless, some may<br />

give rise to human illness.<br />

<strong>Manufactured</strong> water systems that conta<strong>in</strong> heated water and produce aerosols are <strong>of</strong> particular concern. Although this<br />

<strong>in</strong>cludes a diverse range <strong>of</strong> devices, some evaporative water-based air-cool<strong>in</strong>g systems, warm water systems and spas<br />

have been identified as hav<strong>in</strong>g <strong>the</strong> greatest potential to grow and dissem<strong>in</strong>ate <strong>Legionella</strong>, <strong>the</strong> cause <strong>of</strong> Legionnaires’<br />

disease and Pontiac Fever.<br />

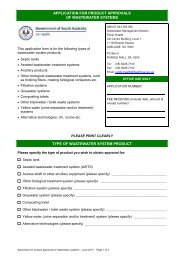

Pursuant to section 109(2)(o) <strong>of</strong> <strong>the</strong> South Australian Public Health Act 2011 (<strong>the</strong> Act), this document is a prescribed<br />

guidel<strong>in</strong>e to assist <strong>in</strong> <strong>the</strong> adm<strong>in</strong>istration and operation <strong>of</strong> <strong>the</strong> South Australian Public Health (<strong>Legionella</strong>) Regulations<br />

2013 (<strong>the</strong> <strong>Legionella</strong> Regulations). Schedule 3 conta<strong>in</strong>s <strong>the</strong> mandatory decontam<strong>in</strong>ation procedures prescribed by <strong>the</strong><br />

<strong>Legionella</strong> Regulations.<br />

Although this Guidel<strong>in</strong>e applies to a range <strong>of</strong> manufactured water systems, <strong>the</strong> focus <strong>of</strong> <strong>the</strong> <strong>Legionella</strong> Regulations<br />

is on high risk manufactured water systems; namely, cool<strong>in</strong>g water systems and warm water systems. This Guidel<strong>in</strong>e<br />

specifies:<br />

> ma<strong>in</strong>tenance and decontam<strong>in</strong>ation procedures;<br />

> <strong>the</strong> keep<strong>in</strong>g <strong>of</strong> records and manuals;<br />

> <strong>the</strong> responsibilities <strong>of</strong> owners and occupiers <strong>of</strong> premises on which manufactured water systems are situated; and<br />

> <strong>the</strong> role <strong>of</strong> relevant authorities <strong>in</strong> monitor<strong>in</strong>g <strong>the</strong> operation <strong>of</strong> such systems.<br />

The <strong>Legionella</strong> Regulations do not apply to high risk manufactured water systems <strong>in</strong>stalled <strong>in</strong> Class 10, Class 1A or 4<br />

build<strong>in</strong>gs or sole-occupancy units <strong>in</strong> Class 2 build<strong>in</strong>gs (as def<strong>in</strong>ed <strong>in</strong> <strong>the</strong> Build<strong>in</strong>g Code <strong>of</strong> Australia), exclud<strong>in</strong>g warm<br />

water systems that serve more than one dwell<strong>in</strong>g.<br />

This Guidel<strong>in</strong>e references a number <strong>of</strong> o<strong>the</strong>r documents that should be read <strong>in</strong> conjunction with it. These documents<br />

<strong>in</strong>clude <strong>the</strong> Act, <strong>the</strong> <strong>Legionella</strong> Regulations, Australian/New Zealand Standard (AS/NZS) 3666: Parts 1, 2 and 3 Airhandl<strong>in</strong>g<br />

and water systems <strong>of</strong> build<strong>in</strong>gs – Microbial control, Handbook SAA/SNZ HB32 <strong>Control</strong> <strong>of</strong> microbial growth<br />

<strong>in</strong> air-handl<strong>in</strong>g and water systems <strong>in</strong> build<strong>in</strong>gs, Australian/New Zealand Standard (AS/NZS) 3500.4 National Plumb<strong>in</strong>g<br />

and Dra<strong>in</strong>age Part 4: Heated water services, and <strong>the</strong> Build<strong>in</strong>g Code <strong>of</strong> Australia.<br />

Users <strong>of</strong> this Guidel<strong>in</strong>e should also be aware <strong>of</strong> <strong>the</strong> requirements <strong>of</strong> <strong>the</strong> Act, <strong>the</strong> South Australian Public Health<br />

(General) Regulations 2013 (<strong>the</strong> General Regulations) and <strong>the</strong> Standard <strong>for</strong> <strong>the</strong> Operation <strong>of</strong> Swimm<strong>in</strong>g Pools and Spa<br />

Pools <strong>in</strong> South Australia.<br />

Note:<br />

Applications <strong>for</strong> determ<strong>in</strong>ations or approvals by <strong>the</strong> M<strong>in</strong>ister under <strong>the</strong> <strong>Legionella</strong> Regulations should be posted to:<br />

The M<strong>in</strong>ister <strong>for</strong> Health and Age<strong>in</strong>g<br />

C/– Health Protection Programs<br />

SA Health<br />

PO Box 6 Rundle Mall<br />

ADELAIDE SA 5000<br />

Or by email to: legionella@health.sa.gov.au<br />

<strong>Guidel<strong>in</strong>es</strong> <strong>for</strong> <strong>the</strong> <strong>Control</strong> <strong>of</strong> <strong>Legionella</strong> <strong>in</strong> <strong>Manufactured</strong> <strong>Water</strong> Systems <strong>in</strong> South Australia

Contents<br />

1. Introduction 1<br />

2. Def<strong>in</strong>itions 3<br />

3. <strong>Legionella</strong> Regulations<br />

cross-reference 5<br />

4. <strong>Legionella</strong> and illness 6<br />

4.1 <strong>Legionella</strong> <strong>in</strong> <strong>the</strong> environment 6<br />

4.2 Risk factors <strong>for</strong> illness 7<br />

4.3 Reduc<strong>in</strong>g risk <strong>in</strong> manufactured water systems 7<br />

5. Spa pools and hydro<strong>the</strong>rapy<br />

pools 8<br />

6. Design, <strong>in</strong>stallation and<br />

commission<strong>in</strong>g <strong>of</strong> systems 9<br />

6.1 Cool<strong>in</strong>g water systems 9<br />

6.2 Hot water systems and warm water systems 10<br />

6.3 Spa baths 10<br />

6.4 Air-houses, humidifiers and nebulisers 11<br />

6.5 Decorative founta<strong>in</strong>s 11<br />

6.6 Ice mach<strong>in</strong>es and o<strong>the</strong>r non-aerosol<br />

produc<strong>in</strong>g devices 11<br />

7. Responsibility <strong>for</strong> manufactured<br />

water systems 12<br />

8. Operation and ma<strong>in</strong>tenance<br />

<strong>of</strong> systems 13<br />

8.1 Cool<strong>in</strong>g water systems 13<br />

8.2 Warm water systems 13<br />

8.3 Hot water systems 14<br />

8.4 Spa baths 14<br />

8.5 Air-houses, humidifiers and nebulisers 14<br />

8.6 Decorative founta<strong>in</strong>s and o<strong>the</strong>r aerosol<br />

produc<strong>in</strong>g devices 14<br />

8.7 Ice mach<strong>in</strong>es and o<strong>the</strong>r non-aerosol<br />

produc<strong>in</strong>g devices 14<br />

8.8 <strong>Water</strong> treatment 15<br />

9. Microbiological test<strong>in</strong>g 16<br />

9.1 Test<strong>in</strong>g <strong>for</strong> <strong>Legionella</strong> 16<br />

9.2 Heterotrophic colony count 17<br />

10. System decontam<strong>in</strong>ation 18<br />

11. Operat<strong>in</strong>g and ma<strong>in</strong>tenance<br />

manuals and ma<strong>in</strong>tenance<br />

log books 19<br />

12. The role <strong>of</strong> relevant<br />

authorities 20<br />

12.1 Annual compliance <strong>in</strong>spections 20<br />

12.2 Random <strong>in</strong>pections 20<br />

12.3 Legionellosis <strong>in</strong>vestigations 20<br />

12.4 Registration <strong>of</strong> systems 21<br />

<strong>Guidel<strong>in</strong>es</strong> <strong>for</strong> <strong>the</strong> <strong>Control</strong> <strong>of</strong> <strong>Legionella</strong> <strong>in</strong> <strong>Manufactured</strong> <strong>Water</strong> Systems <strong>in</strong> South Australia

Contents<br />

Schedule 1<br />

Hot and warm water systems (diagrams) 22<br />

Schedule 2<br />

Procedure <strong>for</strong> sampl<strong>in</strong>g <strong>for</strong> microbiological test<strong>in</strong>g 25<br />

Schedule 3<br />

Procedures <strong>for</strong> decontam<strong>in</strong>ation <strong>of</strong> cool<strong>in</strong>g water<br />

systems and hot water and warm water systems 27<br />

Part 1 – procedure <strong>for</strong> <strong>of</strong>f-l<strong>in</strong>e<br />

decontam<strong>in</strong>ation <strong>of</strong> cool<strong>in</strong>g water systems 27<br />

Part 2 – procedures <strong>for</strong> decontam<strong>in</strong>ation <strong>of</strong><br />

hot water systems and warm water systems 28<br />

Schedule 4<br />

Responses to detection <strong>of</strong> <strong>Legionella</strong> <strong>in</strong> cool<strong>in</strong>g<br />

water systems and warm water systems 29<br />

Part 1 – control strategies <strong>for</strong> <strong>the</strong> presence<br />

<strong>of</strong> <strong>Legionella</strong> <strong>in</strong> cool<strong>in</strong>g water systems 29<br />

Part 2 – control strategies <strong>for</strong> <strong>the</strong> presence<br />

<strong>of</strong> <strong>Legionella</strong> <strong>in</strong> warm water systems 29<br />

Acknowledgements 30<br />

Bibliography 31<br />

Appendix A<br />

Resources and fur<strong>the</strong>r read<strong>in</strong>g 33<br />

<strong>Guidel<strong>in</strong>es</strong> <strong>for</strong> <strong>the</strong> <strong>Control</strong> <strong>of</strong> <strong>Legionella</strong> <strong>in</strong> <strong>Manufactured</strong> <strong>Water</strong> Systems <strong>in</strong> South Australia

1. Introduction<br />

1. Introduction<br />

This document is a prescribed Guidel<strong>in</strong>e under <strong>the</strong> South Australian Public Health Act 2011 (<strong>the</strong> Act) to assist relevant<br />

authorities <strong>in</strong> <strong>the</strong> adm<strong>in</strong>istration and operation <strong>of</strong> <strong>the</strong> South Australian Public Health (<strong>Legionella</strong>) Regulations 2013<br />

(<strong>the</strong> <strong>Legionella</strong> Regulations). It deals specifically with <strong>the</strong> control <strong>of</strong> <strong>Legionella</strong> <strong>in</strong> manufactured water systems. It is<br />

concerned with all manufactured water systems that allow <strong>Legionella</strong> growth and that have <strong>the</strong> potential to generate<br />

aerosols result<strong>in</strong>g <strong>in</strong> human exposure to airborne <strong>Legionella</strong>. Of particular focus are high risk manufactured water<br />

systems which are cool<strong>in</strong>g water systems and warm water systems. Although a potential source <strong>of</strong> <strong>Legionella</strong>, spa<br />

pools, are dealt with by o<strong>the</strong>r legislation; <strong>the</strong> South Australian Public Health (General) Regulations 2013 (<strong>the</strong> General<br />

Regulations).<br />

<strong>Manufactured</strong> water systems that can grow <strong>Legionella</strong> but that do not create aerosols (such as ice mach<strong>in</strong>es and<br />

some chilled water dispensers) are not considered to be a high risk <strong>for</strong> most people but do represent a risk to<br />

immunocompromised people and are mentioned briefly <strong>in</strong> this Guidel<strong>in</strong>e.<br />

The most effective way <strong>of</strong> m<strong>in</strong>imis<strong>in</strong>g <strong>the</strong> growth <strong>of</strong> <strong>Legionella</strong> is to keep water systems visibly clean and to apply<br />

appropriate water treatment. The presence <strong>of</strong> bi<strong>of</strong>ilms, sediments, sludge, solids, scale, corrosion and microorganisms<br />

provide a favourable environment <strong>for</strong> <strong>Legionella</strong> growth.<br />

This Guidel<strong>in</strong>e outl<strong>in</strong>es operation and ma<strong>in</strong>tenance procedures <strong>in</strong>tended to keep systems visibly clean and to m<strong>in</strong>imise<br />

<strong>Legionella</strong> contam<strong>in</strong>ation. It also details <strong>the</strong> prescribed decontam<strong>in</strong>ation procedures that must be followed by system<br />

owners when specified concentrations <strong>of</strong> <strong>Legionella</strong> are detected <strong>in</strong> a water sample collected from regulated high risk<br />

manufactured water systems.<br />

This Guidel<strong>in</strong>e describes <strong>the</strong> role <strong>of</strong> relevant authorities <strong>in</strong> monitor<strong>in</strong>g and en<strong>for</strong>c<strong>in</strong>g compliance with <strong>the</strong> <strong>Legionella</strong><br />

Regulations and <strong>in</strong> ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g registers <strong>of</strong> high risk manufactured water systems. This Guidel<strong>in</strong>e also provides<br />

advice and <strong>in</strong><strong>for</strong>mation <strong>for</strong> use by designers, <strong>in</strong>stallers, owners, operators and ma<strong>in</strong>tenance personnel to ensure that<br />

manufactured water systems are constructed, operated and ma<strong>in</strong>ta<strong>in</strong>ed to m<strong>in</strong>imise <strong>the</strong> risk <strong>of</strong> legionellosis outbreaks<br />

and to comply with <strong>the</strong> requirements <strong>of</strong> <strong>the</strong> Act and <strong>the</strong> <strong>Legionella</strong> Regulations.<br />

In summary, <strong>the</strong> key po<strong>in</strong>ts <strong>of</strong> this Guidel<strong>in</strong>e and <strong>the</strong> <strong>Legionella</strong> Regulations are that:<br />

> Manufacture<br />

– manufactured water systems should be manufactured, <strong>in</strong>stalled, ma<strong>in</strong>ta<strong>in</strong>ed and operated <strong>in</strong> a manner that<br />

prevents <strong>the</strong> transmission <strong>of</strong> disease organisms to persons<br />

– a cool<strong>in</strong>g water system must be fitted with an automatic biocide dos<strong>in</strong>g device and be operat<strong>in</strong>g effectively<br />

at all times while <strong>the</strong> system is <strong>in</strong> operation<br />

– drift elim<strong>in</strong>ators must be fitted to every cool<strong>in</strong>g tower <strong>in</strong> a cool<strong>in</strong>g water system unless o<strong>the</strong>rwise determ<strong>in</strong>ed<br />

by <strong>the</strong> M<strong>in</strong>ister<br />

– pipes after <strong>the</strong>rmostatic mix<strong>in</strong>g valves or <strong>the</strong>ir equivalent to outlet po<strong>in</strong>ts on hot water or warm water systems<br />

should not exceed 6 metres <strong>in</strong> length<br />

> Ma<strong>in</strong>tenance<br />

– high risk manufactured water systems must be <strong>in</strong>spected at least monthly as part <strong>of</strong> a rout<strong>in</strong>e ma<strong>in</strong>tenance<br />

program and be cleaned if found to be dirty<br />

– cool<strong>in</strong>g water systems must be cleaned at least 6 monthly, or more frequently where required to ma<strong>in</strong>ta<strong>in</strong><br />

cleanl<strong>in</strong>ess<br />

– <strong>the</strong> temperature <strong>of</strong> water stored <strong>in</strong> warm water systems must be ma<strong>in</strong>ta<strong>in</strong>ed at a m<strong>in</strong>imum <strong>of</strong> 60°C<br />

– hot water system and warm water system outlet taps that are not used on a weekly basis should be flushed<br />

every week<br />

– dead legs (lengths <strong>of</strong> pipe that do not allow circulation <strong>of</strong> water) should be removed or disconnected<br />

– warm water systems must be completely flushed at least 6 monthly with water <strong>of</strong> not less than 70°C <strong>for</strong><br />

5 m<strong>in</strong>utes (or an equivalent temperature/time comb<strong>in</strong>ation) or be treated with chlor<strong>in</strong>e to provide a m<strong>in</strong>imum<br />

free chlor<strong>in</strong>e residual <strong>of</strong> 1 mg/L at all outlets<br />

– temperature controll<strong>in</strong>g devices such as <strong>the</strong>rmostatic mix<strong>in</strong>g valves or temper<strong>in</strong>g valves should be regularly serviced<br />

<strong>in</strong> accordance with <strong>the</strong> manufacturer’s <strong>in</strong>structions and AS 4032 and, <strong>in</strong> any case, at least once every 12 months<br />

<strong>Guidel<strong>in</strong>es</strong> <strong>for</strong> <strong>the</strong> <strong>Control</strong> <strong>of</strong> <strong>Legionella</strong> <strong>in</strong> <strong>Manufactured</strong> <strong>Water</strong> Systems <strong>in</strong> South Australia page 1

1. Introduction<br />

> Adm<strong>in</strong>istration<br />

– <strong>the</strong> owner <strong>of</strong> premises on which a cool<strong>in</strong>g water or warm water system is situated must ensure that plans <strong>of</strong><br />

<strong>the</strong> system and manuals <strong>for</strong> <strong>the</strong> operation and ma<strong>in</strong>tenance <strong>of</strong> <strong>the</strong> system are available and that records are<br />

ma<strong>in</strong>ta<strong>in</strong>ed <strong>of</strong> any <strong>in</strong>spection, ma<strong>in</strong>tenance, repair, replacement, alteration or upgrad<strong>in</strong>g <strong>of</strong> <strong>the</strong> system. Records<br />

will <strong>in</strong>clude <strong>the</strong> result <strong>of</strong> any test<strong>in</strong>g <strong>of</strong> <strong>the</strong> system, microbiological test<strong>in</strong>g <strong>of</strong> water samples and details <strong>of</strong> <strong>the</strong><br />

type and use <strong>of</strong> biocide<br />

> Public Authorities<br />

– <strong>the</strong> relevant authority must ma<strong>in</strong>ta<strong>in</strong> a register that records details <strong>of</strong> premises on which cool<strong>in</strong>g water systems<br />

or warm water systems are situated<br />

– Cool<strong>in</strong>g water systems and warm water systems must be <strong>in</strong>spected <strong>for</strong> compliance, at least once a year by <strong>the</strong><br />

relevant authority. Alternatively, <strong>the</strong> relevant authority can issue a notice to <strong>the</strong> system owner, requir<strong>in</strong>g that<br />

<strong>the</strong>y engage an <strong>in</strong>dependent, competent third party to undertake <strong>the</strong> <strong>in</strong>spection and prepare a report. The costs<br />

<strong>in</strong>curred <strong>in</strong> <strong>the</strong> annual <strong>in</strong>spection are to be met by <strong>the</strong> owner <strong>of</strong> <strong>the</strong> premises<br />

– <strong>the</strong> relevant authority may require test<strong>in</strong>g <strong>for</strong> <strong>the</strong> presence <strong>of</strong> <strong>Legionella</strong> organisms <strong>in</strong> <strong>the</strong> event that a high risk<br />

manufactured water system is <strong>in</strong>adequately operated or ma<strong>in</strong>ta<strong>in</strong>ed. Test<strong>in</strong>g may also be required as part <strong>of</strong> an<br />

<strong>in</strong>vestigation <strong>of</strong> a case or suspected case or an outbreak <strong>of</strong> legionellosis<br />

– If an owner <strong>of</strong> premises on which a manufactured water system is situated fails to comply with a notice given<br />

by <strong>the</strong> relevant authority, <strong>the</strong> relevant authority may require <strong>the</strong> system to be remediated, shut down and/or<br />

decontam<strong>in</strong>ated and may recover all necessary associated costs from <strong>the</strong> owner<br />

page 2<br />

<strong>Guidel<strong>in</strong>es</strong> <strong>for</strong> <strong>the</strong> <strong>Control</strong> <strong>of</strong> <strong>Legionella</strong> <strong>in</strong> <strong>Manufactured</strong> <strong>Water</strong> Systems <strong>in</strong> South Australia

2. Def<strong>in</strong>itions<br />

2. Def<strong>in</strong>itions<br />

<strong>the</strong> Act <strong>the</strong> South Australian Public Health Act 2011.<br />

aerosol<br />

air-house<br />

airborne water particles less than 10µm <strong>in</strong> diameter.<br />

an <strong>in</strong>dustrial humidifier commonly used <strong>in</strong> pa<strong>in</strong>t, electroplat<strong>in</strong>g and f<strong>in</strong>ish<strong>in</strong>g shops.<br />

authorised <strong>of</strong>ficer a person appo<strong>in</strong>ted to be a State or local authorised <strong>of</strong>ficer under Part 3 Division 5<br />

<strong>of</strong> <strong>the</strong> Act.<br />

automatic biocide<br />

dos<strong>in</strong>g device<br />

biocide<br />

bi<strong>of</strong>ilm<br />

bleed-<strong>of</strong>f<br />

calorifier<br />

clean<br />

cfu/mL<br />

cool<strong>in</strong>g tower<br />

cool<strong>in</strong>g water system<br />

competent person<br />

conta<strong>in</strong>er (heated water)<br />

dead leg<br />

decontam<strong>in</strong>ation<br />

drift<br />

DPD Test Kit<br />

evaporative condenser<br />

a device that automatically discharges a measured amount <strong>of</strong> biocide to a cool<strong>in</strong>g<br />

water system us<strong>in</strong>g a feedback control loop or timer.<br />

a substance capable <strong>of</strong> kill<strong>in</strong>g micro-organisms, <strong>in</strong>clud<strong>in</strong>g <strong>Legionella</strong>.<br />

a complex structure adher<strong>in</strong>g to surfaces that are regularly <strong>in</strong> contact with water,<br />

consist<strong>in</strong>g <strong>of</strong> colonies <strong>of</strong> bacteria and o<strong>the</strong>r microorganisms.<br />

<strong>the</strong> removal <strong>of</strong> water from a system to limit <strong>the</strong> concentration <strong>of</strong> total dissolved<br />

solids and suspended solids.<br />

an apparatus <strong>for</strong> <strong>in</strong>direct heat<strong>in</strong>g <strong>of</strong> water <strong>in</strong> a vessel, <strong>the</strong> source <strong>of</strong> heat is conta<strong>in</strong>ed<br />

with<strong>in</strong> a pipe or coil immersed <strong>in</strong> <strong>the</strong> water.<br />

free from visible sludge, foam, slime, rust, scale, dirt, dust and any deposit or<br />

accumulation <strong>of</strong> impurities, or any <strong>for</strong>eign material.<br />

colony <strong>for</strong>m<strong>in</strong>g units per millilitre.<br />

a device <strong>for</strong> lower<strong>in</strong>g <strong>the</strong> temperature <strong>of</strong> water by evaporative cool<strong>in</strong>g <strong>in</strong> which<br />

atmospheric air is <strong>in</strong> contact with fall<strong>in</strong>g water <strong>the</strong>reby exchang<strong>in</strong>g heat. The term<br />

also <strong>in</strong>cludes those devices which <strong>in</strong>corporate a water-refrigerant or water-water<br />

heat exchanger.<br />

a heat exchange system compris<strong>in</strong>g a heat-generat<strong>in</strong>g plant, a heat-rejection plant<br />

and <strong>in</strong>terconnect<strong>in</strong>g water recirculat<strong>in</strong>g pipe work and associated pumps, valves<br />

and controls. The term <strong>in</strong>cludes cool<strong>in</strong>g towers and evaporative condensers.<br />

as described <strong>in</strong> <strong>the</strong> <strong>Legionella</strong> Regulations.<br />

a vessel, <strong>in</strong>clud<strong>in</strong>g fitt<strong>in</strong>gs, <strong>in</strong> which heated water is stored, sometimes referred to<br />

as a storage conta<strong>in</strong>er, cyl<strong>in</strong>der or tank.<br />

a section <strong>of</strong> a hot water or warm water system that does not permit <strong>the</strong> circulation<br />

<strong>of</strong> hot or warm water.<br />

<strong>the</strong> reduction, to negligible or low concentrations, <strong>of</strong> a known or suspected<br />

contam<strong>in</strong>ant, such as <strong>Legionella</strong>.<br />

water lost from a cool<strong>in</strong>g tower as liquid droplets <strong>in</strong> <strong>the</strong> exhaust air, exclud<strong>in</strong>g<br />

condensation. Drift is not to be confused with plume which is condensed<br />

water vapour.<br />

a test kit conta<strong>in</strong><strong>in</strong>g ‘diethyl-p-phenylene diam<strong>in</strong>e’ a chemical reagent used <strong>in</strong><br />

a colorimetric comparator <strong>for</strong> test<strong>in</strong>g water <strong>for</strong> free, comb<strong>in</strong>ed and total chlor<strong>in</strong>e.<br />

a heat exchanger <strong>in</strong> which refrigerant is cooled by a comb<strong>in</strong>ation <strong>of</strong> air movement<br />

and water spray<strong>in</strong>g.<br />

The General Regulations South Australian Public Health (General) Regulations 2013.<br />

heterotrophic colony count<br />

high risk manufactured<br />

water system<br />

a measure <strong>of</strong> heterotrophic aerobic bacteria present <strong>in</strong> a water sample. It is also<br />

referred to as a heterotrophic plate count, standard plate count or total plate count.<br />

a cool<strong>in</strong>g water system or warm water system.<br />

<strong>Guidel<strong>in</strong>es</strong> <strong>for</strong> <strong>the</strong> <strong>Control</strong> <strong>of</strong> <strong>Legionella</strong> <strong>in</strong> <strong>Manufactured</strong> <strong>Water</strong> Systems <strong>in</strong> South Australia page 3

2. Def<strong>in</strong>itions<br />

hot water system<br />

<strong>in</strong>stantaneous water heater<br />

a reticulated water system that distributes or recirculates hot water (≥60°C) through<br />

<strong>the</strong> majority <strong>of</strong> its branches. A hot water system may <strong>in</strong>clude temperature control<br />

devices located near outlets to regulate <strong>the</strong> delivery temperature. See Figures 3<br />

and 4 <strong>in</strong> Schedule 1.<br />

an unvented water heater <strong>in</strong> which <strong>the</strong> heat energy is applied only while <strong>the</strong> water<br />

flows to an outlet.<br />

The <strong>Legionella</strong> Regulations South Australian Public Health (<strong>Legionella</strong>) Regulations 2013.<br />

manufactured water system<br />

mg/L<br />

outbreak (legionellosis)<br />

owner/occupier<br />

pH<br />

relevant authority<br />

sporadic case<br />

TDS (total dissolved solids)<br />

temperature control device<br />

temper<strong>in</strong>g valve<br />

<strong>the</strong>rmostatic mix<strong>in</strong>g valve<br />

<strong>the</strong> M<strong>in</strong>ister<br />

storage water heater<br />

warm water<br />

warm water system<br />

a manufactured system that <strong>in</strong>corporates water as part <strong>of</strong> its functionality.<br />

milligrams per Litre.<br />

two or more cases <strong>of</strong> legionellosis l<strong>in</strong>ked by time or place.<br />

<strong>in</strong> relation to premises, means a person who has, or is entitled to possession or<br />

control <strong>of</strong> <strong>the</strong> premises and <strong>in</strong>cludes a person who is <strong>in</strong> charge <strong>of</strong> <strong>the</strong> premises.<br />

A reference to an owner <strong>of</strong> premises <strong>in</strong>cludes a reference to an occupier <strong>of</strong> <strong>the</strong><br />

premises.<br />

a scale (rang<strong>in</strong>g from 0 to 14) that <strong>in</strong>dicates <strong>the</strong> acidity (0 to 7 to 14). <strong>Water</strong> with a pH <strong>of</strong> 7 is neutral.<br />

<strong>the</strong> Chief Public Health Officer or a council.<br />

a s<strong>in</strong>gle case <strong>of</strong> legionellosis with no discernible l<strong>in</strong>k to ano<strong>the</strong>r case by time or place.<br />

<strong>the</strong> total weight <strong>of</strong> dissolved solids <strong>in</strong> water, which would rema<strong>in</strong> if all <strong>the</strong> water<br />

were evaporated.<br />

a device used to alter <strong>the</strong> water temperature to produce water that reduces <strong>the</strong><br />

risk <strong>of</strong> scald<strong>in</strong>g to users. Examples <strong>in</strong>clude <strong>the</strong>rmostatic mix<strong>in</strong>g valves and temper<strong>in</strong>g<br />

valves.<br />

a mix<strong>in</strong>g valve that is temperature actuated and is used to temper a hot water<br />

supply with cold water to provide hot water at a lower temperature,<br />

e.g. 50°C, at one or more outlet fixtures.<br />

a mix<strong>in</strong>g valve <strong>in</strong> which <strong>the</strong> temperature <strong>of</strong> <strong>the</strong> water from <strong>the</strong> mixed water outlet<br />

is automatically controlled by a <strong>the</strong>rmostatic element/sensor to a preset temperature<br />

that is suitable <strong>for</strong> direct contact with <strong>the</strong> sk<strong>in</strong>.<br />

<strong>the</strong> M<strong>in</strong>ister <strong>of</strong> <strong>the</strong> Crown to whom <strong>the</strong> adm<strong>in</strong>istration <strong>of</strong> <strong>the</strong> Act has been<br />

committed by <strong>the</strong> Governor, or <strong>in</strong> whom <strong>the</strong> adm<strong>in</strong>istration <strong>of</strong> <strong>the</strong> Act is<br />

o<strong>the</strong>rwise vested.<br />

a water heater that <strong>in</strong>corporates a <strong>the</strong>rmally <strong>in</strong>sulated conta<strong>in</strong>er <strong>in</strong> which <strong>the</strong><br />

water is heated and stored <strong>for</strong> subsequent use. Heated water must be stored at<br />

a m<strong>in</strong>imum temperature <strong>of</strong> 60°C to <strong>in</strong>hibit <strong>the</strong> growth <strong>of</strong> <strong>Legionella</strong> bacteria.<br />

A storage water heater does not <strong>in</strong>clude a calorifier.<br />

water that is

3. <strong>Legionella</strong> Regulations cross-reference<br />

3. <strong>Legionella</strong> Regulations cross-reference<br />

Table 1 briefly summarises <strong>in</strong>dividual regulations with specific requirements from <strong>the</strong> <strong>Legionella</strong> Regulations, and provides<br />

a reference to <strong>the</strong> relevant location with<strong>in</strong> this Guidel<strong>in</strong>e and to <strong>the</strong> correspond<strong>in</strong>g Australian Standards referred to with<strong>in</strong><br />

<strong>the</strong> regulation where applicable. Regulations that are not referenced with<strong>in</strong> this Guidel<strong>in</strong>e have not been <strong>in</strong>cluded.<br />

Table 1<br />

Cross-reference between <strong>the</strong> <strong>Legionella</strong> Regulations, relevant Australian Standards and references<br />

with<strong>in</strong> this Guidel<strong>in</strong>e.<br />

Regulation number<br />

and title<br />

Requirement<br />

Relevant<br />

Australian<br />

Standard<br />

Reference<br />

<strong>in</strong> this<br />

Guidel<strong>in</strong>e<br />

Page<br />

no.<br />

5. Duty to register high risk<br />

manufactured water system<br />

All high risk manufactured water systems must be registered<br />

with <strong>the</strong> relevant authority<br />

12.4 21<br />

6. Register <strong>of</strong> high risk<br />

manufactured water systems<br />

Each relevant authority must keep a register <strong>of</strong> high risk<br />

manufactured water systems registered by <strong>the</strong> relevant<br />

authority<br />

12.4 21<br />

7. Cool<strong>in</strong>g water systems to be<br />

fitted with automatic biocide<br />

dos<strong>in</strong>g devices<br />

The owner <strong>of</strong> premises on which a cool<strong>in</strong>g water system is<br />

<strong>in</strong>stalled must ensure that an automatic biocide dos<strong>in</strong>g device<br />

is fitted to <strong>the</strong> system and is operat<strong>in</strong>g effectively at all times<br />

while <strong>the</strong> system is <strong>in</strong> operation<br />

6.1<br />

8.8.1<br />

9<br />

15<br />

8. Cool<strong>in</strong>g water systems to be<br />

fitted with drift elim<strong>in</strong>ators<br />

Drift elim<strong>in</strong>ators to be fitted to all cool<strong>in</strong>g towers (unless <strong>the</strong><br />

M<strong>in</strong>ister determ<strong>in</strong>es o<strong>the</strong>rwise)<br />

6.1 9<br />

9. Commission<strong>in</strong>g <strong>of</strong> high risk<br />

manufactured water systems<br />

Cool<strong>in</strong>g water systems and components to have appropriate<br />

clean<strong>in</strong>g, pretreatment and microbial control be<strong>for</strong>e be<strong>in</strong>g<br />

brought <strong>in</strong>to service<br />

AS/NZS 3666.1<br />

– Clause 4.7<br />

6. 9<br />

10. Plans and manuals relat<strong>in</strong>g<br />

to high risk manufactured water<br />

systems to be kept readily accessible<br />

Plans, operat<strong>in</strong>g and ma<strong>in</strong>tenance manuals to be kept on<br />

<strong>the</strong> premises <strong>in</strong> a readily accessible place and be available <strong>for</strong><br />

<strong>in</strong>spection upon request by an authorised <strong>of</strong>ficer<br />

AS/NZS 3666.2<br />

– Clause 2.6.1<br />

HB32<br />

6.<br />

11.<br />

9<br />

19<br />

11. High risk manufactured water<br />

systems to be operated and<br />

ma<strong>in</strong>ta<strong>in</strong>ed by competent person<br />

The owner <strong>of</strong> premises with a high risk manufactured water<br />

system <strong>in</strong>stalled to ensure that <strong>the</strong> system is operated and<br />

ma<strong>in</strong>ta<strong>in</strong>ed by sufficiently competent and knowledgeable<br />

person<br />

7. 12<br />

12. Ma<strong>in</strong>tenance <strong>of</strong> cool<strong>in</strong>g<br />

water systems<br />

Cool<strong>in</strong>g water systems to be ma<strong>in</strong>ta<strong>in</strong>ed <strong>in</strong> accordance with<br />

<strong>the</strong> relevant Australian Standard or a program approved by<br />

<strong>the</strong> M<strong>in</strong>ister<br />

AS/NZS 3666.2<br />

– Section 2.5<br />

or<br />

AS/NZS 3666.3<br />

– Section 3<br />

8.1 13<br />

13. Ma<strong>in</strong>tenance <strong>of</strong> warm<br />

water systems<br />

Warm water systems to be ma<strong>in</strong>ta<strong>in</strong>ed <strong>in</strong> accordance with <strong>the</strong><br />

requirements set out <strong>in</strong> regulation 13<br />

AS 4032 (<strong>for</strong><br />

temperature<br />

control devices)<br />

8.2 13<br />

14. Ma<strong>in</strong>tenance log books Up-to-date ma<strong>in</strong>tenance log books to be kept on premises <strong>in</strong><br />

a readily accessible place and be available <strong>for</strong> <strong>in</strong>spection upon<br />

request by an authorised <strong>of</strong>ficer<br />

Log books to be kept <strong>for</strong> at least 5 years<br />

AS/NZS 3666.2<br />

– Clause 2.6.2<br />

HB32<br />

11. 19<br />

15. Annual <strong>in</strong>spection and<br />

microbiological test<strong>in</strong>g<br />

High risk manufactured water systems are to be <strong>in</strong>spected and<br />

have microbiological test<strong>in</strong>g conducted at least once <strong>in</strong> every<br />

12 months<br />

AS/NZS 3896<br />

(<strong>for</strong> microbiological<br />

test<strong>in</strong>g)<br />

9.<br />

12.1<br />

Schedule 2.<br />

16<br />

20<br />

25<br />

16. Power <strong>of</strong> authority to require<br />

microbiological test<strong>in</strong>g <strong>in</strong> o<strong>the</strong>r<br />

circumstances<br />

The authority may serve a notice requir<strong>in</strong>g microbiological<br />

test<strong>in</strong>g when <strong>in</strong>vestigat<strong>in</strong>g an occurrence <strong>of</strong> legionellosis or<br />

if a system is not be<strong>in</strong>g ma<strong>in</strong>ta<strong>in</strong>ed <strong>in</strong> accordance with <strong>the</strong><br />

<strong>Legionella</strong> Regulations<br />

AS/NZS 3896<br />

(<strong>for</strong> microbiological<br />

test<strong>in</strong>g)<br />

12.<br />

Schedule 2.<br />

20<br />

25<br />

17. Responses to detection <strong>of</strong><br />

<strong>Legionella</strong><br />

Upon receipt <strong>of</strong> specified <strong>Legionella</strong> water test<strong>in</strong>g results<br />

from a high risk manufactured water system, <strong>the</strong> owner must<br />

immediately shut down or decontam<strong>in</strong>ate <strong>the</strong> system and<br />

report <strong>the</strong> test results to <strong>the</strong> relevant authority with<strong>in</strong> 24 hours<br />

9.1<br />

Schedule 2.<br />

Schedule 4.<br />

16<br />

25<br />

29<br />

18. Determ<strong>in</strong>ations and<br />

approvals<br />

Applications <strong>for</strong> determ<strong>in</strong>ations and approvals to be made<br />

to <strong>the</strong> M<strong>in</strong>ister on an approved <strong>for</strong>m accompanied by <strong>the</strong><br />

relevant fee and necessary <strong>in</strong><strong>for</strong>mation<br />

Foreword<br />

<strong>Guidel<strong>in</strong>es</strong> <strong>for</strong> <strong>the</strong> <strong>Control</strong> <strong>of</strong> <strong>Legionella</strong> <strong>in</strong> <strong>Manufactured</strong> <strong>Water</strong> Systems <strong>in</strong> South Australia page 5

4. <strong>Legionella</strong> and illness<br />

4. <strong>Legionella</strong> and illness<br />

<strong>Legionella</strong> bacteria must be <strong>in</strong>haled to cause illness. However, most people who are exposed to aerosols conta<strong>in</strong><strong>in</strong>g <strong>Legionella</strong><br />

do not become ill. <strong>Legionella</strong> generally <strong>in</strong>fects <strong>the</strong> lungs, caus<strong>in</strong>g a disease known as legionellosis.<br />

Legionellosis can take <strong>the</strong> <strong>for</strong>m <strong>of</strong> <strong>the</strong> pneumonic, <strong>of</strong>ten very severe and potentially fatal Legionnaires’ disease or <strong>the</strong><br />

non-pneumonic, usually non-fatal Pontiac fever. L. pneumophila, L. anisa, L. feelii and L. micdadei have been associated<br />

with Pontiac fever, while Legionnaires’ disease is most commonly caused by subtypes <strong>of</strong> L. pneumophila serogroup 1,<br />

although o<strong>the</strong>r species can also cause disease. The usual <strong>in</strong>cubation period <strong>for</strong> legionellosis is 2–10 days, and <strong>in</strong>fection causes<br />

flu-like symptoms <strong>in</strong>clud<strong>in</strong>g fever, chest pa<strong>in</strong>, cough, breathlessness, and diarrhoea. Diagnosis is usually made by a series <strong>of</strong><br />

blood tests. Infections caused by L. pneumophila serogroup 1 may also be rapidly identified by a ur<strong>in</strong>ary antigen test.<br />

Occasionally <strong>the</strong> organism is grown from a sample <strong>of</strong> sputum or lung fluid.<br />

Legionellosis <strong>in</strong>fection generally requires treatment with antibiotics. Severe cases <strong>of</strong> <strong>Legionella</strong> pneumophila serogroup 1<br />

<strong>in</strong>fection are treated <strong>in</strong> hospital and may require <strong>in</strong>tensive care.<br />

Infections caused by <strong>Legionella</strong> are notifiable conditions <strong>in</strong> South Australia, mean<strong>in</strong>g <strong>the</strong> doctor and <strong>the</strong> laboratory diagnos<strong>in</strong>g<br />

<strong>the</strong> disease are required to notify all cases to <strong>the</strong> Communicable Disease <strong>Control</strong> Branch <strong>of</strong> <strong>the</strong> South Australian Department<br />

<strong>for</strong> Health and Age<strong>in</strong>g.<br />

O<strong>the</strong>r species have also been identified as causes <strong>of</strong> pneumonic illness, <strong>in</strong>clud<strong>in</strong>g L. longbeachae which is associated with<br />

pott<strong>in</strong>g mixes. While legionellosis from pott<strong>in</strong>g mixes is not covered <strong>in</strong> this Guidel<strong>in</strong>e, fur<strong>the</strong>r <strong>in</strong><strong>for</strong>mation can be obta<strong>in</strong>ed from<br />

o<strong>the</strong>r SA Health publications as referenced <strong>in</strong> Appendix A.<br />

4.1 <strong>Legionella</strong> <strong>in</strong> <strong>the</strong> environment<br />

<strong>Legionella</strong> are widely distributed <strong>in</strong> <strong>the</strong> natural environment and have been isolated from water sources such as lakes,<br />

rivers, streams, groundwater, <strong>the</strong>rmal lagoons, and habitats such as soils and mud. <strong>Legionella</strong> obta<strong>in</strong>s nutrients from<br />

o<strong>the</strong>r micro-organisms such as algae, protozoa and o<strong>the</strong>r bacteria, and by <strong>the</strong> utilisation <strong>of</strong> some organic and <strong>in</strong>organic<br />

substances. <strong>Legionella</strong> multiply at temperatures rang<strong>in</strong>g from 20°C to 45°C, with maximum growth occurr<strong>in</strong>g between<br />

32°C and 43°C. They can survive freez<strong>in</strong>g and are killed with <strong>in</strong>creas<strong>in</strong>g speed as temperatures exceed 45°C. Survival<br />

time decreases from hours at 50°C to m<strong>in</strong>utes at 60°C, while at 70°C <strong>the</strong> organism is killed almost immediately.<br />

<strong>Legionella</strong> from natural sources can enter and colonise manufactured water systems such as air-handl<strong>in</strong>g systems<br />

<strong>in</strong>corporat<strong>in</strong>g cool<strong>in</strong>g towers or evaporative condensers (collectively known as cool<strong>in</strong>g water systems), water supplies,<br />

cold, warm and hot water pipework, spa pools, spa baths, hydro<strong>the</strong>rapy pools, air-houses, humidifiers, nebulisers and<br />

decorative founta<strong>in</strong>s. These systems are commonly found <strong>in</strong> commercial, <strong>in</strong>dustrial, educational, child care, aged and<br />

health care facilities. The potential <strong>for</strong> <strong>Legionella</strong> to grow <strong>in</strong> such systems is shown <strong>in</strong> Figure 1.<br />

Figure 1 shows <strong>the</strong> relationship between proliferation <strong>of</strong> <strong>Legionella</strong> and temperatures <strong>of</strong> various water systems.<br />

The bars represent <strong>the</strong> average range <strong>of</strong> operat<strong>in</strong>g temperature <strong>of</strong> various manufactured water systems.<br />

<strong>Legionella</strong> growth is temperature dependent. In broad terms, <strong>the</strong> temperature characteristics are:<br />

below 20°C dormant<br />

20 to 25°C virtually dormant although very slow growth is possible<br />

25 to 30°C slow growth if o<strong>the</strong>r factors are satisfied<br />

30 to 37°C <strong>in</strong>crease <strong>in</strong> growth rate<br />

37 to 43°C optimum temperature range <strong>for</strong> replication <strong>of</strong> <strong>Legionella</strong><br />

45°C maximum temperature <strong>for</strong> growth<br />

46°C stationary phase (dies over about 1 week)<br />

50°C dies slowly (about 10 hours)<br />

55°C dies <strong>in</strong> about 1 hour<br />

63°C dies <strong>in</strong> a few m<strong>in</strong>utes<br />

70°C dies <strong>in</strong> seconds.<br />

page 6<br />

<strong>Guidel<strong>in</strong>es</strong> <strong>for</strong> <strong>the</strong> <strong>Control</strong> <strong>of</strong> <strong>Legionella</strong> <strong>in</strong> <strong>Manufactured</strong> <strong>Water</strong> Systems <strong>in</strong> South Australia

4. <strong>Legionella</strong> and illness<br />

100 steam boilers<br />

90<br />

80<br />

<strong>Legionella</strong> will<br />

not survive<br />

water temperature (°C)<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

hot water systems<br />

cool<strong>in</strong>g tower<br />

cold water storage<br />

evaporative air cooler<br />

spray humidifier<br />

ma<strong>in</strong>s cold water<br />

air cool<strong>in</strong>g coil condensate<br />

<strong>in</strong>creas<strong>in</strong>g risk <strong>of</strong> proliferation<br />

warm water system, shower<br />

spa pool<br />

heated/<br />

hydro<strong>the</strong>raphy<br />

pools<br />

<strong>Legionella</strong> will<br />

die <strong>in</strong> time<br />

<strong>Legionella</strong> will<br />

multiply<br />

<strong>Legionella</strong> will<br />

rema<strong>in</strong> dormant<br />

Figure 1<br />

<strong>Water</strong> temperature & <strong>in</strong>creas<strong>in</strong>g risk <strong>of</strong> <strong>Legionella</strong> proliferation<br />

(Modified from: New South Wales Health Department, Code <strong>of</strong> Practice <strong>for</strong> <strong>the</strong> <strong>Control</strong> <strong>of</strong> Legionnaires’ disease.)<br />

4.2 Risk factors <strong>for</strong> illness<br />

<strong>Legionella</strong> <strong>in</strong>fection or illness can result from <strong>the</strong> <strong>in</strong>halation <strong>of</strong> aerosols conta<strong>in</strong><strong>in</strong>g <strong>Legionella</strong> bacteria which may<br />

be generated by some manufactured water systems. However, most people who are exposed to <strong>Legionella</strong> do not<br />

become ill. The risk <strong>of</strong> illness is <strong>in</strong>creased by:<br />

> smok<strong>in</strong>g<br />

> be<strong>in</strong>g male (possibly related to smok<strong>in</strong>g)<br />

> chronic heart or lung disease<br />

> diabetes<br />

> kidney failure<br />

> some <strong>for</strong>ms <strong>of</strong> cancer<br />

> be<strong>in</strong>g aged over 50<br />

Infection caused by <strong>Legionella</strong> cannot be transmitted from person to person.<br />

4.3 Reduc<strong>in</strong>g risk <strong>in</strong> manufactured water systems<br />

<strong>Legionella</strong> present <strong>in</strong> bi<strong>of</strong>ilms or protected with<strong>in</strong> amoebae may proliferate <strong>in</strong> a manufactured water system if<br />

temperatures are favourable (25–45°C). The most effective way <strong>of</strong> m<strong>in</strong>imis<strong>in</strong>g <strong>the</strong> presence and growth <strong>of</strong> <strong>Legionella</strong><br />

and reduc<strong>in</strong>g <strong>the</strong> risk <strong>of</strong> disease is to keep systems clean and to use appropriate biocide programs and dis<strong>in</strong>fection<br />

procedures. In any manufactured water system, all wetted surfaces and water bas<strong>in</strong>s should be kept clean and <strong>the</strong><br />

stagnation <strong>of</strong> water should be avoided at all times.<br />

The development <strong>of</strong> bi<strong>of</strong>ilms and <strong>the</strong> effectiveness <strong>of</strong> dis<strong>in</strong>fection will be <strong>in</strong>fluenced by corrosion and <strong>the</strong> deposition<br />

<strong>of</strong> scale and solids. Degraded plumb<strong>in</strong>g, such as decompos<strong>in</strong>g gaskets and seal<strong>in</strong>g washers and corroded pipes<br />

provide sites <strong>for</strong> <strong>the</strong> development <strong>of</strong> bi<strong>of</strong>ilms. Some plumb<strong>in</strong>g materials are known to conta<strong>in</strong> nutrients that enhance<br />

<strong>the</strong> growth <strong>of</strong> bi<strong>of</strong>ilms. The <strong>for</strong>mation <strong>of</strong> bi<strong>of</strong>ilms and deposition <strong>of</strong> scale and solids should be m<strong>in</strong>imised. Materials<br />

used <strong>in</strong> potable water systems should comply with AS/NZS 4020 and all plumb<strong>in</strong>g and dra<strong>in</strong>age products should<br />

comply with SAA MP 52.<br />

The <strong>in</strong>halation <strong>of</strong> contam<strong>in</strong>ated aerosols by a susceptible person may result <strong>in</strong> legionellosis. M<strong>in</strong>imis<strong>in</strong>g <strong>the</strong> generation<br />

and spread <strong>of</strong> any aerosols will reduce <strong>the</strong> risk <strong>of</strong> disease <strong>in</strong> <strong>the</strong> community.<br />

<strong>Guidel<strong>in</strong>es</strong> <strong>for</strong> <strong>the</strong> <strong>Control</strong> <strong>of</strong> <strong>Legionella</strong> <strong>in</strong> <strong>Manufactured</strong> <strong>Water</strong> Systems <strong>in</strong> South Australia page 7

5. Spa pools and hydro<strong>the</strong>rapy pools<br />

5. Spa pools and hydro<strong>the</strong>rapy pools<br />

Spa pools and hydro<strong>the</strong>rapy pools can produce aerosols and provide conditions suitable <strong>for</strong> <strong>Legionella</strong> growth. Spa<br />

and hydro<strong>the</strong>rapy pool operators must be knowledgeable and competent <strong>in</strong> <strong>the</strong> operation and ma<strong>in</strong>tenance <strong>of</strong> public<br />

pools and spas <strong>in</strong> accordance with <strong>the</strong> General Regulations and <strong>the</strong> associated prescribed Standard and Guidel<strong>in</strong>e.<br />

page 8<br />

<strong>Guidel<strong>in</strong>es</strong> <strong>for</strong> <strong>the</strong> <strong>Control</strong> <strong>of</strong> <strong>Legionella</strong> <strong>in</strong> <strong>Manufactured</strong> <strong>Water</strong> Systems <strong>in</strong> South Australia

6. Design, <strong>in</strong>stallation and commission<strong>in</strong>g <strong>of</strong> systems<br />

6. Design, <strong>in</strong>stallation and commission<strong>in</strong>g <strong>of</strong> systems<br />

<strong>Manufactured</strong> or o<strong>the</strong>r water systems that conta<strong>in</strong> warm water and produce aerosol can represent a risk <strong>of</strong><br />

legionellosis.<br />

Evaporative air conditioners, while fall<strong>in</strong>g <strong>in</strong>to this category, have not been associated with any cases <strong>of</strong><br />

legionellosis <strong>in</strong> Australia. However, units should be regularly ma<strong>in</strong>ta<strong>in</strong>ed and kept clean as per <strong>the</strong> manufacturer’s<br />

recommendations (<strong>for</strong> fur<strong>the</strong>r <strong>in</strong><strong>for</strong>mation, refer to AS/NZS 3666.2).<br />

The design and <strong>in</strong>stallation <strong>of</strong> new manufactured water systems and modification <strong>of</strong> exist<strong>in</strong>g systems must comply<br />

with <strong>the</strong> <strong>Legionella</strong> Regulations, and should comply with AS/NZS 3666.1 and this Guidel<strong>in</strong>e. The commission<strong>in</strong>g <strong>of</strong><br />

new or modified plant must <strong>in</strong>clude thorough clean<strong>in</strong>g and <strong>the</strong> provision <strong>of</strong> operation and ma<strong>in</strong>tenance manuals. It is<br />

important to ensure dur<strong>in</strong>g <strong>the</strong> design, <strong>in</strong>stallation and commission<strong>in</strong>g <strong>of</strong> manufactured water systems that <strong>the</strong>y are<br />

appropriately located, with consideration given to access and clean-ability issues. Dead legs <strong>in</strong> cool<strong>in</strong>g water systems,<br />

hot water systems and warm water systems should be avoided. For air-handl<strong>in</strong>g devices <strong>in</strong>corporat<strong>in</strong>g cool<strong>in</strong>g water<br />

systems, <strong>the</strong> location <strong>of</strong> air <strong>in</strong>let and discharge po<strong>in</strong>ts <strong>in</strong> relation to build<strong>in</strong>g geometry, and <strong>the</strong> location <strong>of</strong> <strong>in</strong>let and<br />

discharge po<strong>in</strong>ts <strong>of</strong> adjacent build<strong>in</strong>gs and predom<strong>in</strong>ant w<strong>in</strong>d direction should be considered. Materials used <strong>in</strong> plant<br />

construction should be corrosion resistant and able to withstand extremes <strong>in</strong> water quality and <strong>the</strong> presence <strong>of</strong> water<br />

treatment chemicals.<br />

Upon <strong>in</strong>stallation and commission<strong>in</strong>g <strong>of</strong> new high risk manufactured water systems, Regulation 10 <strong>of</strong> <strong>the</strong> <strong>Legionella</strong><br />

Regulations requires <strong>the</strong> owner to keep plans show<strong>in</strong>g <strong>the</strong> location <strong>of</strong> all parts <strong>of</strong> <strong>the</strong> system. These components<br />

<strong>in</strong>clude (but are not limited to) cool<strong>in</strong>g towers, condensers, drift elim<strong>in</strong>ators, filtration devices, automatic biocide<br />

dos<strong>in</strong>g devices, water <strong>in</strong>lets, waste outlets and discharge po<strong>in</strong>ts, water heat<strong>in</strong>g devices and water storage facilities.<br />

The owner <strong>of</strong> <strong>the</strong> premises is required to ensure <strong>the</strong> plans <strong>for</strong> <strong>the</strong> system are kept <strong>in</strong> a readily accessible place and<br />

made available to an authorised <strong>of</strong>ficer upon request.<br />

6.1 Cool<strong>in</strong>g water systems<br />

Air-handl<strong>in</strong>g systems that <strong>in</strong>corporate water cool<strong>in</strong>g, such as cool<strong>in</strong>g towers and evaporative condensers, conta<strong>in</strong><br />

warm water and can generate aerosols. These systems typically have large <strong>in</strong>ternal surface areas and, if not well<br />

ma<strong>in</strong>ta<strong>in</strong>ed, may accumulate considerable quantities <strong>of</strong> organic material and debris, and provide nutrients and ideal<br />

environments <strong>for</strong> microbial growth.<br />

These systems can be associated with many types <strong>of</strong> facilities, <strong>in</strong>clud<strong>in</strong>g: factories with process cool<strong>in</strong>g operations,<br />

commercial build<strong>in</strong>gs, hospitals, hotels, shopp<strong>in</strong>g centres, schools, dairies, w<strong>in</strong>eries, fruit and vegetable storage sheds,<br />

ice works, cold rooms and dry cleaners.<br />

Well designed systems should be easy to clean and dis<strong>in</strong>fect and should not conta<strong>in</strong> dead legs or sections where<br />

debris and bi<strong>of</strong>ilms may accumulate. Systems should be designed and commissioned with consideration given to <strong>the</strong><br />

quality <strong>of</strong> <strong>the</strong> outside air <strong>in</strong>troduced <strong>in</strong>to <strong>the</strong> system, and <strong>in</strong>stalled at a suitable distance from nearby cool<strong>in</strong>g towers.<br />

In accordance with <strong>the</strong> provisions <strong>of</strong> AS/NZS 3666.1, sections 4.3 and 4.6, cool<strong>in</strong>g towers should be located <strong>in</strong> areas<br />

free from accumulated soils and o<strong>the</strong>r material that may be a source <strong>of</strong> nutrients able to be sucked <strong>in</strong>to <strong>the</strong> system.<br />

Regulation 7 <strong>of</strong> <strong>the</strong> <strong>Legionella</strong> Regulations requires an automatic biocide dos<strong>in</strong>g device to be fitted to a cool<strong>in</strong>g water<br />

system and to be operat<strong>in</strong>g effectively at all times while <strong>the</strong> system is <strong>in</strong> operation. Regulation 8 <strong>of</strong> <strong>the</strong> <strong>Legionella</strong><br />

Regulations requires drift elim<strong>in</strong>ators to be fitted to all cool<strong>in</strong>g towers unless <strong>the</strong> M<strong>in</strong>ister has determ<strong>in</strong>ed o<strong>the</strong>rwise.<br />

<strong>Guidel<strong>in</strong>es</strong> <strong>for</strong> <strong>the</strong> <strong>Control</strong> <strong>of</strong> <strong>Legionella</strong> <strong>in</strong> <strong>Manufactured</strong> <strong>Water</strong> Systems <strong>in</strong> South Australia page 9

6. Design, <strong>in</strong>stallation and commission<strong>in</strong>g <strong>of</strong> systems<br />

6.2 Hot water systems and warm water systems<br />

Hot water systems and warm water systems are used to provide heated water <strong>in</strong> build<strong>in</strong>gs <strong>for</strong> a range <strong>of</strong> purposes<br />

(e.g. bath<strong>in</strong>g or clean<strong>in</strong>g). Hot water systems are those that heat water and distribute or recirculate it through <strong>the</strong><br />

majority <strong>of</strong> <strong>the</strong> pipe work at ≥ 60ºC. To <strong>in</strong>hibit <strong>the</strong> growth <strong>of</strong> <strong>Legionella</strong> bacteria, Regulation 13 <strong>of</strong> <strong>the</strong> <strong>Legionella</strong><br />

Regulations requires heated water <strong>in</strong> warm water systems to be stored at a m<strong>in</strong>imum 60°C. In order to reduce <strong>the</strong><br />

likelihood <strong>of</strong> growth <strong>of</strong> <strong>Legionella</strong>, section 1.9.1 <strong>of</strong> AS/NZS 3500.4 requires heated water <strong>in</strong> hot water systems to<br />

be stored at a temperature above 60°C, or <strong>for</strong> a water heater certified to AS 3498 to be <strong>in</strong>stalled. Temperature<br />

stratification should be avoided <strong>in</strong> heaters and storage conta<strong>in</strong>ers; this can be achieved by <strong>the</strong> <strong>in</strong>stallation <strong>of</strong> a<br />

stirr<strong>in</strong>g or mix<strong>in</strong>g device. Fur<strong>the</strong>r <strong>in</strong><strong>for</strong>mation can be found <strong>in</strong> SAA/SNZ HB32:1995.<br />

Warm water systems are typically found <strong>in</strong> care facilities such as hospitals, early childhood centres, primary<br />

and secondary schools, nurs<strong>in</strong>g homes <strong>for</strong> young, aged, sick or disabled persons and o<strong>the</strong>r health care facilities.<br />

Warm water systems are those that distribute or recirculate water through <strong>the</strong> majority <strong>of</strong> <strong>the</strong> pipe work at a<br />

nom<strong>in</strong>al temperature <strong>of</strong> 45°C. This is achieved by <strong>the</strong> use <strong>of</strong> a temperature controll<strong>in</strong>g device, mix<strong>in</strong>g valve or by<br />

way <strong>of</strong> sett<strong>in</strong>g <strong>the</strong> <strong>the</strong>rmostat on an <strong>in</strong>stantaneous or heat exchange heat<strong>in</strong>g system. The temperature <strong>in</strong> warm<br />

water systems is ideal <strong>for</strong> <strong>the</strong> growth <strong>of</strong> <strong>Legionella</strong>. However, <strong>the</strong>re is <strong>in</strong>creased risk <strong>of</strong> scald<strong>in</strong>g associated with<br />

water temperatures exceed<strong>in</strong>g 50°C. As a consequence, warm water systems require greater ma<strong>in</strong>tenance to<br />

m<strong>in</strong>imise risks from <strong>Legionella</strong>. Figure 2 provides details <strong>of</strong> <strong>the</strong> relative contact times <strong>for</strong> full thickness burns to<br />

occur at vary<strong>in</strong>g water temperatures.<br />

10<br />

time (m<strong>in</strong>utes)<br />

5<br />

at 50°C, 5 m<strong>in</strong>utes <strong>for</strong> an adult or child<br />

at 55°C, 30 seconds <strong>for</strong> an adult and 7 seconds <strong>for</strong> a child<br />

at 60°C, 5 seconds <strong>for</strong> an adult and 1 second <strong>for</strong> a child<br />

at 70°C, 1 second <strong>for</strong> an adult and 0.5 seconds <strong>for</strong> a child<br />

0<br />

40 50 60 70<br />

temperature (°C)<br />

Figure 2<br />

Full thickness burns – contact times with water<br />

Reference: Henriques FC, Moritz AR. Studies <strong>of</strong> <strong>the</strong>rmal <strong>in</strong>jury V: <strong>the</strong> predictability and <strong>the</strong> significance <strong>of</strong> <strong>the</strong>rmally <strong>in</strong>duced rate processes<br />

lead<strong>in</strong>g to irreversible epidermal <strong>in</strong>jury. Arch Pathol 1947; 43: 489–502.<br />

Dead legs should be avoided <strong>in</strong> warm water systems and hot water systems. Where possible, branch ma<strong>in</strong>s should be<br />

less than 6 metres <strong>in</strong> length. Where <strong>the</strong>rmostatic mix<strong>in</strong>g valves or <strong>the</strong>ir equivalent are fitted, <strong>the</strong> length <strong>of</strong> pipework<br />

after <strong>the</strong> valve should be m<strong>in</strong>imised.<br />

6.3 Spa baths<br />

Spa baths are used as ‘fill and empty’ type devices. Spa baths should be designed and <strong>in</strong>stalled to ensure that all pipe<br />

work and pumps are self-dra<strong>in</strong><strong>in</strong>g to prevent stagnation <strong>of</strong> water. Spa baths should comply with AS 3861.<br />

page 10<br />

<strong>Guidel<strong>in</strong>es</strong> <strong>for</strong> <strong>the</strong> <strong>Control</strong> <strong>of</strong> <strong>Legionella</strong> <strong>in</strong> <strong>Manufactured</strong> <strong>Water</strong> Systems <strong>in</strong> South Australia

6. Design, <strong>in</strong>stallation and commission<strong>in</strong>g <strong>of</strong> systems<br />

6.4 Air-houses, humidifiers and nebulisers<br />

Air-houses are <strong>in</strong>dustrial humidifiers used <strong>in</strong> pa<strong>in</strong>t, electroplat<strong>in</strong>g and f<strong>in</strong>ish<strong>in</strong>g shops. Humidifiers can be found<br />

as part <strong>of</strong> an air handl<strong>in</strong>g plant, manufactur<strong>in</strong>g processes, fruit or vegetable storage and <strong>in</strong> domestic sett<strong>in</strong>gs.<br />

Nebulisers are commonly found <strong>in</strong> hospitals, health care facilities and <strong>in</strong> homes. Air-houses, humidifiers and nebulisers<br />

<strong>in</strong>corporat<strong>in</strong>g water reservoirs generate aerosols and have <strong>the</strong> potential to transmit <strong>Legionella</strong>, mak<strong>in</strong>g it imperative<br />

that <strong>the</strong>se systems are properly managed and ma<strong>in</strong>ta<strong>in</strong>ed <strong>in</strong> a clean state. Only sterile water should be used to fill a<br />

nebuliser reservoir or bas<strong>in</strong>.<br />

6.5 Decorative founta<strong>in</strong>s<br />

Aerosols may be generated by <strong>the</strong> splash<strong>in</strong>g or spray<strong>in</strong>g <strong>of</strong> water <strong>in</strong> a founta<strong>in</strong>. The recirculat<strong>in</strong>g water <strong>in</strong> such<br />

systems may be <strong>in</strong>advertently heated (<strong>for</strong> example by submerged light<strong>in</strong>g) produc<strong>in</strong>g conditions that may favour <strong>the</strong><br />

growth <strong>of</strong> <strong>Legionella</strong>. When design<strong>in</strong>g founta<strong>in</strong>s <strong>the</strong>se factors should be taken <strong>in</strong>to consideration.<br />

6.6 Ice mach<strong>in</strong>es and o<strong>the</strong>r non-aerosol produc<strong>in</strong>g devices<br />

<strong>Manufactured</strong> water systems such as ice mach<strong>in</strong>es and chilled water dispensers can also produce conditions that<br />

enable <strong>Legionella</strong> to survive and grow, but due to <strong>the</strong>ir lack <strong>of</strong> aerosol production <strong>the</strong>se devices are only considered<br />

to be a high risk to <strong>the</strong> severely immunocompromised through pulmonary aspiration. Where extraord<strong>in</strong>ary procedures<br />

such as air filtration and restricted food diets are used to protect high risk patients from <strong>in</strong>fection, <strong>the</strong>se procedures<br />

should extend to dr<strong>in</strong>k<strong>in</strong>g water and ice mach<strong>in</strong>es. Ice mach<strong>in</strong>es should be <strong>in</strong>spected monthly and cleaned as<br />

necessary as per <strong>the</strong> manufacturer’s <strong>in</strong>structions, and <strong>in</strong> any event at least once annually.<br />

<strong>Guidel<strong>in</strong>es</strong> <strong>for</strong> <strong>the</strong> <strong>Control</strong> <strong>of</strong> <strong>Legionella</strong> <strong>in</strong> <strong>Manufactured</strong> <strong>Water</strong> Systems <strong>in</strong> South Australia page 11

7. Responsibility <strong>for</strong> manufactured water systems<br />

7. Responsibility <strong>for</strong> manufactured water systems<br />

Regulation 5 <strong>of</strong> <strong>the</strong> <strong>Legionella</strong> Regulations requires <strong>the</strong> owner <strong>of</strong> premises on which a cool<strong>in</strong>g or warm water system<br />

is located to register <strong>the</strong> system with <strong>the</strong> relevant authority. Regulation 11 <strong>of</strong> <strong>the</strong> <strong>Legionella</strong> Regulations also requires<br />

<strong>the</strong> owner <strong>of</strong> premises on which such a system is <strong>in</strong>stalled to ensure that that <strong>the</strong> person responsible <strong>for</strong> <strong>the</strong> operation<br />

and ma<strong>in</strong>tenance <strong>of</strong> <strong>the</strong> system is sufficiently knowledgeable and competent to ensure that <strong>the</strong> system is operated<br />

and ma<strong>in</strong>ta<strong>in</strong>ed as required. A competent person is someone who has had <strong>the</strong> appropriate tra<strong>in</strong><strong>in</strong>g or practical<br />

experience (or both), sufficient to provide safe and satisfactory per<strong>for</strong>mance <strong>of</strong> <strong>the</strong> system <strong>in</strong> compliance with <strong>the</strong><br />

legislative requirements. The knowledge and competence <strong>of</strong> an operator may be assessed by observ<strong>in</strong>g <strong>the</strong> standard<br />

<strong>of</strong> water quality with<strong>in</strong> <strong>the</strong> system and <strong>the</strong> level <strong>of</strong> compliance with <strong>the</strong> <strong>Legionella</strong> Regulations.<br />

The competent person nom<strong>in</strong>ated by <strong>the</strong> owner may be a contractor or company.<br />

page 12<br />

<strong>Guidel<strong>in</strong>es</strong> <strong>for</strong> <strong>the</strong> <strong>Control</strong> <strong>of</strong> <strong>Legionella</strong> <strong>in</strong> <strong>Manufactured</strong> <strong>Water</strong> Systems <strong>in</strong> South Australia

8. Operation and ma<strong>in</strong>tenance <strong>of</strong> manufactured water systems<br />

8. Operation and ma<strong>in</strong>tenance <strong>of</strong> manufactured<br />

water systems<br />

The safe operation and ma<strong>in</strong>tenance <strong>of</strong> manufactured water systems requires frequent visual <strong>in</strong>spections, regular<br />

clean<strong>in</strong>g and, <strong>in</strong> some cases, <strong>the</strong> use <strong>of</strong> water treatment processes. Inspections should be carried out at least once<br />

every month and can be used as a basis <strong>for</strong> assess<strong>in</strong>g <strong>the</strong> efficacy <strong>of</strong> <strong>the</strong> system per<strong>for</strong>mance, clean<strong>in</strong>g programs and<br />

water treatment processes. It is <strong>the</strong> system owner’s responsibility to ensure this takes place.<br />

Regulation 14 <strong>of</strong> <strong>the</strong> <strong>Legionella</strong> Regulations requires up to date ma<strong>in</strong>tenance log books to be kept (see Part 11).<br />

8.1 Cool<strong>in</strong>g water systems<br />

Regulation 12 <strong>of</strong> <strong>the</strong> <strong>Legionella</strong> Regulations requires cool<strong>in</strong>g water systems to be ma<strong>in</strong>ta<strong>in</strong>ed <strong>in</strong> accordance with<br />

section 2.5 <strong>of</strong> AS/NZS 3666.2 or AS/NZS 3666.3 or an alternative ma<strong>in</strong>tenance program approved by <strong>the</strong> M<strong>in</strong>ister.<br />

AS/NZS 3666.2 requires cool<strong>in</strong>g water systems to be <strong>in</strong>spected at least monthly <strong>for</strong> mechanical condition, biocide<br />

dos<strong>in</strong>g and cleanl<strong>in</strong>ess, and to be cleaned at least once every 6 months. A clean system is free from visible sludge,<br />

foam, slime, rust, scale, dirt, dust and o<strong>the</strong>r deposits or growths. Clean<strong>in</strong>g procedures are detailed <strong>in</strong> AS/NZS 3666.2<br />

and SAA/SNZ HB32. <strong>Water</strong> quality parameters such as pH, TDS and temperature should be monitored and recorded.<br />

Inspections and clean<strong>in</strong>g should be carried out more frequently as required by operational conditions or as <strong>in</strong>dicated<br />

by visual <strong>in</strong>spections (operat<strong>in</strong>g conditions, water quality parameters, and <strong>the</strong> general condition <strong>of</strong> <strong>the</strong> cool<strong>in</strong>g tower<br />

and bas<strong>in</strong>). Stagnation <strong>of</strong> water should be avoided, as this can be conducive to <strong>the</strong> growth <strong>of</strong> <strong>Legionella</strong>. AS/NZS<br />

3666.2 requires that cool<strong>in</strong>g water systems that have been shut down are dra<strong>in</strong>ed, cleaned, kept <strong>in</strong> a dry condition<br />

and <strong>for</strong> water treatment to be re<strong>in</strong>stated be<strong>for</strong>e start-up. Alternatively water treatment can be left <strong>in</strong> cont<strong>in</strong>uous<br />

operation, and cool<strong>in</strong>g water circulated through <strong>the</strong> entire system at <strong>in</strong>tervals <strong>of</strong> not greater than once every 48<br />

hours.<br />

Areas around cool<strong>in</strong>g towers should be kept clean to m<strong>in</strong>imise <strong>the</strong> accumulation <strong>of</strong> soil, dust or o<strong>the</strong>r organic<br />

material that could enter <strong>the</strong> system.<br />

8.1.1 Filtration devices<br />

<strong>Water</strong> filters are designed to reduce particulate matter that is suspended <strong>in</strong> <strong>the</strong> water. Suitably designed and correctly<br />

<strong>in</strong>stalled water filtration systems can help to reduce foul<strong>in</strong>g <strong>of</strong> cool<strong>in</strong>g water systems with particulate matter and may<br />

<strong>in</strong>crease <strong>the</strong> effectiveness <strong>of</strong> dis<strong>in</strong>fection processes.<br />

The efficacy <strong>of</strong> filters vary depend<strong>in</strong>g on factors such as type, pore size and media used. Filters should be regularly<br />

<strong>in</strong>spected, cleaned, and flushed as per <strong>the</strong> manufacturer’s <strong>in</strong>structions. Filters should be kept visibly clean, and should<br />

be <strong>in</strong>spected dur<strong>in</strong>g monthly <strong>in</strong>spection and annual compliance <strong>in</strong>spection. The filter media should be replaced<br />

periodically, <strong>in</strong> accordance with <strong>the</strong> manufacturer’s <strong>in</strong>structions.<br />

8.1.2 Trade waste discharge<br />

Discharges from cool<strong>in</strong>g towers have <strong>the</strong> potential to adversely affect <strong>the</strong> sewerage system as <strong>the</strong>y can conta<strong>in</strong> high<br />

levels <strong>of</strong> suspended solids, organic matter, biocides and heavy metals and <strong>the</strong>y may be considered a ‘trade waste’.<br />

Appropriate management practices at each site are to be employed <strong>in</strong> accordance with SA <strong>Water</strong>’s Cool<strong>in</strong>g <strong>Water</strong><br />