Unit-Dose Packaging Builds Brands Unit-Dose Packaging Builds ...

Unit-Dose Packaging Builds Brands Unit-Dose Packaging Builds ...

Unit-Dose Packaging Builds Brands Unit-Dose Packaging Builds ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

001_UDA_Cover.qxd 3/6/07 11:32 AM Page 1<br />

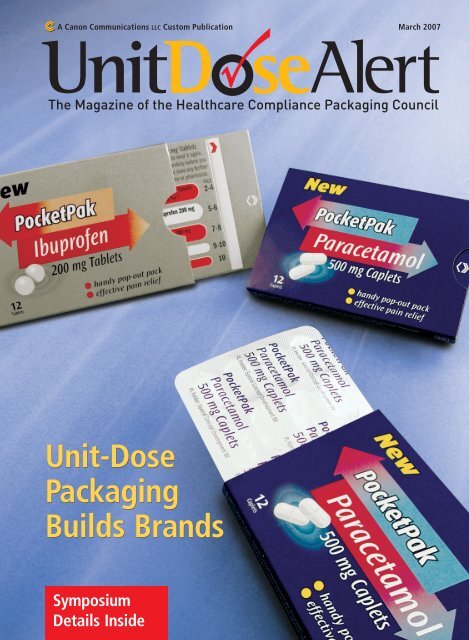

A Canon Communications LLC Custom Publication March 2007<br />

<strong>Unit</strong>-<strong>Dose</strong><br />

<strong>Packaging</strong><br />

<strong>Builds</strong> <strong>Brands</strong><br />

Symposium<br />

Details Inside

002_SymposiumAd.qxd 3/6/07 11:27 AM Page 2<br />

Mark Your<br />

Calendar<br />

PHOTO: Courtesy of the Baltimore Area Convention and Visitors Association<br />

Inner Harbor, Baltimore, MD<br />

for the<br />

Healthcare Compliance<br />

<strong>Packaging</strong> Council’s<br />

15 th Annual National Symposium<br />

on Patient Compliance<br />

May 15–16, 2007<br />

The Tremont Suites Hotel, Baltimore, MD<br />

• Educational Sessions<br />

• Tabletop Exhibitions<br />

• Networking Opportunities<br />

• Sponsorships Available<br />

Visit www.unitdose.org<br />

for program details as they develop.

003_UDA_TOC.qxd 3/6/07 11:27 AM Page 3<br />

March 2007 <strong>Unit</strong> <strong>Dose</strong> Alert, Volume 4, Issue 1<br />

On the cover:<br />

The PocketPak from Burgopak and Structural<br />

Graphics. Photo by Robin Bernstein.<br />

<strong>Unit</strong> <strong>Dose</strong> Alert is a quarterly, copyrightprotected<br />

publication of the Healthcare<br />

Compliance <strong>Packaging</strong> Council.<br />

Material in this publication may not<br />

be reprinted, or otherwise used, without<br />

the express written permission of<br />

the HCPC. For more information on<br />

the HCPC or any material contained in<br />

<strong>Unit</strong> <strong>Dose</strong> Alert, please contact our<br />

headquarters at 131 E. Broad St.,<br />

Ste. 206, Falls Church, VA 22046.<br />

Telephone, 703/538-4030; fax, 703/<br />

538-6305; www.unitdose.org.<br />

<strong>Unit</strong> <strong>Dose</strong> Alert is produced by<br />

Canon Communications LLC and<br />

distributed with Pharmaceutical &<br />

Medical <strong>Packaging</strong> News. The opinions<br />

expressed within are solely those of the<br />

HCPC and/or its members and are not<br />

those of Canon Communications or<br />

Pharmaceutical & Medical <strong>Packaging</strong><br />

News. ©2007 by the Healthcare<br />

Compliance <strong>Packaging</strong> Council. All<br />

rights reserved. Reproduction in whole<br />

or part without written permission is<br />

prohibited.<br />

On the Cover<br />

The PocketPak from Burgopak<br />

and Structural Graphics Takes<br />

Off in the <strong>Unit</strong>ed Kingdom . . . . . 22<br />

Views<br />

Bulletin from the Board<br />

A letter from George Burke,<br />

HCPC’s Chairman of the Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5<br />

News<br />

Industry News..............11<br />

A look at developments in<br />

pharmaceutical compliance<br />

packaging<br />

Member News<br />

Updates on HCPC<br />

members..........................................15<br />

Director’s Chair<br />

A letter from Peter G. Mayberry,<br />

Executive Director,<br />

Healthcare Compliance <strong>Packaging</strong><br />

Council . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

“If manufacturers shipped more product<br />

in unit-dose formats with uniform<br />

consumer information, there would be<br />

fewer dispensing errors in the pharmacy.”<br />

Features<br />

2007 Symposium on Patient Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . 7<br />

Member’s Corner<br />

The IMA Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18<br />

Guest Viewpoint<br />

Thomas Henderson, Vice President, Sales and Marketing<br />

Chesapeake Pharmaceutical <strong>Packaging</strong>–North America. . . . . . . . 20<br />

Sections<br />

Staff Page<br />

Who’s who in the HCPC ......4<br />

Calendar of Events<br />

Where to travel ..................21<br />

Membership Form<br />

Join the HCPC! ................23<br />

<strong>Unit</strong> <strong>Dose</strong> Alert • www.unitdose.org • March 2007 3

004_StaffBox.qxd 3/6/07 11:32 AM Page 4<br />

2007–2008 Board of Directors<br />

Mr. George Burke<br />

Chairman of the Board<br />

President<br />

Sharp Corp.<br />

7451 Keebler Way<br />

Allentown, PA 18106<br />

Mr. Hubert Keil<br />

Vice Chairman of the Board<br />

Managing Director and CEO<br />

Uhlmann <strong>Packaging</strong> Systems<br />

44 Indian Lane E.<br />

Towaco, NJ 07082-1032<br />

Mr. Walter Berghahn<br />

Treasurer<br />

Vice President, <strong>Packaging</strong> Technology<br />

American Health <strong>Packaging</strong><br />

14 Palomino Rd.<br />

Gilford, NH 03249<br />

Mr. Rick Knight<br />

Global Business Manager<br />

Honeywell Healthcare Specialty Films<br />

101 Columbia Rd.<br />

Morristown, NJ 07962<br />

Mr. William Sharpless<br />

Global Market Director<br />

Pharma, Medical, Cosmetic,<br />

and Retail <strong>Packaging</strong><br />

Alcoa Flexible <strong>Packaging</strong><br />

6603 West Broad St.<br />

Richmond, VA 23230<br />

Mr. Shawn Reilley<br />

Executive Vice President<br />

Anderson <strong>Packaging</strong><br />

4545 Assembly Dr.<br />

Rockford, IL 61109<br />

Mr. Renard Jackson<br />

Executive Vice President, Sales and Marketing<br />

Cardinal Health<br />

3001 Red Lion Rd.<br />

Philadelphia, PA 19114<br />

Executive Staff<br />

Peter G. Mayberry<br />

Executive Director<br />

Kathleen Hemming<br />

Associate Director & Editor,<br />

<strong>Unit</strong> <strong>Dose</strong> Alert Magazine<br />

Headquarters Office<br />

Healthcare Compliance <strong>Packaging</strong> Council<br />

131 E. Broad St., Ste. 206<br />

Falls Church, VA 22046<br />

Phone 703/538-4030<br />

Fax 703/538-6305<br />

www.unitdose.org<br />

Sponsorships and Publication<br />

Canon Communications LLC<br />

11444 West Olympic Blvd.<br />

Ste. 900<br />

Los Angeles, CA 90064<br />

Sponsorships: Patricia Spinner,<br />

973/808-1250<br />

4 <strong>Unit</strong> <strong>Dose</strong> Alert • www.unitdose.org • March 2007

005_BulletinBoard.qxd 3/6/07 11:27 AM Page 5<br />

Bulletin from the Board<br />

At Your Service for Another<br />

Term as Chairman<br />

George Burke<br />

Chairman<br />

Healthcare Compliance <strong>Packaging</strong><br />

Council<br />

President<br />

Sharp Corp.<br />

HCPC has raised<br />

our level of<br />

involvement with<br />

Interphex by<br />

showcasing our<br />

award-winning<br />

packages and<br />

staffing a booth in<br />

the <strong>Packaging</strong><br />

Pavilion.<br />

Every two years, the HCPC<br />

holds elections to its Board<br />

of Directors. As reported in<br />

the December issue, we have<br />

recently installed the 2007–2008<br />

Board. During our first meeting<br />

in January, the board set its schedule<br />

for the year as well as selected<br />

officers to serve throughout the<br />

term. I am very pleased to report<br />

that my fellow Board members<br />

have nominated me for another<br />

term as Chairman, a position I<br />

have held since early 2005. I<br />

accepted the nomination with<br />

pride in the knowledge that my<br />

previous service was worthy<br />

of extension.<br />

Serving alongside myself as<br />

officers are Hubert Keil, Vice<br />

Chairman, HCPC, and Managing<br />

Director of Uhlmann <strong>Packaging</strong><br />

Systems LP; and Walter<br />

Berghahn, Treasurer, HCPC,<br />

and Business Development<br />

Manager for AmerisourceBergen<br />

<strong>Packaging</strong> Group. Please<br />

join me in congratulating both<br />

of them on their new duties as<br />

HCPC Officers.<br />

For years, a standard running<br />

joke at many Board meetings<br />

missing some members is<br />

that those absent should be the<br />

ones assigned the most rigorous<br />

tasks. However, at our most<br />

recent meeting, those in attendance<br />

readily took on the additional<br />

leadership responsibilities.<br />

Indeed, the HCPC Board<br />

members are a dedicated group<br />

of industry executives. I can<br />

truly state that I am very pleased<br />

to be of service to the HCPC as<br />

Chairman once again. It is a<br />

position I have thoroughly<br />

enjoyed. I sincerely look forward<br />

to the next two years communicating<br />

with unit-dose packaging<br />

decision-makers such as<br />

you, our members and readers.<br />

This year is off to a great<br />

start with our participation in<br />

Interphex as a continuing sponsor<br />

of this robust pharmaceutical<br />

show. We have raised our<br />

level of involvement with the<br />

event organizers by showcasing<br />

our award-winning packages in<br />

a dedicated area for maximum<br />

exposure. As in the past, the<br />

HCPC will also staff a booth in<br />

the <strong>Packaging</strong> Pavilion and conduct<br />

its annual Compliance<br />

Package of the Year competition<br />

once again on location at the<br />

Javits Center.<br />

Another not-to-be-missed<br />

event is the HCPC’s 15th Annual<br />

National Symposium on<br />

Patient Compliance, to be held<br />

this year in Baltimore. We<br />

believe that this different venue<br />

will provide exciting alternatives<br />

for lodging, dining, and<br />

entertaining. Program information,<br />

registration, sponsorship,<br />

and display opportunities are<br />

detailed elsewhere in this issue.<br />

Be sure to join us May 15–16 at<br />

the Inner Harbor in Baltimore.<br />

<strong>Unit</strong> <strong>Dose</strong> Alert • www.unitdose.org • March 2007 5

006_DirectorsChair.qxd 3/6/07 11:27 AM Page 6<br />

Director’s Chair<br />

How to Define Drug Safety<br />

Peter Mayberry<br />

Executive Director<br />

Healthcare Compliance<br />

<strong>Packaging</strong> Council<br />

The biggest bang for<br />

the buck in terms of<br />

improving drug safety<br />

would be to look<br />

at the way U.S.<br />

pharmaceutical<br />

manufacturers are<br />

allowed to package<br />

and distribute<br />

their products.<br />

As the new Democraticmajority<br />

Congress settles<br />

in and begins implementing<br />

its agenda for the next two<br />

years, one issue that has been<br />

getting tremendous attention on<br />

Capitol Hill is drug safety.<br />

Later this year, in fact, the<br />

Prescription Drug User Fee Act<br />

(PDUFA) is slated to expire. If not<br />

reauthorized, FDA will have little<br />

choice but to stop its participation<br />

in the development of new<br />

drug products — a highly unlikely<br />

scenario. And, as commonly<br />

happens when Congress handles<br />

“must-pass” legislation, it is very<br />

likely that PDUFA reauthorization<br />

will become a vehicle for a<br />

number of issues related to pharmaceuticals.<br />

Indeed, there is<br />

already talk on Capitol Hill of<br />

using the bill as a means of better<br />

monitoring drugs once they are<br />

on the market, and allowing drug<br />

reimportation so that seniors can<br />

have access to cheaper medicine.<br />

To date, however, the primary<br />

focus of drug safety discussion<br />

in the 110th Congress<br />

has centered on FDA, with virtually<br />

no apparent interest being<br />

paid to distribution issues. This<br />

is unfortunate, because, arguably,<br />

the biggest bang for the buck in<br />

terms of improving drug safety<br />

would be to look at the way<br />

pharmaceutical manufacturers<br />

are allowed to package and distribute<br />

their products in the<br />

<strong>Unit</strong>ed States.<br />

Simply stated, if manufacturers<br />

shipped more product in<br />

unit-dose formats with uniform<br />

consumer information, some of<br />

the benefits that would accrue<br />

include:<br />

• Fewer dispensing errors in the<br />

pharmacy.<br />

• Highly improved drug efficacy<br />

(i.e., better assurances that<br />

the drugs will actually work<br />

as intended).<br />

• Less opportunity to introduce<br />

counterfeit product and/or<br />

mix expired product with<br />

product that is still good.<br />

• Far greater opportunity for<br />

pharmacists to counsel<br />

consumers.<br />

• Guarantees that accurate and<br />

reliable consumer information<br />

is dispensed with Rx drugs.<br />

• Improved compliance with<br />

pharmaceutical regimens.<br />

The <strong>Unit</strong>ed States is somewhat<br />

unique in that pharmaceutical<br />

manufacturers are allowed<br />

to ship product in bulk containers<br />

with a single leaflet intended for<br />

physicians and pharmacists.<br />

Switching from the U.S. model to<br />

one that is used throughout much<br />

of the rest of the world — whereby<br />

the same drugs are shipped by<br />

the same manufacturers in unitdose<br />

formats with approved consumer<br />

information — is a timely<br />

initiative. It should be a much<br />

greater part of any Congressional<br />

consideration of a PDUFA<br />

reauthorization bill or any other<br />

initiative geared toward increasing<br />

drug safety for that matter.<br />

6 <strong>Unit</strong> <strong>Dose</strong> Alert • www.unitdose.org • March 2007

007_010_Feature_Symposium.qxd 3/6/07 11:28 AM Page 7<br />

Feature<br />

2007 National Symposium<br />

on Patient Compliance<br />

Join the HCPC at its Annual Educational Event<br />

May 15-16 in Baltimore<br />

Now in its 15th year, the Healthcare Compliance<br />

<strong>Packaging</strong> Council’s annual Symposium<br />

is the singular educational event that focuses<br />

specifically on the pharmaceutical unit-dose<br />

packaging industry. Each year, the latest trends<br />

and topics affecting this area of drug delivery are<br />

examined and addressed by speakers who have<br />

expertise in this packaging niche. Registrants will<br />

find no other conference so highly focused on how<br />

patient compliance is positively impacted through<br />

the use of unit-dose packaging.<br />

Highlights of the 2007 program include an<br />

overview of the Institutes of Medicine Report on<br />

Preventing Medication Errors, as well as commentary<br />

from a member of the Senate Committee<br />

on Health, Education, Labor, and Pensions<br />

on what is in store for the 110th Congress.<br />

Counterfeiting issues as well as FDA’s bar code<br />

rule will also be discussed. This year, representatives<br />

of the Pharmaceutical Printed Literature<br />

Association have been invited to share their<br />

views on pharmaceutical labeling and the new<br />

requirements for package inserts by FDA. Additionally,<br />

an update from the leader of the Ohio<br />

State University study on improving compliance<br />

through unit-dose packaging will be featured on<br />

the second day’s agenda.<br />

All in all, this year’s program offers a tremendous<br />

amount of information on the status of unitdose<br />

packaging and its impact on improving medication<br />

compliance. Registrants will obtain a wealth<br />

of data to bring back to their day-to-day operations<br />

supporting greater use of unit-dose packaging.<br />

The complete program to date is published on<br />

pages 9–10 of this issue of <strong>Unit</strong> <strong>Dose</strong> Alert.<br />

Traditionally, participants hail from various<br />

segments of the pharmaceutical industry. The<br />

HCPC invites clinical-trial operators, pharmacists,<br />

packaging professionals, formulary directors,<br />

and healthcare policymakers to participate.<br />

Indeed, anyone with an interest in the role that<br />

better packaging can play in improving pharmaceutical<br />

compliance and safety is encouraged<br />

to attend.<br />

Over the course of a day and a half, registrants<br />

will not only benefit from the expert testimony<br />

of the speakers, but will also gain a greater<br />

understanding of the many options available for<br />

increasing compliance, improving safety, and positioning<br />

themselves by anticipating future trends in<br />

the pharmaceutical industry. Highlights of the<br />

program also include the awards luncheon and<br />

presentation of the “Compliance Package of the<br />

Year” Award, a tabletop exhibition featuring manufacturers<br />

of compliance enhancing products and<br />

services, and many networking opportunities.<br />

Held at the Tremont Plaza Hotel in Baltimore,<br />

the symposium is easily accessible for key executives<br />

in the pharmaceutical industry, many concentrated<br />

on the I-95 corridor on the East Coast.<br />

<strong>Unit</strong> <strong>Dose</strong> Alert • www.unitdose.org • March 2007 7

007_010_Feature_Symposium.qxd 3/6/07 11:28 AM Page 8<br />

Feature<br />

Hotel Information<br />

Conveniently located in the heart of Baltimore’s thriving downtown business and<br />

cultural district, the Tremont Plaza Hotel offers luxurious comfort to travelers from<br />

any destination. The all-suite property is within walking distance of Baltimore’s<br />

Inner Harbor, Oriole Park at Camden Yards, M&T Bank Stadium, great shopping,<br />

and entertainment. Located at 222 St. Paul Pl., guests are just minutes away from<br />

historic Charles Street’s restaurants and nightlife. A block of rooms has been<br />

reserved for HCPC registrants for the nights of May 14 and 15. To get the room<br />

rate of $159 per night for studio suites, mention the HCPC event. Contact the<br />

Tremont directly at 800/873-6668. The discounted rate applies only through April<br />

23; prevailing rates and availability apply afterward.<br />

Exhibits<br />

A tabletop exhibition will be open from 4:00–6:00 P.M. on Tuesday, May 15,<br />

featuring HCPC members and others who offer compliance packaging services,<br />

materials, and devices. A limited number of tabletop spaces are available to<br />

nonmembers on a first-come, first-served basis.<br />

Fees for display space are as follows:<br />

$750 for HCPC corporate members<br />

(includes two exhibitor badges, no symposium registration, or free with three<br />

paid symposium registrations)<br />

$1250 for HCPC individual members<br />

$1500 for non-HCPC members<br />

(includes two exhibitor badges, no symposium registration)<br />

Electrical hookups are available for an additional $50.<br />

For complete details, visit the “Symposium” page at www.unitdose.org or call the HCPC office at<br />

703/538-4030.<br />

Fees<br />

Event Information<br />

The registration fee includes admission to the entire program and tabletop exhibition,<br />

as well as the welcome reception, awards luncheon, all breaks, and the<br />

exhibit reception.<br />

Registration fees:<br />

$750 for individual HCPC members or<br />

employees of HCPC member companies<br />

$950 for nonmembers<br />

(An early bird discount of $50 is available through April 20.)<br />

All nonmembers receive a full year’s individual membership with each paid<br />

registration.<br />

Cancellation Policy<br />

Cancellations will be accepted through May 8, 2007, but are subject to a $75 processing<br />

fee. Substitutions will be honored at any time, but must be submitted in writing.<br />

Registration<br />

Participants can register online or by mail.<br />

Visit www.unitdose.org to sign up online or to print the registration form.<br />

8 <strong>Unit</strong> <strong>Dose</strong> Alert • www.unitdose.org • March 2007

007_010_Feature_Symposium.qxd 3/6/07 11:28 AM Page 9<br />

Feature<br />

Conference Line-Up<br />

HCPC 15th Annual National Symposium on Patient Compliance<br />

May 14–16, 2007<br />

Tremont Suites Hotel & Conference Center<br />

Baltimore, MD<br />

Monday, May 14, 2007<br />

6:00 P.M.–8:00 P.M.<br />

Welcome Reception/Cocktails<br />

Sponsorship TBA<br />

Tuesday, May 15, 2007<br />

8:00–9:00 A.M.<br />

Breakfast<br />

Sponsorship: Alcoa <strong>Packaging</strong><br />

9:00–9:15 A.M.<br />

Welcoming Remarks<br />

George Burke<br />

Chairman of the Board, HCPC<br />

9:15–10:00 A.M.<br />

Topic: Institutes of Medicine Report on<br />

Preventing Medication Errors<br />

Speaker Name/Title: Albert W. Wu, MD, MPH,<br />

Professor, Health Policy and Management,<br />

Johns Hopkins University (Invited)<br />

Abstract: The Institutes of Medicine Committee<br />

on Preventing Medication Errors released a<br />

study in 2006, which concluded, among other<br />

things, that unit-of-use packaging can play a<br />

key role in reducing medication errors. Dr. Wu<br />

has been invited to outline this research.<br />

10:00–10:45 A.M.<br />

Topic: What Is in Store for Pharmaceuticals<br />

during the 110th Congress<br />

Speaker Name/Title: A Representative from the<br />

Senate Committee on Health, Education,<br />

Labor and Pensions<br />

Abstract: The HELP Committee has broad jurisdiction<br />

over healthcare issues within the U.S.<br />

and, as such, is instrumental in crafting legislation<br />

and conducting oversight of FDA with<br />

regard to pharmaceutical policy. The Committee<br />

has been asked to provide a speaker<br />

who will address issues of importance over the<br />

next two years.<br />

10:45–11:15 A.M.<br />

Morning Break<br />

Sponsorship: Uhlmann <strong>Packaging</strong> Systems L.P.<br />

11:15 A.M.–Noon<br />

Topic: Medication Therapy Management under<br />

Medicare Part D<br />

Speaker/Title: A speaker will be sought from the<br />

Centers for Medicare and Medicaid<br />

Services (CMS)<br />

Abstract: Now that Medicare Part D has been in<br />

place for one full year, an official from CMS<br />

will be requested to address the status of MTM<br />

programs under the new benefit.<br />

Noon – 1:30 P.M.<br />

Lunch and Presentation of the HCPC’s 2006<br />

Compliance Package of the Year Award<br />

Sponsorship TBA<br />

1:30–2:15 P.M.<br />

Topic: An Overview Update on Efforts to<br />

Implement FDA’s Bar Code Rule<br />

Speaker/Title: Philip L. Chao, Office of<br />

Policy and Planning, U.S. FDA (Invited)<br />

Abstract: The U.S. FDA issued final regulations<br />

in 2004 requiring that bar codes be affixed to<br />

all Rx and OTC drug products intended for<br />

use in healthcare facilities. FDA has been<br />

invited to outline how the implementation<br />

of this rule has gone as well as areas of concern<br />

or interest moving forward.<br />

2:15–2:45 P.M.<br />

Afternoon Break<br />

Sponsorship: Sharp Corp.<br />

2:45–3:30 P.M.<br />

Topic: Why Counterfeit Medicines Is an International<br />

Trade Problem, Global Industry Trends,<br />

and the Need for Global Cooperation<br />

Speaker/Title: Jeffrey Gren, Director, Office of<br />

Health and Consumer Goods, U.S. International<br />

Trade Administration (Confirmed)<br />

Abstract: The International Trade Administration<br />

is a division of the U.S. Department of<br />

Commerce and Mr. Gren has been asked to<br />

share his expertise on issues involving the global<br />

aspects of the counterfeit medicines problem.<br />

Mr. Gren will outline why counterfeit medicines<br />

are an international trade problem and<br />

will discuss global industry trends impacting<br />

<strong>Unit</strong> <strong>Dose</strong> Alert • www.unitdose.org • March 2007 9

007_010_Feature_Symposium.qxd 3/6/07 11:28 AM Page 10<br />

Feature<br />

this problem. Specifically, Mr. Gren has been<br />

asked to provide insights on the drug products<br />

that are being counterfeited, where the counterfeits<br />

are coming from, the need for international<br />

cooperation, and steps that ITA/DOC<br />

are taking to address the problem.<br />

3:30–4:15 P.M.<br />

Topic: FDA’s Anticounterfeiting Task Force Goals<br />

for 2007<br />

Speaker Name/Title: Ilisa Bernstein, Director of<br />

Pharmacy Affairs, U.S. FDA (Confirmed)<br />

Abstract: Ms. Bernstein has been asked to outline<br />

the status of FDA’s Pharmaceutical Anti-Counterfeiting<br />

Task Force and provide insights on<br />

FDA’s efforts to create a national track and<br />

trace system for legitimate drug products.<br />

4:15–6:00 P.M.<br />

Reception/Tabletop Displays<br />

Reception Sponsored by: American Health<br />

<strong>Packaging</strong> and Anderson <strong>Packaging</strong><br />

Wednesday, May 16, 2007<br />

8:00–9:00 A.M.<br />

Breakfast<br />

Sponsorship TBA<br />

9:00–9:15 A.M.<br />

Welcoming Remarks<br />

Peter G. Mayberry<br />

HCPC Executive Director<br />

9:15–9:45 A.M.<br />

Topic: An Overview of FDA’s New Labeling<br />

Requirements for Package Inserts<br />

Speaker/Title: Tom Henderson, Chairman of the<br />

Board, Pharmaceutical Printed Literature<br />

Association (Confirmed)<br />

Abstract: The U.S. FDA requires that labeling<br />

intended for use by medical professionals<br />

be shipped with each container of an Rx<br />

drug product. Known as a Package Insert,<br />

or PI, this label is intended to ensure that<br />

drugs are dispensed and consumed safely.<br />

This presentation details FDA regulations<br />

on PI formatting and content that were<br />

approved in 2006.<br />

9:45–10:15 A.M.<br />

Topic: Labeling Rx Products for the Global Market<br />

Speaker/Title: Carol Hammond, Technical<br />

Development Director, Chesapeake Healthcare<br />

<strong>Packaging</strong> (Europe)<br />

Abstract: Ms. Hammond will address considerations<br />

that go into packaging drugs offered for<br />

sale outside the <strong>Unit</strong>ed States. Specific emphasis<br />

will be given to recent EU requirements<br />

regarding use of Braille and child resistance.<br />

Case studies will also be offered on products<br />

that are being packaged for sale in multiple<br />

countries and some recent novel constructional<br />

developments shown.<br />

10:15–10:45 A.M.<br />

Morning Break<br />

Sponsorship TBA<br />

10:45–11:15 A.M.<br />

Topic: Walter Reed Compliance Study<br />

Speaker Name/Title: Jeannie Kim Lee, Pharm.D,<br />

Clinical Pharmacist, Walter Reed Army<br />

Medical Center (Confirmed)<br />

Abstract: In 2006, research was published in the<br />

Journal of the American Medical Association<br />

in which compliance rates were compared<br />

when Rx drugs were dispensed in traditional<br />

cap and vial closures versus when they were<br />

dispensed in multimed blister cards prepared at<br />

the pharmacy. This presentation will provide<br />

an overview of that research.<br />

11:15–11:45 A.M.<br />

Topic: Improving Pharmaceutical Compliance<br />

Through Use of <strong>Unit</strong>-<strong>Dose</strong> <strong>Packaging</strong><br />

Speaker Name/Title: Philip Schneider, Ohio State<br />

University (Invited)<br />

Abstract: Working with a grant from the U.S.<br />

Department of Health and Human Services,<br />

Ohio State University conducted a study on<br />

the impact that unit-dose formats can have in<br />

improving compliance with antihypertension<br />

drugs. Mr. Schneider has been asked to outline<br />

the scope of this research as well as certain<br />

findings that were obtained.<br />

Noon<br />

Closing Remarks/Adjournment<br />

Hubert Keil<br />

HCPC Vice Chairman<br />

Symposium program at time of publication.<br />

Final Program is subject to change.<br />

10 <strong>Unit</strong> <strong>Dose</strong> Alert • www.unitdose.org • March 2007

011_014_IndustryNews.qxd 3/6/07 11:28 AM Page 11<br />

Industry News<br />

The Healthcare Compliance<br />

<strong>Packaging</strong> Council’s 2006<br />

“Compliance Package of the Year” Awards<br />

The Healthcare Compliance <strong>Packaging</strong> Council (HCPC), a notfor-profit<br />

trade association dedicated to the promotion of the<br />

many benefits of unit-dose packaging—especially its ability to<br />

be designed into compliance-enhancing formats—will be accepting<br />

entries for its 2006 “Compliance Package of the Year” Awards<br />

through March 15, 2007.<br />

While there are no fees or other monetary charges required to participate<br />

in this program, qualifying entries must comply with the following:<br />

• Be in a unit-dose format.<br />

• Have at least one compliance-enhancing feature.<br />

• Have been commercially available (anywhere in the world)<br />

at some point during 2006.<br />

• Not require drug products to be “repackaged” by patients.<br />

Information Mediary Corp.’s Med-Ic<br />

Digital Package won the 2005<br />

Compliance Package of the Year in<br />

the Healthcare Compliance <strong>Packaging</strong><br />

Council’s annual competition.<br />

A new category for innovative design has been added to recognize<br />

compliance packages not yet commercially available. Previously<br />

excluded from the competition but now eligible for competition<br />

are prototypes, designs, concept packages, and other formats<br />

that are not commercially available.<br />

The winning entry will receive official recognition from the<br />

HCPC, designating it as the Healthcare Compliance <strong>Packaging</strong><br />

Council’s “Compliance Package of the Year” for 2006. Additional<br />

recognition will be presented to packages selected as “First Runner<br />

Up” and “Second Runner Up” as well as “Innovative Design.”<br />

Each of the winning entries will be promoted by the HCPC during<br />

its 2007 National Symposium on Patient Compliance, in articles<br />

to be published in <strong>Unit</strong> <strong>Dose</strong> Alert (the official HCPC magazine),<br />

and in materials forwarded to media representatives by the<br />

HCPC.<br />

Cash awards in the following amounts will also be granted,<br />

in the form of scholarships, to schools of packaging designated<br />

by winners of the HCPC’s 2006 “Compliance Package of<br />

the Year” Award:<br />

Compliance Package of the Year: $6,000 cash scholarship<br />

First Runner Up:<br />

Second Runner Up:<br />

Innovative Design Winner:<br />

$2,000 cash scholarship<br />

$2,000 cash scholarship<br />

$2,000 cash scholarship<br />

<strong>Unit</strong> <strong>Dose</strong> Alert • www.unitdose.org • March 2007 11

011_014_IndustryNews.qxd 3/6/07 11:28 AM Page 12<br />

Industry News<br />

Official Rules<br />

Entries must be submitted between November 15, 2006 and March 15, 2007. The winning entry will be announced during<br />

the HCPC’s 15th Annual National Symposium on Patient Compliance to be held at the Tremont Suites Hotel and Conference<br />

Center in Baltimore, Maryland, May 15–16, 2007.<br />

• Entrants must submit sample packages, as well as proof of<br />

their commercial availability during 2006. At the HCPC’s<br />

discretion, a statement attesting to commercial availability<br />

will be deemed acceptable. The HCPC reserves the<br />

right, however, to demand verifiable evidence that the<br />

package was indeed commercially available as a qualification<br />

condition.<br />

• Entrants must also submit digital photographs or drawings<br />

of the package so that they may be included in the HCPC<br />

media announcements for the winning entry.<br />

• Packages must be in a unit-dose format and may be intended<br />

for distribution by a pharmaceutical company, a pharmacist,<br />

a home healthcare provider, an in-patient facility,<br />

or another entity. Qualifying entries will not require<br />

patients to “repackage” medications.<br />

• Entries must include a separate form noting the name,<br />

address, and phone number of the company or individual<br />

marketing the product; the name of the person(s) responsible<br />

for its design; and the person who will be responsible<br />

for designating a school of packaging to receive scholarship<br />

funds should the entry win one of the three awards.<br />

• Any additional information regarding the package (i.e.,<br />

promotional literature, other honors or awards that the<br />

package has earned, etc.) may be included, but must be<br />

kept separate from the packaging itself so that it will not<br />

influence the judges’ review. Failure to comply will result<br />

in disqualification.<br />

A panel of judges will be selected by the HCPC. All entries<br />

will be evaluated by HCPC staff to determine eligibility. All<br />

entries determined to meet the established entry qualifications<br />

by HCPC staff will be reviewed by the judging panel. Judges<br />

will be asked to make subjective determinations, on a numerical<br />

scale, of characteristics such as: 1) the package’s ability<br />

to increase pharmaceutical compliance; 2) innovative designs<br />

incorporated into the packaging; and 3) unique features that<br />

distinguish the package from others on the market.<br />

The package receiving the highest combined score will be designated<br />

“Compliance Package of the Year”; the package<br />

receiving the second-highest combined score will be designated<br />

“First Runner Up”; and the package receiving the<br />

third-highest combined score will be designated “Second<br />

Runner Up.” In the case of a tie, judges will be asked to<br />

reevaluate the three packages that received the highest combined<br />

scores during initial review.<br />

The judges’ determination will be final, and the HCPC<br />

reserves the right to withhold the prize should there be no<br />

acceptable entries in any or all of the winning categories.<br />

Cash prizes, in the form of scholarship funds forwarded to<br />

an accredited school of packaging in the <strong>Unit</strong>ed States by<br />

the HCPC and publisher CANON COMMUNICATIONS LLC<br />

based on designations by the winners of each category,<br />

will be awarded as follows: $6,000.00 for the Compliance<br />

Package of the Year; $2,000.00 for the First Runner<br />

Up; $2,000.00 for the Second Runner Up; and $2,000 for<br />

the Innovative Design Winner.<br />

• The HCPC will make a reasonable effort to determine<br />

how each of the winners would like to have their cash<br />

prizes distributed (i.e., which accredited school of packaging<br />

should receive the scholarship funds).<br />

• Should winners in any category fail to designate an accredited<br />

school of packaging within 90 calendar days of the<br />

award’s presentation, the prize will be “forfeited.”<br />

• Winners may not be able to “split” cash prizes by designating<br />

more than one school of packaging.<br />

• Cash prizes will not be awarded to any person or entity<br />

other than an accredited school of packaging for any reason,<br />

under any circumstances.<br />

The HCPC has sole responsibility for forwarding cash<br />

prizes directly to accredited schools of packaging designated<br />

by the winner of each category and will be responsible for<br />

directing the Dean of each school to distribute the funds as<br />

scholarships to one or more students based on financial<br />

need, academic achievement, or any other criteria that the<br />

Dean sees fit.<br />

All entry materials will become the property of the HCPC<br />

and will not be returned. Entries must be mailed to HCPC.<br />

Interested persons may obtain the name of the winner by<br />

sending a self-addressed, stamped envelope to the<br />

address above.<br />

Employees of the HCPC member companies, HCPC individual<br />

members, and their families may submit entries, but<br />

they will automatically disqualify themselves from consideration<br />

as judges should they do so.<br />

THIS CONTEST IS VOID WHERE PROHIBITED BY LAW<br />

12 <strong>Unit</strong> <strong>Dose</strong> Alert • www.unitdose.org • March 2007

011_014_IndustryNews.qxd 3/6/07 11:28 AM Page 13<br />

Industry News<br />

Ed Hancock is Recognized for His<br />

Dedication to the HCPC<br />

At its January board meeting,<br />

the Board of Directors for<br />

the Healthcare Compliance<br />

<strong>Packaging</strong> Council honored<br />

Ed Hancock, President of<br />

AmerisourceBergen <strong>Packaging</strong><br />

Group, for his dedication and<br />

service to the organization. Since<br />

the HCPC’s inception, Ed has been<br />

actively involved in one capacity<br />

or another throughout the association’s<br />

17-year history. Late last<br />

year, Ed notified the HCPC that he<br />

would not seek a board position<br />

for the coming term.<br />

Mr. Hancock was among the<br />

founding members of the HCPC<br />

in 1990, and represented what was<br />

then the American Mirrex Corp.<br />

as Director, FDA Films. He served<br />

as a board member until leaving<br />

to become Vice President, Sales<br />

and Marketing, for <strong>Packaging</strong><br />

Coordinators Inc. in Philadelphia.<br />

While at PCI, Mr. Hancock served<br />

as the HCPC’s technical committee<br />

chair.<br />

In 1993, Mr. Hancock joined<br />

Anderson <strong>Packaging</strong> Inc. of<br />

Throughout his years of<br />

involvement in the HCPC, Mr.<br />

Hancock rarely missed a board<br />

meeting or an HCPC event.<br />

Rockford, IL, as Vice President,<br />

Sales and Marketing and was<br />

appointed President of the<br />

Pharmaceutical Division in<br />

1996. He rejoined the HCPC<br />

Board of Directors in that<br />

capacity and served as Vice<br />

Peter Mayberry, HCPC Executive Director, presents Ed Hancock with a<br />

commemorative plaque at the January 2007 Board Meeting.<br />

Chairman under Dan Gerner’s<br />

Chairmanship. He ascended to<br />

Chairman and served two consecutive<br />

terms through 2000. He<br />

has subsequently been elected to<br />

the HCPC Board<br />

each term until electing<br />

to leave the board<br />

in 2007.<br />

In 2001, Mr.<br />

Hancock joined the<br />

AmeriSource Corp. as<br />

President of American<br />

Health <strong>Packaging</strong>.<br />

AmeriSource subsequently<br />

merged with Bergen Brunswig<br />

to become the AmerisourceBergen<br />

Corp. There, Mr. Hancock<br />

has orchestrated the creation of<br />

the AmerisourceBergen <strong>Packaging</strong><br />

Group (ABPG), an international<br />

pharmaceutical packaging services<br />

provider. With the acquisition<br />

of Brecon in 2006, the ABPG is<br />

now composed of three operating<br />

companies: American Health<br />

<strong>Packaging</strong>, Anderson <strong>Packaging</strong><br />

Inc., and Brecon Pharmaceuticals<br />

Ltd. (Wales, UK). ABPG is structured<br />

as one of AmerisourceBergen<br />

Corp.’s five business units. Mr.<br />

Hancock was named President of<br />

ABPG in 2003.<br />

Throughout his years of<br />

involvement in the HCPC, Mr.<br />

Hancock rarely missed a board<br />

meeting or an HCPC event. He<br />

was constantly available to provide<br />

guidance and leadership to<br />

the organization’s board and staff<br />

members. During the January<br />

2007 Board meeting, he was com-<br />

<strong>Unit</strong> <strong>Dose</strong> Alert • www.unitdose.org • March 2007 13

011_014_IndustryNews.qxd 3/6/07 11:28 AM Page 14<br />

Industry News<br />

HCPC Board members congratulate Ed Hancock, third from left. From left<br />

to right are Shawn Reilley, Anderson <strong>Packaging</strong>; Bill Sharpless, Alcoa<br />

<strong>Packaging</strong>; Walter Berghahn, AmerisourceBergen <strong>Packaging</strong> Group;<br />

George Burke, Sharp Corp.; and Hubert Keil, Uhlmann <strong>Packaging</strong><br />

Systems.<br />

memorated with a plaque and<br />

received everyone’s good wishes.<br />

He stressed that he will “always”<br />

be available to the HCPC and that<br />

his decision to step away from the<br />

Board was hard to make, but necessary<br />

considering the expansion<br />

of his responsibilities within ABC.<br />

“We are going to miss Ed’s input<br />

tremendously,” noted HCPC Executive<br />

Director Peter Mayberry. “He<br />

has been a good friend and great<br />

supporter of the HCPC mission. I<br />

know that the entire association<br />

joins me in wishing Ed all the best<br />

in his future endeavors.”<br />

Visit the HCPC at Interphex<br />

at Booth #3083<br />

The Healthcare Compliance <strong>Packaging</strong> Council is serving again as a promotional partner for<br />

Interphex. One of the largest pharmaceutical trade shows, Interphex is a must-attend event for<br />

anyone involved in pharmaceutical packaging, including all HCPC members. Inside this issue<br />

you will find a ticket for free admission to the exhibition, compliments of the HCPC.<br />

Interphex takes place April 24–26 at the Jacob K. Javits Convention Center in New York City. During<br />

the show, HCPC staff members will distribute copies of <strong>Unit</strong> <strong>Dose</strong> Alert, field questions regarding<br />

compliance packaging issues, promote the association, and solicit members as well as showcase<br />

samples of unit-dose packages from its booth. For the first time, the HCPC will also be provided a<br />

kiosk near the entrance to the main exhibit hall to highlight examples of the “Compliance Package<br />

of the Year” Award winners over the past several years. This opportunity is part of an expanded<br />

agreement with the organizers of Interphex. The HCPC welcomes the publicity to help promote the<br />

many benefits of unit-dose packaging.<br />

Following tradition, the HCPC will conduct its annual “Compliance Package of the Year” Awards<br />

judging during Interphex. The HCPC does this to take advantage of the fact that a skilled pool of<br />

judges is readily available, given the pharmaceutical packaging experts gathering at this event.<br />

On Wednesday afternoon, April 25, the winning packages will be displayed at the HCPC booth.<br />

A formal new release will be available after the show. All winners in our 2006 competition will be<br />

congratulated and honored at the 15th annual Symposium on Patient Compliance to be held May<br />

15–16 in Baltimore, MD. Details on the 2007 symposium are included elsewhere in this issue.<br />

Be certain to stop by the HCPC Booth, #3083, while you are browsing the exhibits in the<br />

<strong>Packaging</strong> Pavilion.<br />

14 <strong>Unit</strong> <strong>Dose</strong> Alert • www.unitdose.org • March 2007

015_017_MemberNews.qxd 3/6/07 11:29 AM Page 15<br />

Member News<br />

Safety-Pak Plus Blister<br />

Lidding Introduced by<br />

Alcoa <strong>Packaging</strong><br />

Alcoa <strong>Packaging</strong> has<br />

announced the availability<br />

of Safety-Pak Plus, its<br />

newest product for pharmaceutical<br />

packaging, to its line of Safety-<br />

Pak blister lidding specifications.<br />

A leading pharmaceutical packaging<br />

supplier, Alcoa manufactures a<br />

variety of packaging materials,<br />

including extrusion- and adhesivelaminated<br />

pouch materials, overwraps<br />

and liner stock, blister lidding, and laminated foil, among others.<br />

This latest innovation utilizes a peel-push CR-opening process, but<br />

its film exterior has the ability for a full-panel-peel without tearing,<br />

making it much simpler for the consumer to gain access to the pushthrough<br />

foil. The exterior film not only provides an easier peel, but also<br />

allows for a higher-quality printing substrate than paper, thereby<br />

enhancing brand graphics and accepting flexo and UV inks from the<br />

in-line printing systems.<br />

During testing, Safety-Pak Plus exhibited greater Mullen burst strength<br />

than do standard Safety-Paks, as well as greater puncture resistance<br />

than traditional, industry-standard CR packaging. Additionally, Alcoa’s<br />

new lid stock offers a broader sealing window that allows for secure seals<br />

at lower temperatures, an advantage for temperature-sensitive pharmaceuticals.<br />

This product characteristic also adds valuable seal-processing<br />

latitude for high-speed rotary sealing equipment.<br />

Contact Georgia Mohr, Alcoa’s marketing manager, for more information<br />

at 814/459-4987.<br />

(Correction: The wrong product shot was originally included with this item, which ran<br />

in the December 2006 issue of <strong>Unit</strong> <strong>Dose</strong> Alert. The correct photo is shown above.)<br />

Klöckner Pentaplast to Display New<br />

Blister Films at Expo Farma 2007<br />

While participating in Expo<br />

Farma 2007 at the World Trade<br />

Center in Mexico City on March<br />

13–16, Klöckner Pentaplast will<br />

display a wide range of pharmaceutical<br />

packaging films at booths<br />

1041 and 1043. Among the newest<br />

products will be Klöckner Pentaplast’s<br />

Pentapharma alfoil SG films<br />

and Pentapharm BlisterPro software<br />

design program.<br />

The Pentapharm alfoil PVdCcoated<br />

film product line has been<br />

extended to include Pentapharm<br />

alfoil SG films for pharmaceutical<br />

and nutraceutical products requiring<br />

outstanding moisture protection<br />

and enhanced performance.<br />

Pentapharm alfoil SG films provide<br />

excellent surface slip characteristics<br />

(low coefficient-offriction)<br />

as compared to standard<br />

PVdC-coated film for higher packaging<br />

line productivity and yield.<br />

This film is available worldwide<br />

from Klöckner Pentaplast and is<br />

the only film on the market that<br />

offers such properties.<br />

Available in two-layer<br />

(PVC/PVdC) or three-layer<br />

(PVC/PE/PVdC) structures for<br />

medium to high moisture barrier,<br />

Pentapharm alfoil SG films have<br />

better thermoforming properties<br />

as compared to conventional<br />

PVdC-coated films. These films<br />

prevent blocking on preheat plates<br />

and offer a more-consistent material<br />

flow during the thermoforming<br />

process. No modifications are<br />

required for preheat plates, thereby<br />

providing additional cost savings.<br />

In addition, Pentapharm<br />

alfoil SG films have improved<br />

mold and blister-to-blister denest<br />

properties that allow for<br />

higher filling rates for gel caps<br />

and other pharmaceuticals.<br />

These films are sealable to all<br />

standard vinyl-compatible lid<br />

stocks; available in transparent<br />

clear and opaque white colors;<br />

and compliant with U.S. FDA<br />

requirements for use in pharmaceutical<br />

packaging.<br />

Also during the Expo Farma<br />

exhibit, Klöckner Pentaplast<br />

will demonstrate its Pentapharm<br />

BlisterPro. This software<br />

program introduces finite<br />

element modeling for thermoforming<br />

of pharmaceutical blister<br />

packages to improve the<br />

film-selection process and provide<br />

package engineering support<br />

services to the pharmaceutical<br />

industry. Pentapharm<br />

BlisterPro allows package<br />

designers, technicians, and engineers<br />

to explore the effects of<br />

tool geometry, film types, and<br />

process conditions before running<br />

actual experiments, thereby<br />

avoiding expensive production<br />

line trials and tooling costs.<br />

In conjunction with the blister<br />

research center, Klöckner Pentaplast<br />

<strong>Unit</strong> <strong>Dose</strong> Alert • www.unitdose.org • March 2007 15

015_017_MemberNews.qxd 3/6/07 11:29 AM Page 16<br />

Member News<br />

Colbert <strong>Packaging</strong> Upgrades<br />

to Full Corporate Member<br />

at the HCPC<br />

Longtime Healthcare Compliance <strong>Packaging</strong><br />

Council individual member Jim Hamilton, President<br />

of Colbert <strong>Packaging</strong> Corp., notified the HCPC early<br />

this year of his company’s intention to upgrade to full<br />

corporate membership. Colbert <strong>Packaging</strong> is a manufacturer<br />

of folding cartons, rigid paper boxes, and<br />

paperboard specialty products. Its folding carton,<br />

flexographic packaging, and pressure-sensitive label<br />

operations are based in Lake Forest, IL; Colbert’s<br />

rigid paper box and contract packaging facilities are<br />

located in South Bend, IN. Yet another folding carton<br />

facility is based in Elkhart, IN.<br />

Colbert <strong>Packaging</strong>'s headquarters located at 28355<br />

N. Bradley Road, Lake Forest, IL 60045.<br />

Colbert <strong>Packaging</strong> executives (left to right) are Brad<br />

Davis, VP/GM Flexographic Division; Jim Hamilton,<br />

President; Lon Johnson, VP Pharmaceutical Sales;<br />

and Glenn Grosskopf, VP Product Development.<br />

Since its founding in 1959, Colbert <strong>Packaging</strong><br />

has built a solid reputation for high-quality products.<br />

Colbert’s contract packaging operation focuses on<br />

blister and heat-seal cards, as well as a variety of<br />

services, including shrink wrapping, repackaging,<br />

warehousing, palletizing, lot tracing, onserts, and<br />

specialty-shaped boxes, among others.<br />

During 2006, Colbert received its first patent<br />

covering the BlisterGuard product line, which is a<br />

clamshell package used for displaying and housing<br />

products or other objects. It is highly pilfer resistant,<br />

yet easy for consumers to open.<br />

For more information, visit www.colbertgpkg.<br />

com or contact Jim Hamilton at jhamilton<br />

@colbertpkg.com.<br />

is the only global supplier to offer<br />

such an integrated technical support<br />

program.<br />

The Klöckner Pentaplast<br />

Group is a leading producer of<br />

films for pharmaceutical, medical<br />

device, and general-purpose thermoform<br />

packaging, as well as<br />

printing and specialty applications.<br />

For more information, visit<br />

www.kpfilms.com.<br />

Sharp Expands<br />

Carded Blister<br />

Capacity<br />

Responding to an increasing<br />

demand from the pharmaceutical<br />

industry, Sharp Corp. has expanded<br />

its carded blister capacity in<br />

Conshohocken, PA. “We are seeing<br />

more opportunities that<br />

involve large volumes, especially<br />

for launch,” says Steve Hamaday,<br />

Director of Engineering. “Carded<br />

blisters have billboard space that<br />

enables the pharmaceutical company<br />

to offer more patient information<br />

and extra panels for<br />

attaching booklets and product<br />

literature. Compliance with many<br />

of today’s drugs is critical for<br />

patient care, and the carding concept,<br />

with proper design and artwork,<br />

easily meets the need.”<br />

To increase its capacity, Sharp<br />

relied on in-house engineering<br />

expertise to upgrade proven equipment<br />

at the Conshohocken site. By<br />

adding automated feeders for cards<br />

and literature, and in-line verification<br />

systems for compliance, Sharp<br />

was able to improve outputs,<br />

reduce labor, and increase compliance<br />

of its very versatile existing<br />

carding lines.<br />

Hamaday says that “because<br />

we make all our tooling in-house<br />

to support our carding lines and<br />

we have multiple equivalent lines,<br />

we are able to tool up and validate<br />

for a product run in half the time<br />

and at a much reduced cost, more<br />

so than with some of our more<br />

high-speed equipment. That<br />

allows us to offer a more costeffective<br />

solution for customers<br />

who are unsure of long-term forecasts<br />

or want to launch with larger<br />

volumes, and then scale back<br />

for ongoing market needs.”<br />

In addition to multiple flexible<br />

carding lines, Sharp has higherspeed<br />

equipment for large product<br />

demands with strong annual<br />

16 <strong>Unit</strong> <strong>Dose</strong> Alert • www.unitdose.org • March 2007

015_017_MemberNews.qxd 3/6/07 11:29 AM Page 17<br />

Member News<br />

pharmaceutical market forecasts.<br />

As summarized by John<br />

Groetsch, Sharp’s Senior Designer,<br />

“Carded blisters promote<br />

greater patient compliance and<br />

ease of access to drug therapy<br />

information. They also offer a<br />

variety of child-resistant designs,<br />

and our customers are now using<br />

this unit-dose format in trade and<br />

sample packages.”<br />

Newest Launches<br />

in <strong>Unit</strong> <strong>Dose</strong> at<br />

American Health<br />

<strong>Packaging</strong><br />

Two more generic pharmaceutical<br />

products are now available<br />

in unit dose formats at American<br />

Health <strong>Packaging</strong>, a business<br />

unit of AmerisourceBergen. Ribavirin<br />

200mg capsules as well as<br />

Ribavirin 200mg tablets are packaged<br />

in unit dose and bar coded to<br />

the dose level. Many American<br />

Heath <strong>Packaging</strong> unit-dose items<br />

are awarded to GPOs and are<br />

therefore stocked by other wholesalers,<br />

also.<br />

American Health <strong>Packaging</strong> is<br />

committed to patient safety and<br />

bar coding initiatives and maintains<br />

an active unit-dose launch<br />

program. For more information,<br />

contact Sid McFadden at<br />

614/492-8177, ext. 309, or via e-<br />

mail at smcfadden@amerisource<br />

bergen.com.<br />

Tool Shop Capabilities Expanded at<br />

Uhlmann <strong>Packaging</strong> Systems<br />

Uhlmann’s tool shop can now offer its<br />

customers tooling, upgrades, and<br />

rebuilds for its blister machines, cartoners,<br />

and feeders.<br />

With the addition of the<br />

new Deckel Maho 80U<br />

Machining Center at<br />

Uhlmann <strong>Packaging</strong> Systems<br />

in Towaco, NJ, the<br />

company now boasts the<br />

world’s most advanced<br />

equipment for pharmaceutical<br />

blister tools, as well as<br />

reduced delivery time and<br />

the largest spare-parts inventory<br />

in the <strong>Unit</strong>ed States.<br />

By investing more than $3<br />

million in capital machinery,<br />

Uhlmann’s tool shop can<br />

now offer its customers unmatched<br />

service and value by providing tooling, upgrades, and<br />

rebuilds for its blister machines, cartoners, and feeders. Precision,<br />

OEM-crafted, and tested tooling can now be delivered within seven<br />

weeks, the shortest lead time in the industry. Reduced by more than<br />

50% from five years ago, Uhlmann projects to cut delivery down by<br />

another 20% in the next 12 months.<br />

“With a total of three Deckel Maho machining centers, Uhlmann’s<br />

tool shop features the most-advanced equipment in the world,” said<br />

Hubert Keil, Uhlmann Managing Director and CEO. “These machines<br />

are at the center of an aggressive and continuing modernization and<br />

improvement plan that allows Uhlmann to react as quickly as possible<br />

to customer needs and requests, helping them to keep pace with the<br />

increasing demands and challenges of the pharmaceutical market.”<br />

Features of the equipment include:<br />

• Five-axis machining for reduced production times and<br />

enhanced quality.<br />

• A six-station programmable palette pool for automatic<br />

loading, unloading, and multiple-tool manufacturing.<br />

• A 180-tool in-machine storage system that allows<br />

for quick changeover with dedicated dimensions and<br />

preset specifications.<br />

• Lights-out operation for extended, unmanned shift capabilities.<br />

“By investing in smart machining and high-tech equipment and by<br />

streamlining our overall processes, Uhlmann can continue to provide<br />

our customers in the <strong>Unit</strong>ed States, Canada, and Puerto Rico with<br />

superior products and services,” added Mr. Keil. “With a staff of longterm,<br />

experienced employees, leading-edge expertise in pharmaceutical<br />

and medical packaging equipment, and a dedication to consistent<br />

high quality, Uhlmann is able to help customers make informed, effective<br />

decisions and solve problems.”<br />

For more information, contact Hubert Keil at 973/402-8855 or<br />

send an e-mail to hkeil@uhlmann-usa.com.<br />

<strong>Unit</strong> <strong>Dose</strong> Alert • www.unitdose.org • March 2007 17

018_019_MemberCorner.qxd 3/6/07 11:29 AM Page 18<br />

Member’s Corner<br />

The IMA Group has about<br />

2700 employees, of whom<br />

more than 1100 are overseas,<br />

and had a consolidated turnover<br />

of 398.8 million Euro for the fiscal<br />

year 2005, with more than 90%<br />

earned on international<br />

markets. The pharmaceutical<br />

sector accounts<br />

for about 83% of the<br />

group’s sales.<br />

The IMA Group has<br />

an extensive sales network<br />

consisting of nine<br />

branches that provide<br />

sales and service in<br />

Germany, Austria,<br />

France, Spain, Portugal,<br />

the <strong>Unit</strong>ed Kingdom,<br />

the <strong>Unit</strong>ed States<br />

(IMA North America<br />

Inc. is the subsidiary<br />

for the USA, Canada,<br />

and Puerto Rico markets),<br />

China, and Thailand;<br />

representative<br />

offices in Central and<br />

East European countries;<br />

and more than 50<br />

agencies covering a<br />

total of more than 70 countries.<br />

IMA is also participating in two<br />

joint ventures in China for production<br />

and service. The group’s<br />

manufacturing facilities currently<br />

include six production plants in<br />

Italy, one in Germany (IMA Kilian),<br />

one in Spain (IMA-Telstar),<br />

one in the <strong>Unit</strong>ed Kingdom (Swiftpack<br />

Automation), one in the<br />

<strong>Unit</strong>ed States (Nova <strong>Packaging</strong><br />

Systems), two in India (Precision<br />

Gears), and three in China.<br />

In 2005, IMA concluded a joint<br />

IMA: More Than 40 Years<br />

of Innovation<br />

Established in 1961, IMA is the world leader in the manufacture<br />

of automatic machines for the processing and packaging of<br />

pharmaceuticals, cosmetics, tea, and coffee.<br />

venture agreement with the Telstar<br />

Group (Spain) in the field of<br />

freeze-drying machinery for the<br />

pharmaceutical industry. In 2006,<br />

IMA acquired the entire share<br />

capital of VIMA Impianti S.r.l., a<br />

IMA manufactures a complete range of blister machines,<br />

from low- to extremely high-speed (up to 1300 blisters/<br />

minute), with or without cartoning.<br />

company that manufactures<br />

machines for powder handling of<br />

pharmaceuticals.<br />

The following companies in the<br />

pharmaceutical and cosmetics sectors<br />

are part of the IMA Group:<br />

Co.ma.di.s. S.p.A., IMA Kilian<br />

GmbH & Co. KG, IMA Libra<br />

S.r.l., Nova <strong>Packaging</strong> Systems<br />

Inc., Precision Gears Pvt Ltd., and<br />

Swiftpack Automation Ltd.<br />

The IMA Group manufactures<br />

a wide range of processing and<br />

packaging machines: machines for<br />

all solid-dose processing requirements,<br />

blister machines, counting<br />

machines, machines for washing<br />

and sterilization of ampules and<br />

vials, aseptic liquid-filling and<br />

closing machines (barrier technology),<br />

freeze-drying<br />

machinery for the pharmaceutical<br />

industry,<br />

multifunction<br />

liquid-filling and closing<br />

machines, unit-dose<br />

filling machines, aseptic<br />

powder-filling<br />

machines, macrodosing<br />

powder-filling<br />

machines, tube-filling<br />

machines, cartoning<br />

machines, labeling<br />

machines, end-of-line<br />

machines, and integrated<br />

packaging lines.<br />

IMA offers the widest<br />

range of machines and<br />

technical solutions for<br />

solid-dose processing<br />

requirements: highshear<br />

mixer granulators,<br />

fluid-bed equipment,<br />

tablet-press<br />

machines, capsule-filling<br />

machines, coating equipment,<br />

and checkweighing machines<br />

for capsules and tablets. Additionally,<br />

thanks to the acquisition<br />

of VIMA Impianti, a complete<br />

range for powder handling,<br />

washing systems, and dedusting<br />

equipment is also available.<br />

Several machines have been<br />

recently launched on the market<br />

to fully respond to the most<br />

sophisticated production requirements<br />

worldwide.<br />

18 <strong>Unit</strong> <strong>Dose</strong> Alert • www.unitdose.org • March 2007

018_019_MemberCorner.qxd 3/6/07 11:29 AM Page 19<br />

Member’s Corner<br />

IMA manufactures a complete<br />

range of blister machines, from<br />

low- to extremely high-speed (up<br />

to 1300 blisters/minute), with or<br />

without cartoning. The newest<br />

machine is the revolutionary compact<br />

and integrated blister line<br />

Giant1, which can be considered a<br />

perfect alternative for just-intime<br />

production of small and<br />

medium batches (up to 350 blisters<br />

and 175 cartons/minute).<br />

The machine concept has been<br />

based on the IMA philosophy<br />

of flexibility in operation and<br />

changeover combined with easy<br />

cleaning and less material/product<br />

waste. IMA stood also in<br />

the forefront to solve product<br />

recall problems faced by the<br />

drug manufacturers by applying<br />

a patented cutting system. This<br />

innovative solution guarantees<br />

that rejected faulty blisters cannot<br />

be matched in further packaging<br />

process, given their different<br />

shapes.<br />

The group offers a complete<br />

range of counting machines manufactured<br />

by both IMA and IMA<br />

Nova. The IMA Conta Series is a<br />

high-speed vision system-based<br />

tablet counter that offers higher<br />

productivity, absolute assurance<br />

of accurate count, and product<br />

integrity. IMA Nova designs,<br />

manufactures, and integrates the<br />

most comprehensive range of<br />

tablet counting and filling<br />

equipment for the pharmaceutical,<br />

nutraceutical, health and<br />

beauty, and cosmetics industries.<br />

Its Lakso, Merrill, Kalish, Fillit,<br />

King, and Swiftpack brands of<br />

equipment have earned an excellent<br />

reputation for engineering elegance,<br />

robust construction, and<br />

long-term reliability. With its facility<br />

in the <strong>Unit</strong>ed States and technical<br />

personnel located worldwide,<br />

IMA Nova provides turnkey solutions<br />

and support for installations<br />

around the globe.<br />

A wide range of horizontal and<br />

vertical cartoners for the pharmaceutical<br />

and cosmetics industries<br />

can be supplied by IMA. The<br />

newest machine is the high-speed<br />

horizontal cartoner Dynamica<br />

(400 cartons/minute), combining<br />

several proven solutions and featuring<br />

an innovative carton transport<br />

system. The machine design<br />

makes it simple to operate, facilitates<br />

accessibility and cleanliness,<br />

and simplifies components loading.<br />

Changeover is extremely easy,<br />

and maintenance is very low. Several<br />

models are available to cover<br />

a large range of sizes. Implementation<br />

of various coding, inspection,<br />

and feeding systems for any<br />

type of carton, leaflet or booklet<br />

and the handling of any pharmaceutical<br />

or cosmetics products<br />

makes the Dynamica cartoner a<br />

suitable choice for flexible,<br />

high-speed carton<br />

packaging projects.<br />

The group offers a<br />

complete range of end-of-line<br />

machines for the pharmaceutical<br />

industry. Among the new models<br />

is the IMA BFB CP18, an automatic<br />

side-loading case packer<br />

incorporating a new concept that<br />

makes it particularly suitable for<br />

the packaging of individual or<br />

bundled cartons/trays into<br />

preglued RS cases. The machine<br />

is extremely compact and accessible,<br />

thanks to its cantilever<br />

design. The case magazine is horizontal<br />

to ease loading. The size<br />

changeover can be carried out in<br />

just a few minutes. The CP18 is<br />

available in two versions (up to<br />

10 or 14 cycles/minute).<br />

IMA’s growth strategy is to<br />

expand the group’s range with<br />

innovative products in order to<br />

strengthen its presence in both<br />

process equipment and packaging<br />

machines. Its approach is<br />

not to just supply innovative<br />

and reliable machines, but<br />

mainly to be a partner for its<br />

customers, guaranteeing fast<br />

after-sales and spare-parts services.<br />

Rooms for trials on soliddose<br />

machines are available at<br />

IMA North America, to provide<br />

opportunities for equipment trials<br />

before purchase.<br />

For further information, contact<br />

IMA North America, headquartered<br />

in Bristol, PA, at 215/<br />

826-8500 or by e-mail at<br />

sales@imausa.net. Visit www.ima.it<br />

or www.imanova.com.<br />

Designed for both multinational pharmaceutical companies as well as contract packaging operations, IMA’s<br />

Giant1 is suitable for just-in-time production of small and medium batches consisting of up to 350 blisters per<br />

minute and 175 cartons per minute.<br />

<strong>Unit</strong> <strong>Dose</strong> Alert • www.unitdose.org • March 2007 19

020_021_GuestViewPt.qxd 3/6/07 11:29 AM Page 20<br />

Guest Viewpoint<br />

<strong>Packaging</strong> and Good Information<br />

Are Key<br />

Thomas Henderson<br />

Chairman, Pharmaceutical Printed<br />

Literature Association<br />

Vice President,<br />

Sales and Marketing<br />

Chesapeake Pharmaceutical<br />

<strong>Packaging</strong> — North America<br />

(Arlington Press)<br />

While most<br />

prescriptions go home<br />

with consumers with<br />

some printed material,<br />

the usefulness and<br />

accuracy of that<br />

“information” is<br />

nowhere near the<br />

quality required<br />

by legislation.<br />

There are a plenty of headlines<br />

in the media and hearings<br />

in Congress about healthcare,<br />

and drugs have captured a<br />

healthy share of attention. Drug<br />

prices and drug safety are probably<br />

the top-ranked topics. The<br />

House of Representatives is<br />

holding hearings on FDA’s drug<br />

approval process; the topic is so<br />

politically correct right now that<br />

the House even got a senator to<br />

come across town to testify!<br />

But there are a lot of other issues<br />

related to medications that need<br />

airing. For 15 years, the Healthcare<br />

Compliance <strong>Packaging</strong> Council<br />

(HCPC) has presented an annual<br />

symposium on what should<br />

always be a major topic of discussion—patient<br />

compliance.<br />

This year, the HCPC’s symposium<br />

will include presentations<br />

organized by the Pharmaceutical<br />

Printed Literature Association<br />

(PPLA). They will focus on how<br />

providing complete and useful<br />

information that has been<br />

reviewed and approved by FDA<br />

directly to patients improves medication<br />

outcomes.<br />

The PPLA’s mission is to support<br />

member efforts to promote<br />

and improve information delivery<br />

to protect patients and support<br />

healthcare professionals. That<br />

mission is different from the<br />

HCPC’s, but the two organizations<br />

share the objective of<br />

improving patient compliance and<br />

safety. Taking medications properly<br />

and safely maximizes the<br />

enormous benefits they offer.<br />

That’s what compliance means.<br />

What is the magnitude of the<br />

issue, focusing on the importance<br />

of information to compliance<br />

•Survey by the National Community<br />

Pharmacists Association:<br />

Three out of four patients receiving<br />

prescriptions admit they<br />

don’t adhere to directions.<br />

•Peer-reviewed article in Archives<br />

of Internal Medicine: “This study<br />

demonstrates spotty physician<br />

counseling about new medication<br />

prescriptions. Physicians<br />

conveyed full medication dosing<br />

directions for less than 60% of<br />

all medications.”<br />

•Carmen Catizone, Executive<br />

Director of the National Association<br />

of Boards of Pharmacy,<br />

says: “…as a consumer, you can<br />

find out more about the ingredients<br />

of a pizza you might buy at<br />

a local parlor than you can about<br />

life saving medications from your<br />

pharmacy.”<br />

The presentations organized by<br />

the PPLA will discuss the legislation<br />

and regulations that affect<br />

patient labeling in both North<br />

America and Europe. With regard<br />

to North America, my presentation<br />

will cover FDA’s new package<br />

insert regulation, which went<br />

into effect in January 2006, more<br />

than five years after the first draft<br />

was circulated.<br />

This regulation is complex and<br />

offers some challenges for compliance.<br />

It has a detailed schedule<br />

for when specific drugs must comply<br />

with this regulation. For those<br />

drugs that come under it, a highlights<br />

section is required. There is<br />

a complex mix of minimum type<br />

sizes, and when and how information<br />

to be distributed to<br />

20 <strong>Unit</strong> <strong>Dose</strong> Alert • www.unitdose.org • March 2007

020_021_GuestViewPt.qxd 3/6/07 11:29 AM Page 21<br />

Guest Viewpoint<br />

patients must be made available<br />

within the package insert for<br />

healthcare professionals.<br />

I will also touch upon legislation<br />

that requires useful patient information<br />

to accompany 95% of all<br />

prescriptions by a specific deadline—a<br />

deadline that passed in<br />

2006. FDA chartered a study by<br />

the University of Wisconsin School<br />

of Pharmacy, which looked at compliance<br />

levels in 2001.<br />

The results were unimpressive.<br />

While most prescriptions go home<br />

with consumers with some printed<br />

material, the usefulness and accuracy<br />

of that “information” is<br />

nowhere near the quality required<br />