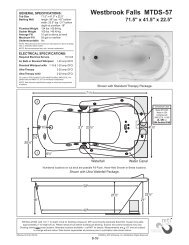

1 Summary and features - Designer Plumbing

1 Summary and features - Designer Plumbing

1 Summary and features - Designer Plumbing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Comfortstar plus<br />

1 <strong>Summary</strong> <strong>and</strong> <strong>features</strong><br />

Model<br />

CHH09CA-13<br />

Remarks<br />

1Ph,115V,60Hz,R410A<br />

CHH012CA-13<br />

1Ph,115V,60Hz,R410A<br />

CHH012CD-13<br />

1Ph,208-230V,60Hz,R410A

Models & specifications<br />

Model CHH09CA-13 CHH012CA-13 CHH012CD-13<br />

Function<br />

Cooling &Heating<br />

Working Temp. Range (Indoor)<br />

60.8 o F-86 o F<br />

Operation Condition Range (Outdoor)(Cooling/heating) 60.8 o F-129 o F/-4-75.2F<br />

Power supply 115V/1Ph/60Hz 208-230V/1Ph/60Hz<br />

Rated current (A)(Cooling/Heating) 6.4/7 10/10.45 5/5.45<br />

LRA of compressor (A) 33 33 33<br />

Fuse or Breaker (A) 15 25<br />

15<br />

Refrigerant <strong>and</strong> Charge* (Ounce)R410a 42 44 44<br />

Size of power supply wire<br />

AWG12<br />

Size of connecting wire between condenser <strong>and</strong><br />

AWG18<br />

evaporator<br />

Piping connection (Gas/Liquid) (inch) (½ / ¼)<br />

Maximum line run (ft) 66<br />

Maximum elevation between condenser <strong>and</strong><br />

39<br />

evaporator (ft)<br />

Climate type<br />

T1<br />

Waterproof level<br />

IP×4<br />

Net weight (indoor/outdoor) (lb) 18.7/88.18 24.3/88.18<br />

Dimension (in) Indoor 30.3x9.8x7.5 35.7×11.4×7.68<br />

Dimension(in) Outdoor 33.38x21.27x12.6<br />

* The pre-charged refrigerant is good for 26 feet line set. For the system required longer line set than 26 feet, please add<br />

additional 0.22 Oz /ft refrigerant into the system.<br />

*The working pressure of suction line for the 3 models above: 123.3-145 PSI(Cooling)/406.1-464PSI(Heating)

2<br />

Specifications <strong>and</strong> technical parameters<br />

Model<br />

CHH09CA-13<br />

Function<br />

COOLING<br />

Rated Voltage<br />

115V<br />

Frequency(Hz) 60HZ<br />

HEATING<br />

Rated Capacity (Btu/h)<br />

10400 12800<br />

Rated Input (W) (High/St<strong>and</strong>ard) 1200/730 1400/800<br />

Rated Current (A)<br />

6.4 7<br />

Air Flow Volume (m 3 /h) (H/M/L) 600<br />

Dehumidifying Volume (l/h) 1.2<br />

SEER / HSPF<br />

16 8<br />

Indoor<br />

unit<br />

Model of Indoor Unit<br />

CHH09CA-13(I)<br />

Fan Motor Speed (r/min)<br />

1160/1010/890<br />

(H/M/L)<br />

Output of Fan Motor (w)<br />

14<br />

Input Power of Heater (w)<br />

/<br />

Fan Motor Capacitor (uF) 1.0<br />

Fan Motor RLA(A) 0.14<br />

Fan Type-Piece<br />

Cross flow fan – 1<br />

Diameter-Length (in) φ 3.8-23<br />

Evaporator<br />

Aluminum fin-copper tube<br />

Pipe Diameter (in) Φ 0.28<br />

Row-Fin Gap(in) 2-0.055<br />

Coil length (l) x height (H) x coil<br />

22.83x9x1<br />

width (L)(in)<br />

Swing Motor Model<br />

MP28VA<br />

Output of Swing Motor (W)<br />

2<br />

Fuse (A)<br />

PCB3.15A transformer0.2A<br />

Sound Pressure Level dB (A)<br />

40/ 36/ 33<br />

(H/M/L)<br />

Dimension (W/D/H)( in)<br />

Dimension of Package<br />

(W/D/H)( in)<br />

Net Weight /Gross Weight (lb)<br />

32.67×8.86×11.22<br />

33.66×10.7×13.22<br />

18.7/27.6<br />

2

Comfortstar plus<br />

Outdoor<br />

unit<br />

Model of Outdoor Unit<br />

Compressor Manufacturer/trademark<br />

Compressor Model<br />

Compressor Type<br />

L.R.A. (A)<br />

Compressor RLA(A)<br />

Compressor Power Input(W)<br />

Overload Protector<br />

Throttling Method<br />

Starting Method<br />

Working Temp Range ()<br />

Condenser<br />

Pipe Diameter (in)<br />

Rows-Fin Gap(in)<br />

Coil length (l) x height (H) x coil width<br />

(L)(<br />

Fan Motor Speed (rpm)<br />

Output of Fan Motor (W)<br />

Fan Motor RLA(A)<br />

Fan Motor Capacitor (uF)<br />

Air Flow Volume of Outdoor Unit<br />

3<br />

Fan Type-Piece<br />

Fan Diameter (in)<br />

Defrosting Method<br />

Climate Type<br />

Isolation<br />

Moisture Protection<br />

Permissible Excessive Operating<br />

Pressure for the Discharge<br />

Permissible Excessive Operating<br />

Pressure Sound Pressure for the Suction Level dB Side(MPa) (A) (H/M/L)<br />

CHH09C A-13(O)<br />

SANYO<br />

C-6RZ092H1AB<br />

Twin rotory<br />

33<br />

3.92<br />

960<br />

Int11l-3979<br />

Capillary throttling<br />

Transducer starting<br />

-7T43<br />

Aluminum fin-copper tube<br />

0.37<br />

2-0.05<br />

25.4X20X1.73<br />

830±20<br />

30<br />

0.3<br />

2.5<br />

1800<br />

Axial fan –1<br />

15.75<br />

Auto defrost<br />

T1<br />

I<br />

IP24<br />

3.8<br />

1.2<br />

55<br />

Connec<br />

tion<br />

Pipe<br />

Dimension (W/D/H)( in)<br />

Dimension of Package (W/D/H)( mm)<br />

Net Weight /Gross Weight (lb)<br />

Refrigerant Charge (oz)<br />

Length (ft)<br />

Gas additional charge(oz/ft)<br />

Outer Diameter<br />

Max Distance<br />

33.38X12.6X21.27<br />

34.6X14.2X23.2<br />

88.18/99.2<br />

R410A / 42<br />

26<br />

0.22<br />

Liquid Pipe (mm)<br />

Φ6(1/4”)<br />

Gas Pipe (mm)<br />

Φ12(1/2”)<br />

Height (ft) 39<br />

Length (ft) 66<br />

If there are any changes in the specifications <strong>and</strong> parameters in the above table, Please refer to the nameplate of the unit.

2<br />

Specifications <strong>and</strong> technical parameters<br />

Model<br />

CHH012CA-13<br />

Function<br />

COOLING<br />

Rated Voltage<br />

115V<br />

Frequency(Hz) 60HZ<br />

HEATING<br />

Rated Capacity (Btu/h)<br />

13900 14000<br />

Rated Input (W) (High/ St<strong>and</strong>ard )<br />

1450/1100 1500/1200<br />

Rated Current (A)<br />

10 10.45<br />

Air Flow Volume (m 3 /h) (H/M/L) 600<br />

Dehumidifying Volume (l/h) 1.2<br />

SEER / HSPF<br />

16 7.7<br />

Indoor<br />

unit<br />

Model of Indoor Unit<br />

CHH012CA-13(I)<br />

Fan Motor Speed (r/min)<br />

1350/1200/1110<br />

(H/M/L)<br />

Output of Fan Motor (w)<br />

22<br />

Input Power of Heater (w)<br />

/<br />

Fan Motor Capacitor (uF) 1.0<br />

Fan Motor RLA(A) 0.152<br />

Fan Type-Piece<br />

Cross flow fan – 1<br />

Diameter-Length (in) φ 3.63-24.3<br />

Evaporator<br />

Aluminum fin-copper tube<br />

Pipe Diameter (in) Φ0.276<br />

Row-Fin Gap(in) 2-0.055<br />

Coil length (l) x height (H) x coil<br />

26.81x12.77x1.5<br />

width (L)(in)<br />

Swing Motor Model<br />

MP28EA<br />

Output of Swing Motor (W) 2<br />

Fuse (A)<br />

Controller3.15 transformer0.2<br />

Sound Pressure Level dB (A)<br />

43 / 40 / 39<br />

(H/M/L)<br />

Dimension (W/D/H)( in)<br />

Dimension of Package<br />

(W/D/H)( in)<br />

Net Weight /Gross Weight (lb)<br />

32.7×8.86×11.2<br />

34.4×12.3×14.6<br />

24.3/33<br />

4

Comfortstar plus<br />

Outdoor<br />

unit<br />

Model of Outdoor Unit<br />

CHH012CA-13(O)<br />

Compressor Manufacturer/trademark<br />

SANYO<br />

Compressor Model<br />

C-6RZ092H1AB<br />

Compressor Type<br />

Twin rotory<br />

L.R.A. (A)<br />

33<br />

Compressor RLA(A) 3.92<br />

Compressor Power Input(W) 960<br />

Overload Protector<br />

Int11l-3979<br />

Throttling Method<br />

Capillary throttling<br />

Starting Method<br />

Transducer starting<br />

Working Temp Range () -7~43<br />

Condenser<br />

Aluminum fin-copper tube<br />

Pipe Diameter (in) 0.37<br />

Rows-Fin Gap(in) 2-0.05<br />

Coil length (l) x height (H) x coil width<br />

25.4X20X1.73<br />

(L)(<br />

Fan Motor Speed (rpm)<br />

830+20<br />

Output of Fan Motor (W) 30<br />

Fan Motor RLA(A) 0.3<br />

Fan Motor Capacitor (uF) 2.5<br />

Air Flow Volume of Outdoor Unit 1800<br />

3<br />

Fan Type-Piece<br />

Fan Diameter (in)<br />

Axial fan –1<br />

15.75<br />

Defrosting Method<br />

Climate Type<br />

Isolation<br />

Moisture Protection<br />

Permissible Excessive Operating<br />

Auto defrost<br />

T1<br />

I<br />

IP24<br />

3.8MPa<br />

Pressure for the Discharge<br />

Permissible Excessive Operating<br />

1.2MPa<br />

Pressure Sound Pressure for the Suction Level dB Side(MPa) (A) (H/M/L)<br />

55<br />

Connec<br />

tion<br />

Pipe<br />

Dimension (W/D/H)( in)<br />

Dimension of Package (W/D/H)( mm)<br />

Net Weight /Gross Weight (lb)<br />

Refrigerant Charge (oz)<br />

Length (ft)<br />

Gas additional charge(oz/ft)<br />

Outer Diameter<br />

Max Distance<br />

Liquid Pipe (mm)<br />

Gas Pipe (mm)<br />

Height (ft)<br />

Length (ft)<br />

33.38X12.6X21.27<br />

34.6X14.2X23.2<br />

88.18/99.2<br />

R410A / 44<br />

26<br />

0.22<br />

Φ6(1/4”)<br />

Φ12(1/2”)<br />

39<br />

66<br />

If there are any changes in the specifications <strong>and</strong> parameters in the above table, Please refer to the nameplate of the unit.<br />

5

2<br />

Specifications <strong>and</strong> technical parameters<br />

Model<br />

Function<br />

Rated Voltage<br />

Frequency(Hz)<br />

COOLING<br />

60HZ<br />

CHH012CD-13<br />

208V230V<br />

HEATING<br />

Rated Capacity (Btu/h)<br />

Rated Input (W) (High/ St<strong>and</strong>ard)<br />

13200 15900<br />

1450/1100 1500/1200<br />

Rated Current (A)<br />

5 5.45<br />

Air Flow Volume (m 3 /h) (H/M/L) 600<br />

Dehumidifying Volume (l/h) 1.2<br />

SEER / HSPF 15 7.7<br />

Indoor<br />

unit<br />

Model of Indoor Unit<br />

Fan Motor Speed (r/min)<br />

(H/M/L)<br />

Output of Fan Motor (w)<br />

Input Power of Heater (w)<br />

Fan Motor Capacitor (uF)<br />

Fan Motor RLA(A)<br />

Fan Type-Piece<br />

Diameter-Length (in)<br />

Evaporator<br />

Pipe Diameter (in)<br />

Row-Fin Gap(in)<br />

Coil length (l) x height (H) x coil<br />

width (L)(in)<br />

Swing Motor Model<br />

Output of Swing Motor (W)<br />

Fuse (A)<br />

Sound Pressure Level dB (A)<br />

(H/M/L)<br />

CHH012CD-13(I)<br />

1350/1200/1110<br />

22<br />

/<br />

1<br />

0.152<br />

Cross flow fan – 1<br />

φ3.63—24.3<br />

Aluminum fin-copper tube<br />

Φ0.27<br />

2-0.05<br />

26.8×12.76×1.5<br />

MP28EA<br />

2<br />

Controller3.15 transformer0.2<br />

43 / 40 / 39<br />

Dimension (W/D/H)( in)<br />

Dimension of Package<br />

(W/D/H)( in)<br />

Net Weight /Gross Weight (lb)<br />

32.7×8.86×11.2<br />

34.4×12.3×14.6<br />

24.3/33<br />

6

Comfortstar plus<br />

Outdoor<br />

unit<br />

Connec<br />

tion<br />

Pipe<br />

Model of Outdoor Unit<br />

Compressor Manufacturer/trademark<br />

Compressor Model<br />

Compressor Type<br />

L.R.A. (A)<br />

Compressor RLA(A)<br />

Compressor Power Input(W)<br />

Overload Protector<br />

Throttling Method<br />

Starting Method<br />

Working Temp Range ()<br />

Condenser<br />

Pipe Diameter (in)<br />

Rows-Fin Gap(in)<br />

Coil length (l) x height (H) x coil width<br />

(L)(<br />

Fan Motor Speed (rpm)<br />

Output of Fan Motor (W)<br />

Fan Motor RLA(A)<br />

Fan Motor Capacitor (uF)<br />

Air Flow Volume of Outdoor Unit<br />

3<br />

Fan Type-Piece<br />

Fan Diameter (in)<br />

Defrosting Method<br />

Climate Type<br />

Isolation<br />

Moisture Protection<br />

Permissible Excessive Operating<br />

Pressure for the Discharge<br />

Permissible Excessive Operating<br />

Pressure Sound Pressure for the Suction Level dB Side(MPa) (A) (H/M/L)<br />

Sound Power Level dB (A) (H/M/L)<br />

Dimension (W/D/H)( in)<br />

Dimension of Package (W/D/H)( mm)<br />

Net Weight /Gross Weight (lb)<br />

Refrigerant Charge (oz)<br />

Length (ft)<br />

Gas additional charge(oz/ft)<br />

Outer Diameter<br />

Max Distance<br />

CHH012CD-13(O)<br />

SANYO<br />

C-6RZ092H1AB<br />

Twin rotory<br />

33<br />

3.92<br />

960<br />

Int11l-3979<br />

Capillary throttling<br />

Transducer starting<br />

-7T43<br />

Aluminum fin-copper tube<br />

0.37<br />

2-0.05<br />

25.4X20X1.73<br />

830±20<br />

30<br />

0.3<br />

2.5<br />

1800<br />

Axial fan –1<br />

15.75<br />

Auto defrost<br />

T1<br />

I<br />

IP24<br />

3.8<br />

1.2<br />

55<br />

65<br />

33.38X12.6X21.27<br />

34.6X14.2X23.2<br />

88.18/99.2<br />

R410A / 44<br />

26<br />

0.22<br />

Liquid Pipe (mm)<br />

Φ6(1/4”)<br />

Gas Pipe (mm)<br />

Φ12(1/2”)<br />

Height (ft)<br />

39<br />

Length (ft)<br />

66<br />

If there are any changes in the specifications <strong>and</strong> parameters in the above table, Please refer to the nameplate of the unit.<br />

7

3<br />

Part name<br />

Air inlet<br />

Indoor Unit<br />

Front panel<br />

Guide louver<br />

Air outlet<br />

Receiving window<br />

LED board<br />

wrapping tape<br />

Wireless remote controll<br />

Outdoor Unit<br />

Air inlet<br />

Drainage hose<br />

Connecting pipe <strong>and</strong> connection wire<br />

Air outlet<br />

8

Comfortstar plus<br />

4<br />

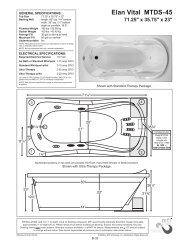

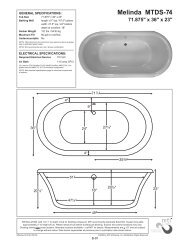

Overall <strong>and</strong> Installing Dimension<br />

UOverall <strong>and</strong> Installing Dimension of Indoor Unit<br />

Air inlet grill<br />

Left piping hole<br />

Top view<br />

Right piping hole<br />

Rear view<br />

Unitmm<br />

Wall-mounting plate<br />

9

UOverall <strong>and</strong> Installing Dimension of Outdoor Unit<br />

Unit: mm<br />

Bolt<br />

Nut<br />

Wrench<br />

10

Comfortstar plus<br />

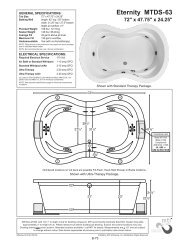

Circuit Diagram<br />

CHH09CA-13;CHH012CA-13<br />

INDOOR UNIT<br />

These circuit diagrams are subject to change without notice. Please refer to the ones stuck on the machines.<br />

11

Comfortstar plus<br />

5 Circuit Diagram<br />

CHH012CD-13<br />

INDOOR UNIT<br />

OUTDOOR UNIT<br />

These circuit diagrams are subject to change without notice. Please refer to the ones stuck on the machines.<br />

12

Comfortstar plus<br />

LOW AMBIENT CONTROL AND CONDENSATE PUMP DIAGRAM<br />

<br />

CHH09CA-13,CHH012CA-13,CHH012CD-13 CONDENSATE PUMP<br />

13

Comfortstar plus<br />

LOW AMBIENT CONTROL DIAGRAM<br />

<br />

14

6<br />

Function manual <strong>and</strong> operation method of remote controller<br />

Function manual of remote controller<br />

This function manual is applicable to D.C. Variable Frequency<br />

6.1.1 Temperature parameters<br />

Room set temperature (T set )<br />

Room ambient temperature (T amb )<br />

6.1.2 Fundamental functions<br />

After powered on, no matter when the compressor is started, the time interval between two startups<br />

cannot be less than 3 minutes.<br />

6.1.2.1 COOL mode<br />

6.1.2.1.1 The condition <strong>and</strong> process of cooling<br />

If T amb T set , COOL mode will act, the compressor <strong>and</strong> outdoor fan will run, <strong>and</strong> the indoor fan will run at the set<br />

speed.<br />

If T amb T set -2 ,<br />

the compressor will stop, the outdoor fan will delay 30 seconds to stop, <strong>and</strong> the indoor fan will<br />

run at the set speed.<br />

If T set -2T amb T set , the unit will keep running in the previous mode.<br />

In this mode, the reversal valve will not be powered on <strong>and</strong> the temperature setting range is 16~30 .<br />

The unit will adjust the running frequency of the compressor automatically according to the change of ambient<br />

temperature.<br />

Start cooling<br />

Tset<br />

Tamd<br />

Tset<br />

3min<br />

Original running state<br />

Stop cooling<br />

Compressor<br />

Outdoor fan<br />

Indoor fan<br />

Set fan speed<br />

6.1.2.1.2 Protection function<br />

Run<br />

Stop<br />

Antifreezing protection<br />

Under cooling <strong>and</strong> drying mode, after the compressor run about 10mins,when the pipe temp.of the<br />

evaporator is to low, the compressor will stop, the outdoor fan will stop after 30s, under cooling<br />

mode the indoor fan <strong>and</strong> swing motor will keep running in the original mode , under drying mode the<br />

indoor fan will run at low fan speed, the swing motor will run in the original mode. When antifreezing<br />

protection is eliminated <strong>and</strong> the compressor has stopped for 3 minutes, the unit will resume running in<br />

the original mode.<br />

The period of antifreezingprotection<br />

Compressor<br />

Outdoor fan<br />

Indoor fan<br />

3 min<br />

Overcurrent protection<br />

Run<br />

Stop<br />

If total current is high, the compressor will run in limited or dropped frequency. When total current goes on<br />

rising over the stated value, the compressor will stop, the outdoor fan will delay 30 seconds to stop.<br />

6.1.2.2 DRY mode<br />

6.1.2.2.1 The condition <strong>and</strong> process of drying<br />

15

Comfortstar plus<br />

If T amb >T set , DRY mode will act, the indoor fan, outdoor fan <strong>and</strong> compressor will run, <strong>and</strong> indoor fan will run at<br />

low speed<br />

If T set -2T amb T set , the unit will keep running in the original mode.<br />

If T amb

over the stated value, the compressor will stop, the outdoor fan will delay 30 seconds to stop.<br />

6.1.2.4 FAN mode<br />

In this mode, the indoor fan will run the fan in High, Med, Low <strong>and</strong> Auto mode. The compressor, outdoor fan<br />

<strong>and</strong> four-way valve will stop.<br />

In this mode, the temperature setting range is 16~30 .<br />

<br />

The unit will adjust the running frequency of the compressor automatically according to the change of ambient<br />

temperature.<br />

6.1.2.5 AUTO mode<br />

In this mode, the system selects COOL, HEAT <strong>and</strong> FAN mode automatically according to the change of ambient<br />

temperature. The protection function is the same with that of COOL/HEAT mode.<br />

The unit will adjust the running frequency of the compressor automatically according to the change of ambient<br />

temperature.<br />

6.1.3 Other control<br />

6.1.3.1 ON / OFF<br />

Each time the On/Off button of the remote controller is pressed, the On/Off state will switch once.<br />

6.1.3.2 MODE selection<br />

Press the MODE button on the remote controller to select <strong>and</strong> display the following modes:<br />

AUTO, COOL, DRY, FAN, <strong>and</strong> HEAT.<br />

6.1.3.3 TEMP. setting button<br />

Each time TEMP + or TEMP - button is pressed, the set temperature will be increased or decreased by 1 .<br />

Adjusting range is 16~30 . In AUTO mode, this button does not function.<br />

6.1.3.4 AUTO key<br />

When the unit is stop, press AUTO key,the unit will run under AUTO mode <strong>and</strong> the swing motor starts.<br />

When the unit is running, press AUTO key,the unit will be stopped.<br />

AUTO/STOP<br />

6.1.3.5 Timer control<br />

The unit is turned on or off according to the timer set by the remote controller.<br />

H<strong>and</strong>ling switch<br />

6.1.3.6 Sleep control<br />

When the air conditioner is in COOL or DRY mode, after Sleep mode has been set properly, the preset T set will<br />

be increased by 1 after the sleep program has run for 1 hour, <strong>and</strong> T set will be increased by another 1 after 2<br />

hours. T set has been increased by 2 totally in two hours. Then the unit will run at this set temperature <strong>and</strong> at<br />

the set speed.<br />

Set temp.T set<br />

T set +2<br />

T set +1<br />

1 h 2 h Above 2h<br />

T set<br />

When the air conditioner is in HEAT mode, after Sleep mode has been set properly, the preset T set will be<br />

decreased by 1 after the sleep program has run for 1 hour, <strong>and</strong> Tset will be decreased by another 1 after 2<br />

hours. T set has been increased by 2 totally in two hours. Then the unit will run at this set temperature <strong>and</strong> at the<br />

set speed.<br />

1 h 2 h Above 2h<br />

T set<br />

T set -1<br />

T set -2<br />

Set temp.T set<br />

In AUTO or FAN mode, the setting temp. will not change.<br />

17

Comfortstar plus<br />

6.1.3.7 Indoor fan control<br />

Use the remote controller to set the indoor fan running at HIGH, MED or LOW speed. At this time the fan will run<br />

at high, medium or low speed. It can also be set to AUTO <strong>and</strong> the indoor fan will select fan speed(HIGH, MED or<br />

LOW) automatically according to ambient temperature.<br />

There are at least 3mins <strong>and</strong> 30s delay for fan speed shift.<br />

6.1.3.8 Power supply for outdoor unit<br />

The power supply for outdoor unit is turned on in AUTO, COOL, HEAT <strong>and</strong> DRY mode under turn-on state.<br />

The power supply for outdoor unit will delay 3 minutes to turn off under turn-off state or in the FAN mode under<br />

turn-on state.<br />

6.1.3.9 Swing control<br />

Use the SWING button of the wireless remote control to control SWING On <strong>and</strong> Off. Swing will only act when<br />

indoor fan is running.After power on, the swing motor turns back to 0 position <strong>and</strong> closes the air outlet vent; if it<br />

does not preset swing, after the unit is turned on, it will turn to the max. air outlet D1 position; then turn back to L<br />

position under COOL mode.Under HEAT mode,the guide louver stays at D1;when in swinging state, it will swing<br />

between L1 <strong>and</strong> D1 position. When the unit is turned off, it will turn back to 0 position.<br />

6.1.3.10 Buzzer control<br />

When the unit is power on or receives remote control signal or the auto key be pressed,the buzzer will give out a beep.<br />

6.1.3.11 Power-off memory function<br />

Contents of memory: Mode; Swing; Set fan speed, Set temperature,Timing etc.<br />

Under turn-on state, when power off <strong>and</strong> power on, the power supply for outdoor unit will be turn on after 3mins .<br />

Under turn-off state, when power off <strong>and</strong> power on, the power supply for outdoor unit will be turn on immediately.<br />

6.1.3.12 Delay Protection of Compressor<br />

Under COOL; DRY; HEAT mode, before each time the compressor starts, there will be 3mins delay.<br />

6.1.4. Common protection function in each mode<br />

6.1.4.1 Overload protection<br />

Ttube:at cooling,it detects the temp. of outdoor heat exchanger,at heating,it detects the temp. of indoor heat exchanger.<br />

When Ttube is detected high, the compressor will run in limited frequency.When Ttube goes on rising over the stated<br />

value, the compressor will stop, under AUTO HEAT or HEAT mode, indoor fan will blow 60s at low fan speed <strong>and</strong><br />

then stop, under other mode, the indoor fan will run at set speed.<br />

6.1.4.2 Compressor discharge temperature protection<br />

When discharge temperature is too high to over the stated value, the compressor will stop, <strong>and</strong> When discharge temp.<br />

resume normal <strong>and</strong> the compressor has stopped for 3 minutes, the unit will resume its original operating status.<br />

6.1.4.3 Communication malfunction<br />

When not receiving correct signal for 3 minutes, the unit has communication malfunction <strong>and</strong> the outdoor unit<br />

stops, it is the same as normal stop when meeting the set temp..<br />

6.1.4.4 Module protection<br />

When module is in protection, the compressor will stop, after the compressor has stopped for 3 minutes, it will<br />

resume to running. During module protection period, the indoor unit displays malfunction <strong>and</strong> the whole unit stops.<br />

18

7 Disassembly procedures<br />

Disassembly procedures for indoor unit<br />

Operation procedures/pictures<br />

8.1.1 Disassembling the front panel <strong>and</strong><br />

electric box cover<br />

Unloose the clasps on both sides <strong>and</strong> lift the panel<br />

upward. Unplug the two connecting terminals of the<br />

display <strong>and</strong> slide out the rear clasp from the groove to<br />

take off the front panel.(you can use panel support bar<br />

to support the panel) Screw off the fixing screws of<br />

the electric box cover <strong>and</strong> open the electric box top cover to take it off.<br />

As shown in Fig.7-1<br />

Panel panel support<br />

bar<br />

Screw<br />

Electric box<br />

top cover<br />

Fig.7-1<br />

Filter<br />

Push the filter up to unloose the clasp to pull out the<br />

two filters.<br />

8.1.2<br />

As shown in Fig.7-2<br />

Filters<br />

Fig.7-2<br />

Disassembling the guide louver<br />

Bend the guide louver with strength <strong>and</strong> let out the<br />

rotating shaft from the groove to take off the guide<br />

louver. As shown in Fig.7-3<br />

Guide louver<br />

Fig.7-3<br />

19

Comfortstar plus<br />

Operation procedures/pictures<br />

Disassembling the front panel body<br />

Unclench the 3 screw covers <strong>and</strong> screw off the 3 pieces<br />

of screws that fix the panel body. Unloose the front <strong>and</strong><br />

rear clasps to take off the panel body.<br />

As shown in Fig.7-4<br />

screw<br />

screw covers<br />

Fig.7-4<br />

Disassembling the electric box cover<br />

Unloose the 3 clasps to take off the electric box cover.<br />

As shown in Fig.7-5<br />

cl<br />

clasps<br />

Fig.7-5<br />

Disassembling the water-tray assy<br />

Unloose the clasp on the left side <strong>and</strong> unplug the<br />

connecting terminal of the stepping motor. Carefully<br />

to remove the water-tray assy because the drainage pipe clasp<br />

is placed here. As shown in Fig7-6, 7-7<br />

water-tray assy<br />

cc<br />

Fig.7-6<br />

connecting terminal<br />

Fig.7-7<br />

20

Operation procedures/pictures<br />

7.1.7 Disassembling the electric box<br />

Screw off the two pieces of screws that fix the electric<br />

box <strong>and</strong> unloose the clasp. Pull out the tube sensor,<br />

unloose the grounding nut <strong>and</strong> unplug the motor<br />

connecting terminal take out the electric box.<br />

As shown in Fig 7-8<br />

Tube sensor<br />

Screws<br />

Grounding nut<br />

Motor connecting<br />

terminal<br />

7.1.8 ||||||||| Disassembling the evaporator assy<br />

Screw off the screws that fix the evaporator, one piece<br />

on the left <strong>and</strong> two pieces on the right. As shown in Fig<br />

7-9, 7-10<br />

Lift the left end of the evaporator slightly upward with<br />

your end <strong>and</strong> push it rearward to let out the side clasps<br />

of the evaporator from the groove. Take out the<br />

evaporator carefully <strong>and</strong> pay attention to protecting the<br />

connecting pipe.<br />

Screw<br />

Fig 7-8<br />

Fig 7-9<br />

Screws<br />

7.1.9 Disassembling the motor<br />

Screw off the 3 pieces of screws that fix the motor<br />

clamp to take off the motor clamp. As shown in Fig.7-<br />

11<br />

Screw off the fixing nut that fixes the cross flow fan to<br />

pull out the motor from the cross flow fan. As shown in<br />

Fig.7-12<br />

Screws<br />

Right motor<br />

clamp<br />

Fig 7-10<br />

Fig 7-11<br />

7.1.10 Disassembling the cross flow fan<br />

Refer to the above steps to take out the cross flow fan<br />

from the base plate after taking out the motor.<br />

s<br />

screws<br />

motor<br />

cross flow fan<br />

Fig 7-12<br />

21

Comfortstar plus<br />

Disassembly Procedures for Outdoor Unit<br />

Operating Procedures / Photos<br />

Disassemble Top Cover <strong>and</strong> H<strong>and</strong>le<br />

Use screwdriver to unscrew the screw at the<br />

h<strong>and</strong>le, <strong>and</strong> remove the h<strong>and</strong>le. Unscrew the three<br />

screws around the top cover, <strong>and</strong> remove the top<br />

cover.<br />

(refer to Figure 7-13)<br />

Top Cover<br />

screw<br />

screw H<strong>and</strong>le<br />

Figure 7-13<br />

Disassemble Rear Grill<br />

Screw out the 4 self tapping screws on<br />

rear side plate <strong>and</strong> chassis of valve supporter<br />

<strong>and</strong> side plate of condenser can take off rear grill.<br />

(refer to Figure 7-14)<br />

screw<br />

Grill<br />

Figure 7-14<br />

2 Disassemble Components of Panel<br />

Screw out the 5 tapping screws on panel <strong>and</strong><br />

chassis of valve supporter <strong>and</strong> side plate of condenser<br />

can take off components of panel.<br />

(refer to Figure 7-15)<br />

Panel<br />

screw<br />

Figure 7-15<br />

22

Operating Procedures / Photos<br />

Disassemble electric install plate<br />

Screw out the 3 bolts that fixing on electric install<br />

plate, plug out lead inserter of compressor <strong>and</strong><br />

fan to take off electric install plate.<br />

(refer to Figure 7-16,7-17)<br />

electric box cover<br />

bolts<br />

Figure 7-16<br />

Disassemble Right Side Plate<br />

bolts<br />

Figure 7-17<br />

Screw out the 5 bolts on rear side plate can take<br />

off right side plate.<br />

(refer to Figure 7-18)<br />

bolts<br />

Disassemble axial-flow vane<br />

Figure 7-18<br />

Loosen tighten nut by spanner to take off nuts,<br />

spring washer, flat washer, <strong>and</strong> take off axial-flow<br />

vane forcibly.<br />

tighten nut<br />

(refer to Figure 7-19)<br />

axial-flow vane<br />

Figure 7-19<br />

23

Comfortstar plus<br />

Operating Procedures / Photos<br />

Disassemble Motor <strong>and</strong> Motor Support<br />

Unscrew the four tapping screws fixing the motor,<br />

<strong>and</strong> remove the motor. Unscrew the two tapping<br />

screws fixing the motor support, <strong>and</strong> lift the motor<br />

support to remove it.<br />

(refer to Figure 7-20)<br />

Motor Support<br />

tapping screws<br />

Motor<br />

Figure 7-20<br />

Disassemble 4-Way Valve<br />

Screw off the holding nut of the 4-way valve coil<br />

<strong>and</strong> remove the coil. Use wet cotton cloth to wrap 4-way valve<br />

the 4-way valve, unsold the four soldering points<br />

connecting the 4-way valve, <strong>and</strong> remove the soldering points<br />

4-way valve. Be quick during the unsoldering holding nut<br />

process, pay attention to keep the wrapping cloth<br />

wet <strong>and</strong> do not allow the soldering flame to burn<br />

the compressor lead-out cable.<br />

(Note: only after discharging all freon).<br />

Figure 7-21<br />

(refer to Figure 7-21)<br />

Disassemble Capillary Subassembly<br />

Unsolder the soldering points connecting the<br />

capillary subassembly <strong>and</strong> the other pipelines, <strong>and</strong><br />

remove the capillary subassembly.<br />

Capillary Subassembly<br />

(refer to Figure 7-22)<br />

Figure 7-22<br />

24

Operating Procedures / Photos<br />

Disassemble Valves<br />

Unscrew the two screws fixing the big valve,<br />

unsolder the soldering point between the big<br />

valve <strong>and</strong> the return-air duct <strong>and</strong> remove the big<br />

valve.<br />

(Note: when unsoldering the soldering point, use<br />

wet cloth to completely wrap the big valve to<br />

prevent valve body from being harmed by high<br />

temperature.)<br />

Unscrew the two screws fixing the small valve,<br />

unsolder the soldering point connecting the small<br />

valve <strong>and</strong> the fork type pipe, <strong>and</strong> remove the small<br />

valve.<br />

(refer to Figure 7-23)<br />

Disassemble Compressor<br />

Small Valves<br />

Big Valves<br />

bolts<br />

Figure 7-23<br />

Unscrew the three nuts with washers at the foot of<br />

the compressor. Unsolder the soldering points at<br />

the suction <strong>and</strong> the discharge pipes of the compressor,<br />

carefully remove the pipes <strong>and</strong> take out the<br />

compressor.<br />

(refer to Figure 7-24)<br />

compressor bolt<br />

Figure 7-24<br />

25

Comfortstar plus<br />

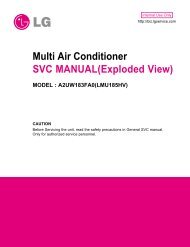

8 Exploded View <strong>and</strong> Components <strong>and</strong> Parts List<br />

Exploded View of Components <strong>and</strong> Parts of Indoor Unit<br />

CHH09CA-13(I),CHH012CA-13(I),CHH012CD-13(I)<br />

26

Components <strong>and</strong> Parts List of Indoor Unit<br />

No Description<br />

Part Code<br />

CHH09CA-13(I)<br />

Qty<br />

1 Wall-Mounting Frame 01252220 1<br />

2 Rear Case 222020012 1<br />

3 Evaporator Assy 01002070 1<br />

4 Cross-Flow Fan 10352001 1<br />

5 Ring of Bearing 76712203 1<br />

6 Drain Hose 05232411 1<br />

7 Water Tray 20182070 1<br />

8 Swing Louver 10582002 1<br />

9 Swing Linkage<br />

1<br />

10 Front Grill 01472005 1<br />

11 Front Case 20002210 1<br />

12 Screw Cap 24252006 3<br />

13 Air Filter 11122002 2<br />

14 Panel 20002812 1<br />

15 Panel 20002814 1<br />

16 Remote Control 30511010 1<br />

17 Light Cover 22242031 1<br />

18 Display Board 30545706 1<br />

19 Display Cover<br />

1<br />

20 Shield Board 26112044 1<br />

21 Guide Louver 26112033 1<br />

22 Guide Louver 26112034 1<br />

23 Step Motor 15212110 1<br />

24 Right Motor Clamp<br />

1<br />

25 Motor<br />

150121082 1<br />

26 Motor Bearing Holder<br />

1<br />

27 Electric Box 201021781 1<br />

28 Electric Box Cover 22242030 1<br />

29 Terminal Board<br />

42011233 1<br />

30 Covering Plate 201220064 1<br />

31 Main PCB<br />

30039146 1<br />

32 Room Sensor<br />

390000451 1<br />

33 Tube Sensor<br />

390000591 1<br />

34 Transformer<br />

43110254 1<br />

35 Wire Clamp 71010003 1<br />

36 Rear Clamp 26112430 1<br />

27

Comfortstar plus<br />

Components <strong>and</strong> Parts List of Indoor Unit<br />

No Description<br />

Part Code<br />

CHH012CA-13(I)<br />

Qty<br />

1 Wall-Mounting Frame 01252384 1<br />

2 Rear Case 22202051 1<br />

3 Evaporator Assy 010021811 1<br />

4 Cross-Flow Fan 10352005 1<br />

5 Ring of Bearing 76712015 1<br />

6 Drain Hose 05232411 1<br />

7 Water Tray 201820302 1<br />

8 Swing Louver 10512041 1<br />

9 Swing Linkage 10582439 1<br />

10 Front Grill 01472004 1<br />

11 Front Case 20002295 1<br />

12 Screw Cap 24252007 3<br />

13 Air Filter 11122440 2<br />

14 Panel 20002828 1<br />

15 Panel 20002831 1<br />

16 Remote Control YB1B4F 30511010 1<br />

17 Light Cover 22242031 1<br />

18 Display Board 30545557 1<br />

19 Display Cover 22432071 1<br />

20 Shield Board 26112048 1<br />

21 Guide Louver 26112043 1<br />

22 Guide Louver 26112042 1<br />

23 Step Motor MP28EA 15212105 1<br />

24 Right Motor Clamp 26112429 1<br />

25 Motor<br />

150120524 1<br />

26 Motor Bearing Holder 26152423 1<br />

27 Electric Box 201021081 1<br />

28 Electric Box Cover 222420175 1<br />

29 Terminal Board T4B3A 42011233 1<br />

30 Covering Plate 20102123 1<br />

31 Main PCB<br />

30039145 1<br />

32 Room Sensor 15K 390000451 1<br />

33 Tube Sensor 20K 390000591 1<br />

34 Transformer 57X25F 43110257 1<br />

35 Wire Clamp 71010003 1<br />

36 Rear Clamp 26112430 1<br />

28

Components <strong>and</strong> Parts List of Indoor Unit<br />

No Description<br />

Part Code<br />

CHH012CD-13(I)<br />

Qty<br />

1 Wall-Mounting Frame 01252384 1<br />

2 Rear Case 22202050 1<br />

3 Evaporator Assy 010021811 1<br />

4 Cross-Flow Fan 10352005 1<br />

5 Ring of Bearing 76712015 1<br />

6 Drain Hose 05232411 1<br />

7 Water Tray 201820302 1<br />

8 Swing Louver 10512041 1<br />

9 Swing Linkage 10582439 1<br />

10 Front Grill 01472004 1<br />

11 Front Case 20002295 1<br />

12 Screw Cap 24252007 3<br />

13 Air Filter 11122440 2<br />

14 Panel 20002828 1<br />

15 Panel 20002831 1<br />

16 Remote Control YB1B4F 30511010 1<br />

17 Light Cover 22242031 1<br />

18 Display Board 30545557 1<br />

19 Display Cover 22432071 1<br />

20 Shield Board 26112048 1<br />

21 Guide Louver 26112043 1<br />

22 Guide Louver 26112042 1<br />

23 Step Motor MP28EA 15212105 1<br />

24 Right Motor Clamp 26112429 1<br />

25 Motor FN22P 15012061 1<br />

26 Motor Bearing Holder 26152423 1<br />

27 Electric Box 201021081 1<br />

28 Electric Box Cover 222420175 1<br />

29 Terminal Board T4B3A 42011233 1<br />

30 Covering Plate 20102123 1<br />

31 Main PCB 9H82 30039085 1<br />

32 Room Sensor 15K 390000451 1<br />

33 Tube Sensor 20K 390000591 1<br />

34 Transformer 57X25F 43110257 1<br />

35 Wire Clamp 71010003 1<br />

36 Rear Clamp 26112430 1<br />

29

Exploded View of Outdoor unit<br />

CHH09CA-13(O)<br />

30

No Description<br />

Part Code<br />

CHH09CA-13(O)<br />

Qty<br />

1 Front Panel 01533007 1<br />

2 Clap Board 01233012 1<br />

3 Reactor Box C 01413504 1<br />

4 PFC Inductance 0.8mH/20A 99070120 1<br />

5 Drainage Connecter 06123401 1<br />

6 Reactor Support Assy 01203102 1<br />

7 Overload Protector 00183003 1<br />

8 Compressor C-6RZ092H1AB 00102004 1<br />

9 Compressor Gasket 76710236 3<br />

10 Bolt 70210007 3<br />

11 Nut 70310011 3<br />

12 Valve Support 01713041 1<br />

13 Right Side Plate Assy 01303071 1<br />

14 Valve 1/2" 07100006 1<br />

15 Valve 1/4" 07100003 1<br />

16 Capillary Assy 1<br />

17 One Way Valve 07130103 1<br />

18 4-Way Valve 430004032 1<br />

19 4-way Rever-sing Valve Component 03023670 1<br />

20 Electric Cover Assy 01413086 1<br />

21 4-way Valve Coil 430004002 1<br />

22 capacitor clamp 1<br />

23 capacitor 1<br />

24 Terminal Board A 42010255 1<br />

25 Electric Box 2 01413025 1<br />

26 electrical filter 1<br />

27 capacitor box1 1<br />

28 capacitor box2 1<br />

29 Electric Box 20113001 1<br />

30 PCB 1<br />

31 Temperature Sensor 3900012123 1<br />

32 Sensor 20K 39000071 1<br />

33 Exhaust Gas Temperature Sensor 50K 39000016 1<br />

34 Electric Box Cover 01413048 1<br />

35 Rectifier S25VB60 46010602 1<br />

36 Sensor Insert 42020063 1<br />

37 Radiator 49010213 1<br />

38 Rear Grill 01473030 1<br />

39 Condenser Assy 0110350713 1<br />

40 Top Cover Assy 01253261 1<br />

41 Motor Support Assy 017030521 1<br />

42 Motor FW30K 15013067 1<br />

43 Axial Flow Fan 10333414 1<br />

44 Nut 70310131 1<br />

45 Front Grill 22413011 1<br />

-31

Exploded View of Outdoor unit<br />

CHH012CA-13(O)<br />

32

No<br />

Description<br />

p1b 1 WG06006622 60829<br />

Part Code<br />

CHH012CA-13(O)<br />

1 Front Panel 01533007 1<br />

2 Clap Board 01233012 1<br />

3 Reactor Box C 01413504 1<br />

4 PFC Inductance 0.8mH/20A 99070120 1<br />

5 Drainage Connecter 06123401 1<br />

6 Reactor Support Assy 01203102 1<br />

7 Overload Protector 00183003 1<br />

8 Compressor C-6RZ092H1AB 00102004 1<br />

9 Compressor Gasket 76710236 3<br />

10 Bolt 70210007 3<br />

11 Nut 70310011 3<br />

12 Valve Support 01713041 1<br />

13 Right Side Plate Assy 01303071 1<br />

14 Valve 1/2" 07100006 1<br />

15 Valve 1/4" 07100003 1<br />

16 Capillary Assy 03103301 1<br />

17 One Way Valve 07130103 1<br />

18 4-Way Valve 430004032 1<br />

19 4-way Rever-sing Valve Component 03023670 1<br />

20 Electric Cover Assy 01413086 1<br />

21 4-way Valve Coil 430004002 1<br />

22 Terminal Board A 42010255 1<br />

22 capacitor clamp 1<br />

23 capacitor 1<br />

24 Terminal Board A 42010255 1<br />

25 Electric Box 2 01413025 1<br />

26 electrical filter 1<br />

27 capacitor box1 1<br />

28 capacitor box2 1<br />

29 Electric Box 20113001 1<br />

30 PCB W9M32A 30039155 1<br />

31 Temperature Sensor 3900012123 1<br />

32 Sensor 20K 39000071 1<br />

33 Exhaust Gas Temperature Sensor 50K 39000016 1<br />

34 Electric Box Cover 01413048 1<br />

35 Rectifier S25VB60 46010602 1<br />

36 Sensor Insert 42020063 1<br />

37 Radiator 49010213 1<br />

38 Rear Grill 01473030 1<br />

39 Condenser Assy 0110350713 1<br />

40 Top Cover Assy 01253261 1<br />

41 Motor Support Assy 017030521 1<br />

42 Motor FW30K 15013067 1<br />

43 Axial Flow Fan 10333414 1<br />

44 Nut 70310131 1<br />

45 Front Grill 22413011 1<br />

Qty<br />

-33

Exploded View of Outdoor Unit<br />

CHH012CD-13(O)<br />

34

Comfortstar plus<br />

Components <strong>and</strong> Parts List of Outdoor Unit<br />

No Description<br />

Part Code<br />

CHH012CD-13(O)<br />

Qty<br />

1 Front Panel 01533007 1<br />

2 Clap Board 01233012 1<br />

3 Reactor Box C 01413504 1<br />

4 PFC Inductance 0.8mH/20A 99070120 1<br />

5 Drainage Connecter 06123401 1<br />

6 Reactor Support Assy 01203102 1<br />

7 Overload Protector 00183003 1<br />

8 Compressor C-6RZ092H1AB 00102004 1<br />

9 Compressor Gasket 76713006 3<br />

10 Bolt 70210007 3<br />

11 Nut 70310011 3<br />

12 Valve Support 01713041 1<br />

13 Right Side Plate Assy 01303071 1<br />

14 Valve 1/2" 07100006 1<br />

15 Valve 1/4" 07100003 1<br />

16 Capillary Assy 03103301 1<br />

17 One Way Valve 07130103 1<br />

18 4-Way Valve 430004032 1<br />

19 4-way Rever-sing Valve Component 03023670 1<br />

20 Electric Cover Assy 01413086 1<br />

21 4-way Valve Coil 430004002 1<br />

22 Terminal Board A 42010255 1<br />

23 Electric Box 2 01413025 1<br />

24 Electric Box 20113001 1<br />

25 PCB W9M32A 30039155 1<br />

26 Temperature Sensor 3900012123 1<br />

27 Sensor 20K 39000071 1<br />

28 Exhaust Gas Temperature Sensor 50K 39000016 1<br />

29 Electric Box Cover 01413048 1<br />

30 Rectifier S25VB60 46010602 1<br />

31 Sensor Insert 42020063 1<br />

32 Radiator 49010213 1<br />

33 Rear Grill 01473030 1<br />

34 Condenser Assy 0110350713 1<br />

35 Top Cover Assy 01253261 1<br />

36 Motor Support Assy 017030521 1<br />

37 Motor FW30K 15013067 1<br />

38 Axial Flow Fan 10333414 1<br />

39 Nut 70310131 1<br />

40 Front Grill 22413011 1<br />

35

9 Troubleshooting<br />

Common section<br />

Analysis in this section is used for D.C. Variable Frequency Series. Before analysis, you can diagnose<br />

according to the code displayed on indoor unit or indicator display on outdoor unit. (Refer to 9.2 Malfunction<br />

display section).<br />

Breaker tripped<br />

or fuse burnt out<br />

When the breaker is set ON, it will<br />

trip at once<br />

When the unit is turned on, the<br />

breaker will trip in a few minutes<br />

Measure the insulating resistance<br />

for grounding to confirm whether<br />

there is electrical leakage or short<br />

circuit in the unit<br />

Insulation malfunction of line or componen<br />

in the air conditioner. Insulation breakdow<br />

occurs after radiation, which causes shor<br />

circuit or electricity leakage. Measure<br />

insulating resistance or use one-by-on<br />

elimination method;<br />

Malfunction of fuse. Replace it.<br />

No power supply<br />

Check power supply circuit<br />

Air<br />

conditi<br />

oner<br />

cannot<br />

start up<br />

Air conditioner<br />

does not response<br />

after powered on.<br />

(The buzzer does<br />

not sound after the<br />

plug is connected<br />

<strong>and</strong> the unit does<br />

not response after<br />

the remote<br />

controller is used<br />

to turn it on)<br />

The power plug is not or poorly<br />

connected<br />

Controller fuse is burnt out<br />

Loose or poor contact of transformer<br />

connection, or transformer malfunction<br />

Check <strong>and</strong> plug well plug, make<br />

loosen contact firm<br />

Change control fuse<br />

Secure the wire connection: measure<br />

the output voltage of the transformer<br />

<strong>and</strong> replace it if the value is wrong<br />

The controller is broken<br />

Replace the controller<br />

Remote<br />

controller does<br />

not receive signal<br />

(When powered<br />

on, the buzzer<br />

will send out a<br />

sound, unless it is<br />

broken)<br />

Batteries of remote controller are low<br />

Malfunction of remote controller<br />

Loose or poor connection of receiving<br />

head<br />

Receiving head is broken<br />

Change battery<br />

First press the "AUTO" button of the<br />

manual switch. If there is no response,<br />

check according to the above method;<br />

if it is normal after the button is<br />

pressed, check if the installation<br />

location <strong>and</strong> wire connection of the<br />

receiving head are correct. If correct,<br />

replace the receiving head, or the<br />

remote controller.<br />

36

Comfortstar plus<br />

Improper setting of temperature<br />

Adjust the set temperature<br />

Whether cooling (heating) load<br />

is proper<br />

Check the estimated load of cooling (heating)<br />

Leakage or shortage of refrigerant<br />

Vacuumize after leakage detection<br />

<strong>and</strong> leakage repair. Charge refrigerant<br />

according to specification.<br />

Malfunction of<br />

refrigerant flow<br />

Leakage occurs between high <strong>and</strong><br />

low pressure inside compressor<br />

Malfunction of four-way valve<br />

Replace the compressor<br />

Replace the four-way valve<br />

Partial blockage of capillary<br />

Replace the capillary<br />

Poor cooling<br />

(heating) effect<br />

Poor thermal insulation of connecting<br />

pipe of indoor <strong>and</strong> outdoor unit<br />

Blockage of cooling system<br />

Use the method of observing condensation<br />

on the evaporator <strong>and</strong> pressure value of<br />

high pressure manometer to see whether<br />

the system is blocked <strong>and</strong> carry out<br />

corresponding h<strong>and</strong>ling on the system<br />

Ensure that both thick pipe <strong>and</strong> thin pipe are insulated<br />

well. The exposed part of the connector <strong>and</strong> copper pipe<br />

must be insulated as well.<br />

Heat exchanger of outdoor unit<br />

is blocked<br />

Air filters are blocked<br />

Clean the dust accumulated on the<br />

surface of the heat exchanger<br />

Clean the filter<br />

Air circulation<br />

is insufficient<br />

Fan speed is set too slow<br />

Fan speed turns low<br />

Improper installation location<br />

for outdoor unit<br />

Set the fan speed to high or medium<br />

speed<br />

Damage of<br />

capacitor<br />

damaged<br />

Damage of<br />

motor<br />

Replace<br />

capacitor<br />

Replace the motor<br />

Outdoor unit should be installed in a<br />

place with well ventilation<br />

the<br />

Outdoor temperature is too high<br />

Flashing or awning can be installed appropriately. If the<br />

max. cooling capacity cannot be satisfied, replacement of<br />

the air conditioner is recommended.<br />

Indoor sealability is inadequate; too many<br />

people go in <strong>and</strong> out frequently; there is<br />

heating unit in the room.<br />

Maintain a certain degree of indoor sealability. Try not to<br />

use appliance with high amount of heat.<br />

37

Abnormal power supply of outdoor unit<br />

Check the circuit according to circuit diagram<br />

When unit is<br />

cooling or<br />

heating, both<br />

compressor <strong>and</strong><br />

outdoor fan don't<br />

run<br />

Damage of outdoor main control board<br />

Breakage of outdoor power module<br />

Improper setting of temperature<br />

Replace the main control board<br />

Replace the power module<br />

Adjust the set temperature<br />

When unit is<br />

cooling or<br />

heating, the<br />

compressor runs<br />

but outdoor fan<br />

doesn't run<br />

Breakage of outdoor fan motor<br />

Wrong wire connection<br />

Breakage of outdoor main control board<br />

Replace the fan motor<br />

Wire according to the circuit diagram<br />

Replace the main control board<br />

Breakage of outdoor fan capacitor<br />

Replace the fan capacitor<br />

Malfunction of compressor<br />

Replace the compressor<br />

When cooling or<br />

heating, outdoor<br />

fan runs, but<br />

compressor<br />

doesn't run.<br />

Poor contact of connection between the<br />

main control board <strong>and</strong> module<br />

Abnormal input of power module<br />

Abnormal output of power module<br />

Re-fasten the connection<br />

Check if input is 320V. If not, replace the<br />

rectifier<br />

Replace the power module<br />

When cooling or<br />

heating, outdoor<br />

fan runs, but<br />

compressor<br />

doesn't run.<br />

Compressor temperature is too high<br />

Wrong wiring<br />

Damage of outdoor main control board<br />

Cool the compressor for 30 min before running<br />

Wire according to the circuit diagram<br />

Replace the outdoor main control board<br />

Fan doesn't run<br />

when FAN mode<br />

is set<br />

Burn-out or broken wire of indoor fan<br />

motor<br />

Wrong wiring<br />

Circuit break or damage of fan motor<br />

capacitor<br />

Repair or change the fan motor<br />

Wire according to the circuit diagram<br />

Replace the indoor main control board<br />

38

Comfortstar plus<br />

Water leakage<br />

Blockage or breakage of drainage hose<br />

Wrap of refrigerant pipe connector is not<br />

tight enough<br />

Replace the drainage hose<br />

Re-wrap <strong>and</strong> make it tight<br />

Fan of indoor unit contacts other parts<br />

Adjust fan location<br />

There is foreign substance in indoor unit<br />

Take out the foreign substance<br />

Abnormal sound<br />

<strong>and</strong> shake<br />

Compressor shakes too much<br />

Touch of pipeline of outdoor unit<br />

Touch of inner plates<br />

Adjust support washer of the compressor <strong>and</strong><br />

tighten loose bolts<br />

Separate the touched pipeline<br />

1. Tighten connecting screws<br />

2.Stick shock-absorbing clay between plates<br />

Touch of outdoor unit fan blade with<br />

outer case<br />

Abnormal sound inside compressor<br />

Adjust louver position<br />

Replace compressor<br />

Abnormal electromagnetic sound inside<br />

four-way valve when heating<br />

Short circuit inside electromagnetic valve.<br />

Replace the electromagnetic valve<br />

Notes<br />

1.When repairing, before the voltage between module PN is measured below 50V, do not touch any terminal<br />

to avoid electric shock.<br />

2.When replacing power module <strong>and</strong> rectifier, be sure to spread the radiating paste evenly.<br />

39

12.2 Malfunction display section<br />

D.C. Variable Frequency Series<br />

When malfunction or protection occurs in the air conditioner, corresponding code will be displayed on the screen<br />

of the indoor unit <strong>and</strong> the indicator of outdoor unit will blink accordingly as well. When protection or malfunction<br />

is eliminated, display will be back to normal<br />

E4: Compressor discharge protection<br />

E5: Low voltage overcurrent protection<br />

E6: Communication malfunction<br />

Display code <strong>and</strong><br />

malfunction<br />

description of<br />

indoor unit<br />

F1: Indoor environmental sensor open or short circuit (the malfunction is detected for 30s<br />

continuously)<br />

F2: Indoor evaporator sensor open or short circuit (the malfunction is detected for 30s continuously)<br />

F3: Outdoor environmental sensor open or short circuit (the malfunction is detected for 30s<br />

continuously)<br />

F4: Outdoor condenser sensor open or short circuit (the malfunction is detected for 30s<br />

continuously)<br />

F5: Outdoor discharge sensor open or short circuit (after the compressor runs for 3 min, the<br />

malfunction is detected for 3s continuously)<br />

H1: Defrosting<br />

H3: Compressor overload protection<br />

H4: System malfunction (i.e. overload protection)<br />

H5: IPM module protection<br />

(Mainboard) Yellow light blinks 1 time<br />

(Mainboard) Yellow light blinks 2 times<br />

Compressor is running (this is normal condition<br />

<strong>and</strong> the display of indoor unit is normal)<br />

Defrosting (display H1)<br />

Indicator display<br />

of outdoor unit<br />

(Mainboard) Yellow light blinks 3 times<br />

(Mainboard) Yellow light blinks 4 times<br />

(Mainboard) Yellow light blinks 5 times<br />

(Mainboard) Yellow light blinks 6 times<br />

(Mainboard) Yellow light blinks 7 times<br />

(Mainboard) Yellow light blinks 8 times<br />

Antifreezing protection (display of indoor unit<br />

displays is normal)<br />

IPM module protection (corresponds to H5 of<br />

indoor unit)<br />

Overcurrent protection (corresponds to E5 of<br />

indoor unit)<br />

Overload protection (corresponds to H4 of<br />

indoor unit)<br />

Discharge protection (corresponds to E4 of<br />

indoor unit)<br />

Compressor overload protection (corresponds to<br />

H3 of indoor unit)<br />

(Mainboard) Red light blinks 1 time<br />

Limited frequency(current)<br />

(Mainboard) Red light blinks 2 times<br />

Dropped frequency (Discharge)<br />

40

Comfortstar plus<br />

(Mainboard) Red light blinks 3 times<br />

Limited frequency(overload)<br />

(Mainboard) Red light blinks 4 times<br />

Dropped frequency (Antifreeze Protection)<br />

Indicator display<br />

of outdoor unit<br />

(Mainboard) Red light blinks 5 times<br />

(Mainboard) Red light blinks 6 times<br />

Malfunction of outdoor tube sensor<br />

Malfunction of outdoor environmental sensor<br />

(Mainboard) Red light blinks 7 times<br />

Malfunction of outdoor discharge sensor<br />

(Mainboard) Red light blinks 8 times<br />

(Mainboard) Green light blinks<br />

Starting temperature is reached. This is normal<br />

condition <strong>and</strong> display of indoor unit is normal<br />

Communication is normal<br />

Note: Malfunction display : blind 0.5s; stop 0.5s, there is 2s' interval between two malfunction displays<br />

Analysis or h<strong>and</strong>ling of some of the malfunction display:<br />

1. Compressor discharge protection (E4):<br />

Possible reasons: shortage of refrigerant; blockage of air filter; poor ventilation or air flow short pass<br />

for condenser; the system has noncondensing gas (such as air, water etc.); blockage of capillary assy<br />

(including filter); leakage inside four-way valve causes incorrect operation; malfunction of<br />

compressor; malfunction of protection relay; malfunction of discharge sensor; outdoor temperature too<br />

high.<br />

H<strong>and</strong>ling method: refer to the malfunction analysis in the above section.<br />

2. Low voltage overcurrent protection (E5):<br />

Possible reason: Sudden drop of supply voltage.<br />

3. Communication malfunction (E6):<br />

H<strong>and</strong>ling method: Check if communication signal cable is connected reliably<br />

4 Sensor open or short circuit (F1, F2, F3, F4, F5):<br />

H<strong>and</strong>ling method: Check whether sensor is normal, connected with the corresponding position on the<br />

controller <strong>and</strong> if damage of lead wire is found<br />

5. Compressor overload protection (H3):<br />

Possible reasons: insufficient or too much refrigerant; blockage of capillary <strong>and</strong> increase of suction temp.;<br />

improper running of compressor, burning in or stuck of bearing, damage of discharge valve;<br />

malfunction of protector.<br />

H<strong>and</strong>ling method: adjust refrigerant amount; replace the capillary; replace the compressor; use<br />

universal meter to check if the contactor of compressor is fine when it is not overheated, if not replace<br />

the protector.<br />

6. System malfunction (H4):<br />

i.e. overload protection. When tube temperature (Check the temperature of outdoor heat exchanger<br />

when cooling <strong>and</strong> check the temperature of indoor heat exchanger when heating) is too high,<br />

protection will be activated.<br />

Possible reasons: Outdoor temperature is too high when cooling; insufficient outdoor air circulation;<br />

refrigerant flow malfunction.<br />

please refer to the malfunction analysis in the previous section for h<strong>and</strong>ling method .<br />

-41

7. Module protection (H5):<br />

H<strong>and</strong>ling method:<br />

Check if the voltage between power module P <strong>and</strong> N is too low <strong>and</strong><br />

if the current is too high. In normal condition, voltage between P <strong>and</strong><br />

N should be about 320V.<br />

Abnormal<br />

Normal<br />

Check power supply circuit of outdoor unit (if PTC resistance<br />

rectifying bridge, reactor, capacitance etc. is ok).<br />

Temperature of power module is too high,<br />

which causes overheating protection<br />

Protection is still displayed<br />

Check if radiating paste is spread<br />

evenly or radiating sticker is stuck<br />

well; if screws of power module<br />

is tightened<br />

Reinstall power module <strong>and</strong><br />

re-spread radiating paste or<br />

stick radiating sticker on the<br />

radiator of power module.<br />

Confirm the setting status of outdoor unit (cooling)<br />

Normal<br />

Poor radiation, heat exchanger<br />

is dirty<br />

Remove obstructions<br />

<strong>and</strong> clean<br />

Confirm if outdoor fan motor is running; unplug the<br />

three connecting wires between U, V, W of compressor<br />

<strong>and</strong> power module. Turn on the unit to see if outdoor<br />

fan runs normally (about 1 minute)<br />

Outdoor fan runs<br />

Confirm if there is voltage output <strong>and</strong> balance of<br />

voltage between any two phases of U, V <strong>and</strong> W.<br />

Outdoor fan stops<br />

Measure the voltage of outdoor<br />

fan connector<br />

Yes<br />

Whether module type<br />

is correct<br />

No<br />

Replace the power module<br />

No voltage<br />

Replace the mainboard<br />

of outdoor unit<br />

Replace the fan<br />

motor<br />

Normal voltage<br />

Abnormal<br />

Replace the module<br />

with correct type<br />

Normal<br />

Measure the three-phase<br />

resistance of compressor<br />

Normal<br />

Whether cylinder of<br />

compressor is stuck<br />

Replace the<br />

compressor<br />

Abnormal<br />

If the unit runs normally after connected<br />

with the new compressor for trial run, the<br />

cylinder of original compressor is stuck<br />

42