M-E Perpetual Pavement Design N3 and N4 - Aapaq.org

M-E Perpetual Pavement Design N3 and N4 - Aapaq.org

M-E Perpetual Pavement Design N3 and N4 - Aapaq.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

29-Sep-11<br />

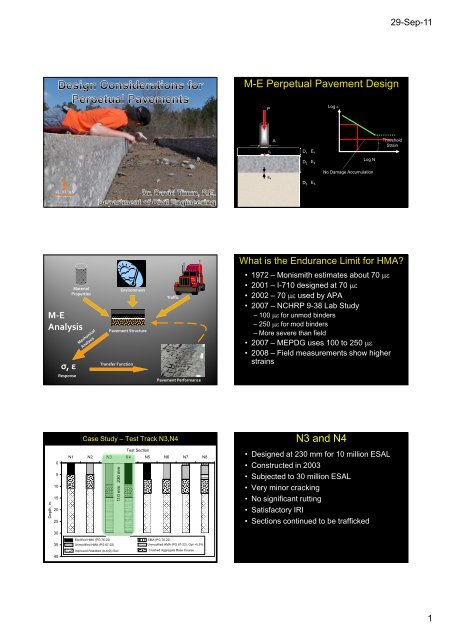

M-E <strong>Perpetual</strong> <strong>Pavement</strong> <strong>Design</strong><br />

P<br />

Log <br />

A<br />

Threshold<br />

Strain<br />

t<br />

D 1<br />

E 1<br />

D 2<br />

E 2<br />

Log N<br />

No Damage Accumulation<br />

v<br />

D 3<br />

E 3<br />

What is the Endurance Limit for HMA<br />

Material<br />

Properties<br />

M‐E<br />

Analysis<br />

σ, ε<br />

Response<br />

Environment<br />

<strong>Pavement</strong> Structure<br />

Transfer Function<br />

Traffic<br />

<strong>Pavement</strong> Performance<br />

• 1972 – Monismith estimates about 70 <br />

• 2001 – I-710 designed at 70 <br />

• 2002 – 70 used by APA<br />

• 2007 – NCHRP 9-38 Lab Study<br />

– 100 for unmod binders<br />

– 250 for mod binders<br />

– More severe than field<br />

• 2007 – MEPDG uses 100 to 250 <br />

• 2008 – Field measurements show higher<br />

strains<br />

Depth, in.<br />

0<br />

5<br />

10<br />

15<br />

20<br />

25<br />

30<br />

Case Study – Test Track <strong>N3</strong>,<strong>N4</strong><br />

Test Section<br />

N1 N2 <strong>N3</strong> <strong>N4</strong> N5 N6 N7 N8<br />

15 50 mm 230 mm<br />

<strong>N3</strong> <strong>and</strong> <strong>N4</strong><br />

• <strong>Design</strong>ed at 230 mm for 10 million ESAL<br />

• Constructed in 2003<br />

• Subjected to 30 million ESAL<br />

• Very minor cracking<br />

No significant rutting<br />

• No significant rutting<br />

• Satisfactory IRI<br />

• Sections continued to be trafficked<br />

35<br />

40<br />

Modified HMA (PG 76-22)<br />

Unmodified HMA (PG 67-22)<br />

Improved Roadbed (A-4(0)) Soil<br />

SMA (PG 76-22)<br />

Unmodified HMA (PG 67-22), Opt +0.5%<br />

Crushed Aggregate Base Course<br />

1

29-Sep-11<br />

<strong>N3</strong><br />

<strong>N4</strong><br />

entile<br />

Perce<br />

100%<br />

90%<br />

80%<br />

70%<br />

60%<br />

50%<br />

40%<br />

30%<br />

20%<br />

10%<br />

Strain Levels<br />

Average<br />

+15<br />

-15<br />

<strong>N3</strong><br />

<strong>N4</strong><br />

Fatigue endurance Limit<br />

0%<br />

0 50 100 150 200 250 300 350 400 450<br />

Microstrain<br />

Depth From <strong>Pavement</strong><br />

Surface, in.<br />

Case Study: Test Track N8 <strong>and</strong> N9<br />

0.0<br />

5.0<br />

10.00<br />

15.0<br />

20.0<br />

25.0<br />

Lift 1<br />

Lift 2<br />

Lift 3<br />

2.3 PG 76-28<br />

2.0<br />

2.9 PG 76-28<br />

3.5<br />

2.8<br />

Lift 4 1.9<br />

6.4<br />

N8<br />

Section<br />

N9<br />

SMA<br />

Dense Graded HMA<br />

250 mm 350 mm<br />

Moisture Content = 10.8%<br />

Unit Weight = 133.4 pcf<br />

Moisture Content = 18.0%<br />

Unit Weight = 126.2 pcf<br />

Dense Graded HMA<br />

PG 64-22<br />

Rich Bottom Layer<br />

PG 64-22<br />

Aggregate Base<br />

(Track Fill)<br />

Subgrade<br />

(A-7-6 Soil)<br />

3.1<br />

Lift 1<br />

Lift 2<br />

Lift 3<br />

Lift 4<br />

26 2.6<br />

3.2<br />

Lift 5<br />

8.4<br />

Moisture Content = 12.9%<br />

Unit Weight = 133.8 pcf<br />

Moisture Content = 17.2%<br />

Unit Weight = 126.9 pcf<br />

100%<br />

90%<br />

Strain Distributions<br />

End Result<br />

80%<br />

70%<br />

N9<br />

N8<br />

Perc centile<br />

60%<br />

50%<br />

40%<br />

No rehab since construction<br />

30%<br />

20%<br />

10%<br />

Fatigue endurance Limit<br />

0%<br />

0 100 200 300 400 500 600 700 800 900 1000 1100 1200<br />

Longitudinal Strain<br />

130 mm mill <strong>and</strong> inlay in 2008<br />

<strong>Pavement</strong> Failure at 3 million ESAL<br />

133 mm mill <strong>and</strong> inlay in 2010 with HPM<br />

2

29-Sep-11<br />

NCAT Test Track Results<br />

2003 Test Sections<br />

entile<br />

Perce<br />

100%<br />

No Fatigue<br />

90%<br />

Fatigue<br />

80%<br />

70%<br />

60%<br />

50%<br />

40%<br />

30%<br />

20%<br />

10%<br />

0%<br />

0 200 400 600 800 1000 1200<br />

Microstrain<br />

N1 2003<br />

N2 2003<br />

<strong>N3</strong> 2003<br />

<strong>N4</strong> 2003<br />

N5 2003<br />

N6 2003<br />

N7 2003<br />

N1 2006<br />

N2 2006<br />

<strong>N3</strong> 2006<br />

<strong>N4</strong> 2006<br />

N8 2006<br />

N9 2006<br />

N10 2006<br />

S11 2006<br />

S13 2000<br />

Fatigue<br />

Ratio<br />

4.5<br />

4.0<br />

3.5<br />

3.0<br />

2.5<br />

2.0<br />

1.5<br />

1.0<br />

0.5<br />

0.0<br />

Fatigue Cracking Occurred<br />

Fatigue Cracking Absent<br />

Max Ratio = 2.11<br />

N1 2003 N2 2003 <strong>N3</strong> 2003 <strong>N4</strong> 2003 N5 2003 N6 2003 N7 2003<br />

Section<br />

Fatigue Ratio<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

2006 Test Sections<br />

Fatigue Cracking Occurred<br />

Fatigue Cracking Absent<br />

Max. Ratio = 2.18<br />

PerRoad 3.5<br />

• Sponsored by APA<br />

• Developed at Auburn University / NCAT<br />

• M-E <strong>Perpetual</strong> <strong>Pavement</strong> <strong>Design</strong> <strong>and</strong> Analysis Tool<br />

– Features layered elastic analysis<br />

– Uses Monte Carlo simulation to model variability<br />

– Generates pavement response distributions<br />

ib ti<br />

0<br />

N1 2006 N2 2006 <strong>N3</strong> 2006 <strong>N4</strong> 2006 N8 2006 N9 2006 N10 2006 S11 2006<br />

Section<br />

3