Effect of Polymer on Shear Strength of Silty Sand - Ejge.com

Effect of Polymer on Shear Strength of Silty Sand - Ejge.com

Effect of Polymer on Shear Strength of Silty Sand - Ejge.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Vol. 14, Bund. A<br />

5<br />

The soil/polymer/water mixture<br />

was processed into dough<br />

using a mechanical kneader. The uniformly<br />

mixed dough was subsequently placed into a steel mold measuring (6*6*2<br />

cm) with density 2.07 g/ /cm 3 .<br />

Finally, the molded specimens were left to dry or cure for a period <str<strong>on</strong>g>of</str<strong>on</strong>g> 1 week at . Specimens c<strong>on</strong>taining<br />

0.025, 0.05 and 0.1 wt. .% (by dry weight) polymer were prepared using this<br />

method.<br />

During the drying process <str<strong>on</strong>g>of</str<strong>on</strong>g> the specimens, the weight loss was recorded as a functi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

time<br />

until a steady value was reached to ensure <strong>com</strong>plete removal <str<strong>on</strong>g>of</str<strong>on</strong>g> water. A period <str<strong>on</strong>g>of</str<strong>on</strong>g> 1 week was enough for<br />

all specimens to dry <strong>com</strong>pletely. Specimens used in this study were prepared for shear direct test in<br />

according<br />

to ASTM D 3080-90.<br />

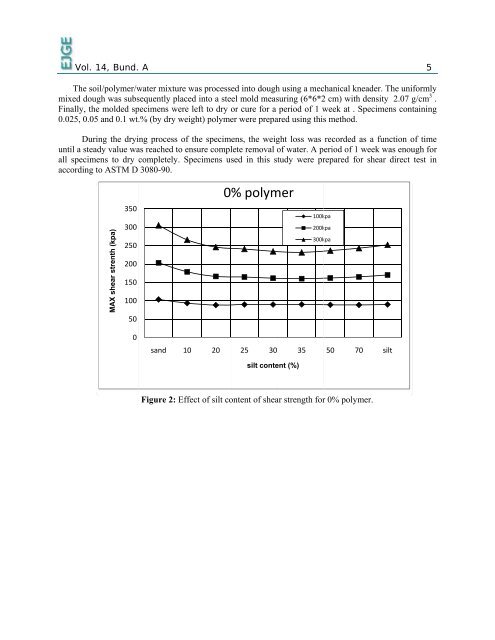

MAX shear strenth (kpa)<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0% polymer<br />

100kpa<br />

200kpa<br />

300kpa<br />

0<br />

sand 10 20<br />

25 30<br />

35<br />

50 70<br />

silt<br />

silt c<strong>on</strong>tent (%)<br />

Figure 2: <str<strong>on</strong>g>Effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> silt c<strong>on</strong>tent <str<strong>on</strong>g>of</str<strong>on</strong>g> shear strength for<br />

0% polymer.