100% Cellular Vinyl PVC® Builder Products - BlueLinx

100% Cellular Vinyl PVC® Builder Products - BlueLinx

100% Cellular Vinyl PVC® Builder Products - BlueLinx

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

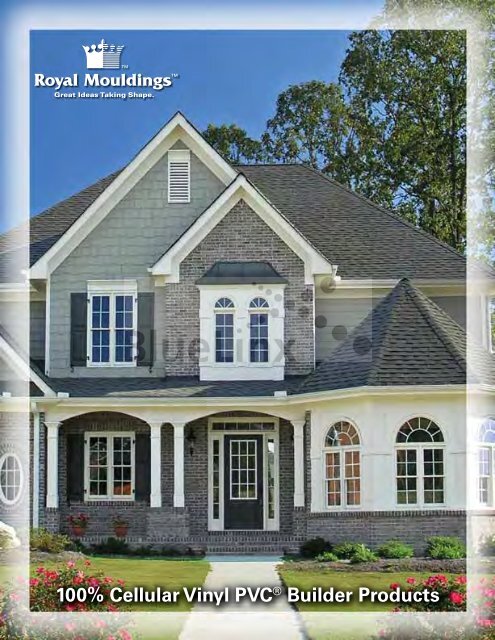

<strong>100%</strong> <strong>Cellular</strong> <strong>Vinyl</strong> PVC ® <strong>Builder</strong> <strong>Products</strong>

Royal Mouldings …<br />

making your dreams last longer<br />

Royal Mouldings is a division of Royal Group and along with Royal Window and Door Profiles, Royal Building<br />

<strong>Products</strong>, Royal Outdoor <strong>Products</strong>, and Royal Pipe Systems, they compile five vertically integrated manufacturers<br />

in the field of polymer based consumer, home improvement and commercial construction products.<br />

Royal Group is owned by Georgia Gulf Company, one of the leading North American manufacturers of and an<br />

international marketer of commodity chemicals as well as polymers and durable, custom and other vinyl based<br />

building and home improvement products.<br />

Royal Mouldings, maintaining a business philosophy of exceeding customers’ expectations, offers to the industry<br />

more than 40 years of continuous growth as a manufacturer and is one of the largest producers of decorative<br />

polymer and <strong>Cellular</strong> <strong>Vinyl</strong> PVC moulding extrusion components and systems in North America. They offer the<br />

most extensive selection of stock and custom colored products available. Quality mouldings, components and<br />

systems are manufactured and distributed from state-of-the-art production facilities in Marion, VA and Bristol,<br />

TN. Royal Mouldings provides quality products, impeccable service, and ability to be a low cost provider of integrated<br />

products consistent with customers’ needs…<br />

Marion, Virginia<br />

Bristol, Tennessee<br />

Don’t trust your investment to anything less than Royal.

What are <strong>Cellular</strong> <strong>Vinyl</strong> and<br />

Polymer Mouldings<br />

Royal Mouldings has pioneered the marketing, promotion<br />

and manufacturing of the <strong>Cellular</strong> process.<br />

This process uses specially formulated resins, such<br />

as PVC, allowing them to expand to a “full size” profile<br />

with a strong inner cell and outside surface that<br />

emulates the benefits of wood without the natural<br />

defects of wood. There are no surface blemishes and<br />

only minimal on-going maintenance. The products<br />

do not rot and are available in the industry’s largest<br />

selection of finishes.<br />

Why are <strong>Cellular</strong> <strong>Vinyl</strong> and Polymer<br />

Mouldings Better<br />

Royal <strong>Cellular</strong> <strong>Vinyl</strong> exceeds the market demand<br />

and homeowner expectations! In today’s economy,<br />

it is essential to conserve energy, not only for cost<br />

purposes but also for environmental reasons. One<br />

of the strongest features of <strong>Cellular</strong> <strong>Vinyl</strong> is energy<br />

efficiency. The material insulates 70% better than<br />

wood and 1600% better than aluminum, something<br />

no wood product can do. Royal Mouldings are specified<br />

for their cost effectiveness, low environmental<br />

impact, proven performance and reliability. Royal<br />

Mouldings are completely safe to use in high moisture<br />

and humidity environments.<br />

What are the Features and Benefits of<br />

<strong>100%</strong> <strong>Cellular</strong> <strong>Vinyl</strong> PVC ® <br />

3 Lifetime Never Rot ® Warranty<br />

3 Ready to Install<br />

• Factory Applied Readi-Finish ®<br />

• Warranted 10 year UV Coating<br />

• No Further Painting Required<br />

• Repaintable with Oil or Latex<br />

3 Low Maintenance<br />

3 Moisture & Termite Proof Material<br />

3 Install Below Grade or Direct to Masonry<br />

3 Does Not Promote Mold or Mildew<br />

3 Superior Nailing & Gluing<br />

• No Grain Raise, Pitch Bleed or Knots<br />

• No Splitting or Cracking<br />

3 Saves Time & Labor<br />

• Prefinished<br />

• Uses Standard Woodworking Equipment<br />

• Long Lengths—Perfect Tip-to-Tip<br />

3 High Energy Efficiency<br />

• 70% Better Insulation than Wood<br />

• 1,600% Better than Aluminum<br />

Table of Contents<br />

Subject<br />

Redi Ship symbol indicates<br />

inventory available to ship from<br />

factory within 5-7 days for qualified<br />

orders. Denoted items come<br />

with a factory-applied finish.<br />

Page<br />

About Royal Mouldings ...................................2<br />

Great Ideas Taking Shape ................................4<br />

Decorative Exterior Mouldings ........................6<br />

Window & Door Trim Systems .....................10<br />

Jamb Extenders ..............................................14<br />

Transom and Ventilation Systems ................15<br />

Envelop® Window Surround System ..........16<br />

Exterior & Interior Quick Trim ® ......................18<br />

Exterior Door Frame .......................................22<br />

Trimplank ® Premium Boards ........................24<br />

Siding Accessories .........................................26<br />

Royal S4S Trimboards ................................28<br />

Royal Trim Boards ® ........................................30<br />

Royal STAIN-ABLE Trim .............................32<br />

Garage Solutions ® ..........................................34<br />

Smart Space System ® ....................................36<br />

Envelop Garage Surround System ...........38<br />

Ceiling & Wall Solutions ............................40<br />

Envelop ® Pole & Post Surrounds ..................42<br />

Interior Mouldings ..........................................44<br />

Installation-Tips & Techniques ......................45<br />

Capabilities ......................................................49<br />

Warranty Information .....................................50<br />

Profile Cross Reference Listing .....................51

Decorative Trim Mouldings • Beaded Planking • Door Frame Com p o n e n t s • W i n d ow Components<br />

Great Ideas Taking Shape<br />

Do it once... Do it right...<br />

Outside & In<br />

Inside & Out<br />

Well-designed homes enhance the value of property in any neighborhood. Beautiful Solutions mouldings,<br />

once reserved for the interior of homes, have come front and center to add classic, chic, or casual<br />

innovation to any style home. Royal Decorative Mouldings allow architects, builders, remodelers and<br />

replacement contractors to add upgrades which enhance value, increase curb appeal and lessen maintenance<br />

long-term. Neighborhoods are returning to yesteryear’s appeal without putting wood in a position to<br />

fail. Royal Mouldings <strong>100%</strong> <strong>Cellular</strong> <strong>Vinyl</strong> PVC® provides professionals and homeowners alike the ability to<br />

Do it once….Do it right...Never go back to wood! ®<br />

4 800-368-3117

Great Ideas Taking Shape<br />

Great idea!<br />

Architectural build-ups using Royal Never Rot ®<br />

Exterior Mouldings instantly increase curb appeal<br />

and value.<br />

Before<br />

Never Rot®<br />

• Lifetime Never Rot ® Warranty<br />

• High Energy Efficiency<br />

• Maintenance So Low It’s a Pleasure...<br />

• Moisture & Termite Proof Material<br />

• Does Not Promote Mold or Mildew<br />

• Factory Finishes and Paintable Finishes<br />

• Repaintable with Oil or Latex Paint<br />

• Ready to Install<br />

• Installs Below Grade or Direct to Masonry<br />

• Superior Nailing & Gluing<br />

• Saves Valuable Time & Labor!<br />

Never Rot ® siding corners have nail fins for<br />

faster installation with better moisture control.<br />

www.royalbuildingproducts.com<br />

5

Decorative Exterior Mouldings<br />

Crown<br />

7662 1” x 8”<br />

Crown<br />

7661 11/16” x 6”<br />

Avail. Length: 16’<br />

Crown WM45<br />

7491 9⁄16” x 5-1⁄4”<br />

Avail. Length: 16’<br />

Crown WM47<br />

2592 11⁄16” x 4-5⁄8”<br />

Avail. Length: 16’<br />

Crown WM48<br />

7541 11⁄16” x 4-1⁄4”<br />

Avail. Length: 16’<br />

Crown WM49<br />

2435 9⁄16” x 3-5⁄8”<br />

Avail. Lengths: 12’, 16’<br />

Crown WM53<br />

2853 9⁄16” x 2-3⁄4”<br />

Avail. Length: 16’<br />

Rams Crown<br />

7158 1-13⁄32” x 2”<br />

Avail. Lengths: 12’, 16’<br />

Pediment<br />

7714 2” x 2-7/8”<br />

Avail. Length: 16’<br />

Decorative Trim<br />

7712 1-1/2” x 1-7⁄8”<br />

Avail. Length: 16’<br />

6 800-368-3117

Decorative Exterior Mouldings<br />

Create custom build-ups<br />

that add value and curb<br />

appeal using only a<br />

few profiles.<br />

A<br />

B<br />

C<br />

D<br />

E<br />

A. 7318, 1 x 4 Trimplank ®<br />

B. 2435 3-5⁄8 Crown<br />

C. 2721 Dentil<br />

D. 7440 1 x 10 Trimplank ®<br />

E. 2450 Base Cap<br />

A<br />

B<br />

C<br />

A. 7158 Rams Crown<br />

B. 2721 Dentil<br />

C. 7311 1 x 6 Trimplank ®<br />

Fits 5/8” Board<br />

Never Rot ® Decorative Trim<br />

<strong>100%</strong> <strong>Cellular</strong> <strong>Vinyl</strong> PVC ®<br />

Rake WM287<br />

7202 1” x 2”<br />

Avail. Lengths: 12’, 16’<br />

Bed Mould WM75<br />

2598 9⁄16” x 1-9⁄16”<br />

Avail. Lengths: 12’, 16’<br />

Backband<br />

7709 1-3/16” x 1-3/8”<br />

Avail. Length: 16’<br />

Fits 3/4” Board<br />

Backband<br />

7152 1-11⁄32” x 1-13⁄32”<br />

Avail. Lengths: 12’, 16’<br />

Fits 3/4” Board<br />

Backband<br />

7715 1-1/8” x 1-9/16”<br />

Fits 1” Board<br />

Backband<br />

7710 1-3/8” x 1-9/16”<br />

Avail. Length: 16’<br />

Colonial Stop<br />

7788 3/8” x 1-1/4”<br />

Avail. Lengths: 12’, 16’<br />

Scotia/Cove WM93<br />

2021 3/4” x 3/4”<br />

Avail. Lengths: 8’, 12’, 16’<br />

www.royalbuildingproducts.com<br />

7

Decorative Exterior Mouldings<br />

Royal Mouldings...<br />

Designing homes around<br />

sustainability, not repairs.<br />

8 800-368-3117

Decorative Exterior Mouldings<br />

Decorative Trim<br />

2753 1” x 1-5⁄16”<br />

Decorative Trim<br />

2754 15⁄16” x 1-1/16”<br />

Decorative Trim<br />

2757 1-1/4” x 1-13/16”<br />

Avail. Length: 16’<br />

Decorative Trim<br />

2756 1” x 1-1⁄16”<br />

Avail. Length: 16’<br />

Decorative Trim<br />

2755 3/4” x 1”<br />

Decorative Trim<br />

2759 1/2” x 1”<br />

Avail. Length: 16’<br />

Shingle Mould WM210<br />

2599 11⁄16” x 1-5⁄8”<br />

Avail. Lengths: 8’, 12’, 16’<br />

Shingle/Panel Mould<br />

7901 21/32” x 1-23/32”<br />

Outside Corner WM205<br />

7719 1-1/8” x 1-1/8”<br />

Avail. Lengths: 12’, 16’<br />

Base Cap WM164<br />

2450 11⁄16” x 1-1⁄8”<br />

Avail. Lengths: 8’, 12’, 16’<br />

Dentil<br />

2721 5⁄8” x 1-1⁄2”<br />

Avail. Lengths: 12’<br />

Dentil<br />

2722 1” x 3-1⁄2”<br />

Avail. Lengths: 12’<br />

Dentil<br />

2740 1-1⁄16” x 3-7⁄16”<br />

Dentil<br />

7357 5⁄8” x 1-5⁄8”<br />

Lattice<br />

2018 1/4” x 1-35/64”<br />

Avail. Length: 12’, 16’<br />

Stop<br />

2330 5/8” x 5/8”<br />

Avail. Lengths: 8’, 12’<br />

Stop WM126<br />

2046 5/16” x 3/4”<br />

Avail. Lengths: 12’, 16’<br />

Quarter Round/Stop<br />

2258 1⁄2” x 13⁄32”<br />

Avail. Length: 8’<br />

Quarter Round WM105<br />

2689 3⁄4” x 3⁄4”<br />

Avail. Lengths: 8’, 16’<br />

Quarter Round WM108<br />

2024 1/2” x 1/2”<br />

Avail. Lengths: 12’, 16’<br />

www.royalbuildingproducts.com<br />

9

Window & Door Trim Systems<br />

Windows & Doors of Opportunity<br />

Whether picking windows, doors or both components for a new<br />

home or as replacement, the best ones boast superior quality,<br />

energy efficiency and an excellent warranty. At Royal Mouldings,<br />

they’ve got you covered. They not only manufacture the finest<br />

replacement parts for contractors and builders, but Royal Mouldings<br />

also manufactures world class systems for the finest window and<br />

door fabricators in the United States and Canada. Contact Royal<br />

Mouldings, your local source for energy saving, code approved windows<br />

and doors.<br />

Brick Mould RM180*<br />

2448 1-1⁄4” x 2”<br />

Avail. Lengths: 8’, 10’, 17’<br />

Brick Mould RM180<br />

7137 1-1⁄4” x 2”<br />

Avail. Lengths: 8’, 17’<br />

10 800-368-3117

Window & Door Trim Systems<br />

Inside and out, Royal Window & Door Trim<br />

out-performs, out-lasts and out-does all<br />

others! The result—minimal maintenance for<br />

builder or homeowner.<br />

• Lifetime Never Rot ®<br />

• Factory-applied Readi-Finish ®<br />

• High Energy Efficiency<br />

• Low Maintenance<br />

Bendable<br />

Brick Mould RM180 †<br />

7886 1-1⁄4” x 2”<br />

Brick Mould RM180 †<br />

7595 1-1⁄4” x 2”<br />

Brick Mould RM180<br />

7371 1-1⁄4” x 2”<br />

Avail. Lengths: 12’, 17’<br />

J-Channel Brick Mould<br />

7351 1-1/4” x 3”<br />

Avail. Lengths: 12’, 17’<br />

West Coast<br />

Brick Mould<br />

7212 1-1⁄4” x 2”<br />

West Coast<br />

Brick Mould<br />

2622 13⁄16” x 1-5⁄16”<br />

Avail. Length: 8’<br />

Florida Brick Mould<br />

7252 11⁄16” x 1-5⁄8”<br />

Avail. Lengths: 7’, 8’, 10’<br />

Brick Mould WM180<br />

7526 1-1⁄4” x 2”<br />

Avail. Lengths: 8’, 10’, 17’<br />

Drip Cap<br />

2791 11⁄16” x 2”<br />

Drip Cap<br />

2449 11⁄16” x 1-5⁄8”<br />

Avail. Lengths: 12’, 16’<br />

Sill<br />

7117 1-1⁄4” x 5-1⁄4”<br />

Avail. Length: 7’<br />

Sill Nose<br />

2345 1-1/2” x 1-5⁄8”<br />

Avail. Length: 16’<br />

Sill Nose<br />

7717 1-3/16” x 2”<br />

Avail. Length: 16’<br />

Sill Nose<br />

7435 1-3/4” x 2-13/16”<br />

Avail. Length: 16’<br />

Sill Nose<br />

7118 1-5⁄16” x 1-3⁄8”<br />

Avail. Lengths: 7’, 12’<br />

Sill Nose<br />

7631 2” x 1-3⁄4”<br />

Sill Nose<br />

7640 2-1⁄4” x 2-3⁄4”<br />

Avail. Length: 16’<br />

* Cold weather nailable<br />

†<br />

Nail fin not shown<br />

www.royalbuildingproducts.com<br />

11

Window & Door Trim Systems<br />

Whether it’s a home, or a home away<br />

from home, demand trim that maintains<br />

its beauty and sustains its value.<br />

• Lifetime Never Rot ® Warranty<br />

• Pre-finished Ready to Install<br />

• Moisture & Termite Proof Material<br />

• Save Time and Labor<br />

• Does Not Promote Mold or Mildew<br />

J-Channel Casing 5/4 x 4<br />

7467 1-1⁄8” x 4-1⁄2”<br />

Avail. Lengths: 12’, 16’<br />

Bendable<br />

J-Channel Casing 5/4 x 4<br />

7885 1-1⁄8” x 4-1⁄2”<br />

RB3 Casing WM523<br />

2369 1” x 3-1/2”<br />

Avail. Lengths: 10’, 16’<br />

J-Channel Casing 5/4 x 6<br />

7651 1-1/8” x 6-1/2”<br />

Avail. Length: 16’<br />

Bendable<br />

J-Channel Casing 5/4 x 6<br />

7883 1-1/8” x 6-1/2”<br />

Casing<br />

7713 11/16” x 1-7/8”<br />

Casing<br />

2839 3⁄4” x 3-27⁄64”<br />

12 800-368-3117

Window & Door Trim Systems<br />

Fits 3/4” Board<br />

Backband<br />

7152 1-11⁄32” x 1-13⁄32”<br />

Avail. Lengths: 12’, 16’<br />

Casing<br />

2747 1-3/64” x 3-1/2”<br />

Avail. Length: 16’<br />

Casing<br />

2852 1” x 3-1/2”<br />

Avail. Length: 16’<br />

Casing/Backband<br />

2590 1-3/16” x 4-1/2”<br />

Avail. Lengths: 12’, 16’<br />

New England Casing<br />

2436 1” x 3-1⁄2”<br />

Fluted Casing–reversible<br />

7209 1” x 3-1⁄2”<br />

Williamsburg Brick<br />

Mould<br />

7216 1-7/32” x 3-1/4”<br />

Avail. Lengths: 12’, 16’<br />

Bendable<br />

Williamsburg Brick<br />

Mould<br />

7884 1-7/32” x 3-1/4”<br />

www.royalbuildingproducts.com<br />

13

Jamb Extenders<br />

Profile 7279<br />

Profile 7759<br />

Jamb Extender<br />

Profile #7382<br />

5/8” x 3-1/8”<br />

Jamb Extender<br />

Profile #7449<br />

5/8” x 5”<br />

Jamb Extender<br />

Profile #7279<br />

5/8” x 2”<br />

Jamb Extender<br />

Profile #7372<br />

5/8” x 3”<br />

Jamb Extender<br />

Profile #7759<br />

2-7/16” x 5-5/8”<br />

Jamb Extender<br />

Profile # 7763<br />

2-7/16” x 3-5/8”<br />

Jamb Extender<br />

Profile #7790<br />

2-7/16” x 8-11/16”<br />

Jamb Extender<br />

Profile #7159<br />

5/8” x 4-13/16”<br />

Jamb Extender<br />

Profile #7160<br />

5/8” x 2-13/16”<br />

Extension Jamb<br />

Profile #7308<br />

9/16” x 2-13/16”<br />

Extension Jamb<br />

Profile #7309<br />

9/16” x 4-13/16”<br />

14<br />

800-368-3117

Transom & Ventilation Systems<br />

Transom System<br />

Door Frame<br />

Profile #7181<br />

1-1/4” x 4-9/16”<br />

Transom Sill<br />

Profile #7213<br />

1-7/32” x 4-1/2”<br />

Stile<br />

Profile #7623<br />

1-21/64” x 1-31/32”<br />

Sash<br />

Profile #7464<br />

1-3/8” x 2-1/2”<br />

Glazing Bead<br />

Profile #878<br />

5/8” x 1-3/64”<br />

Ventilation System<br />

Sill<br />

Profile #2388<br />

1-1/4” x 3-1/2”<br />

Louver Blade<br />

Profile #2389<br />

3/4” x 3-1/2”<br />

Jamb<br />

Profile #2395<br />

3/4” x 2”<br />

www.royalbuildingproducts.com<br />

15

Envelop ® Window Surround System<br />

After<br />

Before<br />

Today’s neighborhood has become more than just houses. It has taken on<br />

a personality that welcomes, comforts, adds security, promotes style and<br />

defines good design. Window surrounds transform each and every home into a<br />

distinct signature.<br />

These <strong>100%</strong> <strong>Cellular</strong> <strong>Vinyl</strong> PVC® decorative Window Envelop® Surrounds add<br />

higher energy efficiency and perform 70% better than wood to provide a higher<br />

degree of insulation from winter’s cold and summer’s heat. The technology of<br />

the surrounds allows them to provide maintenance so low it’s a pleasure...<br />

Clients need never worry about Royal Window Envelop® Surrounds since<br />

they do not rot, chip, split or peel. And by the way, termites don’t like the taste<br />

of <strong>Cellular</strong> <strong>Vinyl</strong> PVC, and mold and mildew can’t grab hold of it. Window<br />

Envelops® will allow any builder, remodeler or contractor to set themselves<br />

apart from average with creative window surrounds that are a snap to install!<br />

• <strong>100%</strong> <strong>Cellular</strong> <strong>Vinyl</strong> PVC ®<br />

• Low Maintenance<br />

• Ready to Install<br />

• Moisture & Termite Proof<br />

• Does Not Promote<br />

Mold or Mildew<br />

• Nails and Screws<br />

Better than Wood<br />

16 800-368-3117

Envelop ® Window Surround System<br />

Easily create these<br />

surrounds with the profiles<br />

shown or make your<br />

own unique design. The only<br />

limit is your imagination.<br />

Regency Refined Sophistication Rams Crown Colonial Elegance<br />

Decorative Trim<br />

Profile #2757<br />

1-1/4” x 1-13/16”<br />

Trimplank ®<br />

Profile #7318<br />

3/4” x 3-1/2”<br />

Rams Crown<br />

Profile #7158<br />

1-13/32” x 2”<br />

Pediment<br />

Profile #7714<br />

2” x 2-7/8”<br />

Trimplank®<br />

Profile #7311<br />

3/4” x 5-1/2”<br />

Crown<br />

Profile #2853<br />

9/16” x 2-3/4”<br />

Trimplank ®<br />

Profile #7311<br />

3/4” x 5-1/2”<br />

Trimplank ®<br />

Profile #7311<br />

3/4” x 5-1/2”<br />

Decorative Trim<br />

Profile #2756<br />

1” x 1-1/16”<br />

Dentil<br />

Profile #2721<br />

5/8” x 1-1/2”<br />

Decorative Trim<br />

Profile #2759<br />

1/2” x 1”<br />

Trimplank ®<br />

Profile #7318<br />

3/4” x 3-1/2”<br />

Decorative Trim<br />

Profile #2754<br />

15/16” x 1-1/16”<br />

Trimplank ®<br />

Profile #7311<br />

3/4” x 5-1/2”<br />

Trimplank ®<br />

Profile #7318<br />

3/4” x 3-1/2”<br />

Sill Nose<br />

Profile #7640<br />

2-1/4” x 2-3/4”<br />

Trimplank ®<br />

Profile #7318<br />

3/4” x 3-1/2”<br />

Sill Nose<br />

Profile #7640<br />

2-1/4” x 2-3/4”<br />

Sill Nose<br />

Profile #7435<br />

1-3/4” x 2-13/16”<br />

www.royalbuildingproducts.com<br />

17

Exterior & Interior Quick Trim ®<br />

Bendable Brick Mould<br />

WM180<br />

2341 1-1/4” x 2”<br />

Avail. Length: 16’<br />

Casing<br />

2716 21⁄32” x 3-9⁄16”<br />

Traditional and affordable,<br />

geometric beauty from arches<br />

to rectangles.<br />

New England Casing<br />

2573 1-1/16” x 3-7/16”<br />

18 800-368-3117

Exterior & Interior Quick Trim ®<br />

Quick Trim ® …<br />

the time saving lineal and radius trim solution.<br />

Casing<br />

7278 1-1/16” x 3-1/2”<br />

Quick Trim ®<br />

Casing<br />

2718 1⁄2” x 3-5⁄16”<br />

Avail. Length: 14’<br />

Casing/Backband<br />

2590 1-3⁄16” x 4-1⁄2”<br />

Avail. Lengths: 12’, 16’<br />

Quick Trim ® by Royal Mouldings is the technological breakthrough<br />

that saves time with prefinished low maintenance<br />

results. Quick Trim ® components are made from <strong>100%</strong> <strong>Cellular</strong> <strong>Vinyl</strong><br />

PVC® that minimizes expansion and contraction for better installation.<br />

Specially formulated Never Rot ® profiles are “bendable”<br />

using convection heat. Create custom round tops, oval, elliptical,<br />

octagon or circles without extra material or labor.<br />

Quick Trim ® requires:<br />

• No Lamination<br />

• No Intensive Costly Labor<br />

• No Expensive Jigs<br />

Bendable<br />

Casing/Backband<br />

7255 1-3⁄16” x 4-1⁄2”<br />

Avail. Lengths: 12’, 16’<br />

RB3 Casing WM523<br />

2369 1” x 3-1⁄2”<br />

Avail. Lengths: 10’, 16’<br />

Quick Trim ® produces<br />

great buildups! This<br />

design was created using<br />

only one<br />

profile...<br />

2369 RB3 Casing!<br />

Fluted Casing–reversible<br />

7209 1” x 3-1⁄2”<br />

New England Casing<br />

2436 1” x 3-1⁄2”<br />

www.royalbuildingproducts.com<br />

19

Interior & Exterior Quick Trim ®<br />

20 800-368-3117<br />

Quick Trim ® simplifies traditional rectangle openings<br />

and defines the most beautiful radius designs.

Interior & Exterior Quick Trim ®<br />

Quick Trim ® …<br />

natural characteristics of wood without its shortcomings:<br />

• Lifetime Never Rot ® Warranty<br />

• Won’t Crack or Splinter<br />

• Low Maintenance<br />

• Moisture Resistant<br />

• Holds Fasteners<br />

Better than Wood<br />

Base WM623<br />

7527 9/16” x 3-1/4”<br />

Avail. Length: 16’<br />

Casing WM376<br />

2342 11⁄16” x 2-1⁄4”<br />

Avail. Length: 16’<br />

Finish Colors:<br />

Clearwood ®<br />

White Readi-Finish ®<br />

Colonial Casing WM445<br />

2343 11⁄16” x 3-1⁄4”<br />

Avail. Length: 16’<br />

Colonial Casing<br />

2351 11⁄16” x 2-1⁄4”<br />

Bendable<br />

Colonial Casing WM356<br />

2991 11⁄16” x 2-1⁄4”<br />

Quick Trim ® is available in paintable<br />

Readi-Finish ® or stainable woodgrain<br />

Clearwood. ®<br />

Colonial Casing WM356<br />

2355 11⁄16” x 2-1⁄4”<br />

Avail. Lengths: 12’, 16’<br />

Casing<br />

2365 11⁄16” x 2-1⁄4”<br />

West Coast Casing<br />

2391 1⁄2” x 2”<br />

West Coast Casing<br />

2428 5⁄8” x 2-3⁄4”<br />

Ranch Casing<br />

2331 11⁄16” x 2-1⁄4”<br />

Casing WM351<br />

2440 11/16” x 2-1/2”<br />

Casing<br />

2631 5⁄8” x 3”<br />

Casing<br />

2717 9⁄16” x 2-17⁄32”<br />

Casing<br />

2746 5/8” x 3-1/2”<br />

Casing<br />

2839 3/4” x 3-7/16”<br />

Casing<br />

2852 1” x 3-1/2”<br />

Avail. Length: 16’<br />

Casing<br />

7263 11/16” x 3-1/2”<br />

Casing<br />

7276 11⁄16” x 2-1⁄2”<br />

Casing<br />

7277 1-1/16” x 3-1/2”<br />

Casing<br />

7262 7⁄16” x 3-1⁄2”<br />

www.royalbuildingproducts.com<br />

21

Exterior Door Frame<br />

Proframe ®<br />

Paintable & Stainable<br />

Door Frames Stand Up<br />

to the Test.<br />

High Velocity Hurricane Zone<br />

22 800-368-3117

Exterior Door Frame<br />

Door Frame<br />

7181 1-1⁄4” x 4-9⁄16”<br />

Avail. Lengths: 7’<br />

P roframe® —the industry’s original door frame component is the first totally Never Rot ®<br />

exterior door trim system made of <strong>100%</strong> <strong>Cellular</strong> <strong>Vinyl</strong> PVC®. Proframe ® by Royal<br />

Mouldings is engineering approved by Miami-Dade County Code to resist extreme weather<br />

conditions and has a UL Listed 20 minute fire rating.<br />

Proframe ® lineal profiles combine with matching Never Rot ® brick mould accessories for traditional<br />

installation. Install Proframe Plus Nail-less Door Frame System to complete the perfect<br />

moisture barrier solution. Trim systems are available finished or with new stainable technology<br />

to match traditional or fiberglass entrance or patio doors.<br />

Weather<br />

Stripping<br />

Door Frame<br />

7604/7605 Moisture Barrier<br />

Alignment Pin<br />

Assembly<br />

Fastener<br />

Door Frame<br />

7251 1-1⁄4” x 5-1⁄4”<br />

Door Frame<br />

7241 1-1⁄4” x 6-9⁄16”<br />

Door Frame<br />

7807 1-1/4” x 7-1/4”<br />

Positioning Fin<br />

Optional Installation<br />

Face Nail-Less<br />

Brick Mould<br />

7635<br />

Before<br />

Door Frame<br />

7465 1-1⁄4” x 6-13⁄16”<br />

Door Frame<br />

7604 1-1⁄4” x 4-9⁄16”<br />

Door Frame<br />

7605 1-1⁄4” x 6-9⁄16”<br />

After<br />

Face Nail-Less<br />

Brick Mould<br />

7635 1-1⁄4” x 2”<br />

Brick Mould<br />

7137 1-1/4” x 2”<br />

Avail. Lengths: 8’, 17’<br />

Brick Mould*<br />

2448 1-1⁄4” x 2”<br />

Avail. Lengths: 8’, 10’, 17’<br />

Finish Colors:<br />

Woodgrain Embossed Texture &<br />

Smooth Surfaces Available<br />

Brick Mould †<br />

7595 1-1⁄4” x 2”<br />

Astragal<br />

7193 1-33⁄64” x 3-13⁄64”<br />

Mullion<br />

7340 2” x 3-1⁄2”<br />

Bright White<br />

Stainable<br />

* Cold weather nailable. † Nail fin not shown<br />

www.royalbuildingproducts.com 23

Trimplank ® Premium Boards<br />

Actual Thicknesses<br />

5/8”<br />

3/4”<br />

1”<br />

Whether doing new construction or remodeling, design versatility<br />

coupled with factory extruded profiles, incredible durability and low<br />

maintenance makes Royal Trimplank ® the product of choice for today’s<br />

homeowners. Royal’s <strong>100%</strong> <strong>Cellular</strong> <strong>Vinyl</strong> PVC ® is specified for its cost<br />

effectiveness, low environmental impact, proven performance and reliability.<br />

Trimplank ® is used effectively for trim, fascia, frieze boards, column<br />

surrounds and custom build-ups. Royal Mouldings Trimplank ® line of <strong>100%</strong><br />

<strong>Cellular</strong> <strong>Vinyl</strong> PVC ® products can help you “Build it Right”.<br />

✓ Lifetime Never Rot ® Warranty<br />

5/8” thickness<br />

✓ Readi-Finished ® — No Further<br />

Painting Required<br />

3/4” thickness<br />

✓ Ready to Install<br />

✓ Moisture & Termite Proof Material<br />

✓ Energy Efficient<br />

1” thickness<br />

✓ Saves Time & Labor<br />

24 800-368-3117

Trimplank ® Premium Boards<br />

Trimplank ® Premium Boards …<br />

from End-to-End & Throughout!<br />

Trimplank ® 1x2<br />

2150 5/8” x 1-1/2”<br />

Avail. Length: 12’<br />

Trimplank ® 1x4<br />

7446 5/8” x 3-1/2”<br />

Trimplank ® 1x6<br />

7445 5/8” x 5-1/2”<br />

Trimplank ® 1x8<br />

7444 5/8” x 7-1/4”<br />

Trimplank ® 1x10<br />

7443 5/8” x 9-1/4”<br />

Trimplank ® 1x12<br />

7442 5/8” x 11-1/4”<br />

Trimplank ® 1x4<br />

7318 3/4” x 3-1/2”<br />

Avail Lengths: 8’, 12’, 16’<br />

Trimplank ® 1x6<br />

7311 3/4” x 5-1/2”<br />

Avail Lengths: 8’, 12’, 16’<br />

Trimplank ® 1x8<br />

7312 3/4” x 7-1/4”<br />

Avail Lengths: 8’, 12’, 16’<br />

Trimplank ® 1x10<br />

7440 3/4” x 9-1/4”<br />

Avail Lengths: 8’, 12’, 16’<br />

Trimplank ® 1x12<br />

7439 3/4” x 11-1/4”<br />

Avail Lengths: 12’<br />

Trimplank ® 5/4x4<br />

7482 1” x 3-1/2”<br />

Avail Lengths: 8’, 12’<br />

Trimplank ® 5/4x6<br />

7483 1” x 5-1/2”<br />

Avail Lengths: 8’, 12’, 16’<br />

Trimplank ® 5/4x8<br />

7441 1” x 7-1/4”<br />

Trimplank® 2 x 2<br />

2542 1-1⁄2” x 1-1⁄2”<br />

Avail. Lengths: 8’, 12’, 16’<br />

Inside Corner<br />

2536 1-1⁄4” x 1-1⁄4”<br />

Avail. Lengths: 10’, 16’<br />

Flat Utility Trim<br />

(Smooth)<br />

2709 5⁄16” x 5-13⁄16”<br />

Avail. Length: 16’<br />

Flat Utility Trim<br />

(Embossed)<br />

2709 5⁄16” x 5-13⁄16”<br />

Avail. Lengths: 8’, 16’<br />

www.royalbuildingproducts.com<br />

25

Siding Accessories<br />

Woodgrain Embossed<br />

Texture and Smooth<br />

Surfaces Available for<br />

Siding Accessories<br />

Before<br />

Siding Accessories... The Finishing Touch<br />

Never Rot ® <strong>100%</strong> <strong>Cellular</strong> <strong>Vinyl</strong> PVC ® Siding Accessories are the perfect complement and solution to most siding<br />

styles. Royal Mouldings Siding Corners offer fast nail fin installation for better moisture control and less<br />

labor. Never Rot ® inside corners help join siding seams where water liabilities occur. <strong>100%</strong> <strong>Cellular</strong> <strong>Vinyl</strong> PVC ®<br />

Siding Accessories provide 70% more than wood and 1600% more than aluminum in energy efficiency with better<br />

durability and low maintenance.<br />

26 800-368-3117

Siding Accessories<br />

Outside Corner –<br />

Smooth<br />

7653 5-1⁄2” x 5-1⁄2”<br />

Avail. Lengths: 10’, 19’6”<br />

Don’t put wood in a position<br />

to fail. With all the benefits<br />

of wood and none of the<br />

drawbacks, Never Rot ® is the<br />

ideal choice for remodeling and<br />

new construction.<br />

Never Rot ® Siding Corners serve to<br />

provide the corners of any home<br />

with definition, differentiation,<br />

and most of all protection!<br />

Outside Corner –<br />

Smooth<br />

7652 3-1/2” x 3-1/2”<br />

Avail. Length: 10’<br />

Outside Corner –<br />

Embossed<br />

2805 5-1⁄2” x 5-1⁄2”<br />

Avail. Lengths: 10’, 19’6”<br />

Outside Corner –<br />

Embossed<br />

2804 3-1⁄2” x 3-1⁄2”<br />

Avail. Length: 10’<br />

Inside and Outside Corners Add Style<br />

and Protection<br />

Outside Corner<br />

7235 3-3⁄4” x 3-3⁄4”<br />

Avail. Length: 10’<br />

Outside Corner<br />

7253 3-1⁄2” x 3-1⁄2”<br />

Avail. Length: 10’<br />

Inside Corner<br />

2536 1-1⁄4” x 1-1⁄4”<br />

Avail. Lengths: 10’, 16’<br />

B<br />

A<br />

C<br />

D<br />

5-1/2” Siding Outside Corner<br />

A. Moisture Barrier Tape C. Siding Corner<br />

B. Nail Fin D. Siding<br />

Inside Corner<br />

2542 1-1/2” x 1-1/2”<br />

Avail. Lengths: 10’, 16’<br />

Inside Corner<br />

7236 1-1⁄4” x 1-1⁄4”<br />

Avail. Length: 10’<br />

Siding Starter Strip<br />

2449 11⁄16” x 1-5⁄8”<br />

Avail. Lengths: 12’, 16’<br />

D<br />

C<br />

A<br />

B<br />

J-Channel Casing<br />

5/4 x 6<br />

7651 1-1/8” x 6-1/2”<br />

Avail. Length: 16’<br />

J-Channel Casing<br />

5/4 x 4<br />

7467 1-1/8” x 4-1/2”<br />

Avail. Lengths: 12’, 16’<br />

J-Channel Brick Mould<br />

7351 1-1/4” x 2”<br />

Avail. Length: 16’<br />

Siding Starter Strip<br />

A. Siding Starter Strip C. Siding Corner<br />

B. 1x8 Trim Board D. Siding<br />

www.royalbuildingproducts.com<br />

27

Royal S4S Trimboard<br />

Smooth/Smooth<br />

4”<br />

6”<br />

8”<br />

Reversible –<br />

Woodgrain/Smooth<br />

AVAILABLE FINISHES<br />

10”<br />

12”<br />

Available:<br />

– 3 Standard Thicknesses<br />

– 5 Standard Widths<br />

– Standard 18-ft Lengths & Custom<br />

28 800-368-3117

Royal S4S Trimboard<br />

Royal S4S Trimboard eliminates the extra<br />

work edge cut dirt creates making every job<br />

quick and clean from start to finish. Enjoy all<br />

the benefits of dimensional sanded lumber<br />

without the worries of rot, replacement<br />

or high maintenance. Improve every trim<br />

project you install while saving time using<br />

Royal S4S Trimboard.<br />

• Smooth 4-Sided Finish<br />

• True Square – Stay Clean Edges<br />

• Poly Select ® Face & Edge Surface<br />

• Ready to Install<br />

• Paintable<br />

• <strong>100%</strong> <strong>Cellular</strong> <strong>Vinyl</strong> PVC ®<br />

• Lifetime Never Rot ® Warranty<br />

Royal Mouldings –<br />

A history of innovation – A reputation<br />

of quality.<br />

5<br />

∕8” 3<br />

∕4” 1”<br />

NEW!<br />

Sizes Available<br />

Nominal<br />

Width<br />

Actual<br />

Dimensions<br />

Basic Trim<br />

Board Edges<br />

Stay Clean<br />

Edges<br />

Profile<br />

5/8 Thickness<br />

Pieces<br />

Per 1/2<br />

Unit<br />

<br />

Actual<br />

Length<br />

5/8” x 4” 5/8” x 3-1/2” 7827 130 18’<br />

5/8” x 6” 5/8” x 5-1/2” 7828 80 18’<br />

5/8” x 8” 5/8” x 7-1/4” 7829 60 18’<br />

5/8” x 10” 5/8” x 9-1/4” 7830 50 18’<br />

5/8” x 12” 5/8” x 11-1/4” 7831 40 18’<br />

4/4 Thickness<br />

1” x 3” 3/4” x 2-1/2” 7833 171 18’<br />

1” x 4” 3/4” x 3-1/2” 7834 117 18’<br />

1” x 5” 3/4” x 4-1/2” 7871 90 18’<br />

1” x 6” 3/4” x 5-1/2” 7835 72 18’<br />

1” x 8” 3/4” x 7-1/4” 7836 54 18’<br />

1” x 10” 3/4” x 9-1/4” 7837 45 18’<br />

1” x 12” 3/4” x 11-1/4” 7838 36 18’<br />

5/4 Thickness<br />

5/4” x 3” 1” x 2-1/2” 7874 133 18’ & 20’<br />

5/4” x 4” 1” x 3-1/2” 7840 91 18’ & 20’<br />

5/4” x 5” 1” x 4-1/2” 7875 70 18’ & 20’<br />

5/4” x 6” 1” x 5-1/2” 7841 56 18’ & 20’<br />

5/4” x 8” 1” x 7-1/4” 7842 42 18’ & 20’<br />

5/4” x 10” 1” x 9-1/4” 7843 35 18’ & 20’<br />

5/4” x 12” 1” x 11-1/4” 7844 28 18’ & 20’<br />

www.royalbuildingproducts.com<br />

29

Royal Trim Board ®<br />

• Lifetime Never Rot ®<br />

• DURABLE PolySelect ® 2-Sided Surface<br />

• Clean, Precise Edges<br />

• Consistent High Density<br />

• Moisture Proof<br />

• Mills & Miters with Standard Tools<br />

• Paintable<br />

• Does Not Promote Mold<br />

• Colorfast Surface & Core<br />

• HIGH Energy Efficiency<br />

30 800-368-3117

Royal Trim Board ®<br />

Sizes Available<br />

Nature takes its toll on the exterior of any<br />

home. Royal Trim Board ® is the ideal<br />

new construction and remodeling solution<br />

to battle severe weather and seasonal elements.<br />

Made of <strong>100%</strong> <strong>Cellular</strong> <strong>Vinyl</strong> PVC ® ,<br />

Royal Trim Boards ® are an improved alternative<br />

to other composite and wood boards.<br />

Offering design versatility coupled with<br />

unmatched Poly Select ® surface durability<br />

makes Royal Trim Board ® the “Best Board<br />

in the Business” ® .<br />

Never Put Wood in a Position to Fail!<br />

Royal Trim Board ® Thicknesses<br />

t 3/8” thickness<br />

t 1/2” thickness<br />

t 5/8” thickness<br />

t 3/4” thickness<br />

Nominal<br />

Width<br />

Actual<br />

Dimensions<br />

Profile<br />

Pieces Per<br />

1/2 Unit<br />

Actual<br />

Length<br />

3/8 Thickness Trim Boards<br />

3/8” x 4” 3/8” x 3-1/2” 2880 208 18’<br />

3/8” x 6” 3/8” x 5-1/2” 2881 128 18’<br />

3/8” x 8” 3/8” x 7-1/4” 2882 96 18’<br />

3/8” x 10” 3/8” x 9-1/4” 2884 80 18’<br />

3/8” x 12” 3/8” x 11-1/4” 2885 64 18’<br />

3/8 Thickness Sheet Stock<br />

3/8” x 4’ 3/8” x 48” 2878 32 8’,10’,12’,18’,20’<br />

1/2 Thickness Trim Boards<br />

1/2” x 4” 1/2” x 3-1/2” 2873 156 18’<br />

1/2” x 6” 1/2” x 5-1/2” 2874 96 18’<br />

1/2” x 8” 1/2” x 7-1/4” 2875 72 18’<br />

1/2” x 10” 1/2” x 9-1/4” 2876 60 18’<br />

1/2” x 12” 1/2” x 11-1/4” 2877 48 18’<br />

1/2 Thickness Sheet Stock<br />

1/2” x 4’ 1/2” x 48” 2871 24 8’,10’,12’,18’,20’<br />

5/8 Thickness Trim Boards<br />

5/8” x 4” 5/8” x 3-1/2” 2832 130 18’<br />

5/8” x 6” 5/8” x 5-1/2” 2833 80 18’<br />

5/8” x 8” 5/8” x 7-1/4” 2834 60 18’<br />

5/8” x 10” 5/8” x 9-1/4” 2835 50 18’<br />

5/8” x 12” 5/8” x 11-1/4” 2836 40 18’<br />

5/8 Thickness Sheet Stock<br />

5/8” x 4’ 5/8” x 48” 2838 19 8’,10’,12’,18’,20’<br />

4/4 Thickness Trim Boards<br />

1” x 3” 3/4” x 2-1/2” 2898 162 18’<br />

1” x 4” 3/4” x 3-1/2” 2826 117 18’<br />

1” x 5” 3/4” x 4-1/2” 2899 90 18’<br />

1” x 6” 3/4” x 5-1/2” 2827 72 18’<br />

1” x 8” 3/4” x 7-1/4” 2828 54 18’<br />

1” x 10” 3/4” x 9-1/4” 2829 45 18’<br />

1” x 12” 3/4” x 11-1/4” 2830 36 18’<br />

4/4 Thickness Sheet Stock<br />

1” x 4’ 3/4” x 48” 2837 16 8’,10’,12’,18’,20’<br />

5/4 Thickness Trim Boards<br />

5/4” x 4” 1” x 3-1/2” 2866 91 18’,20’<br />

5/4” x 5” 1” x 4-1/2” 2901 70 18’,20’<br />

5/4” x 6” 1” x 5-1/2” 2867 56 18’,20’<br />

5/4” x 8” 1” x 7-1/4” 2868 42 18’,20’<br />

5/4” x 10” 1” x 9-1/4” 2869 35 18’,20’<br />

5/4” x 12” 1” x 11-1/4” 2870 28 18’,20’<br />

5/4 Thickness Sheet Stock<br />

5/4” x 4’ 1” x 48” 2864 12 8’,10’,12’,18’,20’<br />

t 1” thickness<br />

Woodgrain Embossed Texture and Smooth<br />

Surfaces Available for Trim Board ®<br />

www.royalbuildingproducts.com<br />

31

Royal STAIN-ABLE Trim<br />

Light Oak Dark Oak Cherry Mahogany<br />

STAIN-ABLE Finish Examples<br />

Examples Only<br />

Royal STAIN-ABLE Trim<br />

• Lifetime Never Rot ® • High Energy Efficiency<br />

• Low Maintenance<br />

• Moisture Proof<br />

• Ready to Stain<br />

• Termite Proof<br />

• Superior Nailing & Gluing • No Splitting or Cracking<br />

Staining Instructions<br />

Detailed Instructions on Page 48.<br />

• Use a high quality, EXTERIOR heavy bodied<br />

gel stain.<br />

• Apply a smooth even coat of gel stain<br />

to substrate.<br />

• Allow to penetrate for five minutes.<br />

• Wipe off excess material with a clean cloth.<br />

• Control color by amount of excess<br />

stain removed.<br />

• Apply clear coat following manufacturer’s<br />

instructions.<br />

• Always follow manufacturer’s directions.<br />

32 800-368-3117

Royal STAIN-ABLE Trim<br />

Finally, A Trim That’s STAIN-ABLE!<br />

Door Frame*<br />

7181 1-1/4” x 4-9/16”<br />

Door Frame*<br />

7241 1-1/4” x 6-9/16”<br />

Door Frame*<br />

7604 1-1/4” x 4-9/16”<br />

Enlarged View of Stainable Surface<br />

Face Nail-Less<br />

Door Frame*<br />

7605 1-1/4” x 6-9/16”<br />

Brick Mould*<br />

2448 1-1/2” x 2”<br />

Brick Mould*<br />

7635 1-1/4” x 2”<br />

Florida Brick Mould*<br />

7252 11/16” x 1-5/8”<br />

West Coast<br />

Brick Mould*<br />

7212 1-1/4” x 2”<br />

Base WM623*<br />

7527 9/16” x 3-1/4”<br />

Base Cap*<br />

2450 11/16” x 1-1/8”<br />

Beaded Planking*<br />

2352 3/8” x 5-15/32”<br />

Scotia/Cove WM93*<br />

2021 3/4” x 3/4”<br />

Quarter Round WM105*<br />

2689 3/4” x 3/4”<br />

Mullion*<br />

7340 2” x 3-1/2”<br />

Astragal*<br />

7193 1-33/64” x 3-13/64”<br />

Trimplank® 1x8*<br />

7312 3/4” x 7-1/4”<br />

Trimplank® 1x4*<br />

7318 3/4” x 3-1/2”<br />

Trimplank® 1x6*<br />

7311 3/4” x 5-1/2”<br />

Trimplank® 1x2*<br />

2150 5/8” x 1-1/2”<br />

Trimplank® 2x2*<br />

2542 1-1/2” x 1-1/2”<br />

Stop*<br />

2330 5/8” x 5/8”<br />

Jamb*<br />

2497 11/16” x 5-13/16”<br />

Inside Corner*<br />

2536 1-1/4” x 1-1/4”<br />

* All profiles shown on this page are stainable.<br />

www.royalbuildingproducts.com<br />

33

Garage Door Trim System<br />

Brick Mould<br />

7137 1-1/4” x 2”<br />

Avail. Lengths: 8’, 17’<br />

Brick Mould<br />

2448 1-1⁄4” x 2”<br />

Avail. Lengths: 8’, 10’, 17’<br />

*cold weather nailable<br />

Jamb<br />

2328 5⁄8” x 4-9⁄16”<br />

Jamb<br />

2497 11/16” x 5-13/16”<br />

Avail. Lengths: 7’, 10’,<br />

16’<br />

Jamb<br />

2398 5⁄8” x 6-13⁄16”<br />

Utility Trim (Smooth)<br />

2709 5/16” x 5-13/16”<br />

Avail. Length: 16’<br />

Utility Trim (Embossed)<br />

2709 5/16” x 5-13/16”<br />

Avail. Lengths: 8’, 16’<br />

Thermo*Stop Mini<br />

2914 13/32” x 1-1/2”<br />

Thermo*Stop<br />

2100 7/16” x 1-7/8”<br />

Thermo*Stop<br />

2016 7⁄16” x 1-7/8”<br />

Thermo*Stop<br />

2149 7⁄16” x 2”<br />

Avail. Lengths: 7’, 9’, 16’<br />

Thermo*Stop<br />

2211 7/16” x 2”<br />

Thermo*Stop<br />

2213 7/16” x 2”<br />

Thermo*Stop<br />

2591 1/2” x 3-1/4”<br />

34 800-368-3117

Garage Door Trim System<br />

Before<br />

After<br />

A B C<br />

Garage Solutions ®<br />

Both inside and outside the garage, Royal Mouldings<br />

provide maintenance so low it’s a pleasure!<br />

Royal Mouldings’ Garage Door Trim System is the energy<br />

efficient way to seal out moisture, dirt and bugs. Enjoy the<br />

beauty and sustainability of Royal Garage Solutions ® . Made from<br />

durable <strong>100%</strong> <strong>Cellular</strong> <strong>Vinyl</strong> PVC® offering 70% better insulation<br />

performance over wood and 1600% better than aluminum. Ready<br />

to install system includes Never Rot ® Brick Mould, Jamb and<br />

ThermokStop ® II Garage Door Stop. All are prefinished, moisture<br />

resistant, termite proof and have a Never Rot ® lifetime warranty.<br />

A Brick Mould B Jamb C ThermokStop ® II<br />

Never Rot ® Garage Trim Solutions<br />

• Lifetime Never Rot ® Material • Dent Resistant<br />

• Moisture Resistant<br />

• Reduces Energy Costs<br />

• Seals Out Dirt, Bugs,<br />

Wind, Snow & Water<br />

• Strong & Durable<br />

Available Colors:<br />

A B C<br />

White*<br />

Almond<br />

Sandstone*<br />

Bronze*<br />

Brown*<br />

* Profiles 2448 (8’ and 10’), 2497 (7’ and 10’) and 2149 (7’ and 9’) are available<br />

in white, sandstone, bronze or brown.<br />

www.royalbuildingproducts.com<br />

35

Smart Space System ®<br />

B<br />

A<br />

Available Colors:<br />

C<br />

Royal Mouldings’ Smart Space System ® organizes<br />

any space while protecting walls from<br />

damage and moisture. Smart Space ® organizer<br />

Slat Wall components interlock for versatile<br />

results and utilize standard pegboard hardware<br />

for simple low cost storage solutions. Smart<br />

Space System ® components may be installed<br />

separately or with Royal Mouldings’ unique<br />

Base & Wainscot System for maximum value<br />

and wall protection. Made from <strong>100%</strong> <strong>Cellular</strong><br />

<strong>Vinyl</strong> PVC ® , the wall system deflects moisture,<br />

dirt and bugs while shielding your walls from<br />

every day use.<br />

Bright<br />

White<br />

Light<br />

Grey*<br />

Greyed<br />

Taupe*<br />

* Available by special order. Minimum quantities apply.<br />

Organize and add value to your<br />

home and start enjoying your<br />

garage once again!<br />

36 800-368-3117

Smart Space System ®<br />

Garage clean-up can be fast and easy with Royal<br />

Mouldings’ Base & Wainscot System that deflects<br />

water and protects your walls.<br />

Narrow Bead<br />

A<br />

Wide Bead<br />

Reversible Beaded<br />

Wall Planking*<br />

7718 1/4” x 7-1/2”<br />

Cap/Base Trim*<br />

7716 5/8” x 3”<br />

D<br />

• <strong>100%</strong> <strong>Cellular</strong> <strong>Vinyl</strong> PVC ®<br />

• Low Maintenance<br />

• Easy To Install<br />

• Moisture & Termite Proof Material<br />

• Energy Efficient<br />

• Does Not Promote Mold or Mildew<br />

• Expandable<br />

Cap Trim*<br />

2566 1” x 3”<br />

Cap Trim*<br />

2764 3⁄4” x 1-3⁄4”<br />

Avail. Length: 8’<br />

D<br />

Base<br />

2854 11/16” x 3-1/2”<br />

Avail. Lengths: 8’, 10’<br />

C<br />

Slat Wall<br />

7242 3⁄4” x 6”<br />

Avail. Length: 8’<br />

A<br />

Hidden Nail Fin<br />

Beaded Ceiling and<br />

Wall Planking*<br />

2352 3⁄8” x 5-15⁄32”<br />

Avail. Lengths: 8’, 12’, 16’<br />

Slat Wall<br />

7386 3⁄4” x 8-11/16”<br />

Avail. Lengths: 8’, 10’<br />

* Profile 7716 is for use only with Reversible Beaded Wall Planking 7718. Profiles 2566 and 2764 are for use only with Beaded Ceiling and Wall Planking 2352.<br />

www.royalbuildingproducts.com<br />

B<br />

37

Envelop Garage Surround System<br />

Envelop Garage Door<br />

Surrounds by Royal<br />

Add Value and Curb Appeal<br />

E nvelop Garage Door<br />

Surrounds are the<br />

perfect upsell for new or<br />

replacement garage doors.<br />

Available in a variety of<br />

styles to complement any<br />

type of architecture, these<br />

surrounds are pre-finished,<br />

easy to install and<br />

have exceptionally low<br />

maintenance. From your<br />

Before<br />

customers’ point of view, Envelop Garage<br />

Door Surrounds add curb appeal and set their<br />

homes apart from others in the neighborhood.<br />

Available Styles<br />

After Installation of<br />

Refined Sophistication Envelop Surround<br />

Colonial Elegance Rams Crown Refined Sophistication Decadence<br />

38 800-368-3117

Envelop Garage Surround System<br />

Features and Benefits<br />

• Lifetime Never Rot ® Warranty<br />

• Ready to Install<br />

• Factory Applied Readi-Finish ®<br />

• Warranted 10 year UV Coating<br />

• No Further Painting Required<br />

• Repaintable with Oil or Latex<br />

• Low Maintenance<br />

• Moisture & Termite Proof Material<br />

• Installs Direct to Masonry<br />

• Does Not Promote Mold or Mildew<br />

• Superior Nailing and Gluing<br />

• Uses Standard Woodworking Equipment<br />

• Long Lengths – Perfect Tip-to-Tip<br />

After Installation of<br />

Rams Crown Envelop Surround<br />

Before<br />

Decadence Refined Sophistication Rams Crown Colonial Elegance<br />

A<br />

A<br />

A<br />

A<br />

B<br />

B<br />

B<br />

B<br />

E<br />

D<br />

C<br />

D<br />

C<br />

C<br />

A<br />

Royal Trim Board ®<br />

Profile #2826<br />

3/4” x 3-1/2”<br />

A<br />

Trimplank ®<br />

Profile #7318<br />

3/4” x 3-1/2”<br />

A<br />

Rams Crown<br />

Profile #7158<br />

1-13/32” x 2”<br />

A<br />

Pediment<br />

Profile #7714<br />

2” x 2-7/8”<br />

B<br />

Rams Crown<br />

Profile #7158<br />

1-13/32” x 2”<br />

B<br />

Crown<br />

Profile #2853<br />

9/16” x 2-3/4”<br />

B<br />

Trimplank ®<br />

Profile #7311<br />

3/4” x 5-1/2”<br />

B<br />

Trimplank ®<br />

Profile #7311<br />

3/4” x 5-1/2”<br />

C<br />

Dentil<br />

Profile #2740<br />

1-1/16” x 3-7/16”<br />

C<br />

Dentil<br />

Profile #2721<br />

5/8” x 1-1/2”<br />

C<br />

Decorative Trim<br />

Profile #2759<br />

1/2” x 1”<br />

D<br />

Shingle Mould<br />

Profile #2599<br />

11/16” x 1-5/8”<br />

D<br />

Trimplank ®<br />

Profile #7311<br />

3/4” x 5-1/2”<br />

E<br />

Royal Trim Board ®<br />

Profile #2868<br />

1” x 7-1/4”<br />

www.royalbuildingproducts.com<br />

39

Ceiling & Wall Solutions<br />

An attractive porch ceiling<br />

can provide an architectural<br />

signature and simple elegance<br />

to any home. Never Rot ® <strong>100%</strong><br />

<strong>Cellular</strong> <strong>Vinyl</strong> PVC ® Beaded<br />

Planking offers just that without<br />

the added maintenance of wood.<br />

Each prefinished beaded plank<br />

is ready to install and can be<br />

easily painted with oil or latex<br />

for custom results. Never Rot ®<br />

Beaded Planking special design<br />

and unique nail fin construction<br />

makes it much easier to install<br />

than standard tongue and groove<br />

planking, offering faster results<br />

with less exposed fasteners to fill<br />

or cover. Classic designs using<br />

today’s technology—spoil your<br />

home with Never Rot ® Beaded<br />

Planking today!<br />

Beaded Planking<br />

• Nail Fin Technology<br />

Makes Any Ceiling or<br />

Wainscot Easy to Install<br />

• Prefinished—Ready<br />

to Install<br />

• Moisture Proof Material<br />

• Fewer Exposed Fasteners<br />

to Putty or Caulk.<br />

• Repaintable with Oil or<br />

Latex Paint<br />

• Installs with Nails or Glue<br />

Ceiling planking shown, extruded to color.<br />

40 800-368-3117

Ceiling & Wall Solutions<br />

Never Rot ® Beaded Boards dress<br />

any ceiling or wall in style while<br />

protecting against moisture damage.<br />

Hidden Nail Fin<br />

Beaded Ceiling and<br />

Wall Planking*<br />

2352 3⁄8” x 5-15⁄32”<br />

Avail. Lengths: 8’, 12’, 16’<br />

Beauty, not moisture, should be the focus of the bathroom.<br />

Narrow Bead<br />

Hidden Nail Fin<br />

Wide Bead<br />

Beaded Ceiling and<br />

Wall Planking – Blue*<br />

2352 3⁄8” x 5-15⁄32”<br />

Beaded Planking<br />

7888 1/2” x 5-1/4”<br />

Reversible Beaded<br />

Wall Planking*<br />

7718 1/4” x 7-1/2”<br />

Cap Trim*<br />

2566 1” x 3”<br />

Cap Trim*<br />

2764 3⁄4” x 1-3⁄4”<br />

Avail. Length: 8’<br />

Cap/Base Trim*<br />

7716 5/8” x 3”<br />

Base Cap WM164<br />

2450 11⁄16” x 1-1⁄8”<br />

Avail. Lengths: 8’, 12’, 16’<br />

Scotia/Cove WM93<br />

2021 3/4” x 3/4”<br />

Avail. Lengths: 8’, 12’, 16’<br />

Quarter Round/Stop<br />

2258 1⁄2” x 13⁄32”<br />

Avail. Length: 8’<br />

Bed Mould WM75<br />

2598 9⁄16” x 1-9⁄16”<br />

Avail. Lengths: 12’, 16’<br />

Quarter Round WM105<br />

2689 3⁄4” x 3⁄4”<br />

Avail. Lengths: 8’, 12’, 16’<br />

Base WM623<br />

7527 9/16” x 3-1/4”<br />

Avail. Lengths: 12’, 16’<br />

* Profile 7716 is for use only with Reversible Beaded Wall Planking 7718. Profiles 2566 and 2764 are for use only with Beaded Ceiling and Wall Planking 2352.<br />

www.royalbuildingproducts.com<br />

41

Envelop ® Pole & Post Surrounds<br />

3-1⁄2” Jack Post Kit<br />

0ENVL08003, 0ENVL10003<br />

Avail. Lengths: 8’, 10’<br />

4” x 4” Round Kit<br />

0ENVL08001, 0ENVL10001<br />

Avail. Lengths: 8’, 10’<br />

6” x 6” Kit<br />

0ENVL08002, 0ENVL10002<br />

Avail. Lengths: 8’, 10’<br />

4” x 4” Square Kit<br />

Avail. Lengths: 8’, 10’<br />

42 800-368-3117<br />

Please Note: Envelop ® Kits alone are non-load<br />

bearing and require poles or posts for support.

Envelop ® Pole & Post Surrounds<br />

Envelop ® —the beautiful solution<br />

to interior poles and posts.<br />

Transform unsightly support poles and exposed<br />

pipes into beautiful decorative columns. Envelop ®<br />

Pole and Post Surround is your solution for both<br />

interior and exterior applications. This unique interlocking<br />

system snaps together in less than five minutes,<br />

with an easy-to-use kit including top and bottom<br />

trim, and surround.<br />

3 Prefinished Ready to Install<br />

3 Unique Interlocking System<br />

Makes Assembly a “Snap”<br />

3 Quick Fit Top and Bottom Trim<br />

Included for Decorative Results<br />

Envelop ® Pole & Post<br />

Surrounds Enjoy the<br />

Outdoors Too...<br />

www.royalbuildingproducts.com<br />

43

Interior Mouldings<br />

1<br />

2<br />

5<br />

4<br />

3<br />

Decorative moulding creates style, enhances value and adds architectural detail.<br />

Interior mouldings serve both functional and aesthetic<br />

purposes, protecting walls and adding visual interest.<br />

Crown Moulding (1) accentuates high ceilings and provides<br />

an attractive transition from wall to ceiling. Crown<br />

is also an ideal way to bridge the gap between different,<br />

even contrasting, colors. Crown allows the eye to take in<br />

the changes without sensing a stark difference.<br />

Casings (2) define doors and windows while, again,<br />

serving in other roles, including protection and energy<br />

efficiency. Special mouldings can be combined to create<br />

“build-ups” that accent architectural details.<br />

Base Moulding (3) provides a finished transition between<br />

wall and floor, hiding any gaps between wall board and<br />

floor covering. Because of the propensity for drywall<br />

and plaster to dent or crack, base moulding is critical<br />

for protecting walls from damage. Combine Quarter<br />

Round (4) with Base Moulding for added visual appeal<br />

and transition assistance.<br />

Chair Rail (5) brings both form and function to a room.<br />

In dining areas, it protects your walls from bumps by<br />

chairs. Anywhere chair rail is utilized, it adds visual<br />

interest and dimension to a wall. Chair rail is ideal for<br />

rooms where you want to incorporate multiple colors<br />

on a wall.<br />

44 800-368-3117

Installation Tips & Techniques<br />

Tools<br />

• Safety glasses and power miter saw: carbide saw blade with 80<br />

teeth or more recommended.<br />

• Miter box and hand saw: Limited angle adjustment (not<br />

recommended for crown).<br />

• Coping saw: Only needed if you choose the coping technique to<br />

install the moulding.<br />

• Angle gage: To create the correct miter, you must determine the<br />

wall corner angle.<br />

• Glue: To adhere the miter joints, Royal Mouldings strongly<br />

recommends gluing all joints with PVC or “Pipe Cement.”<br />

• Hammer & nails or a pneumatic nail gun.<br />

Other tools may include a tape measure, pencil, C-clamp, putty<br />

and caulk.<br />

Cutting<br />

Use standard woodworking equipment for cutting. If using a<br />

power miter saw, a carbide toothed blade is recommended. Use<br />

any brand of spray furniture polish on saw blade as a lubricant for<br />

easier cutting.<br />

Wall Angles<br />

It will also benefit you to measure the wall angles on each corner.<br />

This will help you calculate the correct miter angle. NOTE: It is not<br />

uncommon for corner angles in most homes to be off as much<br />

as 3°. If you were installing 5” crown moulding the 3° difference<br />

would result in a 3/8” gap in the miter joint. To help you calculate<br />

the proper angle Royal has an angle calculator listed on their web<br />

site, www.royalbuildingproducts.com.<br />

• Left and Right hand positioning: the side of the trim you are cutting<br />

is as important as its position on the saw table. The positions<br />

are illustrated above.<br />

Vertical Miters<br />

Use this technique for cutting baseboard, chair<br />

rail, quarter round, and splice miters. Align<br />

trim back against fence.<br />

Inside corners: A left hand inside corner is<br />

shown in the photo.<br />

• Step 1: Place the trim on the saw table in<br />

the left hand vertical position and rotate the<br />

angle gage “clock wise” to 45°, or the desired<br />

angle setting, and make the cut.<br />

• Step 2: To cut the mating piece, simply rotate<br />

the table angle gage to the opposite 45° or desired angle, and<br />

place the next piece of trim on the saw table in the right hand<br />

vertical position. Cut the trim.<br />

Outside Corners: A right hand outside corner is shown in the<br />

photo.<br />

• Step 1: To complete this, place the trim on the saw table in the<br />

right hand vertical position and rotate the<br />

angle gage “clock wise” to 45°, or preferred<br />

angle setting, and make the cut.<br />

• Step 2: To cut the mating piece simply rotate<br />

the table angle gage to the opposite 45° or<br />

desired angle, and place the next piece of<br />

trim on the saw table in the left hand vertical<br />

position.<br />

Horizontal Miters<br />

Use this technique for cutting window and door casings. Align trim<br />

back on saw table.<br />

• Step 1: A left hand miter is shown in the photo to the right. To get<br />

the setup in the photo, adjust the saw table angle<br />

to the “clock wise” 45° or predetermined angle.<br />

Then lay the trim on the table in the left hand<br />

horizontal position and proceed to cut.<br />

• Step 2: To cut the mating piece simply rotate<br />

the table angle to the opposite 45° or preferred<br />

angle, and place the next piece of trim on the<br />

saw table in the right hand horizontal position.<br />

After the cut is made the miter joints are ready<br />

for assembling.<br />

Compound Position Miters<br />

Use this technique for cutting Crown moulding. This is the most<br />

complicated of all the mitering cuts. Note: When cutting Crown<br />

Mouldings in the compound position, remember “upside down<br />

& backwards”. This term is used<br />

because the “TOP” of the trim that<br />

is positioned against the ceiling<br />

after installation rests on the saw<br />

table during the mitering process,<br />

and the “BACK” of the trim that is<br />

placed against the wall, after installation,<br />

is set against the fence during<br />

the cutting procedure.<br />

Compound Inside<br />

Corner Miters<br />

Left hand inside corner miter shown in photo.<br />

Step 1: Place the top of the profile against the saw table and the<br />

back of the profile against the fence in a left hand compound<br />

position. Then adjust the table angle gage “clock wise” to 45° or<br />

calculated angle, and cut.<br />

Step 2: Place the top of the profile against<br />

the saw table and the back of the profile<br />

against the fence in a right hand compound<br />

position. Then move the table angle<br />

gage the opposite calculated angle, and<br />

cut.<br />

www.royalbuildingproducts.com<br />

45

Installation Tips & Techniques<br />

Compound Outside Corner Miters<br />

Left hand outside corner miter shown in photo.<br />

• Step 1: The trim should lie on the saw table in a<br />

left hand compound position. The saw is to be<br />

adjusted “counter clock-wise” to the calculated<br />

angle before cutting.<br />

• Step 2: Put the mating piece of trim on the saw<br />

in the right hand compound position. Then<br />

move the table angle gage to the opposite calculated<br />

angle and cut. The miter joint is ready<br />

to be put together.<br />

Splice Miters<br />

This technique is used to join mouldings together in a linear<br />

run or when a wall is longer than the trim you are installing.<br />

Most splice cuts are made in the vertical<br />

position. In the photo below of<br />

a splice miter, note the only change<br />

made in producing the joint is the<br />

right hand & left hand positions. The<br />

saw angle should remain at the same<br />

45° setting.<br />

Return Miters<br />

This technique is utilized when moulding ends with an exposed,<br />

unfinished end that would require finishing “paint, stain, etc.”<br />

This miter joint will create a finished edge.<br />

• Step 1: To produce this miter, cut the trim as though you were<br />

turning an outside corner (45° saw setting).<br />

• Step 2: Rotate the saw to the opposite 45° and cut a short piece<br />

to mate to the first cut. Glue miter joint together before attaching<br />

trim to wall. See photo below.<br />

Coping Joints<br />

Coping is simply transferring the contour<br />

“profile” of one piece of trim to<br />

the end of another piece of trim, then<br />

cutting the profile line so that, when finished,<br />

the second piece of trim will mate<br />

with the first with a nice joint.<br />

• Step 1: Cut the first piece of trim to<br />

length and position it on the wall. Use<br />

straight cuts, no angles.<br />

• Step 2: To create the profile line, cut the second piece of moulding<br />

at a 45° as though you were cutting an inside corner.<br />

• Step 3: Following the profile line as a guide cut the trim<br />

with a coping saw.<br />

• Step 4: The moulding should be ready for installation.<br />

Nailing<br />

Install Never Rot ® mouldings and trim using 6d and 8d galvanized<br />

nails and/or recommended adhesives (see chart on this<br />

page). Place nails 12” on center. Nails should be approximately<br />

3⁄4” from each edge. If nailing product at 40˚F or below, predrilling<br />

is required. Pneumatic nailing is also recommended.<br />

Fastening Royal Trim Board ® and<br />

Royal S4S Trimboard<br />

Use fasteners designed for wood trim and wood siding (thinner<br />

shank, blunt head, full round head) with trim board. Use only<br />

fasteners intended for exterior use such as stainless steel or hotdipped<br />

galvanized.<br />

DO NOT USE staples, small brads and wire nails. The fasteners<br />

should be long enough to penetrate the solid wood substrate a<br />

minimum of 1-1/2”.<br />

Use two fasteners per every framing member for trim board<br />

applications. Trim boards 12” or wider as well as sheets will<br />

require additional fasteners. Fasteners must be installed no more<br />

than 2” from the end of each board.<br />

Trim boards should be fastened into a flat, solid substrate.<br />

Fastening trim boards into hollow or uneven areas must be<br />

avoided. Unless product is installed in lower temperatures (< 40°F)<br />

pre-drilling is typically not required. Thinner trim products (3/8”<br />

and 1/2”) are not intended to be ripped into trim pieces. They are to<br />

be glued to a substrate and mechanically fastened.<br />

Gluing<br />

Gluing Miter Joints<br />

Royal Mouldings strongly recommend gluing all miter joints on<br />

PVC mouldings using a quality instant glue and/or PVC cement.<br />

It may seem unconventional, but the benefits out weigh the<br />

inconvenience. When assembling splice and return miters try<br />

gluing the mouldings together before installation. This will allow<br />

you to fit the joints uninhibited, and fasten the trim to the wall<br />

as one unit. Fitting these joints on the wall can be difficult and<br />

possibly jeopardize the integrity of the miter joint.<br />

Fastening Royal Never Rot ® Moulding<br />

and Trim to the Wall<br />

PVC trim can be nailed with finishing nails and/or glued. Our<br />

recommendations for the nails are paneling, finishing, or pneumatic<br />

finish nails. For the glue, recommended products are PL<br />

Glues/PC —200, 300, 400/LIQUID NAILS applied according to<br />

manufacturer’s directions. Glue alone is not advised for crown<br />

mouldings.<br />

Adhesive Selection for <strong>Cellular</strong> <strong>Vinyl</strong><br />

The following brands have been laboratory tested and approved<br />

for use with Royal <strong>Cellular</strong> <strong>Vinyl</strong>; however, individual conditions<br />

may vary and these adhesives may not perform under every<br />

circumstance. Other brands may also be suitable, but always test<br />

before using.<br />

G: Good Bond F: Fair Bond P: Poor Bond<br />

Int/Ext Adhesive<br />

Wood Steel Sheetrock Masonry<br />

Dow <strong>100%</strong> Silicone® F F G –<br />

Dap 230 Latex® F P G –<br />

Tru Test® (Tru Value®) G P G –<br />

Contech PL-400® F F G –<br />

Better Than Nails® G F G G<br />

Liquid Nails LN-901 G – G G<br />

Heavy Duty®<br />

For Interior Use Only<br />

G.E. Silicone® F G G –<br />

USG Cove Base Adh. ® G G G –<br />

OSI Quick Bond® G P G G<br />

Expansion and Contraction: Royal Mouldings exterior PVC<br />

products, as manufactured, may expand and contract due to<br />

temperature variations. To reduce or eliminate open joints, the<br />

preferred method is the use of adhesive commonly called pipe<br />

glue or PVC pipe cement. When bonded correctly with this adhesive,<br />

the joint becomes an integral part of the system to which<br />

it is being applied.<br />

46 800-368-3117

Installation Tips & Techniques<br />

Installation<br />

Never Rot ® Brick Mould & Jamb<br />

1. Remove old jamb, brick mould and garage door stop with a pry<br />

bar or hammer.<br />

2. Measure the top opening from side to side and cut jamb to fit with<br />

a fine tooth power- or hand saw.<br />

3. Install top jamb piece using 8d galvanized finishing nails to 2x4 or<br />

2x6 structural frame members. Alternate nailing from side to side,<br />

nailing every 12” and approximately 3/4” from each edge. Note: If<br />

nailing product at 40ºF or below, pre-drilling is required.<br />

4. Measure and cut jamb side pieces to fit from top jamb to floor.<br />

Nail as directed.<br />

5. Measure top brick mould to overlap the jamb material by 1/2”. This<br />

will allow for a 1/8”–1/4” reveal around the jamb. Reveal should be<br />

both on top and sides. Cut 45º angle on ends, butt or angle joint<br />

middle seam if needed. *Note: Reveal may vary depending on siding,<br />

siding J-channel, brick or block installation.<br />

6. Install brick mould using 10d or 3” galvanized finishing nails,<br />

spaced 12” on center. Use PVC cement in the mitered joint for<br />

optimum fit. * Note: nails should penetrate structural frame at<br />

least one inch.<br />

7. Measure and cut side brick mould trim to fit. Install as directed.<br />

Never Rot ® Garage Door ThermokStop ® II<br />

1. When installing Garage Door ThermokStop® II alone, open the<br />

garage door and remove old door stop with standard claw hammer.<br />

2. Close garage door. Begin Garage Door ThermokStop® installation<br />

by measuring and marking 1/2” from outside of garage door<br />

several places around the jamb. Connect the marks with a straight<br />

edge, then open door again.<br />

3. Measure top opening from side to side and cut Garage Door<br />

Thermo*Stop® ends square with fine tooth power- or hand saw.<br />

4. Place grooved side against jamb and inner edge, (where hard vinyl<br />

joins weatherstrip) along marked lines. Nail in place with 6d galvanized<br />

finishing nails in the pre-punched nail guides or 8” on center.<br />

5. Measure and cut each piece to fit, from top piece to floor. With<br />

grooved side against jamb, position nail as directed.<br />

6. For a good drainage and overlap, trim side stop pieces at a 45°<br />

angle with scissors where the soft vinyl weather stripping meets<br />

the top.<br />

Never Rot ® Wainscot<br />

1. Cut pieces to the desired length.<br />

2. Apply construction adhesive to the back of one piece of wainscot.<br />

3. Starting in a corner of the room and making sure the nailing<br />

fin faces away from the corner, press the first piece into place.<br />

4. Nail through the fin into the wall.<br />

5. Continue gluing and nailing until you come to the corner. At<br />

this point, it may be necessary to rip the last corner piece so<br />

that it will fit.<br />

6. Repeat along each wall.<br />

Never Rot ® Ceiling Planking<br />

1. Allow 1/4” on each end for expansion.<br />

2. With the nailing fin positioned away from the wall, face nail the<br />

first piece against one side of the ceiling. Nail the nailing fin on the<br />

first piece on maximum 16” centers.<br />

3. Insert the next piece into the slot and continue nailing through the<br />

fin on maximum 16” centers until ceiling is completely covered.<br />

4. Use PVC cement where plank ends must be butted together.<br />

5. The last piece will probably need its width adjusted. Measure,<br />

mark, and rip it to the desired width.<br />

6. Face nail the last piece as close to the wall as possible.<br />

7. Cover edges with crown or trim moulding.<br />

CAUTION: Ceiling planking should never be used for<br />

load-bearing application. Attic space above porch should be vented.<br />

Never Rot ® Siding Corners<br />

1. Insert nailing fins into corner trim as shown.<br />

2. Cut the trim pieces so that they touch the<br />

soffit on top and extend 1/8” below the sheathing<br />

on bottom.<br />

B<br />

A<br />

C<br />

5-1/2” Siding<br />

Outside Corner<br />

A. Moisture Barrier Tape<br />

B. Nail Fin<br />

C. Siding<br />

Corner<br />

D. Siding<br />

A B C<br />

D<br />

Touches<br />

Soffit<br />

A. Brick Mould B. Jamb C. ThermokStop ® II<br />

Royal Smart Space System Organizer<br />

Mount the system by screwing directly into the studs. Screws<br />

should be #8, minimum, in size and long enough to penetrate<br />

studs by 1⁄2 their length. Length may vary depending on wall construction.<br />

Join panel ends over studs to maximize load capacity.<br />

3. Measure from the corner: 4” for 3-1⁄2” trim and<br />

6” for 5-1⁄2” trim and make several V-marks from<br />

top to bottom. Use these marks to line up the<br />

edge of the nailing fin or to strike a chalk line for<br />

alignment.<br />

4. While lining up the edge of the nailing<br />

fin with the V-marks (or chalk line),<br />

apply nails through the pre-punched<br />

holes, 18” (MAX) apart.<br />

5. Apply 4” window and door sealing tape<br />

so that it fully covers both nailing fins,<br />

from the soffit to the bottom of the<br />

sheathing.<br />

1 ⁄8” Below<br />

Sheathing<br />

www.royalbuildingproducts.com<br />

47

Installation Tips & Techniques<br />

Painting<br />

Painting Royal <strong>Cellular</strong> <strong>Vinyl</strong> PVC<br />

Royal’s factory applied Readi-Finish® requires no painting for protection.<br />

Desired custom finishes can be achieved using oil based or latex<br />

paints. To maintain warranty for custom colors in darker shades, use of<br />

paints with <strong>Vinyl</strong>Safe Technology from Sherwin Williams is recommended.<br />

(Dark colors are considered any color that falls within the lightness<br />

(L) value of 56 to 0 noting that 100 is white and 0 is black.)<br />

Royal Trim Board® and Royal S4S Trimboard may be painted to<br />

achieve a color other than that supplied.<br />

1. Scuff Sand using 220 grit sandpaper to remove any foreign matter<br />

and to promote adhesion. Clean sanding residue and paint with a<br />

latex acrylic paint. For darker colors refer to Sherwin Williams<br />

<strong>Vinyl</strong>Safe Color Technology. Allow to dry per manufacturer’s<br />

directions.<br />

2. Apply a second coat (if required to<br />

achieve desired color).<br />

Touch-Up for Exterior Mouldings<br />

A complete line of touch-up products is available<br />

from Royal Mouldings for pre-finished woodgrain<br />

colors, painted colors and Clearwood® ready to<br />

stain finishes. Also recommended:<br />

• Dap® “All Purpose” Painter’s Putty®<br />

• Minwax High Performance Wood Filler®<br />

• Elmer’s Fill-N-Finish Light Wood Filler®<br />