Download Spec Sheet PDF - X-Rite

Download Spec Sheet PDF - X-Rite

Download Spec Sheet PDF - X-Rite

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

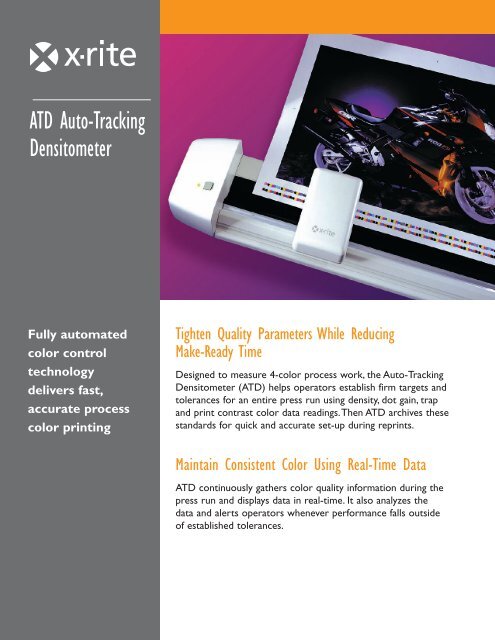

ATD Auto-Tracking<br />

Densitometer<br />

Fully automated<br />

color control<br />

technology<br />

delivers fast,<br />

accurate process<br />

color printing<br />

Tighten Quality Parameters While Reducing<br />

Make-Ready Time<br />

Designed to measure 4-color process work, the Auto-Tracking<br />

Densitometer (ATD) helps operators establish firm targets and<br />

tolerances for an entire press run using density, dot gain, trap<br />

and print contrast color data readings.Then ATD archives these<br />

standards for quick and accurate set-up during reprints.<br />

Maintain Consistent Color Using Real-Time Data<br />

ATD continuously gathers color quality information during the<br />

press run and displays data in real-time. It also analyzes the<br />

data and alerts operators whenever performance falls outside<br />

of established tolerances.

Features<br />

• The ATD densitometer measures an entire<br />

color bar in just seconds and transmits data<br />

to the ATD software. Select from industry<br />

standard Status T, Status E, or Status I density<br />

response.<br />

• The ATD software displays color data in<br />

real time in easy-to-view graphical formats.<br />

• Powerful software tools continuously<br />

analyze density, dot gain, ink trap, print<br />

contrast, hue-error and grayness.When<br />

deviations from targets or tolerances occur,<br />

the operator is alerted immediately.<br />

• The ATD helps press operators make timely<br />

color adjustments, which results in consistent<br />

color quality and minimized waste during<br />

the press run.The ATD also identifies the<br />

specific ink keys that need to be adjusted.<br />

At the end of each run, the ATD software<br />

generates printed reports summarizing the<br />

job and detailing color reproduction data,<br />

color tolerances, and much more.<br />

Benefits<br />

The ATD reduces make-ready time by<br />

automating many steps in the process.<br />

This means you need fewer trial-and-error<br />

adjustments.You cut back the run-waste for<br />

each job. And you operate much more<br />

efficiently, which boosts profits.<br />

The ATD also gives operators quality<br />

control feedback.The ATD locks-in color<br />

okay information, then displays run data to<br />

help press operators maintain color quality<br />

within tolerances.The ATD software saves<br />

this color data so operators can get repeat<br />

jobs or multiple forms up and running<br />

quickly.<br />

<strong>Spec</strong>ifications<br />

Product includes Windows ® -based<br />

data acquisition software, and<br />

several standard, measurable<br />

test-image files.<br />

System Requirements<br />

450Mhz or higher class<br />

computer running Windows ®<br />

98/NT4/2000, hard drive space for<br />

application and data, and<br />

free serial port for connection<br />

to ATS hardware.<br />

Measuring Geometry<br />

45°/0° per ANSI PH2.17<br />

Light Source<br />

Gas Pressure @ 2850°K<br />

<strong>Spec</strong>tral Sensor<br />

DRS Technology (31pt)<br />

<strong>Spec</strong>tral Range<br />

400nm - 700nm<br />

Reflectance Range<br />

0 - 200%R<br />

Repeatability On White<br />

0.2 ∆E max. ±0.01 Density max.<br />

0.4 ∆E max. ±0.01 Density max. Polarized<br />

Density Reproducibility<br />

±0.02 Density @ 1.5 Density<br />

Density Range<br />

0-2.5D<br />

Calibration<br />

Automatic<br />

Scan Spot Size<br />

(Total Scanned Spot)<br />

3.0mm (.118") x 3.5mm (.138") Large<br />

2.3mm (.091") x 3.5mm (.138") Med<br />

1.2mm (.047") x 3.5mm (.138") Small<br />

Polarization Filter<br />

Factory option for Large and<br />

Medium apertures only.<br />

Patch Width (along scan path)<br />

3.8mm (.15") min.<br />

Patch Height<br />

5.0mm (.20") min. Large<br />

3.2mm (.128") min. Med<br />

2.0mm (.078") min. Small<br />

Paper Thickness<br />

1.5mm (.06") max.<br />

Scanning Rate<br />

150mm/sec. (6.8mm patch)<br />

100mm/sec. (4.8 mm patch)<br />

Scanning Width Available<br />

ATS40 standard: 1016mm (40")<br />

Other sizes available to fit<br />

common press configurations.<br />

Color Bar Location<br />

Paper edge to 38mm (1.5")<br />

from edge<br />

Color Bar Alignment<br />

Automatic centering of<br />

measurement on color bar.<br />

Paper set against stop.<br />

Paper Hold Down<br />

Vacuum activated with<br />

measurement command<br />

Power Required Station<br />

110 / 240 VAC, 50-60 Hz, 4/2A<br />

Pump<br />

115 / 230 VAC, 50-60 Hz, 4/2A<br />

INFORMATION PROVIDED IN THIS DOCUMENT IS PROVIDED “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESSED OR IMPLIED WARRANTIES OF<br />

MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR PURPOSE. The user assumes the entire risk as to the accuracy and the use of this information. All<br />

text must be copied without modification and all pages must be included. All components of this information must be distributed together. This information<br />

may not be distributed for profit. X-<strong>Rite</strong>® are registered trademarks of X-<strong>Rite</strong>, Incorporated. Other brand and product names are trademarks of their respective<br />

holders. All trademarks may be registered in the United States and/or other countries. Product design and specifications subject to change without notice.<br />

© X-<strong>Rite</strong>, Incorporated 2006.<br />

X-RITE GLOBAL HEADQUARTERS<br />

Grandville, Michigan USA • +1 616 534-7663 • +1 800 248-9748 • FAX +1 616 534-8960<br />

xrite.com<br />

L7-132 (07/06)<br />

4 3 2 1 X 75% 50% 75% 50% 75% 50% 75% 50% 4 3 2 1 P 2+4 2+3 3+4 P 1 2 3 4 50% 75% 50% 75% 50% 75% 50% 75% X 1<br />

X-<strong>Rite</strong> ® 2.0mm © 2001