Single-head cutting machine

Single-head cutting machine

Single-head cutting machine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

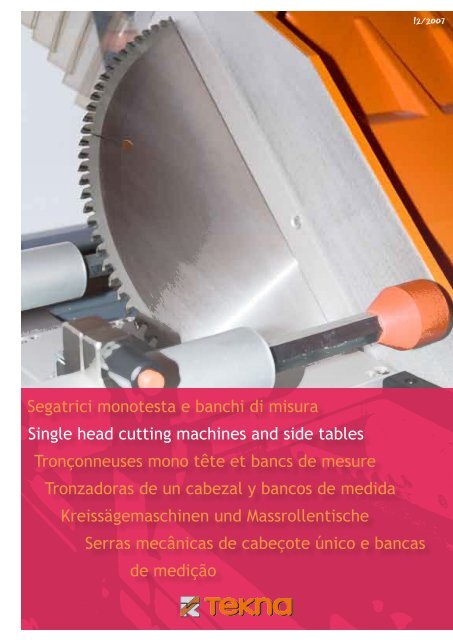

12/2007<br />

Segatrici monotesta e banchi di misura<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables<br />

Tronçonneuses mono tête et bancs de mesure<br />

Tronzadoras de un cabezal y bancos de medida<br />

Kreissägemaschinen und Massrollentische<br />

Serras mecânicas de cabeçote único e bancas<br />

de medição

Who is Tekna<br />

Since 40 years TEKNA means <strong>machine</strong>s for processing aluminium windows and doors.<br />

Based on the long experience in the use of aluminium extrusions for the Fenestration Industry<br />

and partnership with its customers, Tekna has been developing solutions to solve specific<br />

fabrication needs as well as to improve the overall productivity of its customers. It is based<br />

on the combination of the expertise being built in the Fenestration Industry and the know-how<br />

available in the long time established Machine Tools market that Tekna is today able to offer to<br />

its customers cost effective and high productive fabrication solutions together with high skilled<br />

and custom oriented services. A large variety of Tekna customers, varying from small shops to<br />

large multinational companies, are today using these solutions in both Fenestration, Industries<br />

and Transportation markets.<br />

Nowadays the market made an enormous breakthrough: the windows and doors manufacturer<br />

does not only produce windows and doors but also fire stop heavy doors, industrial and garage<br />

doors, various components.<br />

Tekna has again been the very first to launch in the market solutions for these specific fabrication<br />

needs: the Machining Centers.<br />

The results Tekna has achieved prove its competence deriving from the vast experience in the<br />

aluminium market:<br />

• more then 100.000 <strong>machine</strong>s manufactured<br />

• more then 80.000 punching <strong>machine</strong>s and blanking tools<br />

• more then 18.000 companies supplied worldwide.<br />

With a commercial network that counts 6 companies and more than 200 dealers worldwide plus<br />

continuous and considerable investments in persons, means and infrastructures, TEKNA looks<br />

into the future striving every day with its usual keenness and persistency.

TK 133 CNC<br />

TK 133 - TK 133 E<br />

TK 123 P<br />

TK 137 - TK 138<br />

TK 101 A - TK 101 M<br />

TK 100<br />

TK 113 A<br />

TK 801 E - TK 801 D<br />

TK 802 M - TK 802 F<br />

TK 802 SX - 85400<br />

04<br />

08<br />

12<br />

16<br />

20<br />

24<br />

26<br />

28<br />

30

Tk<br />

133 CNC<br />

Semi-automatic single-<strong>head</strong> <strong>cutting</strong> <strong>machine</strong><br />

Blade dia 500 mm to get very good <strong>cutting</strong> capabilities<br />

Full protection with complete cover and front automatic lowering closure<br />

Strong cast iron <strong>head</strong><br />

Head powered double tilting from -45°/90°/22°30’ by means of a direct current<br />

motor managed by a positioner<br />

Oleo-pneumatic blade advancement<br />

Chips ejection through the <strong>head</strong><br />

Chips collection drawer<br />

Optional<br />

Side tables 801/E, 801/D, 802/M, 802/F<br />

LH loading tables 802/SX, 85400<br />

Clamps complete with high/low pressure<br />

safety device<br />

4 <strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables

Blade motor power<br />

Maximum installed power<br />

Working pressure<br />

Power supply<br />

Blade motor revolutions<br />

Blade shaft diameter<br />

Blade diameter<br />

2,2 kW<br />

2,5 kW<br />

6 ÷ 7 bar<br />

230/400 V<br />

50 ÷ 60 Hz<br />

2800 rpm<br />

30 mm<br />

500 mm<br />

Tk<br />

133 CNC<br />

Degrees that can be carried out -45° 90° 22°30’<br />

Dimensions<br />

Weight<br />

915 x 1410 x 1500 mm<br />

450 Kg<br />

Full enclosure to provide noise<br />

reduction and complete accident<br />

protection<br />

Opening upper protection<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables<br />

5

Tk<br />

133 CNC<br />

Electronic tilting of the <strong>head</strong> from<br />

–45°/90°/22°30’<br />

Electronic device to digitally set the<br />

<strong>cutting</strong> angle, complete with display<br />

6<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables

Tk<br />

133 CNC<br />

350<br />

90°<br />

300<br />

250<br />

45°<br />

200<br />

150<br />

22°30’<br />

100<br />

50<br />

0<br />

50<br />

100<br />

150<br />

200<br />

Electronics<br />

Centesimal electronic positioner with 3 pre-set positions (45°/90°/-45°) and 5<br />

more positions can be set by the user on any angle between 22°30’ and -45°<br />

Possibility to store in memory machining cycles up to a maximum of 5 cuts<br />

Display showing the angle of the <strong>head</strong><br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables<br />

7

TK<br />

133<br />

Clamps complete with high/low pressure<br />

safety device<br />

133 133 E<br />

Blade motor power 2,2 kW 2,2 kW<br />

Maximum installed power 2,5 kW 2,5 kW<br />

Working pressure 6 ÷ 7 bar 6 ÷ 7 bar<br />

Power supply<br />

230/400 V<br />

50 ÷ 60 Hz<br />

230/400 V<br />

50 ÷ 60 Hz<br />

Blade motor revolutions 2800 rpm 2800 rpm<br />

Blade shaft diameter 30 mm 30 mm<br />

Blade diameter 500 mm 500 mm<br />

Degrees that can be carried out -45° 90° 22°30’ -45° 90° 22°30’<br />

Dimensions 915 x 1410 x 1500 mm 850 x 1470 x 1650 mm<br />

Weight 450 Kg 370 Kg<br />

8<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables

Tk<br />

133 E<br />

Clamps complete with high/low pressure<br />

safety device<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables<br />

9

Tk<br />

133<br />

Semi-automatic single-<strong>head</strong> <strong>cutting</strong> <strong>machine</strong><br />

Blade dia 500 mm to get very good <strong>cutting</strong> capabilities<br />

Full protection with complete cover and front automatic lowering<br />

closure<br />

Strong cast iron <strong>head</strong><br />

Double pneumatic tilting of the <strong>head</strong> from -45°/90°/22°30’<br />

Display showing the angle of the <strong>head</strong><br />

Oleo-pneumatic blade advancement<br />

Chips ejection through the <strong>head</strong><br />

Chips collection drawer<br />

Optional<br />

Side tables 801/E, 801/D, 802/M, 802/F<br />

LH loading tables 802/SX, 85400<br />

TK<br />

133 E<br />

Semi-automatic single-<strong>head</strong> <strong>cutting</strong> <strong>machine</strong><br />

Blade dia 500 mm to get very good <strong>cutting</strong> capabilities<br />

Strong cast iron <strong>head</strong><br />

Double pneumatic tilting of the <strong>head</strong> from – 45°/90°/22°30’<br />

Display showing the angle of the <strong>head</strong><br />

Oleo-pneumatic blade advancement<br />

Chips ejection through the <strong>head</strong><br />

Optional<br />

Side tables 801/E, 801/D, 802/M, 802/F<br />

LH loading tables 802/SX, 85400<br />

10<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables

Full enclosure to provide noise<br />

reduction and complete accident<br />

protection<br />

Opening upper protection<br />

Goniometer for governing intermediate<br />

angles<br />

Pneumatic tilting of the <strong>head</strong> from<br />

–45°/90°/22°30’<br />

350<br />

90°<br />

300<br />

250<br />

45°<br />

200<br />

150<br />

22°30’<br />

Automatic drop of the blade protection<br />

100<br />

50<br />

0<br />

50<br />

100<br />

150<br />

200<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables<br />

11

Tk<br />

123 P<br />

<strong>Single</strong>-<strong>head</strong> <strong>cutting</strong> <strong>machine</strong><br />

Blade dia 500 mm to get very good <strong>cutting</strong> capabilities<br />

Strong cast iron <strong>head</strong><br />

Double pneumatic tilting of the <strong>head</strong> from –45°/90°/22°30’<br />

Manual blade advancement<br />

Chips ejection through the <strong>head</strong><br />

Optional<br />

Side tables 801/E, 801/D, 802/M, 802/F<br />

LH loading tables 802/SX, 85400<br />

Clamps complete with high/low pressure<br />

safety device<br />

12<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables

Blade motor power<br />

Working pressure<br />

Power supply<br />

Blade motor revolutions<br />

Blade shaft diameter<br />

Blade diameter<br />

2,2 kW<br />

6 ÷ 7 bar<br />

230/400 V<br />

50 ÷ 60 Hz<br />

2800 rpm<br />

30 mm<br />

500 mm<br />

Tk<br />

123 P<br />

Degrees that can be carried out -45° 90° 22°30’<br />

Dimensions<br />

Weight<br />

850 x 1350 x 1510 mm<br />

260 Kg<br />

Adjustable blade protection<br />

Goniometer for governing intermediate<br />

angles<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables<br />

13

Tk<br />

123 P<br />

Pneumatic tilting of the <strong>head</strong> from<br />

–45°/90°/22°30’<br />

Safety during the rotation of the <strong>head</strong><br />

through a two-hands control on the<br />

console<br />

14<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables

Tk<br />

123 P<br />

350<br />

90°<br />

300<br />

250<br />

45°<br />

200<br />

150<br />

22°30’<br />

100<br />

50<br />

0<br />

50<br />

100<br />

150<br />

200<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables<br />

15

TK<br />

137<br />

Clamps complete with high/low pressure<br />

safety device<br />

137 138<br />

Blade motor power 3 kW 3 kW<br />

Maximum installed power 3,5 kW 3,5 kW<br />

Working pressure 6 ÷ 7 bar 6 ÷ 7 bar<br />

Power supply<br />

230/400 V<br />

50 ÷ 60 Hz<br />

230/400 V<br />

50 ÷ 60 Hz<br />

Blade motor revolutions 2800 rpm 2800 rpm<br />

Blade shaft diameter 30 mm 30 mm<br />

Blade diameter 600 mm 600 mm<br />

Degrees that can be carried out -20° 90° 20° 90°<br />

Dimensions 1000 x 1300 x 1500 mm 1000 x 1300 x 1500 mm<br />

Weight 600 Kg 600 Kg<br />

16<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables

Tk<br />

138<br />

Clamps complete with high/low pressure<br />

safety device<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables<br />

17

Tk<br />

137<br />

<strong>Single</strong>-<strong>head</strong> <strong>cutting</strong> <strong>machine</strong> with upwards blade<br />

Blade dia 600 mm to get very good <strong>cutting</strong> capabilities<br />

Oleo-pneumatic blade upstroke<br />

Spray lubrication<br />

Full protection with complete cover and front automatic lowering<br />

closure<br />

Chips collection drawer<br />

Optional<br />

Side tables 801/E, 801/D, 802/M, 802/F<br />

For all cuts between 20°/90°/-20°<br />

TK<br />

138<br />

<strong>Single</strong>-<strong>head</strong> <strong>cutting</strong> <strong>machine</strong> with upwards blade<br />

Blade dia 600 mm to get very good <strong>cutting</strong> capabilities<br />

Oleo-pneumatic blade upstroke<br />

Micro dropped minimal lubrication<br />

Full protection with complete cover and front automatic lowering<br />

closure<br />

Chips collection drawer<br />

Optional<br />

Side tables 801/E, 801/D, 802/M, 802/F<br />

LH loading tables 802/SX, 85400<br />

Pusher<br />

It cuts at 90°. If associated to a pusher<br />

it can execute in-sequence cuts<br />

18<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables

200<br />

150<br />

90°<br />

100<br />

45°<br />

50<br />

0<br />

50<br />

100<br />

150<br />

200<br />

250<br />

300<br />

200<br />

150<br />

90°<br />

100<br />

50<br />

0<br />

50<br />

100<br />

150<br />

200<br />

250<br />

300<br />

350<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables<br />

19

TK<br />

101 A<br />

Vertical clamps complete with a<br />

high/low pressure safety device<br />

101 A 101 M<br />

Blade motor power 1,1 kW 1,1 kW<br />

Maximum installed power 1,5 kW 1,5 kW<br />

Working pressure 6 ÷ 7 bar 6 ÷ 7 bar<br />

Power supply<br />

230/400 V<br />

50 ÷ 60 Hz<br />

230/400 V<br />

50 ÷ 60 Hz<br />

Blade motor revolutions 2800 rpm 2800 rpm<br />

Blade shaft diameter 30 mm 30 mm<br />

Blade diameter 420 mm 400 mm<br />

Degrees that can be carried out -25° 90° 22°30’ -25° 90° 22°30’<br />

Dimensions 610 x 855 x 1270 mm 610 x 855 x 1270 mm<br />

Weight 200 Kg 200 Kg<br />

20<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables

Tk<br />

101 M<br />

Vertical clamps complete with a<br />

high/low pressure safety device<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables<br />

21

Tk<br />

101 A<br />

Cutting <strong>machine</strong> with upwards blade<br />

Oleo-pneumatic blade upstroke<br />

Considerable <strong>cutting</strong> capacity<br />

For all cuts between 22°30’/90°/-25°<br />

Spray lubrication<br />

Complete protection<br />

Profile locking system<br />

Optional<br />

Side tables 801/E, 801/D, 802/M, 802/F<br />

LH loading tables 802/SX, 85400<br />

Mechanical stops of the rotating table<br />

on 45° 90° -45° and trimming position<br />

Possibility to move backwards the<br />

vertical support level to increase the<br />

<strong>cutting</strong> and trimming capacity<br />

Length trimming with special device<br />

TK<br />

101 M<br />

Cutting <strong>machine</strong> with upwards blade<br />

Manually operated blade upstroke<br />

Considerable <strong>cutting</strong> capacity<br />

For all cuts between 22°30’/90°/-25°<br />

Spray lubrication<br />

Complete protection<br />

Profile locking system<br />

Optional<br />

Side tables 801/E, 801/D, 802/M, 802/F<br />

LH loading tables 802/SX, 85400<br />

22<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables

100<br />

90°<br />

50<br />

22°30’<br />

45°<br />

0<br />

50<br />

100<br />

150<br />

200<br />

100<br />

90°<br />

50<br />

22°30’<br />

45°<br />

0<br />

50<br />

100<br />

150<br />

200<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables<br />

23

Tk<br />

100<br />

Cutting <strong>machine</strong> with upwards blade<br />

Manual <strong>cutting</strong> <strong>machine</strong> for small workshops or sites<br />

Considerable <strong>cutting</strong> capacity<br />

For all cuts between 45°/90°/-45°<br />

Simple use<br />

Suitable also for panels <strong>cutting</strong><br />

Profile locking system<br />

Bench rotation to ensure bars<br />

Profile locking system<br />

24<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables

Blade motor power<br />

Power supply<br />

Blade motor revolutions<br />

Blade shaft diameter<br />

Blade diameter<br />

0,75 kW<br />

230/400 V<br />

50 ÷ 60 Hz<br />

2800 rpm<br />

32 mm<br />

350 mm<br />

Tk<br />

100<br />

Degrees that can be carried out -45° 90° 45°<br />

Dimensions<br />

Weight<br />

535 x 685 x 760 mm<br />

64 Kg<br />

Optional<br />

Base rotation to keep the bars aligned<br />

100<br />

90°<br />

50<br />

45°<br />

0<br />

50<br />

100<br />

150<br />

200<br />

250<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables<br />

25

Tk<br />

113 A<br />

Portable sawing <strong>machine</strong><br />

Low-weight <strong>machine</strong> to ensure portability on sites<br />

Simple use<br />

The rotation of the working <strong>head</strong> allows 90º and 45º cuts (right and left) and<br />

intermediate angles.<br />

Tilting range 0º -45º<br />

Blade lowering is manually operating<br />

Profile locking system<br />

<strong>Single</strong>-phase power supply<br />

140 x 70 mm 12 x 85 mm 20 x 85 mm 95 x 70 mm 140 x 45 mm H max: 50 mm<br />

26<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables

Blade motor power<br />

Power supply<br />

Blade motor revolutions<br />

Blade shaft diameter<br />

Blade diameter<br />

Dimensions<br />

Weight<br />

1,4 kW<br />

230 V<br />

50 ÷ 60 Hz<br />

2890 rpm<br />

32 mm<br />

300 mm<br />

530 x 470 x 440 mm<br />

18 Kg<br />

Tk<br />

113 A<br />

90° cuts RH and LH angle cuts<br />

Cuts with tilted <strong>head</strong> - capability to<br />

get the combinations necessary for the<br />

obtainment of composite cuts<br />

Profile locking system<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables<br />

27

Tk<br />

801 E<br />

Table for <strong>cutting</strong> <strong>machine</strong>s<br />

Powered displacement managed by a measure electronic positioner<br />

Two leg table provided with rollers, precision guide - carriage with rack and encoder<br />

Combinable with any model of <strong>cutting</strong> <strong>machine</strong> and also with <strong>machine</strong>s for different operations<br />

<strong>Single</strong>-phase power supply<br />

Electronics<br />

Electronic device for positioning<br />

Possibility to:<br />

• store in memory 80 different <strong>cutting</strong> measures<br />

• store in memory work programs (machining measures and number of pieces) up to maximum 8<br />

programs, each with 10 different cuts<br />

• manage the piece-counter, after having connected a micro – blade return stroke<br />

Display showing the set <strong>cutting</strong> size at the tenth of millimeter<br />

Possibility to work with inches<br />

Tk<br />

801 D<br />

Table for <strong>cutting</strong> <strong>machine</strong>s<br />

Manual displacement of the measure stop by means of a hand-wheel with pneumatic lock<br />

Two leg table provided with rollers, precision guide - carriage with rack and encoder<br />

Combinable with any model of <strong>cutting</strong> <strong>machine</strong> and also with <strong>machine</strong>s for different operations<br />

<strong>Single</strong>-phase power supply<br />

Electronics<br />

Display showing the set <strong>cutting</strong> size at the tenth of millimeter<br />

Possibility to work with inches<br />

For not calculating by hand the sizes of a <strong>cutting</strong> list, it is possible to visualize the displacements<br />

referred to a certain length<br />

Motor power<br />

Working pressure<br />

Power supply<br />

Translation<br />

Speed<br />

Lengths that can be measured<br />

Dimensions (4000 mm)<br />

Dimensions (6000 mm)<br />

Weight (4000 mm)<br />

Weight (6000 mm)<br />

28<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables

RH side table for <strong>cutting</strong> <strong>machine</strong>s<br />

Manual displacement of the measure stop by means of a hand-wheel and the size required can be<br />

read through the lens on the millimetered band<br />

Combinable with any model of <strong>cutting</strong> <strong>machine</strong> and also with <strong>machine</strong>s for different operations<br />

Tk<br />

802 M<br />

LH strong and sturdy loading table, steel structure complete with sliding rollers<br />

Tk<br />

802 F<br />

801 E 801 D 802 M 802 F<br />

0,19 kW - - -<br />

6 ÷ 7 bar 6 ÷ 7 bar 6 ÷ 7 bar -<br />

230 V<br />

50 ÷ 60 Hz<br />

230 V<br />

50 ÷ 60 Hz<br />

- -<br />

Motorized Manual Manual Manual<br />

15 m/1’ - - -<br />

0/4000 - 6000 mm 0/4000 - 6000 mm 0/4000 mm 0/4000 - 6000 mm<br />

4810 x 530 x 1200 mm<br />

4810 x 630 x 1200 mm<br />

6810 x 530 x 1200 mm<br />

6810 x 630 x 1200 mm<br />

110 Kg<br />

120 Kg<br />

160 Kg<br />

175 Kg<br />

4720 x 600 x 1150 mm<br />

4720 x 700 x 1150 mm<br />

6720 x 600 x 1150 mm<br />

6720 x 700 x 1150 mm<br />

100 Kg<br />

110 Kg<br />

150 Kg<br />

165 Kg<br />

4600 x 600 x 1050 mm<br />

4600 x 700 x 1050 mm<br />

-<br />

60 Kg<br />

70 Kg<br />

- -<br />

4600 x 360 x 1100 mm<br />

4600 x 460 x 1100 mm<br />

6600 x 360 x 1100 mm<br />

6600 x 460 x 1100 mm<br />

50 Kg<br />

60 Kg<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables<br />

29

Left side aluminium made table for profile loading, complete with sliding rollers<br />

Tk<br />

802 SX<br />

LH strong and sturdy loading table, steel structure complete with sliding rollers<br />

85400<br />

802 SX 85400<br />

Lengths that can be measured 0/4000 mm 0/4000 mm<br />

Dimensions (4000 mm)<br />

Weight<br />

3100 x 280 x 1000 mm<br />

3100 x 380 x 1000 mm<br />

23 Kg<br />

30 Kg<br />

4690 x 300 x 850 mm<br />

4690 x 400 x 850 mm<br />

50 Kg<br />

60 Kg<br />

30<br />

<strong>Single</strong> <strong>head</strong> <strong>cutting</strong> <strong>machine</strong>s and side tables

T h e o t h e r T e k n a m a c h i n e s<br />

M a c h i n i n g<br />

c e n t r e s<br />

D o u b l e m i t r e<br />

s a w s<br />

Copy milling and end<br />

milling <strong>machine</strong>s<br />

Various <strong>machine</strong>s and<br />

punching <strong>machine</strong>s

Headquarters and subsidiaries<br />

Sales / service staff<br />

Dealers<br />

TEKNA S.r.l. • Via Monte Bisbino, 56 • 20021 Baranzate (Milano)<br />

Tel. (+39) 02 356961 • Fax (+39) 02 3562293<br />

tekna@tekna.it • www.tekna.it<br />

TEKNACENTRO S.r.l.<br />

Via Sferracavalli, 132<br />

03043 Cassino (FR)<br />

Tel. (+39) 077 6311695<br />

Fax (+39) 077 6311167<br />

teknacentro@tekna.it<br />

TEKNA NORDEST<br />

Via Senatore Fabbri, 56<br />

Località Lovadina<br />

31027 Spresiano (TV)<br />

Tel. (+39) 0422 881656<br />

Fax (+39) 0422 724875<br />

TkNordEst@tekna.it<br />

TK MAQUINARIA S.L.<br />

Barberà del Valles<br />

Barcelona<br />

Tel. (+34) 93 7181981<br />

Fax (+34) 93 7192164<br />

tekna@tekna.es<br />

TK PORTUGUESA Lda<br />

Montalvo<br />

Tel. (+351) 249 739969<br />

Fax (+351) 249 739119<br />

info@tkportuguesa.com<br />

TK PORTO<br />

Serzedo<br />

V.Nova Gaia<br />

Tel. (+351) 22 7623563/4<br />

Fax (+351) 22 7623565<br />

Movil (+351) 91 755775<br />

TEKNA DEUTSCHLAND GmbH<br />

Milser Straße 37<br />

33729 Bielefeld<br />

Tel. (+49) 521 923737 0<br />

Fax (+49) 521 923737 2<br />

tekna@tekna.info<br />

www.tekna-deutschland.de<br />

South America<br />

Christian Robledo<br />

Tel. (+54) 911 61289539<br />

Fax (+54) 11 43425602<br />

c.robledo@tekna.it<br />

TEKNA USA Corp.<br />

905 Pingree Road, Unit B<br />

Crystal Lake. IL 60014<br />

Toll free 877-477-4840 • Phone 815-477-4840<br />

Fax 815-477-4870<br />

info@teknausa.com • www.teknausa.com<br />

China<br />

Gao Yong<br />

China Mobile 86 13902406199<br />

tekna@126.com<br />

www.tekna.cn