You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

9 Maintenance and repair<br />

Adjusting proximity switch (METRO H** only) METRO 0.5 to 1.5<br />

Note<br />

Make sure that no parts fall into the unit.<br />

Cover the opening of the machine and bin.<br />

Unscrew the M6 hexagon-headed screw [7]. Using a forked wrench (WAF 9), push against the<br />

contact surface of the piston rod [4].<br />

Press the spacer rod [3] back manually and pull the sealing disk [5] out.<br />

Remove the spring [8].<br />

Slacken the hexagon nut [1] on the pneumatic cylinder [11].<br />

Unscrew the pneumatic cylinder [11] and remove the implosion valve [2].<br />

Loosen the spacer rod with forked wrench (WAF 9). Using a forked wrench (WAF 9), push against<br />

the contact surface of the piston rod [10].<br />

Unscrew the spacer rod [3].<br />

Installation<br />

Assemble in reverse order.<br />

Make sure that the sealing disk [5] contacts the seal [6] after assembly.<br />

Lock the thread of the piston rod [9] with Loctite 270 and the hexagon-headed screw [7] with Loctite<br />

242.<br />

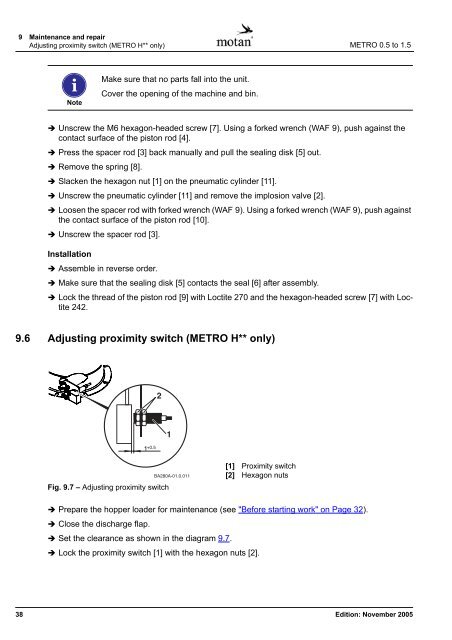

9.6 Adjusting proximity switch (METRO H** only)<br />

2<br />

1<br />

Fig. 9.7 – Adjusting proximity switch<br />

[1] Proximity switch<br />

[2] Hexagon nuts<br />

Prepare the hopper <strong>loader</strong> for maintenance (see "Before starting work" on Page 32).<br />

Close the discharge flap.<br />

Set the clearance as shown in the diagram 9.7.<br />

Lock the proximity switch [1] with the hexagon nuts [2].<br />

38 Edition: November 2005