Pre-recorded DVD Master, Stamper and Disc Analysis - DaTARIUS

Pre-recorded DVD Master, Stamper and Disc Analysis - DaTARIUS

Pre-recorded DVD Master, Stamper and Disc Analysis - DaTARIUS

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Pre</strong>-<strong>recorded</strong> <strong>DVD</strong><br />

<strong>Master</strong>, <strong>Stamper</strong> <strong>and</strong> <strong>Disc</strong> <strong>Analysis</strong><br />

■ <strong>Master</strong>*, stamper <strong>and</strong> disc analysis in one module<br />

■ According to the <strong>DVD</strong> Forum specification<br />

■ Based on Pulstec <strong>DVD</strong> drive<br />

■ Multi-Dimensional calibration<br />

■ HF, jitter, mechanical <strong>and</strong> tracking parameters checked<br />

■ Radial tilt control, focus offset compensation <strong>and</strong> slicing<br />

level adjustment for jitter measurement<br />

■ Local defect detection/missing pits<br />

■ Error flag analysis (PI-errors, PI-fail, PO-fail)<br />

■ Split test with any other <strong>DaTARIUS</strong> <strong>DVD</strong> Analyzer<br />

■ Double-Check function<br />

■ Control data simulation<br />

■ <strong>DVD</strong>-9 OTP sector number check<br />

■ CSS check<br />

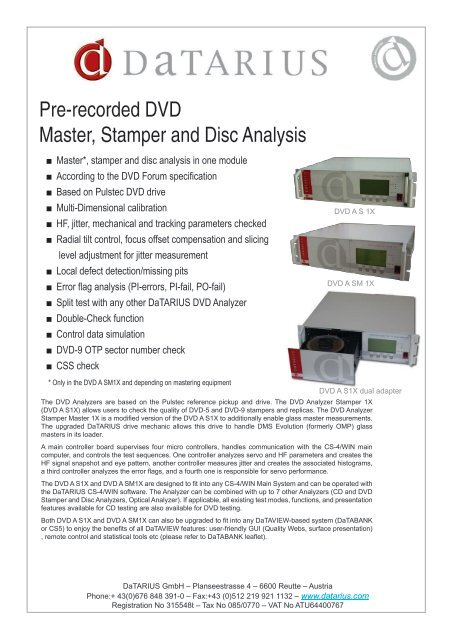

<strong>DVD</strong> A S 1X<br />

<strong>DVD</strong> A SM 1X<br />

* Only in the <strong>DVD</strong> A SM1X <strong>and</strong> depending on mastering equipment<br />

<strong>DVD</strong> A S1X dual adapter<br />

The <strong>DVD</strong> Analyzers are based on the Pulstec reference pickup <strong>and</strong> drive. The <strong>DVD</strong> Analyzer <strong>Stamper</strong> 1X<br />

(<strong>DVD</strong> A S1X) allows users to check the quality of <strong>DVD</strong>-5 <strong>and</strong> <strong>DVD</strong>-9 stampers <strong>and</strong> replicas. The <strong>DVD</strong> Analyzer<br />

<strong>Stamper</strong> <strong>Master</strong> 1X is a modified version of the <strong>DVD</strong> A S1X to additionally enable glass master measurements.<br />

The upgraded <strong>DaTARIUS</strong> drive mechanic allows this drive to h<strong>and</strong>le DMS Evolution (formerly OMP) glass<br />

masters in its loader.<br />

A main controller board supervises four micro controllers, h<strong>and</strong>les communication with the CS-4/WIN main<br />

computer, <strong>and</strong> controls the test sequences. One controller analyzes servo <strong>and</strong> HF parameters <strong>and</strong> creates the<br />

HF signal snapshot <strong>and</strong> eye pattern, another controller measures jitter <strong>and</strong> creates the associated histograms,<br />

a third controller analyzes the error flags, <strong>and</strong> a fourth one is responsible for servo performance.<br />

The <strong>DVD</strong> A S1X <strong>and</strong> <strong>DVD</strong> A SM1X are designed to fit into any CS-4/WIN Main System <strong>and</strong> can be operated with<br />

the <strong>DaTARIUS</strong> CS-4/WIN software. The Analyzer can be combined with up to 7 other Analyzers (CD <strong>and</strong> <strong>DVD</strong><br />

<strong>Stamper</strong> <strong>and</strong> <strong>Disc</strong> Analyzers, Optical Analyzer). If applicable, all existing test modes, functions, <strong>and</strong> presentation<br />

features available for CD testing are also available for <strong>DVD</strong> testing.<br />

Both <strong>DVD</strong> A S1X <strong>and</strong> <strong>DVD</strong> A SM1X can also be upgraded to fit into any DaTAVIEW-based system (DaTABANK<br />

or CS5) to enjoy the benefits of all DaTAVIEW features: user-friendly GUI (Quality Webs, surface presentation)<br />

, remote control <strong>and</strong> statistical tools etc (please refer to DaTABANK leaflet).<br />

<strong>DaTARIUS</strong> GmbH – Planseestrasse 4 – 6600 Reutte – Austria<br />

Phone:+ 43(0)676 848 391-0 – Fax:+43 (0)512 219 921 1132 – www.datarius.com<br />

Registration No 315548t – Tax No 085/0770 – VAT No ATU64400767

© 2008 <strong>DaTARIUS</strong> M-03 / 04<br />

© 2008 <strong>DaTARIUS</strong> M-03 / 04<br />

Measured parameters<br />

CS5/CS4 <strong>DVD</strong> Analyzer can also measure <strong>recorded</strong> <strong>DVD</strong>±R/RW/DL<br />

<strong>DVD</strong> A <strong>DVD</strong> A Double-Check: This feature comm<strong>and</strong>s the<br />

S1X SM 1X analyzer (or another analyzer in split mode)<br />

to re-check, in 1X, a suspicious position.<br />

I14H reflectivity <br />

Measured I14N relative parameters peak to peak value for the longest pits/l<strong>and</strong>s I14/I14H <br />

<strong>DVD</strong> A<br />

<br />

<strong>DVD</strong> A Double-Check: This feature comm<strong>and</strong>s the<br />

S1X SM 1XSplit Test: The CS-4/WIN Software can<br />

CS5/CS4 <strong>DVD</strong> Analyzer can also measure <strong>recorded</strong> <strong>DVD</strong>±R/RW/DL<br />

analyzer (or another analyzer in split mode)<br />

I3N relative peak to peak value for the longest pits/l<strong>and</strong>s I3/I3H combine<br />

to re-check,<br />

up to<br />

in 1X,<br />

8 analyzers<br />

a suspicious<br />

to<br />

position.<br />

reduce<br />

RESI14H Resolution reflectivity I3/114 measuring time. The <strong>DVD</strong> Analyzers can be<br />

ASYd I14N asymmetry relative peak to peak value for the longest pits/l<strong>and</strong>s I14/I14H combined<br />

Split Test:<br />

with any<br />

The<br />

<strong>DaTARIUS</strong><br />

CS-4/WIN<br />

<strong>DVD</strong><br />

Software<br />

analyzer<br />

can<br />

TCS * track crossing signal<br />

in split test mode.<br />

I3N relative peak to peak value for the longest pits/l<strong>and</strong>s I3/I3H combine up to 8 analyzers to reduce<br />

I14VRES I14H Resolution variation over I3/114one revolution measuring time. The <strong>DVD</strong> Analyzers can be<br />

Control Data: In the case of SACD or copy<br />

IVDASYd I14H asymmetry variation over the disc <br />

combined with any <strong>DaTARIUS</strong> <strong>DVD</strong> analyzer<br />

protected discs, on which control data is<br />

IVDF TCS * filtered track I14H crossing variation signal over the disc in split test mode.<br />

scrambled or missing, control data will be<br />

I14DI14V I14H I14H difference variation between over one layer revolution 0 <strong>and</strong> layer 1 simulated<br />

Control<br />

in<br />

Data:<br />

order<br />

In<br />

to<br />

the<br />

allow<br />

case<br />

normal<br />

of SACD<br />

testing<br />

or copy<br />

R14H IVD I14H I14H measured variation at over radial the position disc sequences.<br />

protected discs, on which control data is<br />

HFVd IVDF I14 filtered amplitude I14H variation within over one the disc revolution scrambled or missing, control data will be<br />

IBVd I14D I14L I14H variation difference within between one revolution layer 0 <strong>and</strong> layer 1 Sector<br />

simulated<br />

Number<br />

in<br />

Check<br />

order to<br />

for<br />

allow<br />

<strong>DVD</strong>-9<br />

normal<br />

OTP<br />

testing<br />

HFLR14H HF I14H low measured at radial position For<br />

sequences.<br />

<strong>DVD</strong> 9 OTP, a sector number check is<br />

DOHFVd HD I14 drop-out amplitude variation within one revolution <br />

performed on layer 0’s last sector, layer 1’s<br />

TRPd IBVd track I14L pitch variation within one revolution first sector <strong>and</strong> lead-out’s last sector, then<br />

Sector Number Check for <strong>DVD</strong>-9 OTP<br />

ATP0,1 average track pitch measured over the whole layer <br />

compared with the information stored in the<br />

HFL HF low For <strong>DVD</strong> 9 OTP, a sector number check is<br />

control data.<br />

SVYd DO scanning HD drop-out velocity performed on layer 0’s last sector, layer 1’s<br />

CSS Check: Performs a CSS key check to<br />

BPL TRPd 0,1 begin track program pitch layer 0,1 first sector <strong>and</strong> lead-out’s last sector, then<br />

ensure that the key on layer 0 is the same<br />

BLO ATP0,1 begin average lead-out track layer pitch 0,1measured over the whole layer <br />

compared with the information stored in the<br />

as on layer 1.<br />

ECC 0,1 eccentricity - control data.<br />

SVYd scanning velocity <br />

BLI 0,1 begin lead-in layer 0,1 <br />

CSS Check: Performs a CSS key check to<br />

BPL 0,1 begin program layer 0,1 Resolution,<br />

ensure that<br />

<strong>Pre</strong>sentation,<br />

the key on layer<br />

Procedures<br />

0 is the same<br />

ELO BLO 0,1 0,1 end begin lead-out lead-out layer layer 0, 1 0,1 Most<br />

as<br />

of<br />

on<br />

the<br />

layer<br />

listed<br />

1.<br />

parameters are measured<br />

JC* ECC 0,1 Jitter eccentricity combined - <strong>and</strong> sampled continuously. One set of data<br />

JITBLI 0,1 Continuously begin lead-in measured layer 0,1Jitter is presented<br />

Resolution,<br />

for<br />

<strong>Pre</strong>sentation,<br />

every 512 sectors/<br />

Procedures<br />

32 ECC<br />

SLEELO 0,1 Slicing end Level lead-out layer 0, 1 frames<br />

Most<br />

(corresponding<br />

of the listed parameters<br />

to 1 MB of<br />

are<br />

data,<br />

measured<br />

or<br />

TLCJC* Tilt Jitter Level combined Compensation <br />

about<br />

<strong>and</strong><br />

one<br />

sampled<br />

data set<br />

continuously.<br />

per each 0.75<br />

One<br />

seconds,<br />

set of data<br />

FOF Focus Offset at reference play-back speed).<br />

JIT Continuously measured Jitter is presented for every 512 sectors/ 32 ECC<br />

PIESLE parity Slicing inner Level code errors frames (corresponding to 1 MB of data, or<br />

<strong>Stamper</strong> Adapter - dual adapter option<br />

PIFTLC parity Tilt inner Level code Compensation fails about one data set per each 0.75 seconds,<br />

In order to play <strong>DVD</strong> stampers, a<br />

POFOF parity Focus outer Offset code fails (uncorrectable) compensation<br />

at reference<br />

glass<br />

play-back<br />

is required<br />

speed).<br />

to simulate<br />

APIE PIE average parity PIE inner measured code errors over the whole disc the replica’s polycarbonate substrate. With<br />

TPP tangential push pull the<br />

<strong>Stamper</strong><br />

<strong>DaTARIUS</strong><br />

Adapter<br />

<strong>DVD</strong> Analyzer<br />

- dual adapter<br />

dual adapter<br />

option<br />

PIF parity inner code fails <br />

RNSd radial tracking error signal option<br />

In<br />

,<br />

order<br />

there are<br />

to play<br />

two options<br />

<strong>DVD</strong><br />

for<br />

stampers,<br />

playing<br />

a<br />

POF parity outer code fails (uncorrectable) <br />

RAD1 radial tracking error signal - stampers.<br />

compensation<br />

The first<br />

glass<br />

option<br />

is required<br />

places<br />

to<br />

a glass<br />

simulate<br />

APIE average PIE measured over the whole disc <br />

compensation<br />

the replica’s<br />

layer<br />

polycarbonate<br />

over the whole<br />

substrate.<br />

stamper.<br />

With<br />

FE TPP Focus tangential Error push pull - With<br />

the<br />

this<br />

<strong>DaTARIUS</strong><br />

option, regular<br />

<strong>DVD</strong><br />

replicas<br />

Analyzer<br />

can<br />

dual<br />

also<br />

adapter<br />

be<br />

RPP* RNSd Radial radial Push tracking Pull error signal played<br />

option<br />

(using<br />

, there<br />

an appropriate<br />

are two options<br />

mount).<br />

for<br />

The<br />

playing<br />

DPT* RAD1 Differential radial tracking phase error tracking signal error signal - second<br />

stampers.<br />

option<br />

The<br />

utilizes<br />

first<br />

a small<br />

option<br />

compensation<br />

places a glass<br />

DPA* FE asymmetry Focus Error of the differential phase tracking error signal - glass<br />

compensation<br />

mounted directly<br />

layer over<br />

onto<br />

the whole<br />

the pickup<br />

stamper.<br />

RPP* Radial Push Pull optic.<br />

With<br />

<strong>Stamper</strong>s<br />

this option,<br />

can<br />

regular<br />

then be<br />

replicas<br />

played<br />

can<br />

without<br />

also be<br />

DPT* Differential phase tracking error signal<br />

any<br />

played<br />

covering,<br />

(using<br />

but<br />

an<br />

the<br />

appropriate<br />

glass will need<br />

mount).<br />

to be<br />

The<br />

<br />

removed<br />

second<br />

before<br />

option utilizes<br />

replicas<br />

a small<br />

can be<br />

compensation<br />

played.<br />

DPA* asymmetry of the differential phase tracking error signal <br />

* These parameters are measured in single speed on several positions, in some cases in the ‘open loop’ condition, where (This<br />

glass<br />

second<br />

mounted<br />

option<br />

directly<br />

is not available<br />

onto the<br />

on the<br />

pickup<br />

applicable. Positions can either be selected automatically (equally distributed throughout the disc), or can be specified st<strong>and</strong>ard<br />

optic.<br />

<strong>DVD</strong><br />

<strong>Stamper</strong>s<br />

Analyzer<br />

can<br />

S1X.)<br />

then be played without<br />

any covering, but the glass will need to be<br />

by the user.<br />

removed before replicas can be played.<br />

¹ These parameters are measured in single speed.<br />

Glass <strong>Master</strong> Adapter (<strong>DVD</strong> A SM 1X)<br />

* These parameters are measured in single speed on several positions, in some cases in the ‘open loop’ condition, where (This second option is not available on the<br />

DMS Evolution glass masters have no<br />

Technical applicable. specifications:<br />

Positions can either be selected automatically <strong>DVD</strong> (equally A S1X distributed - <strong>DVD</strong> throughout A SM1X the disc), or can be specified st<strong>and</strong>ard <strong>DVD</strong> Analyzer S1X.)<br />

centre hole but a small metallic ball fixed on<br />

Size by (W the x user. H x D), Weight:<br />

PULSTEC <strong>DVD</strong> Drive <strong>and</strong> PUH Specifications<br />

the centre of the reverse side. magnetic<br />

48.3 ¹ These x 13.2 parameters x 65.5 cm are (19” measured frame size); in single speed. Wavelength: 650 +/- 5nm<br />

Glass <strong>Master</strong> Adapter (<strong>DVD</strong> A SM 1X)<br />

mechanism installed in the drive’s turntable<br />

weight: 13.0 kg<br />

Numerical Aperture: 0.6 +/- 0.02<br />

DMS Evolution glass masters have no<br />

Technical specifications:<br />

<strong>DVD</strong> A S1X - <strong>DVD</strong> A SM1X<br />

will lock the master via the ball. Replicas are<br />

Max. Laser Power: 0.3 mW<br />

centre hole but a small metallic ball fixed on<br />

Size (W x H x D), Weight:<br />

PULSTEC <strong>DVD</strong> Drive <strong>and</strong> PUH Specifications also magnetically fixed on the turntable via a<br />

Radial Tilt Control: +/- 1°<br />

the centre of the reverse side. A magnetic<br />

48.3 x 13.2 x 65.5 cm (19” frame size);<br />

special<br />

mechanism<br />

adapter<br />

installed<br />

installed through<br />

in the drive’s<br />

their centre<br />

turntable<br />

weight: 13.0 kg<br />

hole.<br />

HF<br />

HF<br />

Digital Time-based Mechanical<br />

Time-based Mechanical<br />

Servo & Tracking<br />

Servo & Tracking Digital<br />

Wavelength: 650 +/- 5nm<br />

Numerical Aperture: 0.6 +/- 0.02<br />

Max. Laser Power: 0.3 mW<br />

Radial Tilt Control: +/- 1°<br />

Specifications subject to change without notice<br />

will lock the master via the ball. Replicas are<br />

also magnetically fixed on the turntable via a<br />

special adapter installed through their centre<br />

hole.<br />

Specifications subject to change without notice<br />

<strong>DaTARIUS</strong> GmbH – Planseestrasse 4 – 6600 Reutte – Austria<br />

Phone:+ 43(0)676 848 391-0 – Fax:+43 (0)512 219 921 1132 – www.datarius.com<br />

Registration No 315548t – Tax No 085/0770 – VAT No ATU64400767