Export Requirements for Packaging Machines - Moeller

Export Requirements for Packaging Machines - Moeller

Export Requirements for Packaging Machines - Moeller

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

NEWS +++ NEWS +++ NEWS<br />

1st Automation structure<br />

Touch display – Central PLC – Control wiring – Fieldbus –<br />

Remote I/o<br />

Complex wiring systems connected to the central PLC become<br />

unnecessary through the use of touch displays and remote I/Os.<br />

For the first time, the touch display also offers a communication<br />

link to an ERP system. An onsite production manager is no longer<br />

required here, and machine data can now be accessed remotely.<br />

Together with the fieldbus, remote I/Os are used to replace<br />

complex machine cabling. Remote I/Os function at the same time<br />

as data collectors that are interconnected by means of a fieldbus.<br />

These types of architectures are nowadays in widespread use.<br />

They also integrate components such as hydraulic valves. In other<br />

words, each innovation stage integrates more functions such as<br />

a hydraulic or electric drive. The significant feature here is that<br />

<strong>for</strong> the first time the data from the machine is now fed and made<br />

available to a higher-level system.<br />

2nd Automation structure<br />

Touch display – Central PLC – Control wiring – Fieldbus –<br />

SmartWire-DT – Remote I/o<br />

This automation structure is basically the same as the previously<br />

described structure, however with the key difference that the<br />

use of SmartWire-DT considerably reduces the wiring required<br />

<strong>for</strong> pilot devices, motor starters and circuit-breakers. For example,<br />

pushbutton actuators, indicator lights, and switching devices<br />

can be fed with the operational current and integrated in the<br />

communication structure via a single SmartWire-DT line. The<br />

clear and simple structure there<strong>for</strong>e shortens also the test and<br />

commissioning phase as well as the wiring required. SmartWire-<br />

DT is connected via gateways to Profibus or CANopen fieldbus<br />

systems. Compared to the overall engineering design, the<br />

requirements in the SmartWire-DT line are considerably reduced.<br />

Other components such as sensors and actuators are primarily<br />

connected via remote I/Os to fieldbus systems.<br />

3rd Automation structure<br />

hmI/PLC with integrated SmartWire-DT – Fieldbus –<br />

Remote I/o<br />

The touch display PLC replaces the central PLC. A gateway<br />

to the fieldbus is no longer required; the SmartWire-DT line is<br />

connected directly to the HMI-PLC. Operating data from the motor<br />

feeders, such as motor current, thermal motor load, switching<br />

states, trip indications such as overload, short-circuit, phase<br />

loss, is transferred via SmartWire-DT to the HMI/PLC. Servo<br />

drives, frequency inverters and some sensors are integrated<br />

SolutionS 23 News<br />

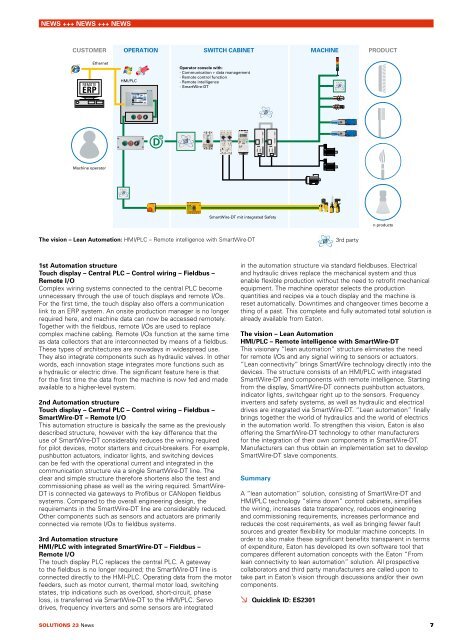

CUSTOMER OPERATION SWITCH CABINET<br />

MACHINE<br />

PRODUCT<br />

REMOTE<br />

ERP<br />

Ethernet<br />

Machine operator<br />

HMI/PLC<br />

Operator console with:<br />

- Communication + data management<br />

- Remote control function<br />

- Remote intelligence<br />

- SmartWire-DT<br />

SmartWire-DT mit integrated Safety<br />

The vision – Lean Automation: HMI/PLC – Remote intelligence with SmartWire-DT 3rd party<br />

in the automation structure via standard fieldbuses. Electrical<br />

and hydraulic drives replace the mechanical system and thus<br />

enable flexible production without the need to retrofit mechanical<br />

equipment. The machine operator selects the production<br />

quantities and recipes via a touch display and the machine is<br />

reset automatically. Downtimes and changeover times become a<br />

thing of a past. This complete and fully automated total solution is<br />

already available from Eaton.<br />

The vision – Lean Automation<br />

hmI/PLC – Remote intelligence with SmartWire-DT<br />

This visionary “lean automation” structure eliminates the need<br />

<strong>for</strong> remote I/Os and any signal wiring to sensors or actuators.<br />

“Lean connectivity” brings SmartWire technology directly into the<br />

devices. The structure consists of an HMI/PLC with integrated<br />

SmartWire-DT and components with remote intelligence. Starting<br />

from the display, SmartWire-DT connects pushbutton actuators,<br />

indicator lights, switchgear right up to the sensors. Frequency<br />

inverters and safety systems, as well as hydraulic and electrical<br />

drives are integrated via SmartWire-DT. “Lean automation” finally<br />

brings together the world of hydraulics and the world of electrics<br />

in the automation world. To strengthen this vision, Eaton is also<br />

offering the SmartWire-DT technology to other manufacturers<br />

<strong>for</strong> the integration of their own components in SmartWire-DT.<br />

Manufacturers can thus obtain an implementation set to develop<br />

SmartWire-DT slave components.<br />

Summary<br />

A “lean automation” solution, consisting of SmartWire-DT and<br />

HMI/PLC technology “slims down” control cabinets, simplifies<br />

the wiring, increases data transparency, reduces engineering<br />

and commissioning requirements, increases per<strong>for</strong>mance and<br />

reduces the cost requirements, as well as bringing fewer fault<br />

sources and greater flexibility <strong>for</strong> modular machine concepts. In<br />

order to also make these significant benefits transparent in terms<br />

of expenditure, Eaton has developed its own software tool that<br />

compares different automation concepts with the Eaton “From<br />

lean connectivity to lean automation” solution. All prospective<br />

collaborators and third party manufacturers are called upon to<br />

take part in Eaton’s vision through discussions and/or their own<br />

components.<br />

Quicklink ID: ES2301<br />

n products<br />

7