Oxygen sensor monitoring a deterioration of a three-way ... - UMEL

Oxygen sensor monitoring a deterioration of a three-way ... - UMEL

Oxygen sensor monitoring a deterioration of a three-way ... - UMEL

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

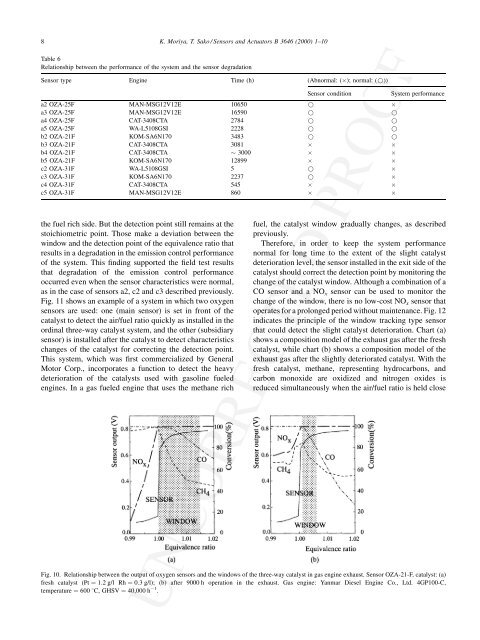

8 K. Moriya, T. Sako / Sensors and Actuators B 3646 (2000) 1–10<br />

Table 6<br />

Relationship between the performance <strong>of</strong> the system and the <strong>sensor</strong> degradation<br />

Sensor type Engine Time (h) (Abnormal: (); normal: (*))<br />

Sensor condition<br />

System performance<br />

a2 OZA-25F MAN-MSG12V12E 10650 * <br />

a3 OZA-25F MAN-MSG12V12E 16590 * *<br />

a4 OZA-25F CAT-3408CTA 2784 * *<br />

a5 OZA-25F WA-L5108GSI 2228 * *<br />

b2 OZA-21F KOM-SA6N170 3483 * *<br />

b3 OZA-21F CAT-3408CTA 3081 <br />

b4 OZA-21F CAT-3408CTA 3000 <br />

b5 OZA-21F KOM-SA6N170 12899 <br />

c2 OZA-31F WA-L5108GSI 5 * <br />

c3 OZA-31F KOM-SA6N170 2237 * <br />

c4 OZA-31F CAT-3408CTA 545 <br />

c5 OZA-31F MAN-MSG12V12E 860 <br />

the fuel rich side. But the detection point still remains at the<br />

stoichiometric point. Those make a deviation between the<br />

window and the detection point <strong>of</strong> the equivalence ratio that<br />

results in a degradation in the emission control performance<br />

<strong>of</strong> the system. This finding supported the field test results<br />

that degradation <strong>of</strong> the emission control performance<br />

occurred even when the <strong>sensor</strong> characteristics were normal,<br />

as in the case <strong>of</strong> <strong>sensor</strong>s a2, c2 and c3 described previously.<br />

Fig. 11 shows an example <strong>of</strong> a system in which two oxygen<br />

<strong>sensor</strong>s are used: one (main <strong>sensor</strong>) is set in front <strong>of</strong> the<br />

catalyst to detect the air/fuel ratio quickly as installed in the<br />

ordinal <strong>three</strong>-<strong>way</strong> catalyst system, and the other (subsidiary<br />

<strong>sensor</strong>) is installed after the catalyst to detect characteristics<br />

changes <strong>of</strong> the catalyst for correcting the detection point.<br />

This system, which was first commercialized by General<br />

Motor Corp., incorporates a function to detect the heavy<br />

<strong>deterioration</strong> <strong>of</strong> the catalysts used with gasoline fueled<br />

engines. In a gas fueled engine that uses the methane rich<br />

fuel, the catalyst window gradually changes, as described<br />

previously.<br />

Therefore, in order to keep the system performance<br />

normal for long time to the extent <strong>of</strong> the slight catalyst<br />

<strong>deterioration</strong> level, the <strong>sensor</strong> installed in the exit side <strong>of</strong> the<br />

catalyst should correct the detection point by <strong>monitoring</strong> the<br />

change <strong>of</strong> the catalyst window. Although a combination <strong>of</strong> a<br />

CO <strong>sensor</strong> and a NO x <strong>sensor</strong> can be used to monitor the<br />

change <strong>of</strong> the window, there is no low-cost NO x <strong>sensor</strong> that<br />

operates for a prolonged period without maintenance. Fig. 12<br />

indicates the principle <strong>of</strong> the window tracking type <strong>sensor</strong><br />

that could detect the slight catalyst <strong>deterioration</strong>. Chart (a)<br />

shows a composition model <strong>of</strong> the exhaust gas after the fresh<br />

catalyst, while chart (b) shows a composition model <strong>of</strong> the<br />

exhaust gas after the slightly deteriorated catalyst. With the<br />

fresh catalyst, methane, representing hydrocarbons, and<br />

carbon monoxide are oxidized and nitrogen oxides is<br />

reduced simultaneously when the air/fuel ratio is held close<br />

Fig. 10. Relationship between the output <strong>of</strong> oxygen <strong>sensor</strong>s and the windows <strong>of</strong> the <strong>three</strong>-<strong>way</strong> catalyst in gas engine exhaust. Sensor OZA-21-F, catalyst: (a)<br />

fresh catalyst (Pt ¼ 1:2 g/l Rh ¼ 0:3 g/l); (b) after 9000 h operation in the exhaust. Gas engine: Yanmar Diesel Engine Co., Ltd. 4GP100-C,<br />

temperature ¼ 600 8C, GHSV ¼ 40;000 h 1 .<br />

UNCORRECTED PROOF