38CKB(N) Wiring Diagrams - Carrier

38CKB(N) Wiring Diagrams - Carrier

38CKB(N) Wiring Diagrams - Carrier

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

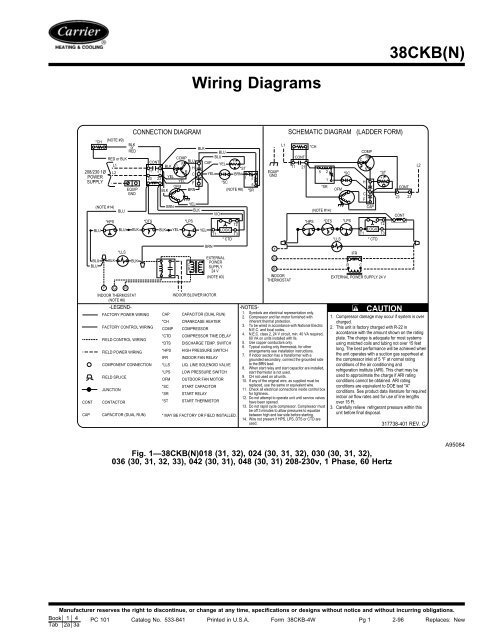

<strong>38CKB</strong>(N)<br />

<strong>Wiring</strong> <strong>Diagrams</strong><br />

CONT<br />

CAP<br />

*CH<br />

208/230 1Ø<br />

POWER<br />

SUPPLY<br />

Y G R<br />

INDOOR THERMOSTAT<br />

(NOTE #6)<br />

-LEGEND-<br />

FACTORY POWER WIRING<br />

FACTORY CONTROL WIRING<br />

FIELD CONTROL WIRING<br />

FIELD POWER WIRING<br />

COMPONENT CONNECTION<br />

FIELD SPLICE<br />

JUNCTION<br />

CONTACTOR<br />

BLK or<br />

RED<br />

CAPACITOR (DUAL RUN)<br />

CONNECTION DIAGRAM SCHEMATIC DIAGRAM (LADDER FORM)<br />

RED or BLK<br />

COMP<br />

CONT<br />

BLU<br />

L1<br />

S<br />

BLK C<br />

H<br />

L2 11 21<br />

R<br />

C<br />

23 23<br />

YEL<br />

YEL<br />

F<br />

EQUIP<br />

BLK<br />

OFM<br />

BRN<br />

GND<br />

(NOTE #14)<br />

BLU<br />

BLU<br />

BLU<br />

(NOTE #9)<br />

*HPS<br />

BLK<br />

BLU<br />

BLU<br />

*LLS<br />

BLK<br />

BLK<br />

*DTS<br />

BLK<br />

BRN<br />

CAP<br />

*CH<br />

COMP<br />

*CTD<br />

*DTS<br />

*HPS<br />

IFR<br />

*LLS<br />

*LPS<br />

OFM<br />

*SC<br />

*SR<br />

*ST<br />

YEL<br />

YEL<br />

BLK<br />

*LPS<br />

C<br />

R<br />

BLK<br />

BLU<br />

BLU<br />

CAP YEL<br />

+ t<br />

*ST<br />

YEL<br />

BRN<br />

1 2<br />

*SC<br />

5<br />

(NOTE #8) *SR<br />

YEL<br />

BRN<br />

INDOOR BLOWER MOTOR<br />

VIO<br />

T2<br />

LOGIC<br />

T1<br />

T3<br />

* CTD<br />

EXTERNAL<br />

POWER<br />

SUPPLY<br />

24 V<br />

(NOTE #3)<br />

CAPACITOR (DUAL RUN)<br />

CRANKCASE HEATER<br />

COMPRESSOR<br />

COMPRESSOR TIME DELAY<br />

DISCHARGE TEMP. SWITCH<br />

HIGH PRESSURE SWITCH<br />

INDOOR FAN RELAY<br />

LIQ. LINE SOLENOID VALVE<br />

LOW PRESSURE SWITCH<br />

OUTDOOR FAN MOTOR<br />

START CAPACITOR<br />

START RELAY<br />

START THERMISTOR<br />

* MAY BE FACTORY OR FIELD INSTALLED.<br />

EQUIP<br />

GND<br />

Y<br />

G<br />

R<br />

L1<br />

INDOOR<br />

THERMOSTAT<br />

CONT<br />

11 21<br />

*CH<br />

*HPS<br />

5 2<br />

1<br />

*SR<br />

(NOTE #14)<br />

*DTS<br />

-NOTES-<br />

1. Symbols are electrical representation only.<br />

2. Compressor and fan motor furnished with<br />

inherent thermal protection.<br />

3. To be wired in accordance with National Electric<br />

N.E.C. and local codes.<br />

4. N.E.C. class 2, 24 V circuit, min. 40 VA required,<br />

60 VA on units installed with lls.<br />

5. Use copper conductors only.<br />

6. Typical cooling only thermostat, for other<br />

arrangements see installation instructions.<br />

7. If indoor section has a transformer with a<br />

grounded secondary, connect the grounded side<br />

to the BRN lead.<br />

8. When start relay and start capacitor are installed,<br />

start thermistor is not used.<br />

9. CH not used on all units.<br />

10. If any of the original wire, as supplied must be<br />

replaced, use the same or equivalent wire.<br />

11. Check all electrical connections inside control box<br />

for tightness.<br />

12. Do not attempt to operate unit until service valves<br />

have been opened.<br />

13. Do not rapid cycle compressor. Compressor must<br />

be off 3 minutes to allow pressures to equalize<br />

between high and low side before starting.<br />

14. Wire not present if HPS, LPS, DTS or CTD are<br />

used.<br />

OFM<br />

*LLS<br />

*SC<br />

*LPS<br />

R<br />

IFR<br />

COMP<br />

C<br />

R<br />

H<br />

C<br />

F<br />

CAP<br />

*ST<br />

+t<br />

T2<br />

LOGIC<br />

T1 T3<br />

* CTD<br />

EXTERNAL POWER SUPPLY 24 V<br />

C<br />

S<br />

CONT<br />

23 23<br />

CONT<br />

CAUTION<br />

1. Compressor damage may occur if system is over<br />

charged.<br />

2. This unit is factory charged with R-22 in<br />

accordance with the amount shown on the rating<br />

plate. The charge is adequate for most systems<br />

using matched coils and tubing not over 15 feet<br />

long. The best performance will be achieved when<br />

the unit operates with a suction gas superheat at<br />

the compressor inlet of 5 °F at normal rating<br />

conditions of the air conditioning and<br />

refrigeration institute (ARI). This chart may be<br />

used to approximate the charge if ARI rating<br />

conditions cannot be obtained. ARI rating<br />

conditions are equivalent to DOE test "A"<br />

conditions. See product data literature for required<br />

indoor air flow rates and for use of line lengths<br />

over 15 Ft.<br />

3. Carefully relieve refrigerant pressure within this<br />

unit before final disposal.<br />

L2<br />

317738-401 REV. C<br />

Fig. 1—<strong>38CKB</strong>(N)018 (31, 32), 024 (30, 31, 32), 030 (30, 31, 32),<br />

036 (30, 31, 32, 33), 042 (30, 31), 048 (30, 31) 208-230v, 1 Phase, 60 Hertz<br />

A95084<br />

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.<br />

Book 1 4 PC 101 Catalog No. 533-841 Printed in U.S.A. Form <strong>38CKB</strong>-4W Pg 1 2-96 Replaces: New<br />

Tab 2a 3a

CONNECTION DIAGRAM<br />

*CH (NOTE #9)<br />

BLK<br />

RED or BLK<br />

BLU BLU<br />

RED or BLK<br />

COMP BLU CAP +t°<br />

S<br />

YEL<br />

L1<br />

BLK C<br />

H<br />

*ST<br />

208/230 1Ø L2<br />

11 21<br />

C<br />

POWER<br />

YEL<br />

R<br />

YEL BRN<br />

1 2<br />

13 23<br />

SUPPLY<br />

*SC<br />

YEL F<br />

5<br />

(NOTE #8)<br />

EQUIP CONT OFM<br />

*SR<br />

GND<br />

BRN<br />

BLK<br />

BLU<br />

BRN<br />

(NOTE #14)<br />

BLK<br />

VIO<br />

YEL<br />

*HPS<br />

*DTS<br />

*LPS<br />

T2<br />

BLU BLU BLK BLK YEL YEL LOGIC<br />

T1 T3<br />

*CTD<br />

BRN<br />

*LLS<br />

BLU<br />

BLU<br />

EQUIP<br />

GND<br />

Y<br />

BLK<br />

BLK<br />

Y G R<br />

INDOOR THERMOSTAT (NOTE #5)<br />

L1 *CH<br />

G<br />

R<br />

INDOOR THERMOSTAT<br />

SCHEMATIC DIAGRAM<br />

(LADDER FORM)<br />

IFR<br />

R<br />

C<br />

INDOOR BLOWER MOTOR<br />

CONT<br />

C R COMP<br />

11 21<br />

S<br />

*ST<br />

5 2<br />

*SC<br />

+t°<br />

1 H<br />

*SR<br />

OFM<br />

CONT<br />

C<br />

F CAP 23 13<br />

(NOTE #14)<br />

*CTD CONT<br />

*HPS *DTS *LPS<br />

T2<br />

LOGIC<br />

T1 T3<br />

*LLS<br />

IFR<br />

C<br />

R<br />

EXTERNAL POWER SUPPLY 24 V<br />

EXTERNAL POWER<br />

SUPPLY 24V<br />

(NOTES #3 & #6)<br />

L2<br />

FACTORY POWER WIRING<br />

FACTORY CONTROL WIRING<br />

FIELD CONTROL WIRING<br />

FIELD POWER WIRING<br />

COMPONENT CONNECTION<br />

FIELD SPLICE<br />

JUNCTION<br />

CONT CONTACTOR<br />

CAP CAPACITOR (DUAL RUN)<br />

*CH CRANKCASE HEATER<br />

COMP COMPRESSOR<br />

*CTD COMPRESSOR TIME DELAY<br />

*DTS DISCHARGE TEMP. SWITCH<br />

*HPS HIGH PRESSURE SWITCH<br />

IFR INDOOR FAN RELAY<br />

*LLS LIQ. LINE SOLENOID VALVE<br />

*LPS LOW PRESSURE SWITCH<br />

OFM OUTDOOR FAN MOTOR<br />

*SC START CAPACITOR<br />

*SR START RELAY<br />

*ST START THERMISTOR<br />

* MAY BE FACTORY OR FIELD<br />

INSTALLED.<br />

-LEGEND-<br />

-NOTES-<br />

1. Symbols are electrical representation only.<br />

2. Compressor and fan motor furnished with inherent thermal<br />

protection.<br />

3. To be wired in accordance with National Electric N.E.C.<br />

and local codes.<br />

4. N.E.C. class 2, 24 V circuit, min. 40 VA required, 60 VA on<br />

units installed with LLS.<br />

5. Use copper conductors only.<br />

6. Connection for typical cooling only thermostat, for other<br />

arrangements, see installation instructions.<br />

7. If indoor section has a transformer with a grounded<br />

secondary, connect the grounded side to the BRN lead.<br />

8. When start relay and start capacitor are installed, start<br />

thermistor is not used.<br />

9. CH not used on all units.<br />

10. If any of the original wire, as supplied, must be replaced,<br />

use the same or equivalent wire.<br />

11. Check all electrical connections inside control box for<br />

tightness.<br />

12. Do not attempt to operate unit until service valves have<br />

been opened.<br />

13. Do not rapid cycle compressor. Compressor must be off<br />

3 minutes to allow pressures to equalize between high<br />

and low side before starting.<br />

14. Wire not present if HPS, LPS, DTS or CTD are used.<br />

321939-101 REV. B<br />

Fig. 2—<strong>38CKB</strong>060 (30, 31) 208-230v, 1 Phase, 60 Hertz<br />

A95018<br />

2

208/230 3Ø<br />

POWER<br />

SUPPLY<br />

L2<br />

L1<br />

L3<br />

CONNECTION DIAGRAM SCHEMATIC DIAGRAM (LADDER FORM)<br />

BLU<br />

CONT<br />

BLK<br />

11 21<br />

13 23<br />

RED or BLK<br />

RED or BLK<br />

YEL<br />

*CH (NOTE #8)<br />

COMP<br />

T1 T2<br />

T3<br />

CAP<br />

YEL<br />

EQUIP<br />

GND<br />

L1<br />

CONT<br />

11 21<br />

*CH<br />

T1<br />

COMP<br />

T3<br />

T2<br />

CAP<br />

L2<br />

CONT<br />

L3<br />

ALERT !<br />

SEE NOTE #11<br />

BLU<br />

Y<br />

BLU<br />

BLK<br />

G<br />

EQUIP GND<br />

*LLS<br />

*HPS<br />

R<br />

BLK<br />

BLU<br />

IFR<br />

BLK<br />

BRN<br />

*LPS<br />

YEL<br />

OFM<br />

YEL<br />

C<br />

R<br />

BLK<br />

BRN<br />

BRN<br />

YEL<br />

VIO<br />

T2<br />

LOGIC<br />

T1<br />

T3<br />

CTD<br />

EXTERNAL<br />

POWER<br />

SUPPLY<br />

24 V<br />

(NOTES #3 & #6)<br />

Y<br />

G<br />

R<br />

INDOOR<br />

THERMOSTAT<br />

*HPS<br />

OFM<br />

23 13<br />

CONT<br />

*LPS<br />

T2<br />

LOGIC<br />

T1 T3<br />

*LLS<br />

CTD<br />

IFR<br />

R C<br />

EXTERNAL POWER SUPPLY 24 V<br />

-LEGEND-<br />

CONT<br />

CAP<br />

INDOOR THERMOSTAT<br />

(NOTE #5)<br />

FACTORY POWER WIRING<br />

FACTORY CONTROL WIRING<br />

FIELD CONTROL WIRING<br />

FIELD POWER WIRING<br />

COMPONENT CONNECTION<br />

FIELD SPLICE<br />

JUNCTION<br />

CONTACTOR<br />

CAPACITOR (DUAL RUN)<br />

INDOOR BLOWER MOTOR<br />

*CH CRANKCASE HEATER<br />

COMP COMPRESSOR<br />

*CTD COMPRESSOR TIME DELAY<br />

IDF INDOOR FAN<br />

*HPS HIGH PRESSURE SWITCH<br />

IFR INDOOR FAN RELAY<br />

*LLS LIQ. LINE SOLENOID VALVE<br />

*LPS LOW PRESSURE SWITCH<br />

OFM OUTDOOR FAN MOTOR<br />

* MAY BE FACTORY OR FIELD INSTALLED.<br />

-NOTES-<br />

CAUTION<br />

1. Symbols are electrical representation only.<br />

2. Compressor and fan motor furnished with inherent 1. Compressor damage may occur if system is over<br />

thermal protection.<br />

charged.<br />

3. To be wired in accordance with National Electric 2. This unit is factory charged with R-22 in<br />

N.E.C. and local codes.<br />

4. N.E.C. class 2, 24 V circuit, min. 40 VA required, accordance with the amount shown on the rating<br />

60 VA on units installed with lls.<br />

plate. The charge is adequate for most systems<br />

5. Use copper conductors only.<br />

using matched coils and tubing not over 15 feet<br />

6. Typical cooling only thermostat, for other<br />

arrangements see installation instructions.<br />

long. The best performance will be achieved when<br />

7. If indoor section has a transformer with a grounded the unit operates with a suction gas superheat at<br />

secondary, connect the grounded side to the BRN lead. the compressor inlet of 5 °F at normal rating<br />

8. If any of the original wire, as supplied must be<br />

replaced, use the same or equivalent wire.<br />

conditions of the air conditioning and<br />

9. Check all electrical connections inside control box refrigeration institute (ARI). This chart may be<br />

for tightness.<br />

used to approximate the charge if ARI rating<br />

10. Do not attempt to operate unit until service valves conditions cannot be obtained. ARI rating<br />

have been opened.<br />

11. Do not rapid cycle compressor. Compressor must conditions are equivalent to DOE test "A"<br />

be off 3 minutes to allow pressures to equalize<br />

conditions. See product data literature for required<br />

between high and low side before starting.<br />

indoor air flow rates and for use of line lengths<br />

12. It is imperative to connect 3Ø field power to unit with<br />

correct phasing. wrong phasing will cause reverse over 15 Ft.<br />

rotation of scroll compressor which will result in 3. Carefully relieve refrigerant pressure within this<br />

reduced current draw, elevated noise level and<br />

unit before final disposal.<br />

improper operation. If rotation is reversed, simply<br />

interchange any two of the three power connections<br />

on field side.<br />

319390-401 REV.C<br />

Fig. 3—<strong>38CKB</strong>030 (50, 51), 036 (50, 52, 60, 62), 042 (50, 51, 61),<br />

048 (50, 51, 60, 61), 060 (50, 51, 60, 61) 208/230v and 460v, 3 Phase, 60 Hertz<br />

A94414<br />

3

Copyright 1996 CARRIER Corp. • 7310 W. Morris St. • Indianapolis, IN 46231<br />

38ckb4w<br />

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.<br />

Book 1 4 PC 101 Catalog No. 533-841 Printed in U.S.A. Form <strong>38CKB</strong>-4W Pg 4 2-96 Replaces: New<br />

Tab 2a 3a