UNIVERSITY OF KERALA

UNIVERSITY OF KERALA

UNIVERSITY OF KERALA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

(ii)<br />

(iii)<br />

(iv)<br />

(v)<br />

(vi)<br />

(vii)<br />

(viii)<br />

(ix)<br />

(x)<br />

(xi)<br />

Determination of alcohol (ethanol) percentage of wine by Ebulliometry.<br />

Estimation of Total/free SO 2 in wine / juice / must by Ripper titrimetric method.<br />

Protein stability test / Heat stability test of wine<br />

Lab scale and pilot scale production of wine from different fruits.<br />

Tartarate and bitartrate stability test / Cold stability test of wine.<br />

Determination of Acetaldehyde content, phenol content of wine by titrimetric method.<br />

Sensory analysis of hydrogen sulphide and Mercaptans in wine.<br />

Methanol estimation/ alcohol estimation by specific gravity method.<br />

Estimation of reducing and total sugar by copper reduction technique.<br />

Determination of total tannin content by visible spectrometry.<br />

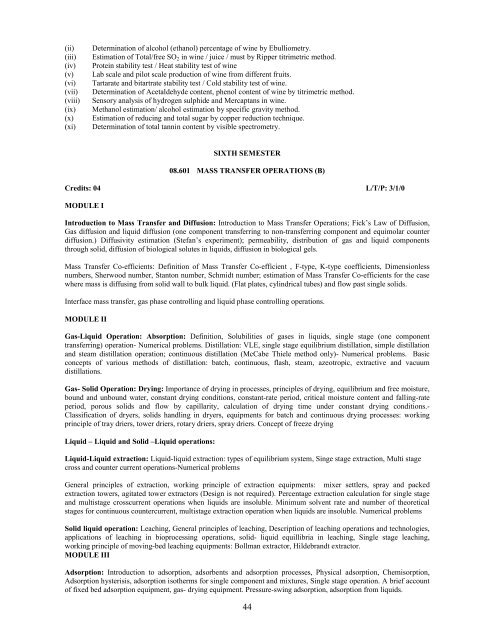

SIXTH SEMESTER<br />

08.601 MASS TRANSFER OPERATIONS (B)<br />

Credits: 04 L/T/P: 3/1/0<br />

MODULE I<br />

Introduction to Mass Transfer and Diffusion: Introduction to Mass Transfer Operations; Fick’s Law of Diffusion,<br />

Gas diffusion and liquid diffusion (one component transferring to non-transferring component and equimolar counter<br />

diffusion.) Diffusivity estimation (Stefan’s experiment); permeability, distribution of gas and liquid components<br />

through solid, diffusion of biological solutes in liquids, diffusion in biological gels.<br />

Mass Transfer Co-efficients: Definition of Mass Transfer Co-efficient , F-type, K-type coefficients, Dimensionless<br />

numbers, Sherwood number, Stanton number, Schmidt number; estimation of Mass Transfer Co-efficients for the case<br />

where mass is diffusing from solid wall to bulk liquid. (Flat plates, cylindrical tubes) and flow past single solids.<br />

Interface mass transfer, gas phase controlling and liquid phase controlling operations.<br />

MODULE II<br />

Gas-Liquid Operation: Absorption: Definition, Solubilities of gases in liquids, single stage (one component<br />

transferring) operation- Numerical problems. Distillation: VLE, single stage equilibrium distillation, simple distillation<br />

and steam distillation operation; continuous distillation (McCabe Thiele method only)- Numerical problems. Basic<br />

concepts of various methods of distillation: batch, continuous, flash, steam, azeotropic, extractive and vacuum<br />

distillations.<br />

Gas- Solid Operation: Drying: Importance of drying in processes, principles of drying, equilibrium and free moisture,<br />

bound and unbound water, constant drying conditions, constant-rate period, critical moisture content and falling-rate<br />

period, porous solids and flow by capillarity, calculation of drying time under constant drying conditions.-<br />

Classification of dryers, solids handling in dryers, equipments for batch and continuous drying processes: working<br />

principle of tray driers, tower driers, rotary driers, spray driers. Concept of freeze drying<br />

Liquid – Liquid and Solid –Liquid operations:<br />

Liquid-Liquid extraction: Liquid-liquid extraction: types of equilibrium system, Singe stage extraction, Multi stage<br />

cross and counter current operations-Numerical problems<br />

General principles of extraction, working principle of extraction equipments: mixer settlers, spray and packed<br />

extraction towers, agitated tower extractors (Design is not required). Percentage extraction calculation for single stage<br />

and multistage crosscurrent operations when liquids are insoluble. Minimum solvent rate and number of theoretical<br />

stages for continuous countercurrent, multistage extraction operation when liquids are insoluble. Numerical problems<br />

Solid liquid operation: Leaching, General principles of leaching, Description of leaching operations and technologies,<br />

applications of leaching in bioprocessing operations, solid- liquid equillibria in leaching, Single stage leaching,<br />

working principle of moving-bed leaching equipments: Bollman extractor, Hildebrandt extractor.<br />

MODULE III<br />

Adsorption: Introduction to adsorption, adsorbents and adsorption processes, Physical adsorption, Chemisorption,<br />

Adsorption hysterisis, adsorption isotherms for single component and mixtures, Single stage operation. A brief account<br />

of fixed bed adsorption equipment, gas- drying equipment. Pressure-swing adsorption, adsorption from liquids.<br />

44