FLAIL MOWERS - MULCHERS - SaMASZ Sp. z oo

FLAIL MOWERS - MULCHERS - SaMASZ Sp. z oo

FLAIL MOWERS - MULCHERS - SaMASZ Sp. z oo

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

FOR PROFESSIONALS<br />

<strong>FLAIL</strong> <strong>MOWERS</strong> - <strong>MULCHERS</strong><br />

REAR, FRONT AND SIDE<br />

EXTENSION ARMS AND FITTINGS

TYPES OF <strong>FLAIL</strong> KNIVES<br />

STANDARD<br />

~ 1kg<br />

<strong>FLAIL</strong> <strong>MOWERS</strong><br />

GENERAL DATA<br />

TYPE I Flail knives are heavy (1kg) and<br />

durable. The most frequently used type<br />

TABLE OF CONTENTS:<br />

<strong>FLAIL</strong> <strong>MOWERS</strong><br />

GENERAL DATA<br />

p. 3<br />

of flails in Poland.<br />

OPTION<br />

The <strong>SaMASZ</strong> company offers a very wide variety of flail mowers.<br />

This includes rear, front and side type with tilt adjustment as well as arm-type machines.<br />

KB - REAR AND FRONT<br />

MIDDLE CLASS<br />

p. 4 - 5<br />

TYPE III Knives - designed<br />

for mulching trees<br />

and shrubs.<br />

Flail Mowers - Mulchers are designed for works related<br />

to maintenance of municipal infrastructure,<br />

urban greenery and orchards. Machines of this<br />

wing road shoulders, ditches, as well as slopes and<br />

counter-slopes. Mulchers are designed for mowing<br />

grass, shredding it into pieces and then spreading<br />

KB - REAR AND FRONT<br />

HEAVY DUTY<br />

p. 6 - 7<br />

TYPE IV Knives - designed<br />

for mowing grass,<br />

hay, corn stalks, tobacco<br />

and for gleaning.<br />

type are used for mowing grass, shrubs, bushes<br />

(up to 10 cm) and cutting weeds on uncultivated<br />

areas to leave windrows. Particularly useful in mo<br />

the material all over the mowed area. This enables<br />

obtaining a natural windrow, mineralisation of<br />

floral remains and re-introducing them to the soil.<br />

KBK - REAR (WITH p. 8<br />

DAMPER)<br />

AGRICULTURAL HEAVY DUTY<br />

KBR - REAR AND SIDE<br />

MIDDLE CLASS<br />

KBRP - REAR SIDE ON<br />

PANTOGRAPH<br />

HEAVY DUTY<br />

KWT - EXTENSION ARM<br />

REAR + EQUIPMENT<br />

p. 9<br />

p. 10 - 11<br />

p. 12 - 13<br />

KNIVES APPLIED IN LAMA<br />

STANDARD<br />

Steel sheet knives<br />

These knives are well proven in mowing<br />

well-maintained road shoulders, feature<br />

high wear strength, owing to application<br />

of hardened steel, and their low overall<br />

weight leaves cutterbar bearings minimally<br />

loaded and in result head overall<br />

durability is improved.<br />

0. 14 kg<br />

LIGHT CLASS -„LAMA”<br />

MIDDLE CLASS<br />

<strong>FLAIL</strong> <strong>MOWERS</strong> - <strong>MULCHERS</strong><br />

ϕ 168<br />

ϕ 133<br />

ϕ 108<br />

1. Drive shaft with diameter - ϕ 108 mm<br />

2. Mulching shrubs and bushes (up to ϕ 8 cm)<br />

3. Ground following bar with diameter - ϕ 133 mm<br />

4. Fair operating conditions<br />

HEAVY DUTY<br />

ϕ 168<br />

ϕ 168<br />

CAMEL 900<br />

EXTENSION ARM<br />

REAR + EQUIPMENT<br />

KOLIBER 400<br />

EXTENSION ARM<br />

REAR + EQUIPMENT<br />

MOWING HEADS<br />

Lama and KW<br />

p. 14 - 15<br />

p. 16 - 17<br />

p. 18<br />

OPTION<br />

„Mini-hammer” knives<br />

Thanks to their bigger weight and<br />

strenghtened construction these knives<br />

are well proven in mowing neglected<br />

road shoulders, are resistant to stones,<br />

andthanks to application of hardened<br />

steel they last longer.<br />

Both knife types are installed in special<br />

holders, thanks to which forces transmitted<br />

onto flail-bar are lower if potentially<br />

hit by a stone, therefore durability of bar<br />

bearings and the whole machine is improved.<br />

1. Drive shaft with diameter - ϕ 133 mm<br />

2. Mulching shrubs and bushes (up to ϕ 8 cm)<br />

3. Ground following bar with diameter - ϕ 168 mm<br />

4. Fairly difficult operating conditions<br />

ϕ 133<br />

1. Drive shaft with increased diameter -<br />

ϕ 168 mm<br />

2. Mulching shrubs and bushes (up to ϕ 10 cm)<br />

3. Ground following bar with diameter - ϕ 168 mm<br />

4. Very difficult operating conditions<br />

5. Sliding skids and internal cover made of Hardox<br />

steel<br />

6. Bars resistant to deflections<br />

OPERATING FITTINGS<br />

p. 19<br />

0.3 kg<br />

7. Higher durability of thick-walled drive shaft and<br />

ground folowing bar<br />

2 3

<strong>FLAIL</strong> <strong>MOWERS</strong><br />

REAR AND FRONT<br />

MIDDLE CLASS<br />

KB 110<br />

KB 140<br />

KB 160<br />

Perfect for<br />

municipal<br />

works<br />

KB Middle Class Mowers are<br />

perfect for mowing uncultivated<br />

areas, paths in orchards,<br />

cutting weeds, shrubs and<br />

grass on uncultivated areas.<br />

Durable housing and inclined<br />

rubber shield enable safe<br />

mowing nearby roads, parks<br />

2<br />

and other traffic congested<br />

living areas.<br />

4<br />

1. Drive transmission<br />

through belt gear acts as an<br />

3<br />

1<br />

overload clutch<br />

Option with hydraulic shift within up<br />

to 40 cm - for charge.<br />

2. To prepare mower to operate on<br />

tractor’s front re-mount linkage hitch onto<br />

the other side of the mower. If tractor has<br />

leftward gear then operator can modify it by dismounting<br />

central gear and turning it by 180°<br />

3. Mower is manually adjustable in relation to either tractor’s left<br />

or right. Telescopic link is mounted as standard<br />

Designation:<br />

1. Mulching shrubs and bushes (up to ϕ 8 cm),<br />

2. Mowing weeds and grasses on uncultivated areas<br />

- fairly difficult operating conditions.<br />

Advantages:<br />

1. Properly suited flail weight (1kg) as well as precise<br />

mounting and bolt arrangement on bar improve<br />

mower operating efficiency in difficult conditions,<br />

2. Mounting on tractor’s either fron or rear 3-point<br />

linkage,<br />

3. Simple flail replacement,<br />

4. Perfect ground following for even mowing<br />

height,<br />

5. Silent cutterbar,<br />

6. Top quality protective chains at the front and<br />

rubber shield at the back provide more accurate<br />

protection against thrown stones,<br />

7. PTO shaft with overruning clutch as standard,<br />

8. Mowing height adjustment from 3 to 8 cm thanks<br />

to ground following bar,<br />

9. Strenghtened housing and flail bar bearings,<br />

10. Easily replacable skids made of HARDOX steel,<br />

11. Additional internal and external strenghtening<br />

of housing with hardened HARDOX steel.<br />

4. New stronger housing and barrel bearing are additionally protected against<br />

external damages<br />

Type<br />

Operating<br />

width<br />

[m]<br />

Operating<br />

output<br />

[ha/h]<br />

Knives<br />

[pcs.]<br />

KB 110 1,10 ~ 0,50 10<br />

V-belts<br />

Cutterbar<br />

diameter<br />

[mm]<br />

Tractor<br />

power<br />

[HP]*<br />

PTO<br />

[rpm]<br />

3-point<br />

linkage<br />

Cat.<br />

Measurements<br />

w / l / h<br />

[cm]<br />

KB 140 1,40 ~ 0,60 12 4 ϕ 133 40 540 I-II 171 / 104 / 70 465<br />

20<br />

Weight<br />

[kg]<br />

141 / 109 / 70 325<br />

KB 160 1,60 ~ 1,00 14 60 191 / 104 / 70 500<br />

* Note! Power values apply only to municipal works - few mowing occasions per year.<br />

** If KB 140 or KB 160 mowers are ordered for tractor’s front then gear 1000 rpm should be ordered as well.<br />

4 5

<strong>FLAIL</strong> <strong>MOWERS</strong><br />

REAR AND FRONT<br />

HEAVY DUTY<br />

KB 182<br />

KB 202<br />

KB 252<br />

Solid,<br />

durable<br />

construction<br />

KB heavy duty mowers<br />

have new drive shafts with<br />

increased diameter ϕ 168<br />

applied, owing to which<br />

overall durability of the<br />

sub-assembly is improved.<br />

What is more, this modification<br />

enables mulching<br />

bushes and branches with<br />

diameter of up to 10 cm.<br />

4<br />

3<br />

1<br />

2<br />

ϕ 168<br />

KB heavy<br />

duty mowers<br />

have also increased<br />

diameter and thickness<br />

of flail bar. Solid and thick-<br />

-walled shaft onto which heavy flails<br />

(1kg) with bolt arrangement are mounted operates<br />

efficiently in difficult conditions.<br />

Designation:<br />

1. Mulching shrubs and bushes (up to ϕ 10 cm),<br />

2. Mowing weeds and grass on uncultivated areas.<br />

Perfect in difficult operating conditions.<br />

Advantages:<br />

1. Solid, thick-walled shaft with cutting knives (flails)<br />

for operation in difficult conditions,<br />

2. Mouting with use of 3-point linkage either on<br />

tractor’s front or rear,<br />

3. Hydraulic shift of cutterbar in relation to tractor’s<br />

axis,<br />

4. Internal shield of cutterbar made of HARDOX<br />

steel,<br />

5. Solid and durable construction,<br />

6. Drive transmission through belt gear acts as as<br />

overload clutch,<br />

7. PTO shaft with overrunning clutch as standard,<br />

8. Operating height adjustment from 3 to 8 cm<br />

thanks to ground following bar,<br />

9. Strengthened housing and flail bar bearings located<br />

inside to protect them against damage,<br />

10. Easily replaceable skids made of HARDOX steel,<br />

11. Simple flail replacement,<br />

12. Perfect ground folowing for even mowing<br />

height,<br />

13. Top quality protective chains at the front and<br />

rubber shield at the back provide more accurate<br />

protection against thrown stones,<br />

14. Modification of mower’s operating position<br />

from rear to front upon re-installation of upper<br />

link mounted on two pins,<br />

15. Thick-walled drive and ground following shafts<br />

for higher durability.<br />

1. Shift is possible thanks to hydraulic<br />

cylinder. Hydraulics enables position modification<br />

through shifting of operating assembly over guides<br />

2. Innovative construction of frame and cutterbar make up compacted<br />

and solid construction, which enables quick modification of position from rear<br />

to front<br />

3. Linkage with cutterbar suspended on tube guides<br />

4. Construction of rear and front type flail mowers enables operation on both tractor’s front or rear<br />

Type<br />

Operating<br />

width<br />

[m]<br />

Operating<br />

output<br />

[ha/h]<br />

KB 182 1,80 ~ 1.30<br />

Knives<br />

[pcs.]<br />

16<br />

Cutterbar<br />

diameter<br />

[mm]<br />

Tractor<br />

power<br />

[HP]*<br />

PTO<br />

[rpm]<br />

3-point linkage<br />

hitch<br />

Cat.<br />

Dimensions<br />

w / l / h<br />

[cm]<br />

KB 202 2,00 ~ 1.60 ϕ 168 80 1000 II 242 / 104 / 70 715<br />

70<br />

Weight<br />

[kg]<br />

215 / 104 / 70 700<br />

KB 252 2,50 ~ 2.20 20 90 290 / 104 / 70 840<br />

* Note! Power values apply only to municipal works - few mowing occasions per year.<br />

6 7

<strong>FLAIL</strong> <strong>MOWERS</strong><br />

REAR (WITH DAMPER) -<br />

AGRICULTURAL<br />

HEAVY DUTY<br />

KBK 181<br />

KBK 201<br />

KBK 251<br />

<strong>FLAIL</strong> <strong>MOWERS</strong><br />

REAR SIDE<br />

MIDDLE CLASS<br />

KBR 140<br />

KBR 160<br />

KBK mowers with operating widths of<br />

1.80 m, 2.00 m and 2.50 m have been<br />

designed particularly for agricultural<br />

works. KBK mowers have gone through<br />

numerous modifications, which<br />

resulted in extending their lifespan.<br />

KBR mowers are machines mounted<br />

on tractor’s rear 3-point linkage.<br />

They are perfect for mowing<br />

road shoulders, ditches, slopes,<br />

greenery belts (inclination up to<br />

-65°, +90°). Strong, thick-walled<br />

shaft with cutting knives (flails), allows the ma-<br />

Designation and advantages:<br />

Designation:<br />

1. KBK mowers are perfect for corn, grain, tobacco<br />

stubbles, etc.<br />

2. Mulching corn stubble is an effecting way to<br />

fight European Corn Borer, which endangers corn<br />

plantations more frequently than ever<br />

KBK mowers have been equipped with an outlet<br />

damper, which enables free windrow distribution<br />

outside the machine, what in result reduces<br />

tractor’s power consumption.<br />

Advantages:<br />

1. Outlet damper,<br />

2. Strenghtened linkage designed for operation<br />

under heavy loads,<br />

3. Mulcher’s housing comprises two shields - the<br />

inner made of HARDOX steel,<br />

4. Strenghtened flail shaft - thick wall tube with<br />

diameter - ϕ 168 applied to extend the shaft’s<br />

lifespan,<br />

5. Solid and well bedded bearings of flail shaft<br />

applied,<br />

6. Perfect ground following for optimal mowing<br />

quality,<br />

7. High quality flail knives,<br />

8. Top quality protective chains,<br />

9. Quick flail replacement,<br />

10. Drive transmission through belt gear acts as<br />

overload clutch,<br />

11. PTO shaft with overrunning clutch as standard,<br />

12. Possibility of mounting hydraulic cylinder for<br />

cutterbar shifting.<br />

chine to operate in difficult conditions (mulching<br />

shrubs and bushes up to 8 cm diameter).<br />

The mower is<br />

protected against<br />

damage in<br />

case of driving<br />

onto an obstacle<br />

by hydraulic<br />

safety device,<br />

which forces its<br />

retraction and at<br />

the same time<br />

lifts the machine up even up to 50 cm thanks to hydraulic<br />

cylinder. Upon passing by an obstacle the mower automatically<br />

returns to its operating position - no operator’s<br />

action required.<br />

1. Mowing weeds, grass and mulching shrubs and<br />

bushes on uncultivated areas,<br />

2. Hydraulic safety device as standard,<br />

3. Adjustable mowing height from 3 to 8 cm with<br />

use of ground following bar,<br />

4. Hydraulic cylinder as standard,<br />

5. Double shield of cutterbar where the inner is<br />

made of HARDOX steel,<br />

6. Drive transmission through belt gear acts as<br />

overload clutch,<br />

7. Adjustable pins enable machine shift either right<br />

or left in relation to tractor,<br />

8. Overrunning clutch mounted between flail bar<br />

and angular gear as standard,<br />

9. PTO shaft with overrunning clutch as standard,<br />

10. Solid housing and flail bar bearings.<br />

90°<br />

65°<br />

KBR mowers are machines<br />

which feature:<br />

Durability, versatility and<br />

high operating output.<br />

Perfect for mowing slopes<br />

(inclination up to<br />

-65°, +90°).<br />

Type<br />

Operating<br />

width<br />

[m]<br />

Operating<br />

output<br />

[ha/h]<br />

Knives<br />

[pcs.]<br />

Cutterbar<br />

diameter<br />

[mm]<br />

Tractor<br />

power<br />

[HP]*<br />

PTO<br />

[rpm]<br />

3-point linkage<br />

hitch<br />

Cat.<br />

Dimensions<br />

w / l / h<br />

[cm]<br />

KBK 181 1,80 ~ 1.30<br />

70<br />

216 / 136 / 70 625<br />

16<br />

KBK 201 2,00 ~ 1.60 ϕ 168 80 1000 II 230 / 136 / 70 645<br />

KBK 251 2,50 ~ 2.20 20 90 285 / 136 / 70 770<br />

Weight<br />

[kg]<br />

Type<br />

Operating<br />

width<br />

[m]<br />

Operating<br />

output<br />

[ha/h]<br />

Knives<br />

[pcs.]<br />

KBR 140 1,40 ~ 0.60 12<br />

Cutterbar<br />

diameter<br />

[mm]<br />

ϕ 133<br />

Tractor power<br />

[HP]*<br />

50<br />

PTO<br />

[rpm]<br />

Linkage<br />

hitch<br />

Cat.<br />

Length<br />

[cm]<br />

540 II 150<br />

KBR 160 1,60 ~ 1.00 14 70 705<br />

Weight<br />

[kg]<br />

670<br />

* Note! Power values apply only to municipal works - few mowing occasions per year.<br />

* Note! Power values apply only to municipal works - few mowing occasions per year.<br />

8 9

<strong>FLAIL</strong> <strong>MOWERS</strong><br />

REAR SIDE<br />

ON PANTOGRAPH<br />

HEAVY DUTY<br />

KBRP 160<br />

KBRP 200<br />

For mowing<br />

in difficult<br />

conditions<br />

KBRP rear side type<br />

mowers on pantograph<br />

90°<br />

KBRP mowers are machines mounted<br />

on tractor’s rear. These machi-<br />

complement our offer of<br />

nes are perfect for mowing road<br />

heavy duty machines de-<br />

shoulders, slopes, green division<br />

signed for maintenance of<br />

belts (incination up to -60°; +90°).<br />

green areas and roads. The-<br />

Mowers equipped with type I kni-<br />

se are machines which meet<br />

ves are able to shred trunks with<br />

demands of both agricultural<br />

E<br />

diameter even up to 10 cm.<br />

as well as municipal services.<br />

60°<br />

High manufacture quality and<br />

unbelivable durability of components<br />

guarantee reliable operation<br />

even with load exceeding<br />

1,500 manhour anually.<br />

Downward tilt may reach even 60°.<br />

Choke valve (see magnification) on<br />

cylinder enables sm<strong>oo</strong>th adjustment<br />

of machine’s position.<br />

KBRP mowers have two mechanical safety devices:<br />

1. Enabling lifting of cutterbar when driving over<br />

an obstacle<br />

2. Retracting cutterbar when driving onto an obstacle<br />

A<br />

KBRP with extension arm applied,<br />

thanks to wide range of shifting<br />

(172 cm), enables operation as either<br />

rear or side type mower.<br />

Operating range of KBRP mowers [cm]<br />

Type A B C D E<br />

Designation:<br />

1. Mulching shrubs and bushes (up to ϕ 10 cm)<br />

2. Mowing slopes, embankment, ditches and channels<br />

Advantages:<br />

1. These mowers feature wide range of operation<br />

in horizontal (up to 170 cm), which enables passing<br />

by obstacles (e.g. road signs) with no need of changing<br />

tractor’s trajectory,<br />

2. Possibility of mounting on both tractor’s side as<br />

well as its rear,<br />

3. New cutterbar of thick-walled tube with diameter<br />

ϕ 168 mm,<br />

4. Mechanical safety device as standard,<br />

5. High quality flail knives,<br />

6. New shaft bearing bedding – bigger bearings located<br />

inside linkage frame to protects them against<br />

mechanical damages,<br />

7. Hydraulic control as standard,<br />

8. Possibility of mowing surfaces with inclination<br />

of + 90°- 60°,<br />

9. Internal shield of cutterbar is made of HARDOX<br />

steel - improved lifespan and wear protection,<br />

10. Owing to use of pantograph it is perfect for<br />

heavy duty works,<br />

11. Mower is mounted on standard tractor’s 3-point<br />

linkage,<br />

12. Perfect ground following for optimal mowing<br />

quality,<br />

13. Solid wide-angle PTO shaft with overrunning<br />

clutch.<br />

Type<br />

B<br />

Operating<br />

width<br />

[m]<br />

Operating<br />

output<br />

[ha/h]<br />

KBRP 160 1,60 ~ 1.00<br />

KBRP 160 205 52 289 160 140<br />

KBRP 200 205 52 329 200 180<br />

KBRP Mulchers on pantograph meet standards of both municpal service<br />

companies as well as individual farmers offering services of mowing<br />

road shoulders, slopes, embankments, ditches and water channels.<br />

Mowers have new, more powerful flail bar bearings assembly applied.<br />

Bearings are placed inside lnkage frame, which protects them against<br />

mechanical damage.<br />

C<br />

D<br />

Hedge<br />

trimming<br />

Road<br />

shoulder<br />

mowing<br />

0÷90° 0÷60°<br />

Knives<br />

[pcs.]<br />

14<br />

Cutterbar<br />

diameter<br />

[mm]<br />

ϕ 168<br />

Tractor<br />

power<br />

[HP]*<br />

from 70<br />

PTO<br />

[rpm]<br />

Linkage<br />

hitch Cat.<br />

540 II<br />

KBRP 200 2,00 ~ 1.60 16 from 80 825<br />

* Note! Power values apply only to municipal works - few mowing occasions per year.<br />

Weight<br />

[kg]<br />

760<br />

10 11

EXTENSION<br />

ARM<br />

REAR<br />

KWT 550<br />

KWT 650<br />

KWT 650/KW 140<br />

For<br />

hard to<br />

reach<br />

locations<br />

1<br />

2<br />

3<br />

4<br />

KWT Extension arm<br />

is available in two versions -<br />

with range of 5.5 m and 6.5 m,<br />

and is mounted on tractor’s rear<br />

3-point linkage Cat. II. On contrast<br />

to KWT 550, KWT 650 has<br />

hydrauliacly extended fly jib of<br />

telescopic arm. Extension arm<br />

is equipped with branded independent<br />

hydraulics and c<strong>oo</strong>ler<br />

with 150-liter oil tank.<br />

Advantages:<br />

1. Quick operating fitting replacement,<br />

2. Own reliable hydraulics,<br />

3. Mounting on tractor’s standard 3- point linkage Cat. II,<br />

4. Hydraulic safety device as standard,<br />

5. Application of choke valves enables sm<strong>oo</strong>th and precise adjustment<br />

of operating arm speed,<br />

6. Strenghtened construction of arms and links made of hard steel,<br />

7. Integrated temperature and oil gauges,<br />

8. Wide range of operation up to 6.65 m ( KWT 650 with KW 140 head).<br />

1 2 3<br />

B<br />

Range of operation of KWT arm with mowing head [cm]<br />

E<br />

Head A B C D E F G<br />

550/110 570 440 340 110 640 290 190<br />

D<br />

550/125 570 450 340 130 640 290 190<br />

F<br />

550/140 580 450 350 150 650 290 190<br />

550/Lama 120 580 450 350 120 650 290 190<br />

Hydraulic pump - hydraulic engine<br />

assembly has oil c<strong>oo</strong>ler<br />

installed to protect hydraulics<br />

from overaheating.<br />

Oil filters with integral impurity<br />

gauge, installed in hydraulics<br />

protect engine against damage.<br />

Hydraulic safety device protects<br />

machine against damage - in<br />

the event of driving onto an obstacle<br />

extension arm is retracted.<br />

G<br />

C<br />

650/110 650 530 430 110 720 300 190<br />

650/125 660 530 430 130 720 300 190<br />

650/140 675 540 440 150 730 300 190<br />

650/Lama 120 670 540 440 150 730 300 190<br />

4<br />

A<br />

Type<br />

Operating range<br />

of arm<br />

[m]<br />

Tractor’s weight<br />

[kg]<br />

PTO rpm<br />

[rpm]*<br />

Control<br />

Transport<br />

width/height/length<br />

[m]<br />

Weight [kg]<br />

KWT 550/KW 110 5,70 4 000<br />

1 320<br />

KWT 650/KW 110 6,50 5 000 1 400<br />

Additional valve on lifting cylinder<br />

protects the arm from ssible owing to link control pa-<br />

electric control is possible.<br />

As standard, arm control is po-<br />

As an option, installation of<br />

540 link 2,00 / 3,50 / 0,88<br />

KWT 550/Lama 120 5,80 3 700 1 250<br />

falling even if hydraulic hose is nel from tractor’s cabin equipped<br />

with a handle and a joystick.<br />

KWT 650/Lama 120 6,70 4 000 1 320<br />

broken.<br />

* As an option: PTO 1,000 rpm and electric control on order<br />

12 13

EXTENSION<br />

ARMS<br />

REAR<br />

INNOVATION!<br />

CAMEL 900<br />

9-METER REACH<br />

Wide range<br />

of operation<br />

CAMEL 900 + Lama 120<br />

Camel Extension arm with 9-meter reach is the biggest machine of this type the <strong>SaMASZ</strong> company has<br />

to offer. The machine has hydraulically extended fly jib of telescopic arm. Extension arm is equipped with<br />

branded indpendent hydraulics and c<strong>oo</strong>ler with 150-liter oil tank.<br />

Reach [cm]<br />

A 900<br />

B 690<br />

C 660<br />

D 120<br />

E 960<br />

Operating reach of CAMEL 900<br />

extension arm with LAMA 120 [cm]<br />

mowing head<br />

Standard equipment:<br />

• Hydraulic safety device<br />

• 3-point linkage strengthening links<br />

• Temperature and oil gauges<br />

• Control panel with link control<br />

• Road lights<br />

F 520<br />

Optional equipment:<br />

• Control panel with electric control<br />

Transport positions:<br />

Advantages:<br />

• Wide range of operation up to 9 m<br />

(Lama 120 head)<br />

• Own reliable hydraulics<br />

• Soild arm and link construction<br />

• Sm<strong>oo</strong>th and precise adjustment<br />

of operating arm speed, owing to<br />

choke valves<br />

• As standard, 3-point linkage<br />

strengthening links<br />

Machine type<br />

Operating<br />

reach<br />

[m]<br />

Control<br />

PTO rpm*<br />

[rpm]<br />

Min. tractor’s<br />

weight<br />

[kg]<br />

Transport<br />

width<br />

[m]<br />

Transport<br />

height<br />

[m]<br />

Weight<br />

[kg]<br />

Camel 900 9,00 link 540 5 500 2,25 4,00 1 370<br />

* As an option: PTO 1,000 rpm and electric control on order<br />

14 15

EXTENSION<br />

ARMS<br />

REAR<br />

INNOVATION!<br />

KOLIBER 400<br />

4-METER REACH<br />

Light,<br />

small,<br />

popular !<br />

KOLIBER 400 + Lama 120<br />

Advantages:<br />

1. Low machine’s weight enables extension arm to be<br />

mounted on a light tractor,<br />

2. Innovative construction,<br />

3. High mounted main b<strong>oo</strong>m enables safe drive over<br />

mileage poles.<br />

Operating reach of KOLIBER 400 extension arm with<br />

LAMA 120 [cm] mowing head<br />

A B C D E F<br />

410 310 270 120 455 220<br />

Standard equipment:<br />

• Hydraulic latch on main cylinder<br />

• Drive-on mechanical safety device<br />

• 3-point linkage strenghtening links<br />

• Temperature and oil gauges<br />

• Control panel with link control<br />

• 120-liter oil tank<br />

• Oil c<strong>oo</strong>ler<br />

• Road lights<br />

Hydraulic latch on main cylinder<br />

along with adjustable choke valve.<br />

Optional equipment:<br />

• Control panel with electric control<br />

Feeding hydraulic assembly Transport position - visible<br />

Koliber 400 4,00 55 link 540 2 400 2,30 2,60 530<br />

and distributor - solid and efficient.<br />

rear bumper with lights.<br />

* As an option: PTO 1,000 rpm and electric control on order<br />

16 17<br />

Machine<br />

type<br />

Operating<br />

reach of arm<br />

[m]<br />

Tractor<br />

power<br />

[HP]<br />

Control<br />

PTO rpm*<br />

[rpm]<br />

Min. tractor’s<br />

weight<br />

[kg]<br />

Transport<br />

width<br />

[m]<br />

Transport<br />

height<br />

[m]<br />

Weight<br />

[kg]

MOWING HEADS<br />

LAMA 120<br />

LAMA 140<br />

KW 110<br />

KW 125<br />

KW 140<br />

OPERATING<br />

FITTINGS<br />

Mowing head is designed for grass trimming. It features low weight to considerably improve operation<br />

comfort.<br />

Quick and simple replacement of mowing heads - operating fittings! All you have to do is to unscrew 6<br />

bolts and screw them back again.<br />

DITCH SLUDGER - OR 080<br />

Designed for cleaning ditches of sludge,<br />

plants and blanket sand.<br />

Type OR 080<br />

Operating width [max] 80 cm<br />

Knives 8<br />

Required pump output 80-100 l/min<br />

Hydraulic pressure<br />

Drive and control<br />

210 bar<br />

hydraulic<br />

Weight [kg] 230<br />

Lama 120 Koliber 400 / Lama 120<br />

SCISSOR-TYPE TRIMMER - PG 150 PG 200<br />

Perfect for both vertical and horizontal<br />

trimming of branches, bushes and hedges.<br />

Type PG 150 PG 200<br />

Operating width [m] 1,50 2,00<br />

Thickness of cut branches<br />

max [mm]<br />

Required pump output<br />

[L/min]<br />

100 100<br />

45-60 45-60<br />

Hydraulic pressure<br />

160 bar<br />

Weight [kg] 190 240<br />

ROAD SHOULDER GRINDER - RP 110<br />

Designed for grinding and profiling<br />

road shoulders to provide proper drainage<br />

from road into ditch.<br />

Type RP 110<br />

Operating width [m] 1,10<br />

Rotor’s diameter<br />

Required pump output<br />

[L/min]<br />

420 mm<br />

70 -100<br />

KW 125<br />

KW 140 / KWT 650<br />

Following wheel<br />

Hydraulic pressure<br />

YES<br />

210 bar<br />

Weight [kg] 230<br />

Type KW 110 KW 125 KW 140 LAMA 120 LAMA 140<br />

Operating width [m] 1.10 1.25 1.40 1.20 1.40<br />

Knives 10 10 12 20 24<br />

Required pump output<br />

[L/min]<br />

90 - 100<br />

TRUNK GRINDER - FP 20<br />

Designed for grinding trunks after cut<br />

down trees.<br />

Typ FP 20<br />

L / H / W<br />

Hydraulic pressure<br />

Required pump output<br />

[L/min]<br />

Grinding wheel<br />

60 / 47 / 50 cm<br />

210 Bar<br />

70-100<br />

ϕ 370 x 12 mm<br />

Hydraulic pressure [bar] 210 210 210 210 210<br />

T<strong>oo</strong>th count on wheel 12<br />

Weight [kg] 260 290 330 185 220<br />

Weight [kg] 90<br />

18<br />

19

ABOUT US<br />

From the very beggining passion and constant searching for the best solutions<br />

have been crucial for <strong>SaMASZ</strong> employees and have led to company’s success.<br />

Main factors contributing to our constant and dynamic development are close<br />

contact with our customers and openness to their needs. Thanks to dialogue<br />

with our present and future customers reaching out for their demands we<br />

are creating and reinforcing the basis of dynamic success. We are bulidng the<br />

brand, which is recognizable not only in the whole Europe but also worldwide .<br />

We are analyzing every aspect of operation of our machines and watching every component in order to ensure faultless<br />

operation in any conditions. Our strength lies in reliability of offered equipment, close collaboration with our customers<br />

and quick reaction to their needs.<br />

This has led to developing of intelligent agricultural and municipal technology based on high functionality of equipment<br />

- factor which is decisive when it comes to successful operation. Therefore, on its basis we are proud to create the whole<br />

range of our products<br />

DESIGNERS<br />

Reaching for the constant development of the equipment, <strong>SaMASZ</strong> is investing<br />

in research works. We employ the most talented Polytechnic graduates, which<br />

are not only experts in their fields, but also put a lot of passion into their tasks.<br />

Therefore, the company can always rely on their competence and reliability.<br />

SERVICE<br />

Our service carries on warranty repairs and post-warranty repairs both in Poland<br />

and abroad. All warranty claims are received by phone or on letter by our<br />

Service Department. All claims are registered and upon each of them a protocol<br />

is drawn.<br />

All warranty and post-warranty repairs are made in quick and professional manner.<br />

<strong>Sp</strong>ecially trained and well equipped service mechanicians arrive to Clients<br />

in their modern service cars to perform repairs quickly and effectively.<br />

We are constantly analyzing types and frequency of defects and what follows we are introducing modifications to improve<br />

both quality and durability of our machines and their sub-assemblies.<br />

SPARE PARTS<br />

<strong>Sp</strong>are parts for <strong>SaMASZ</strong> machines are packed and sent to different locations in<br />

Poland by our <strong>Sp</strong>are Parts Department which also runs our own store.<br />

We accept orders by phone, fax or e-mail. Any order placed by 13.00 is later sent<br />

the same day.<br />

<strong>Sp</strong>are Parts Department also sends operator’s manuals, catalogues and spare<br />

parts lists.<br />

The <strong>SaMASZ</strong> company is leader in Poland and one of top European companies in manufacturing forage machines. Our wide<br />

range of products includes also municipal machines, that is mainly falil mowers and snow plows.<br />

Our main goal is constant development and improvement in construction of our machines as well as introduction of top<br />

modern achivements of global technology into our manufacturing process in order to obtain world’s top quality.<br />

<strong>SaMASZ</strong> <strong>Sp</strong>. z o.o.<br />

tel. +48 85 664 70 31<br />

fax. +48 85 664 70 41<br />

email: samasz@samasz.com<br />

15-161 Białystok<br />

ul. Trawiasta 15<br />

Poland<br />

www.samasz.com<br />

Your dealer:<br />

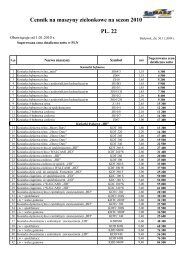

Edition 1 / 2012