ISUZU LAID BARE - Isuzu Trucks

ISUZU LAID BARE - Isuzu Trucks

ISUZU LAID BARE - Isuzu Trucks

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

at the heart of the roaD traNSPort iNDuStry<br />

<strong>ISUZU</strong> <strong>LAID</strong> <strong>BARE</strong><br />

We asked <strong>Isuzu</strong> to provide three of their<br />

latest models at 7.5, 12 & 18-tonne GVW<br />

to check out their productivity.<br />

They didn’t disappoint!<br />

Words: John Phillips and Kevin Swallow / Images: Tom Lee<br />

ProDuctivity teSt<br />

iSuZu<br />

rePriNt<br />

gaiN weight – gaiN £s

EffICIENCY<br />

PRODUCTIVITY<br />

Productivity can be measured by the ▲ The move away from energetic approach; as such, it isn’t always suited to older<br />

effectiveness of your workforce or the effectiveness of 7.5 tonnes (far right) workers who enjoy grandfather rights to 7.5-tonners.<br />

your trucks. To achieve maximum productivity you need is still open to debate Therefore operators have to pay a younger HGV Cat C<br />

to pitch expenditure against income. The latter should be qualifed driver who can drive much heavier vehicles.<br />

consistent, verging on the upwardly mobile, and you It all sounds negative for the 7.5-tonne truck, but it has<br />

should allow for standing and running costs, reinvestment far from had its day. Volume-conscious operators, home<br />

and a 20% proft margin. delivery services, local authorities and own-account<br />

How close operators can get to that business model, as operators still all swear by it.<br />

recommended in the National CPC Licence literature, is<br />

open to debate. So what is there to consider? Purchase Restricted drivers<br />

price, depreciation, insurance, VED rates, wages, fuel costs, The market developed after 1978 when licensing laws<br />

payload and vehicle utilisation are just some of the factors. restricted drivers on a car licence to driving vehicles with<br />

When it comes to specifying vehicles, feet operators tend a maximum GVW of 7.5 tonnes, down from 10 tonnes,<br />

to stick with what they know. But times are changing and before a heavy goods licence was required. In 1989, the<br />

practices set out by previous generations might not be as market peaked at more than 19,000 units. Since 1998,<br />

productive today as they were. With increasing weight sales of 7.5-tonners have fallen from more than 15,500<br />

categories, licensing laws, speed restrictions and potential units to 9,670 last year. The 7.5 to 12-tonne market has<br />

payload, the boundaries of effciency continue to shift. enjoyed growth to more than 1,300 units from 1,150 in<br />

Whether two small vans are cheaper to run than one 2007, whereas the 12 to 15-tonne market has slipped to<br />

7.5-tonne truck is debatable as it requires two drivers, two 1,390 units, down 290 against 2004 fgures. And, apart<br />

wages, and two sets of standing and running costs to make from a blip for digital tachographs, the 18-tonne market<br />

up the payload weight. Frequent, time-sensitive delivery has remained fairly consistent at 7,000-8,000 units a year.<br />

schedules might swing it – and, of course, the use of small While the 7.5-tonne sector has dwindled, operators<br />

vans bypasses speed and licensing issues. moving up the weight chain to 18 tonnes replace those<br />

The trend is always up the weight table and speed who are moving out of that category towards heavier<br />

issues have created a level playing feld for all two-axle vehicles at 26 tonnes. ■<br />

chassis-cabs requiring an O-licence.<br />

An increasingly important factor is that anyone who “Times are changing and practices set out<br />

passed their car driving test after 1 October 1997 cannot by previous generations might not be as<br />

drive a 7.5-tonne truck on their car licence. However,<br />

7.5-tonne work is traditionally multi-drop and requires an productive today as they were”<br />

ODDS_NP_CMREPRINT-P2-5 3 19/3/09 15:34:27

CASE STUDY: 7.5 TONNES<br />

Blaenau Gwent County Borough Council added 11 <strong>Isuzu</strong><br />

Forward N75.190 7.5-tonne rigids, ftted with rear-loading<br />

NTM refuse collection bodies, to work on residential<br />

recycling in South Wales.<br />

Similar to our test vehicle, the<br />

council’s trucks were specifed<br />

with Easyshift transmission.<br />

Transport manager Neil Hughes<br />

says that during the tender process,<br />

<strong>Isuzu</strong> came out on top because of<br />

its willingness to meet the council’s<br />

specifc requirements.<br />

“The <strong>Isuzu</strong>/NTM combination is<br />

much lighter than the other options<br />

we looked at, giving us an impressive<br />

payload of just over two tonnes.<br />

This enables us to achieve greater<br />

effciency on each vehicle’s daily<br />

route,” he says.<br />

The company bought 11 vehicles:<br />

fve collect and dispose kitchen<br />

waste, fve collect cardboard from<br />

residential properties and the fnal<br />

vehicle is a support backup vehicle<br />

to both operations.<br />

The <strong>Isuzu</strong> recycling vehicles, which<br />

have an estimated working life of at<br />

For further information: www.roadtransport.com EffICIENCY<br />

MODEL<strong>ISUZU</strong> FORWARD F75.190 OPERATORBLAENAU GWENT COUNCIL<br />

TEST VEHICLE SPECIFICATIONS<br />

least fve years, are based at the main council depot in<br />

Brynmawr and are working on daily<br />

routes that cover a 35-mile radius including Ebbw Vale,<br />

Tredegar, Abertillery and Brynmawr.<br />

BEST<br />

EConomy<br />

Engine: <strong>Isuzu</strong> Euro-4 intercooled, common<br />

rail diesel using exhaust gas recirculation<br />

with diesel particulate defuser<br />

Cylinders: Four in-line<br />

Capacity: 1,997cc<br />

Power: 188hp [140kW] at 2,600rpm<br />

Torque: 513Nm at 1,500-2,600rpm<br />

Transmission: Six-speed, MZZ6F automated<br />

Ratios: 6.39, 3.77, 1.97, 1.35, 1.00 and 0.78:1<br />

Rear axle ratio: 4.10:1<br />

Brakes: ABS divided hydraulic,<br />

with brake booster; front, 310mm<br />

ventilated discs; rear,<br />

320x120mm drums<br />

Cab: <strong>Isuzu</strong> Hexapod day cab<br />

Fuel tank: 100 litres<br />

Wheelbase: 4,475mm<br />

Body: 20ft GRP box body<br />

Kerb weight [full tanks, no driver]: 4,376kg<br />

ODDS_NP_CMREPRINT-P2-5 4 19/3/09 15:34:33

EffICIENCY<br />

PRODUCTIVITY<br />

CASE STUDY:12 TONNES<br />

MODEL <strong>ISUZU</strong> FORWARD F120.240 OPERATOR HOPWELLS<br />

Frozen food supplier Hopwells<br />

is continuing its trend of ordering<br />

<strong>Isuzu</strong> products by adding 12 frstproduction,<br />

12-tonne Forward F120s<br />

to its feet.<br />

The trucks, ftted with RVL<br />

refrigerated bodies and Hubbard<br />

720L refrigeration systems, will<br />

operate out of Hopwells’ seven sites<br />

across the country.<br />

Fleet manager David Williams<br />

says the order pushes the company<br />

towards a dedicated <strong>Isuzu</strong> feet<br />

– and key to the decision was the<br />

performance of the 7.5-tonne trucks.<br />

“The new 12-tonne <strong>Isuzu</strong> trucks<br />

continue the <strong>Isuzu</strong> philosophy of<br />

maximising payload, combined with<br />

all-round superb performance. Our<br />

distribution schedules are based on<br />

time-sensitive deliveries – and with<br />

<strong>Isuzu</strong>, reliability is the key.<br />

“We can rely on them day in and<br />

day out, as we get minimum downtime with the <strong>Isuzu</strong> feet.<br />

Quite simply, we fnd them virtually indestructible,” he says.<br />

The vehicles will make more than 25 deliveries a day<br />

and cover more than 60,000km a year.<br />

TEST VEHICLE SPECIFICATIONS<br />

GRoWInG<br />

maRKET<br />

“The new 12-tonne <strong>Isuzu</strong> trucks continue<br />

the <strong>Isuzu</strong> philosophy of maximising payload,<br />

combined with all-round superb performance”<br />

Engine: <strong>Isuzu</strong> Euro-4 intercooled, common<br />

rail diesel, using exhaust gas recirculation<br />

with diesel particulate defuser<br />

Cylinders: Six in-line<br />

Capacity: 7.8-litre<br />

Power: 236hp [176kW] at 2,400rpm<br />

Torque: 706Nm at 1,450rpm<br />

Transmission: Six-speed MRZ manual<br />

Ratios: 6.62, 4.09, 2.36, 1.53, 1.00 and 0.72:1<br />

Rear axle ratio: 4.33:1<br />

Brakes: ABS air over hydraulic;<br />

front, 370x150mm drums; rear,<br />

370x150mm drums<br />

Cab: <strong>Isuzu</strong> Hexapod day cab<br />

fuel tank: 127 litres<br />

Wheelbase: 4,990mm<br />

Body: 22ft GRP box body<br />

Kerb weight [full tanks, no driver]: 5,689kg<br />

ODDS_NP_CMREPRINT-P2-5 5 19/3/09 15:34:36

CASE STUDY: 18 TONNES<br />

The frst 18-tonne Forward in the UK has been snapped<br />

up by Sittingbourne, Kent-based company The Dodd’s<br />

Group and will work on its Palletforce feet, handling<br />

overnight palletised freight distribution.<br />

Managing director David Pink<br />

was impressed by the vehicle<br />

at its launch and decided to<br />

try <strong>Isuzu</strong> for the frst time. “The<br />

truck is performing well and the<br />

driver in particular is impressed<br />

by its driving characteristics and<br />

comfort,” he says.<br />

The <strong>Isuzu</strong> Forward F180.260<br />

has<br />

a 27ft Boalloy Fastruck curtainsider<br />

body featuring a rear-mounted<br />

Anteo tuckaway tail-lift.<br />

The vehicle covers more than<br />

350km a day and is part of a 12strong<br />

feet of 18-tonners operating<br />

on palletised distribution work. It is<br />

supported by<br />

a fve-year repair and maintenance<br />

contract through MC Truck & Bus<br />

in Maidstone, Kent.<br />

While it is early days, the <strong>Isuzu</strong> is<br />

giving similar fuel economy fgures<br />

For further information: www.roadtransport.com<br />

MODeL <strong>ISUZU</strong> FORWARD F180.260 OPeRATOR THE DODD’S GROUP<br />

TEST VEHICLE SPECIFICATIONS<br />

to the group’s existing feet of Mercedes-Benz Axors. “It’s<br />

a smart-looking vehicle and the driver is happy with it.<br />

However, I think we’ll need to run it for a year to get a true<br />

idea of the fuel economy fgures,” Pink says.<br />

BEST<br />

ProducTiviTy<br />

engine: <strong>Isuzu</strong> Euro-4 intercooled, common<br />

rail diesel, using exhaust gas recirculation<br />

with diesel particulate defuser<br />

cylinders: Six in-line<br />

capacity: 7.8-litre<br />

Power: 256hp [191kW] at 2,400rpm<br />

Torque: 761Nm at 1,450rpm<br />

Transmission: Six-speed Eaton manual<br />

Ratios: 6.08, 3.53, 2.09, 1.35, 1.00<br />

and 0.79:1<br />

Rear axle ratio: 5.38:1<br />

Brakes: Full air with ABS; front,<br />

434x44mm disc; rear, 434x44mm disc<br />

cab: <strong>Isuzu</strong> Hexapod rest-cab<br />

fuel tank: 200 litres<br />

Wheelbase: 5,500mm<br />

Body: 25ft GRP box body<br />

Kerb weight [full tanks, no driver]: 7,802kg<br />

efficiency

EffICIENCY<br />

PRODUCTIVITY<br />

Standing and running costs<br />

By John Phillips<br />

Our COST CALCuLATIONS are based on the cost<br />

table format used by our sister magazine Motor Transport<br />

and comprise two elements, standing costs and running<br />

costs.<br />

Standing – or fxed – costs normally include insurance,<br />

vehicle excise duty, depreciation, drivers’ wages and<br />

establishment (overheads), but we have excluded the<br />

latter two as they will be specifc to a given operation<br />

and do not signifcantly affect the comparison.<br />

Depreciation is taken as a straight line down to zero<br />

over a fve-year period.<br />

The running costs include current fgures for tyres,<br />

maintenance and fuel, the latter being based on the latest<br />

national average price of diesel at the pump, in this case<br />

81.65p/litre (excluding VAT).<br />

Maintenance is the only running cost variable, the<br />

calculation shown in the table being for an annual<br />

mileage of 90,000km.<br />

The computer programme we used adjusts the<br />

maintenance fgures for the lower and higher mileages<br />

used accordingly.<br />

The total operating cost is the sum of the standing<br />

and running costs: excluding the driver costs and<br />

overheads means the ‘total cost per kilometre’ fgures<br />

shown in our table represent only about a third of<br />

their normal inclusive value.<br />

So, how did our three contenders fare in terms of<br />

their operating costs?<br />

Compared with the N75 7.5-tonner, the F120 12-tonner<br />

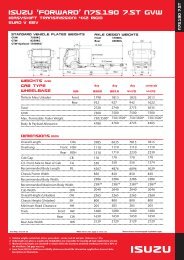

ANNUAL STANDING COSTS (£)<br />

Vehicle insurance:<br />

Licences:<br />

Depreciation:<br />

Total:<br />

Standing costs (£)<br />

Per week (45 weeks):<br />

Per day (225 days):<br />

Per hour (1,800 hours):<br />

Running costs/kilometre (p) (90,000km)<br />

Fuel:<br />

Oil:<br />

Tyres:<br />

Maintenance:<br />

Total:<br />

Total cost/kilometre (p)<br />

60,000km/annum:<br />

90,000km/annum:<br />

120,000km/annum<br />

“The computer programme we used adjusts<br />

the maintenance fgures for the lower and<br />

higher mileages used accordingly”<br />

n75.190<br />

3,419<br />

165<br />

6,758<br />

10,342<br />

229.82<br />

45.96<br />

4.07<br />

12.24<br />

0.19<br />

1.19<br />

6.40<br />

20.02<br />

39.06<br />

31.51<br />

27.24<br />

F120.240<br />

4,401<br />

200<br />

9,131<br />

13,732<br />

305.16<br />

61.03<br />

5.40<br />

13.92<br />

0.21<br />

1.24<br />

6.60<br />

21.97<br />

46.76<br />

37.23<br />

32.21<br />

F180.260<br />

4,628<br />

650<br />

10,971<br />

16,249<br />

361.08<br />

72.22<br />

6.39<br />

16.62<br />

0.25<br />

1.56<br />

9.05<br />

27.48<br />

56.71<br />

45.53<br />

40.18<br />

proved to be about 18% more expensive to operate, the<br />

F180 close to 45% more costly. However, when you start<br />

to compare payloads and fuel consumption fgures a<br />

different picture emerges.<br />

The F120, for example, carried more than twice the<br />

N75’s payload for a fuel premium of just 11%, clearly<br />

highlighting the infuence that driver licensing, as<br />

opposed to practicality, has had over the 7.5-tonne<br />

sector over the years.<br />

Compared with the N75, the F180 carried 3.25 times<br />

the payload for a fuel consumption increase of almost<br />

26%. The corresponding fgures when compared with the<br />

F120 were 1.6 times and 16.3% respectively.<br />

Breaking down the operating costs in terms of the cost<br />

per tonne of payload carried, the N75 came out at 2.25<br />

times that of the F180, and 1.7 times that of the 12-tonner.<br />

Compared with the F120, the 18-tonner’s fgure was 1.3.<br />

From the F180’s perspective, these fgures mean its cost<br />

per tonne of payload carried is less than half that of the<br />

7.5-tonner and 75% of the F120.<br />

Clearly then, the cost and productivity fgures show that<br />

in the real world, payload is king. running costs,<br />

especially fuel, are important, and operators obviously<br />

have to match their vehicles to their operation. But in the<br />

majority of cases, they should go for the highest suitable<br />

weight category and the maximum payload potential.<br />

ODDS_NP_CMREPRINT-P2-5 7 19/3/09 15:34:44

ThE RESULTS<br />

We took the three vehicles and flled them with ballast to their GVW. Then we used the High<br />

Speed Circuit at Millbrook Proving Ground, driving at constant speeds of 64, 80 and 85km/h,<br />

covering a total of 100km.<br />

This produced three sets of fuel consumption fgures and an overall fuel fgure. After refuelling<br />

using tank-top-to-tank-top we unloaded the vehicles and weighed them to provide kerb<br />

weights with full tanks and no driver.<br />

The test vehicles were driven by Rikki Chequer, Kevin Swallow and Brian Weatherley from<br />

Commercial Motor.<br />

Xxxxx Fuel and xxxxx payload/vehicles<br />

xxxxxxxxx<br />

64km/h - litres used per 33.3km (mpg)<br />

80km/h - litres used per 33.3km (mpg)<br />

85km/h - litres used peer 33.3km (mpg)<br />

Total litres over 100km (mpg)<br />

Payload - kg<br />

Productivity - litres<br />

DIMENSIONS<br />

Cost of fuel at 81.65p/litre (ex VAT) over<br />

100km divided by payload per tonne<br />

7.5t<br />

4.01 (23.5)<br />

5.34 (17.6)<br />

5.70 (16.5)<br />

15.05 (18.8)<br />

3,124<br />

4.81<br />

£3.93<br />

12t<br />

5.25 (17.9)<br />

5.65 (16.6)<br />

6.05 (15.5)<br />

16.95 (16.7)<br />

6,311<br />

2.69<br />

£2.20<br />

For further information: www.roadtransport.com EffICIENCY<br />

18t<br />

5.89 (16.0)<br />

7.01 (13.4)<br />

7.34 (12.8)<br />

20.24 (13.9)<br />

10,198<br />

1.98<br />

£1.62<br />

The productivity fgures are achieved by calculating the amount of fuel consumed divided<br />

by the tonnes carried divided by the distance travelled. This gives a fgure of litres used per<br />

tonne-kilometre, or lit/t-km. To calculate the cost of fuel used per tonne-kilometre, the number<br />

of litres used is multiplied by 81.65p – the cost of diesel (ex-VAT).<br />

Commercial Motor would like to thank <strong>Isuzu</strong> for providing the three vehicles, and Millbrook<br />

Proving Ground for providing the test weights and allowing us to perform the test.<br />

We would also like to extend our gratitude to Michael Crowfoot of Crowfoots Carriers,<br />

who provided the 12-tonne truck.<br />

Reprinted from COMMERCIAL MOTOR 19/02/09<br />

Kevin Swallow<br />

The idea behind this<br />

productivity test<br />

was to compare<br />

fuel use with<br />

payload over a set<br />

distance. According<br />

to standing and<br />

running costs, the<br />

18-tonne option is the most expensive<br />

to buy, put on the road and continue<br />

working. The 7.5-tonner is the cheapest.<br />

Our test mpg fgures are better for<br />

the lightest vehicle and the total fuel bill<br />

is less. But when it comes to payload,<br />

the tables are turned. While fuel use<br />

is greater on the 18-tonne vehicle,<br />

the payload on the heaviest truck –<br />

over three times as big – more than<br />

makes up for it.<br />

for each tonne-kilometre, the 18tonner<br />

uses 2.8 litres less than the 7.5tonner<br />

and reduces the cost per tonne<br />

at the pumps by £2.31 (ex-VAT). The<br />

12-tonner plays devil’s advocate, with its<br />

fuel economy and running costs closer<br />

to the 7.5-tonner and its productivity<br />

fgure and cost per tonne-kilometre<br />

closer to the 18-tonne truck.<br />

It isn’t for Commercial Motor to<br />

endorse one weight category over<br />

another; it’s for the operator to work<br />

out, according to the operation, which<br />

vehicle would best suit their set-up.<br />

But, with driver licensing laws and<br />

speed restrictions, the long-term<br />

picture suggests that the 7.5-tonner’s<br />

traditional benefts – matching the<br />

speed of a 3.5-tonne panel van with<br />

better payload – are gone.<br />

Now the 7.5-tonne truck is a small<br />

fsh in a big pond as it fails to match the<br />

payload potential of its heavier twoaxle<br />

brethren. Emphasis has moved<br />

away from the 7.5-tonner – but will<br />

operators?<br />

ODDS_NP_CMREPRINT-P2-5 8 19/3/09 15:34:46