Mechanized Plasmarc Cutting Torch - ESAB Welding & Cutting ...

Mechanized Plasmarc Cutting Torch - ESAB Welding & Cutting ...

Mechanized Plasmarc Cutting Torch - ESAB Welding & Cutting ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

section 5<br />

Maintenance<br />

5.7 Removal and Replacement of the <strong>Torch</strong> Body<br />

WARNING<br />

Electric Shock Can Kill!<br />

Before performing torch maintenance:<br />

• Turn power switch of the power source console to the OFF position<br />

• Disconnect primary input power.<br />

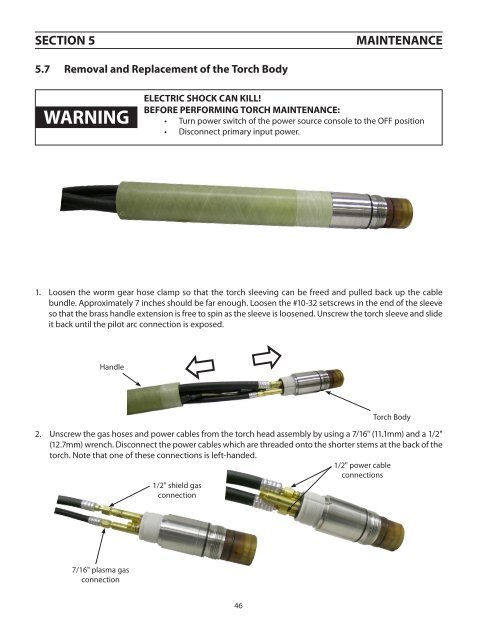

1. Loosen the worm gear hose clamp so that the torch sleeving can be freed and pulled back up the cable<br />

bundle. Approximately 7 inches should be far enough. Loosen the #10-32 setscrews in the end of the sleeve<br />

so that the brass handle extension is free to spin as the sleeve is loosened. Unscrew the torch sleeve and slide<br />

it back until the pilot arc connection is exposed.<br />

Handle<br />

<strong>Torch</strong> Body<br />

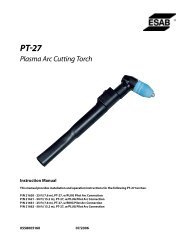

2. Unscrew the gas hoses and power cables from the torch head assembly by using a 7/16" (11.1mm) and a 1/2"<br />

(12.7mm) wrench. Disconnect the power cables which are threaded onto the shorter stems at the back of the<br />

torch. Note that one of these connections is left-handed.<br />

1/2" power cable<br />

connections<br />

1/2" shield gas<br />

connection<br />

7/16" plasma gas<br />

connection<br />

46