Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

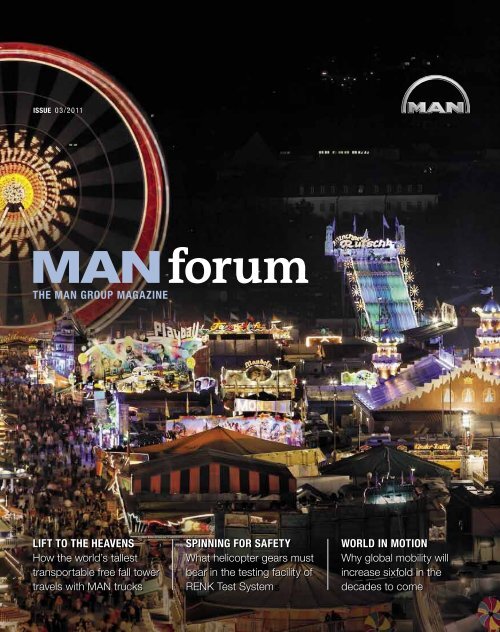

issue 03/2011<br />

the man group magaZine<strong>foru</strong>m<br />

Lift to in the heavens<br />

How the world’s tallest<br />

transportable free fall tower<br />

travels with <strong>MAN</strong> trucks<br />

spinning for safety<br />

What helicopter gears must<br />

bear in the testing facility of<br />

RENK Test System Systems<br />

worLd in motion<br />

Why global mobility will<br />

increase sixfold six-fold in in the<br />

decades to come

Musical MaritiMe voyage<br />

this massive hall of MaN Diesel & turbo’s Primeserv academy usually serves as<br />

a training site for engineers working on huge ship engines. this summer, it became<br />

the venue for a special concert played by the augsburg Philharmonic orchestra,<br />

with its musicians seeking “Far-away Maritime Worlds”, and invoking melodies that<br />

reflect the magic of the seas. the musical voyage was visually framed by one remaining<br />

diesel giant at the back of the stage and a four-stroke single cylinder unit dating<br />

back to 1906, set up next to the glass frontage of the hall.

masthead<br />

<strong>MAN</strong> ForuM – the <strong>MAN</strong> Group magazine<br />

is published four times a year in German and English.<br />

Published by <strong>MAN</strong> SE,<br />

Andreas Lampersbach, Corporate Communications,<br />

Ungererstrasse 69, 80805 Munich, Germany<br />

www.man.eu<br />

editors-iN-ChieF Claudia Weber, Inés Gutiérrez,<br />

Tel.: +49. 89. 36098-384, Fax: +49. 89. 36098-382,<br />

E-Mail: <strong>foru</strong>m@man.eu<br />

PublishiNg house Burda Creative Group GmbH/<br />

BurdaYukom Publishing,<br />

Konrad-Zuse-Platz 11, 81829 Munich, Germany<br />

Tel.: +49. 89. 30620-0, Fax: +49. 89. 30620-100,<br />

www.burdayukom.com<br />

editors Klaus-Peter Hilger (resp.), Kirti Letsch<br />

iNterNAtioNAl editors Patricia Preston,<br />

Asa C. Tomash<br />

<strong>MAN</strong>AgiNg editor Marlies Viktorin<br />

CoNtributors Katharina Becker, Dr. Martin Kaluza,<br />

Christine Karl, Verena Nitsche, Barbara Rott, Marcus<br />

Schick, David Selbach<br />

CreAtive direCtor Anita Mrusek<br />

Art direCtor Robert Neuhauser<br />

Photo editors Michelle Otto (resp.),<br />

Elke Latinovic, Anka Müller, Benno Sänger,<br />

Cover F1online<br />

ePP Silvana Mayrthaler<br />

ProduCtioN Wolfram Götz (resp.),<br />

Franz Kantner, Cornelia Sauer<br />

PriNtiNg Pinsker Druck und Medien GmbH,<br />

84048 Mainburg, Germany<br />

Printed on Galaxi Supermat<br />

reProduCtioN permitted with reference.<br />

Any changes must be coordinated with the editors.<br />

CoPyright ©2011 by <strong>MAN</strong> SE<br />

and Burda Creative Group GmbH<br />

>>> iN tANdeM toWArds suCCess<br />

First entering the job market or embarking on a career<br />

is often not easy. Conflicts must be resolved<br />

and far-reaching decisions be made. In such situations,<br />

it helps to exchange ideas with someone who<br />

has already been through them. This is precisely the<br />

point of mentoring: People with experience in life<br />

and their professions act as mentors, standing by<br />

the side of those who are at the onset of their careers.<br />

<strong>MAN</strong> supports numerous programs, where<br />

students or junior executives are accompanied by a mentor for a certain period of time.<br />

What our author Katharina Becker did not suspect, was how much the old hands also<br />

profited from the exchange with young people. Apparently, guiding and supporting others<br />

can be a way to explore one’s own self (page 20).<br />

>>> Meet the big <strong>MAN</strong><br />

Since this spring, the agricultural machinery manufacturer<br />

Krone has been traveling the western United States to present<br />

its forage harvester of the latest generation in action. The<br />

motto of the road show is “Meet the big <strong>MAN</strong>,” a reference to<br />

the <strong>MAN</strong> diesel engines up to 1,078 hp strong that drive the giant<br />

machines. The interested audience was especially impressed<br />

by the smooth running of the motor, reports Hartwig<br />

Janssen, North American Krone sales manager: “We often<br />

heard that the machine doesn’t sound like a diesel at all.” A<br />

statement, by the way, that had our author Martin Kaluza<br />

take notice. For <strong>MAN</strong> agricultural machinery customers had said the almost identical thing<br />

before: The tractors built by <strong>MAN</strong> under the designation ‘Ackerdiesel’ until 1963 were already<br />

considered atypical of diesels at that time—and ran extra smoothly (page 42).<br />

>>> MeetiNg the Future With oPtiMisM<br />

In March of this year, 219 children lost their parents on the<br />

east coast of Japan. This is only one of the sad statistics emerging<br />

from the Tōhoku earthquake and the resulting tsunami. In<br />

her conversation with Ko Sasaki, the president of <strong>MAN</strong> Diesel<br />

& Turbo Japan Ltd., our colleague Kirti Letsch was moved by<br />

the optimism shining through when he spoke about the future<br />

of his country. In April 2011, <strong>MAN</strong> SE donated generously<br />

to the SOS Children’s Village in Fukuoka. The funds are designated<br />

for the construction of a second SOS Children’s Village<br />

in the center of the area affected by the earthquake (page 9).<br />

<strong>foru</strong>m 03/2011 03<br />

contributors

04<br />

standards<br />

02 PERSPEcTIVE<br />

03 conTRIbuToRS<br />

03 MaSThEad<br />

47 foRuM quIz<br />

30<br />

20<br />

42<br />

10

news<br />

06 Additional traineeships; record sales for <strong>MAN</strong><br />

Latin America; compressors for gas storage<br />

project; new <strong>MAN</strong> Board member; contribution to<br />

SOS Children’s Village in Japan; hybrid truck test<br />

interview<br />

10 ‘mobility could increase sixfold’<br />

Stephen Perkins heads the think tank for future<br />

traffic, logistics and environmental issues at the<br />

OECD in Paris. An exchange about the worldwide<br />

mobility needs of tomorrow.<br />

feature<br />

14 master of free fall<br />

At 66 meters in length, the Power Tower is<br />

the highlight at every fair for those with heads<br />

for heights. <strong>MAN</strong> trucks carry the world’s tallest<br />

free-fall tower from town to town.<br />

technology<br />

26 powerful all-rounder<br />

It feeds a small town with energy, balances<br />

electricity supply fluctuations of wind turbines or<br />

melts plastics: a close-up of the new six-megawatt<br />

gas turbine of <strong>MAN</strong> Diesel & Turbo.<br />

30 surge of savings<br />

Recently introduced and revolving very slowly, the<br />

G-engine of <strong>MAN</strong> Diesel & Turbo allows for the<br />

application of even larger ship propellers. The result:<br />

fuel savings of up to seven percent.<br />

32 groundwork for iron birds<br />

Helicopter gears must meet the highest of<br />

reliability standards. At the RENK Test System<br />

GmbH site in Augsburg, Germany, they are<br />

tested to the very limit.<br />

company<br />

20 the value of experience<br />

Within the <strong>MAN</strong> Group, mentoring programs<br />

are a vital instrument for HR development:<br />

Participants relate how they work and how to<br />

benefit from these plans.<br />

38 looking for the best solution<br />

The new Service Engineering department at<br />

<strong>MAN</strong> Truck & Bus keeps a very close eye on<br />

the customer. On how to improve structures<br />

and processes for optimized service quality.<br />

<strong>foru</strong>m 03/2011 05<br />

contents<br />

42 from motor plow to giant chippers<br />

For the last nine decades, <strong>MAN</strong> machinery has<br />

worked the land. Once motorized by 21 hp, the<br />

strongest agricultural equipment now runs with<br />

up to 1,078 hp. The milestones of a long tradition.<br />

46 closing words<br />

Be it during training or rising through the ranks of<br />

management—intensive facilitation and personal<br />

guidance play a key role at <strong>MAN</strong>, explains Chief<br />

Human Resources Officer, Jörg Schwitalla.

06<br />

news<br />

perfect double: Comedian Max giermann posing as<br />

goalkeeper oliver Kahn in the “Man kahn” campaign.<br />

> CaMpaign<br />

Bus comedy with Oliver Kahn<br />

together with the Man soccer team bus,<br />

the legendary german goalkeeper oliver<br />

Kahn and comedian Max giermann, known<br />

from the “switch reloaded” television<br />

sketch show, are the stars in 12 video clips<br />

created by Man se. the first episodes of<br />

the german version are already live at www.<br />

Manschaftsbus.de. Kahn and giermann—<br />

playing the role of Kahn’s trainee—travel<br />

across germany in Man’s football team<br />

coach, experiencing the humorous side of<br />

everyday soccer life. “Man kahn” is the title<br />

of the comedy series, borrowed from the<br />

company’s brand campaign slogan, “Man<br />

kann” (“We are your Man”). the two actors<br />

waxed enthusiastically about the campaign<br />

concept: “the idea of the double Kahn<br />

convinced me immediately,” says the goalie<br />

of his first comedy role. “i have hardly ever<br />

laughed as much as during filming with<br />

Max giermann. He is a perfect double.”<br />

and giermann adds: “filming with oliver<br />

Kahn was fabulous. i’m looking forward<br />

to the next episode.”<br />

> Career opportunities for young people<br />

Additional apprenticeship places<br />

Man ramps up its training capacity,<br />

creating additional apprenticeships<br />

at its sites in germany.<br />

For the start of this year’s vocational training program, the <strong>MAN</strong> Group will be<br />

taking on one more trainee than originally planned at each of its German production<br />

sites. This marks the company’s contribution to the campaign launched by<br />

the IG Metall metals union in North Rhine - Westphalia under the slogan “One<br />

extra training slot per company”, which <strong>MAN</strong> Diesel & Turbo has already taken<br />

part in. According to Jörg Schwitalla,Chief Human Resources Officer at <strong>MAN</strong> SE,<br />

“fostering young talent is a key factor in <strong>MAN</strong>’s ability to compete. We need young<br />

and motivated people to remain globally competitive with our products and<br />

services in the future.” Participating in the campaign, adds Schwitalla, will give<br />

even more young people the opportunity to develop their talents, ideas and desire<br />

to perform well, as they become acquainted with the diverse range of <strong>MAN</strong>’s technologies.<br />

Overall, there are about 2,000 trainees working in <strong>MAN</strong>’s German plants<br />

and sales offices, with the worldwide total at around 2,900.

Photos: Hauke Dressler, SOS Kinderdorf<br />

> rECOrd SALES<br />

Reaching the half million mark<br />

After a mere 15 years, <strong>MAN</strong> Latin America has just produced<br />

its 500,000th vehicle at its factory in resende,<br />

Brazil. Located in the south of the federal state rio de<br />

Janeiro, the plant produces trucks of the Constellation,<br />

Worker and delivery series as well as bus chassis for the<br />

Volksbus model. The sales figures were also a cause for<br />

celebration: With 5,200 vehicles sold, July 2011 was the<br />

best July in company history. in the first half of 2011,<br />

<strong>MAN</strong> Latin America had already reinforced the position<br />

of market leader in the truck segment that it has held for<br />

the last eight years, by increasing its market share from<br />

28.1 to 30.6 percent.<br />

New truck delivery: Almost one truck<br />

out of three rolling on the streets of<br />

Brazil comes from <strong>MAN</strong> Latin America.<br />

> SOS ChiLdrEN’S ViLLAgE<br />

Employees lend a hand<br />

<strong>foru</strong>m 03/2011 07<br />

Energetic employees make for<br />

enthusiastic children: <strong>MAN</strong> supports commitment<br />

to young people and their offspring.<br />

As of fall 2011, <strong>MAN</strong> Group employees can contribute half of one<br />

workday to a pilot project to help at the vocational training center of<br />

the SOS Children’s Village in Nuremberg. “<strong>MAN</strong> doesn’t just strive to<br />

commit to social causes as a company. Our employees also wish to<br />

do their share and we want to support that,” says Yvonne Benkert,<br />

senior manager for Corporate Responsibility at <strong>MAN</strong> SE, who<br />

initiated the project. The SOS Children’s Village currently supports<br />

some 800 young people with challenging backgrounds who are just<br />

entering their working lives. Remedial teaching better qualifies<br />

them for vocational training or a job. In the meantime, the adjoining<br />

day care center looks after their children. <strong>MAN</strong> staff can now<br />

participate in four different projects: Renovating the youngsters’<br />

communal quarters, offering job interview training to adolescents,<br />

servicing the outdoor play equipment at the day care center or<br />

reading aloud to small children indoors. If the Nuremberg pilot<br />

project proves popular with employees, more projects are planned—<br />

even on an international scale.

08<br />

news<br />

> EmployEE survEy<br />

Every vote counts<br />

lively interest: About<br />

80 percent of all mAN<br />

staff took part in<br />

the employee survey.<br />

From India to Brazil, from Denmark to South Africa: This year,<br />

47,200 employees of the <strong>MAN</strong> Group had the opportunity of<br />

participating in a Group-wide employee survey—with data privacy<br />

and anonymity the number one priority. A response rate of<br />

80 percent made for outstanding participation. The results of the<br />

survey will provide a basis for discussing <strong>MAN</strong>’s strengths and<br />

potential for improvement, as well as introducing concrete changes.<br />

Based on the results, the Management Board of <strong>MAN</strong> SE has<br />

identified a number of top issues for the <strong>MAN</strong> Group. The objective:<br />

Continue to move <strong>MAN</strong> forward and boost employee satisfaction<br />

levels. Jörg Schwitalla, Chief Human Resources Officer at <strong>MAN</strong> SE,<br />

explains: “Apart from getting more openness and honesty into our<br />

communications processes, we also need to make an even stronger<br />

effort in making customers the focus of all our activities. And: We<br />

intend to live our <strong>MAN</strong> management culture and make it tangible.”<br />

radial compressors of this type<br />

are supplied to the Netherlands<br />

by mAN Diesel & Turbo.<br />

> powEr supply<br />

Compressors for gas storage project<br />

The Abu Dhabi National Energy Company (PJSC) is currently<br />

building western Europe’s largest gas reservoir in<br />

the Netherlands. The gas storage facility will be built in<br />

Alkmaar, near the North Sea, and feature a capacity of<br />

4.1 billion cubic meters. <strong>MAN</strong> Diesel & Turbo was commissioned<br />

to supply the entire compressor technology.<br />

In all, the company will be delivering six compressor<br />

systems. While proving highly efficient, <strong>MAN</strong>’s compressors<br />

are also notable for their highly eco-friendly operations.<br />

For example, the hermetic sealing of each unit ensures<br />

that no gas can escape. Gas reservoirs are needed<br />

in order to balance out seasonal fluctuations in consumption,<br />

ensuring that a reliable supply of natural gas<br />

is available at all times.<br />

> humAN rEsourcEs<br />

René Umlauft appointed to the Board<br />

As of september 1, 2011, rené umlauft was<br />

appointed a deputy member of the mAN sE<br />

management Board. At the same time, the Berlin<br />

native (46) became the cEo of the mAN division<br />

mAN Diesel & Turbo. umlauft had been working<br />

for siemens since 1991, most recently serving as<br />

head of the company’s renewable Energy Division.<br />

New appointment to the<br />

mAN management Board:<br />

As of fall 2011, rené<br />

umlauft serves to bolster<br />

the power Engineering<br />

business unit.

Photo: Simon Katzer, Hauke Dressler<br />

ko sasaki is president of MAn diesel &<br />

Turbo Japan. in July 2011, he visited<br />

the sOs Children’s Village in Fukuoka.<br />

> A CALL TO ...<br />

Ko Sasaki<br />

<strong>MAN</strong> Forum: Hello, Mr. Sasaki. The events in<br />

Fukushima earlier this year shocked the entire<br />

world. How are you doing today?<br />

Ko Sasaki: We are gradually recovering from the<br />

catastrophe. In economic terms, things are looking<br />

up, and progress is being made with the shutdown<br />

of the Fukushima I atomic power station. At the<br />

same time, the nuclear contamination of agricultural<br />

products is alarming. The government needs<br />

to take faster action to deal with this.<br />

What is the mood like in the country?<br />

Fairly optimistic. People’s willingness to help is astonishing.<br />

A great many volunteers, including<br />

many young people in particular, have come forward<br />

to help with the work of reconstruction. There<br />

is clear determination to recover from the catastrophe<br />

and make a positive step forward.<br />

You recently visited the SOS Children’s Village in<br />

Fukuoka. Does it house many earthquake victims?<br />

Fukuoka is too far from the affected area—about<br />

1,100 kilometers. So SOS Children’s Villages want to<br />

open a new place in Sendai. A generous donation<br />

made by <strong>MAN</strong> SE should help to make this possible.<br />

How could the work of the SOS Children’s<br />

Village be described?<br />

It is important for us to raise awareness and acceptance<br />

levels for the Children’s Villages. The Children’s<br />

Village in Fukuoka was only set up in 2010.<br />

Until that time, there were few institutions of this<br />

kind in Japan. Orphaned children are mostly sent to<br />

children’s homes—foster families hardly exist at all.<br />

There is growing interest, however. Since the Children’s<br />

Village in Fukuoka opened a year ago, it has<br />

already had 1,800 visitors.<br />

What impressed you the most on your<br />

recent visit?<br />

It made me aware of what a lot of ground we have<br />

to make up in this area. I was very impressed by<br />

how passionate the staff members of the Children’s<br />

Village feel about their work.<br />

> ExpAnsiOn<br />

New <strong>MAN</strong> site in Munich<br />

> Hybrid TruCk TriAL<br />

Customer tests in Munich<br />

<strong>foru</strong>m 03/2011 09<br />

Easy access: the new MAn offices are<br />

well connected with the public transport<br />

network and the freeway.<br />

since the beginning of 2011, the MAn Group has hired well over<br />

1,000 additional staff members at locations in Munich. Thus, the<br />

company is now opening a new business location, moving into<br />

spacious offices in the parkstadt-schwabing complex located in<br />

the north of the city. beginning in the fall of 2011, the 20,600<br />

square meters of office space has housed employees of the sales<br />

subsidiary MAn Truck & bus AG and MAn Finance international,<br />

as well as some corporate departments of MAn sE.<br />

<strong>MAN</strong> Truck & Bus is currently putting its new hybrid truck to the test in<br />

Munich. In cooperation with wholesaler Arndt GmbH Co. KG, two <strong>MAN</strong><br />

TGL 12.220 Hybrid distribution trucks are used. The test operation is<br />

intended to provide key empirical values that <strong>MAN</strong> can use for the<br />

further optimization of its hybrid truck. Stefan Kerschl, project leader at<br />

<strong>MAN</strong> Truck & Bus, comments: “Reliability, economy and environmental<br />

friendliness are the crucial factors for hybrid drives if they are going to<br />

succeed on the market. Using them in delivery vehicles will give us<br />

valuable performance data under real conditions.” <strong>MAN</strong> Truck & Bus<br />

expects the TGL Hybrid to cut fuel costs by as much as 15 percent.

10<br />

interview<br />

‘Mobility could increase sixfold’<br />

In the coming years, trucks and buses will become increasingly important for the transport of passengers and<br />

goods, forecasts Stephen Perkins, head of the Joint Transport Research Centre of the International Transport Forum<br />

at the OECD in Paris. He explains how mobility can still be managed in a world with nine billion people.<br />

<strong>MAN</strong> Forum: The world’s population is expected to reach the<br />

seven billion mark this fall. In 2025 it will be eight billion,<br />

and by 2050 more than nine billion. Is the volume of transport<br />

increasing at the same rate?<br />

Perkins: Actually, it’s increasing even faster. The number of passenger<br />

kilometers will be multiplied three or four times over the<br />

same period. In China, the number of trips taken could very likely<br />

even be multiplied by six. This development also depends on the<br />

question of whether China will follow the Japanese model—with<br />

highly concentrated big cities and a well-developed public transport<br />

system—or rather imitate the European and North American<br />

pattern, with far-flung residential settlements.<br />

Is that why mobility is increasing more rapidly than the<br />

population? Because the Chinese are emulating the Europeans?<br />

No, it is because incomes are rising. More and more people commute<br />

from the suburbs to the city, the number of business trips is<br />

growing and people take more holidays. The volume of freight is<br />

rising at a disproportionate rate, because increasingly production<br />

operations are distributed around the globe. It is still very much<br />

cheaper to transport small quantities of unfinished products just<br />

in time for final assembly than to ship big consignments which<br />

have to be put into intermediate storage at the plant.<br />

A growing proportion of freight transport is being handled<br />

by road, by truck. Why is this?<br />

Roads are everywhere, with a greater reach than other transport<br />

modes. They are flexible, suited for the growing commercial<br />

sector and also provide the first and final legs for other transport<br />

channels. Road’s main competitor is rail. If the rail system were<br />

to carry all of the forecast growth in freight, enormous investments<br />

in infrastructure would be required. So it’s all about<br />

making transport and logistics as efficient as possible. In this<br />

regard, long trucks can also help reduce the number of vehicles<br />

on the primary routes.<br />

In many countries, high-capacity trucks are a controversial<br />

topic. Critics are afraid that they present an increased risk of<br />

accidents, because these vehicles are so difficult to control.<br />

They are not difficult to control. In fact, they are equipped to<br />

higher standards than the average vehicle. Braking performance<br />

is better. The length of the vehicle means the benefits of some advanced<br />

safety technologies such as lane guard systems are particularly<br />

significant. Until such advanced technologies are required<br />

on all vehicles, there is an opportunity for voluntary agreements<br />

or special licensing arrangements for higher-capacity vehicles to<br />

be equipped to the highest standards. The costs of these systems<br />

can be easily covered, as long trucks are much more profitable<br />

than conventional vehicles.<br />

Will air travel, road and rail at least be more effectively<br />

interlinked in future?<br />

It’s hard to say. The problem is always the same: Reloading a consignment<br />

from one mode of transport to another costs money. But<br />

logistics businesses have strong incentives for finding the most efficient<br />

combinations, as the transport operations of companies like<br />

DHL and TNT show every day. Allowing the market to drive efficiencies<br />

on all the modes is important to achieving efficient system-wide<br />

intermodal links.<br />

What about oil prices? How can road transport continue to<br />

look more appealing than rail in future, when the cost of gas<br />

goes on mounting as it has done in the past?<br />

Despite increases in oil prices, other factors like labor and capital<br />

weigh heavier in transport costs, and overall transport costs account<br />

on average for only a few percentage points of the final cost of<br />

goods. The cost of gas could continue to rise for quite a while without<br />

changing the situation, and in real terms today’s oil price is only<br />

around 10 percent higher than the peak in the second oil crisis in<br />

1980. In addition, manufacturers such as <strong>MAN</strong> are developing technologies<br />

to optimize engines, improve aerodynamics and reduce<br />

Photo: Prisca Martaguet

“Long trucks are much more profitable<br />

than conventional vehicles.”<br />

Stephen Perkins, head of the Joint Transport Research Centre at the OECD

12<br />

> personal profile<br />

Stephen Perkins<br />

stephen perkins heads the Joint Transport<br />

research Centre of the international Transport<br />

<strong>foru</strong>m (iTf) at the organization for<br />

economic Cooperation and Development<br />

(oeCD) in paris. The iTf is an international<br />

government organization that serves as a<br />

transport policy think tank for its 52 member<br />

states and organizes an annual meeting<br />

of all ministers of transport in leipzig,<br />

Germany. The newest member nation is<br />

China, with official accession proceedings<br />

currently underway. after completing his<br />

studies in energy economics and environmental<br />

science at imperial College london<br />

and the University of east anglia, perkins<br />

worked for the international energy agency<br />

(iea) in paris, another oeCD branch. at the<br />

iTf, the 51-year-old British national focuses<br />

on regulation issues and pricing models<br />

designed for managing congestion and reducing<br />

environmental pollution.<br />

drag and rolling resistance. All these improvements could reduce<br />

fuel consumption and CO 2 emissions by 20 percent.<br />

Do you think that electrical drives and hybrid truck engines are<br />

the shape of the future for trucks?<br />

The development of hybrid and electrical drives is moving fast<br />

and I wouldn’t like to try to forecast the future here, but present<br />

trends in the long-distance haulage market indicate that the diesel<br />

engine has a clear advantage. For the inner city, for short-distance<br />

trips, hybrid and electric drives are viable, however, and<br />

have a great advantage in terms of noise. And at ports and on<br />

plant premises where pollutant emissions are a problem, electric<br />

drives are already taking over, such as in the ports of Los Angeles.<br />

Back to infrastructure: You’ve said that it is hard to imagine how<br />

existing roads will cope with so much more traffic. Isn’t this<br />

especially true in fast-growing countries like China and India?<br />

India has just launched a major road expansion program. And<br />

China probably actually has more infrastructure capacity than it<br />

needs—at least in critical areas like ports. The roads of western industrial<br />

nations are in principle sufficient to handle the expected<br />

growth—provided that money is invested in better transport management<br />

systems.<br />

Really? Central Europe is already choked by traffic jams...<br />

Away from ports and other major freight generators, traffic jams<br />

are mainly caused by passenger cars, so traffic management solutions<br />

have to address cars as well as trucks. The best thing would be<br />

a flexible toll, where the prices would vary in accordance with road<br />

use, based on clearly defined and fair regulations. Technically, it<br />

could be based on the German Toll Collect system, for instance.<br />

Couldn’t intelligent control systems also help to regulate the<br />

flow of traffic? By GPS and autopilot?

Photo: Prisca Martaguet<br />

> freight traffic<br />

Trucks will become the<br />

backbone of global trade<br />

experts forecast that the share of truck<br />

traffic will grow to 73 percent of overall<br />

freight traffic by 2030. especially china<br />

will see a much increased significance<br />

of trucks as a means of transportation.<br />

Source: Transport Outlook 2011,<br />

International Transport Forum<br />

2005<br />

2030<br />

2050<br />

92<br />

89<br />

Yes, indeed. Although the main advantage of the road system is<br />

that drivers can decide for themselves how and where to travel.<br />

Navigation systems that are permanently online and communicate<br />

with one another can help guide traffic away from congested<br />

links, however.<br />

You seem to be assuming that there isn’t going to be any change<br />

in the demand for mobility. Yet many young people in the<br />

west are not actually concerned any more with having a car of<br />

their own and are looking for alternatives.<br />

That is indeed true. And there’s a whole raft of innovative approaches<br />

which meet this trend. Car sharing for instance. Electrical<br />

cars, provided at small charging stations around the city, similar<br />

to hire cycles, are to be piloted in a number of cities including<br />

Paris. You could also imagine contracts of the sort you get with a<br />

mobile phone. The customer buys the electric car and rents the<br />

battery, as that is the most expensive element.<br />

84<br />

SOUTH AMERICA<br />

72<br />

77<br />

81<br />

54<br />

48<br />

40<br />

NORTH AMERICA<br />

PACIFIC<br />

EUROPE<br />

25<br />

89<br />

86<br />

90<br />

CHINA<br />

OTHER COUNTRIES<br />

<strong>foru</strong>m 03/2011 13<br />

And in parallel to this, societies are getting older all the time.<br />

Don’t we need quite different strategies to cope with this?<br />

Of course. People of advancing age tend to use cars less and are<br />

more likely to rely on public transport. But then public transport<br />

needs to be geared to accommodate them—with low-floor buses,<br />

easily accessible seats and hand holds. All features that benefit<br />

other users too. The trend is designing public transport systems<br />

to be accessible for all.<br />

So will trains and buses become increasingly important for<br />

passenger transport?<br />

It’s a similar situation to that with freight. Rail-based systems<br />

can’t just be developed overnight. But if you keep a lane free for<br />

buses, as is the case today in many parts of London, you have<br />

created massive new capacity at a stroke. In cities, of course, buses<br />

can also use an electrical drive system. In any case, they have<br />

a big future ahead of them. <<br />

46<br />

87<br />

91 94<br />

56

Photos: Sorin Morar, imago/Peter Widmann<br />

>>> “Any of you without a last will: Not<br />

making it was a mistake!” Addressing her<br />

guests, Christina Bruch-Schneider does not<br />

exactly mince words. Then she pushes the<br />

button. And down it goes. From a height of<br />

63 meters. Straight as a die, at a speed of 15<br />

meters per second. We are on the 66-metertall<br />

Power Tower, the highest transportable<br />

free fall tower in the world. ”You all still look<br />

fine,” whoops Christina Bruch-Schneider<br />

master of free fall<br />

The soaring and regal highlight of every funfair: the Power Tower.<br />

<strong>MAN</strong> trucks carry the colossus across Germany—<br />

and to its seasonal pinnacle, the Munich Oktoberfest.<br />

Several steel floor slabs<br />

provide the basis for the<br />

180-ton giant.<br />

into the microphone. “But that was only for<br />

starters. Part two is still to come.” And with<br />

that she fires the gondola and its ten and a<br />

half thousand kilos back up to the 13th story<br />

of the Power Tower, with its 32 ecstatically<br />

screaming and foot-stomping passengers.<br />

“You want more? You can have more!”<br />

“Experience enhancement through<br />

commandos” is the term in show business<br />

circles. And Christina Bruch-Schneider can<br />

<strong>foru</strong>m 03/2011 15<br />

feature<br />

issue those like no other. That is why patrons<br />

are flocking in droves, craving the<br />

adrenaline kick that comes with speed and<br />

acceleration. And the dizzy altitude is another<br />

factor in this extraordinary thrill<br />

ride. The Power Tower is among the top attractions<br />

at every fun fair and festival. To<br />

make this amusement ride shine in all its<br />

glory, showman Ewald Schneider has to<br />

meet a huge logistics challenge each and

16<br />

feature<br />

every time. It takes about three days for him<br />

and his team of nine to 20 assistants to set<br />

up the 180-ton cult tower, which occupies<br />

an area of 21 by 22 meters. As this is such an<br />

elaborate procedure, the family business<br />

attends only major events—such as the famous<br />

24-hour endurance race at Le Mans,<br />

the Winter Wonderland in London, the<br />

Hamburg Dom festival and, of course, the<br />

Munich Oktoberfest.<br />

Reliable MaN fleet<br />

The Schneiders and their Power Tower travel<br />

with an entourage consisting of five traction<br />

vehicles—all made by <strong>MAN</strong>—plus 11<br />

trailers and attachments. Even on the Autobahn,<br />

the tower makes an impressive showing—a<br />

spectacular convoy. It takes five trailers<br />

to carry the mast alone, conveniently<br />

disassembled into six parts, from one festival<br />

to the next. Just a few days ago, Ewald<br />

Schneider added a new, specially manufactured<br />

motor tractor with crane to his pool<br />

of <strong>MAN</strong> vehicles. The truck was used for the<br />

first time at the Fall Festival in Rosenheim,<br />

Upper Bavaria. The next stop was the famous<br />

Munich Oktoberfest. “It’s the perfect<br />

vehicle,” enthuses Schneider. 44 years old,<br />

he was born in Eastern Westphalia and now<br />

resides in Munich. Indeed, the <strong>MAN</strong> vehicle<br />

is a real showman’s truck. The silver 33.540<br />

TGX with a six-cylinder power set has been<br />

specially designed with three axles. Its tail<br />

02<br />

01<br />

03<br />

1. Part of the gondola swings into view. The cabin<br />

can accommodate 32 brave passengers.<br />

2. Practiced choreography: The team needs around<br />

three days to get the tower set up.<br />

3. The size of mill wheels, these brake disks catch<br />

the cabin just a few meters off the ground.<br />

supports a regal telescopic crane for lifting<br />

massive loads. “This way, the truck helps us<br />

with setting up and dismantling and it is<br />

also powerful enough to pull our trailers,<br />

which weigh tons,” says Schneider during<br />

set-up in Rosenheim.<br />

colossus of MaNy toNs<br />

Such multitasking capability is a top priority<br />

for show people when it comes to their<br />

vehicle fleet. “We clock between 30,000 and<br />

40,000 kilometers per year. That isn’t much<br />

for a traction unit,” observes Schneider.<br />

With its <strong>MAN</strong> fleet, the family company<br />

transports the individual tower components,<br />

gondola elements, supports, the<br />

workshop container, as well as the personnel<br />

vehicle and accommodation caravans to<br />

about 10 events every year. The heavyweight<br />

record is set by the tower’s central<br />

unit, weighing in at 58 tons. With its two<br />

1,200 hp electric motors, the gears, cable<br />

winches and brake disks, it provides the<br />

foundation as well as the physical centerpiece<br />

of the structure. Four projecting steel<br />

struts give the tower a secure base. Setting<br />

it up the way its inventor intended requires<br />

a high degree of experience and accurate visual<br />

measurements. “The base and the load<br />

carrying points have to fit together perfectly,”<br />

says Ewald Schneider. “Basically, we are<br />

rebuilding the foundations from scratch<br />

each and every time.” And the team does it<br />

Photos: Sorin Morar

Operated by remote control,<br />

the telescopic crane of<br />

the <strong>MAN</strong> truck is ideal for<br />

lifting heavy loads.

18<br />

feature<br />

with great diligence. Experts from the local<br />

planning authorities and the TÜV, Germany’s<br />

quality standards authority, check meticulously<br />

to make sure that all safety regulations<br />

are followed.<br />

One of the biggest challenges for the<br />

troupe is that of positioning complex technology<br />

and high-end equipment securely in<br />

a very confined space. While setting up the<br />

tower, every switching maneuver and every<br />

manual operation must be absolutely accurate.<br />

Everything runs according to a practiced<br />

setup plan. After all, pitches at festivals<br />

are valuable commodities.<br />

tough job, but never boring<br />

In order to assemble the five tower elements<br />

with their brightly colored lights down to<br />

the nearest millimeter, a special big crane<br />

moves into action. Using a kind of joystick,<br />

the crane driver lifts parts weighing tons<br />

from the flatbed trucks arriving in close<br />

succession, swings them like toys into the<br />

air and places them precisely on top of one<br />

another. This calls for maximum concentration<br />

from the whole team. “Show people are<br />

jacks-of-all-trades, because they must be<br />

lending a hand wherever it’s needed,” says<br />

Schneider, describing the job profile. This<br />

applies both to assembly and to operation.<br />

It can happen that the boss has to repair a<br />

transformer, or the electrician may have to<br />

stand in at the cash desk or whip the crowd<br />

01<br />

03<br />

into a frenzy. “It may be a tough job at times,<br />

but it’s never boring,” says Christina Bruch-<br />

Schneider, who is busy with her bookkeeping<br />

even while the tower is being set up.<br />

Ewald Schneider and his wife were literally<br />

born into the travelling show circuit<br />

and its business. She comes from a long line<br />

of an established Düsseldorf showbiz family.<br />

“I grew up with big wheels and rollercoasters.<br />

I’m the eighth generation of my<br />

family to be touring folk festivals.” Her hus-<br />

02<br />

04<br />

1. Ewald and Christina Schneider both come from<br />

long-established show-business families.<br />

2. A canine guest throughout Germany: Oskar the<br />

Dog never misses a festival.<br />

3. The Schneider outfit takes its principal attraction,<br />

the Power Tower, from one city to the next.<br />

4. The <strong>MAN</strong> fleet arrives early in the foothills of the<br />

Bavarian Alps; assembly in Rosenheim can begin.<br />

band can look back at 250 years of folk festival<br />

history carved into his family tree. “My<br />

great-grandfather had hippodromes, with<br />

pony rides as the special attraction. I was<br />

presented with my first autoscooter at the<br />

age of 16. That was my first step in the direction<br />

of independence.” The Schneiders have<br />

three children, aged 18, 15 and six. Just like<br />

their parents before them, they are educated<br />

at boarding schools. Will they be going<br />

into show business as well? “We’ll have to<br />

see about that,” says Christina Bruch-Schneider.<br />

“School takes priority. We are all well<br />

aware how hard and laborious this job is.”<br />

Family with a Fun Fair gene<br />

Ewald Schneider junior, the 15-year-old,<br />

seems to have already developed a taste for<br />

the family tradition. During his school<br />

breaks, he helps set up the tower, assisting<br />

his father in lifting the last unit of the<br />

brightly colored backdrop to its lofty position<br />

with the telescopic crane of the <strong>MAN</strong><br />

TGX. “Power Tower” is written on it in red<br />

lights, together with “13th Floor”. As the last<br />

component of the façade is screwed into<br />

place, the glamour is already palpable. The<br />

plastic seats with their orange safety bolts<br />

gleaming like life jackets are still vacant as<br />

yet. The gaze is drawn up and further up, to Morar<br />

the very top of the tower. Yes, indeed: “Any<br />

Sorin<br />

of you without a last will: Not making it was<br />

a mistake!” Let the good fair times roll. < Photos:

The Power Tower is considered<br />

the tallest transportable<br />

free fall tower in the world.<br />

In less than five seconds, it<br />

drops from a height of more than<br />

60 meters to ground level. This<br />

earned the tower an entry in<br />

the Guinness Book of Records.<br />

> RecoRd fIGuRes<br />

Power Tower – the fastest route<br />

between heaven and earth<br />

Total height: 66 meters<br />

drop: 63 meters<br />

speed rising: 6.5 meters per second<br />

speed falling: max. 15 meters per second<br />

Weight of the gondola (loaded): circa 10,500 kilos<br />

Passenger capacity: 32<br />

Total weight of the equipment: circa 180 tons

20<br />

The value of experience<br />

Talent, diligence and a little luck are generally considered indispensable<br />

success factors. Yet young professionals need role models just<br />

as urgently. With tailored mentoring programs, the <strong>MAN</strong> Group supports and<br />

nurtures men and women in their career development.<br />

Properly sowing the seeds: From the beginning, mentors offer advice and inspiration to career entrants.

Photos: www.saengerphotodesign.de<br />

“What mentors teach<br />

their mentees can’t<br />

be learned from books.”<br />

Harika Yücebilgiç, talent management<br />

specialist at <strong>MAN</strong> SE, Munich<br />

Deeper roots, faster growth: Mentees tap the networks of their mentors to learn more about the company environment.<br />

<strong>foru</strong>m 03/2011 21<br />

company

22<br />

“Mentors experience a real<br />

sense of appreciation that they can<br />

pass on their experience.”<br />

Martina Zimmermann, head of Worldwide Organization Personnel<br />

Development, <strong>MAN</strong> Diesel & Turbo, Augsburg<br />

Sustainable growth: Through mentoring programs, companies pass on valuable expertise to the next generations.

Photo: Kenji Aoki<br />

>>> Harika Yücebilgiç is certain: “Mentors<br />

can teach their mentees what can’t be<br />

learned from books.” As talent management<br />

specialist at <strong>MAN</strong> SE in Munich, Yücebilgiç<br />

manages <strong>MAN</strong>’s mentoring program at the<br />

Technical University of Munich (TUM).<br />

Since 2007, the commercial vehicle and engine<br />

manufacturing company has supported<br />

programs at TUM whereby alumni—former<br />

students of the university—assume a<br />

year-long mentorship for current students.<br />

This involves not only entry into professional<br />

life, career planning, leadership and<br />

technical issues, but also personal matters,<br />

such as juggling family commitments and<br />

professional life, work-life balance, or conflict<br />

management. In addition to first-hand<br />

support, mentors offer their protégés access<br />

to their own networks to facilitate internships,<br />

diploma theses or job placements.<br />

“<strong>MAN</strong> considers it a fundamental<br />

social responsibility to provide support today<br />

for the generation of tomorrow,” says<br />

Jörg Schwitalla, Chief Human Resources Officer<br />

at <strong>MAN</strong> SE and patron of the TUM<br />

mentoring program. “Our experienced<br />

mentors offer students an important jumpstart<br />

for their careers. On the other hand,<br />

we get to know motivated young people,<br />

who contribute new ideas to the company.”<br />

<strong>MAN</strong>’s commitment also emphasizes its<br />

appeal as an employer, by strengthening<br />

the company’s reputation and assisting in<br />

personnel recruitment.<br />

aluMni for students<br />

Is an internship advisable after studying<br />

abroad? How can doctoral work be reconciled<br />

with family commitments? These and<br />

other questions are the topics of discussion<br />

for Robin Sonneborn, who took up his mechanical<br />

engineering studies at TUM in May<br />

2011, and for his <strong>MAN</strong> mentor Sven Eisenbach.<br />

Now working for <strong>MAN</strong> Diesel & Turbo<br />

in Augsburg, the computational engineer<br />

says that while a student, he had been grateful<br />

to talk to friends of his parents about career<br />

issues. “It does help to exchange views<br />

with someone who has already had the experiences<br />

that still lie ahead,” says Sonneborn.<br />

When asked if she would like to join<br />

the TUM program as a mentor, Fernanda<br />

Kleffmann did not hesitate for a second. “I<br />

really liked the idea. It was something I’d always<br />

wanted to do,” says Kleffmann, who<br />

comes from Brazil and now works as a logistics<br />

project manager at <strong>MAN</strong> Truck & Bus in<br />

Dachau, near Munich. Since the spring of<br />

2011, she has been mentoring 26-year-old<br />

mechanical engineering student Kerstin<br />

Schmidt-Thrö. They meet once a month to<br />

discuss job applications, contact networks<br />

or planning trade fairs. “I enjoy sharing my<br />

expertise,” says the 33-year-old. “This kind<br />

of mentoring isn’t a monologue at all, but<br />

rather an exchange. I also tell her about my<br />

projects. We meet at eye level, that was very<br />

important to me.”<br />

The idea of mentoring was resurrected<br />

just a few years ago to benefit HR development.<br />

And yet it is by no means a passing<br />

fad. The concept dates back to Greek mythology:<br />

Before setting off for the Trojan<br />

war, Odysseus asked his confidant named<br />

Mentor to look after his son Telemachus in<br />

his absence, introduce him to society and<br />

stand by him as fatherly figure and advisor.<br />

Referring to this story, mentoring today describes<br />

the specific exchange of information<br />

between people on different developmental<br />

and hierarchic levels.<br />

The first mentoring programs deliberately<br />

targeted the advancement of women,<br />

who are rarely found in top positions even<br />

with outstanding abilities. Contact with<br />

persons in executive positions is particularly<br />

useful to them. Traditionally shaped by<br />

industrial production, <strong>MAN</strong> is industry average<br />

with a female ratio of about 11 percent.<br />

In order to boost this figure—not least in<br />

<strong>foru</strong>m 03/2011 23<br />

company<br />

view of skilled labor shortages—<strong>MAN</strong> proactively<br />

supports promotion programs to<br />

encourage women in technical professions,<br />

such as the mentorING scheme (ING being<br />

the German abbreviation for engineer) at<br />

the Technical University of Munich. Female<br />

students of electronics and IT, mechanical<br />

and construction engineering, computer<br />

sciences, and physics receive the support<br />

and advice of an experienced mentor for a<br />

year at a time and can attend numerous<br />

events on topics such as career planning,<br />

professional bearing or how to make a good<br />

impression, or job application training.<br />

external Mentors<br />

Tanja Reissenweber is another beneficiary<br />

of targeted advancement for women. When<br />

the 40-year-old took up her first management<br />

position at the Bavarian home loan<br />

bank LBS, she was proposed for the crossmentoring<br />

program, an initiative by Munich’s<br />

social services department, aimed at<br />

female executive staff, which brings together<br />

mentors and mentees from different<br />

companies in pairs. “I wanted a clear view of<br />

my career goals,” explains Reissenweber.<br />

Her mentor came from <strong>MAN</strong>—an advantage,<br />

she thinks. “I wouldn’t have been so<br />

open with someone from my own company.”<br />

And besides, the relevant issues in the<br />

two companies differ less than some would<br />

assume: leadership issues, self-presentation,<br />

compatibility of family and career.<br />

“We used a project in order to make Tanja<br />

Reissenweber more visible in her company,”<br />

says her mentor Wolfgang Weiss, personnel<br />

developer at <strong>MAN</strong> Truck & Bus Germany,<br />

one year and many meetings down the line.<br />

“He helped me recognize the value of my<br />

contribution and to stop playing it down as<br />

something to be taken for granted,” says<br />

Reissenweber, in appreciation of her mentor.<br />

“He was very skillful in asking me pointed<br />

questions and thus helped me in heading

24<br />

company<br />

off in the right direction.” She now has a<br />

better view of her career. Although being a<br />

committed executive she has deliberately<br />

decided against taking the next step on the<br />

career ladder. Unlike in the past, however,<br />

she now contemplates the idea of going into<br />

business for herself, she says. Just like Tanja<br />

Reissenweber, female junior executives at<br />

<strong>MAN</strong> can also benefit from experienced<br />

mentors at other Munich companies such<br />

as Allianz, Siemens and Wacker Chemie.<br />

international exchange<br />

Martina Zimmerman, head of Worldwide<br />

Organization Personnel Development,<br />

could never have imagined the enormous<br />

interest that young people would have in<br />

the experience of the older generation. Last<br />

year, <strong>MAN</strong> Diesel & Turbo in Augsburg<br />

launched an internal mentoring program<br />

with 10 mentoring pairings. In it, executives<br />

with international experience support<br />

selected young talents beyond location<br />

and national boundaries. “The feedback<br />

was quite overwhelming,” reports a<br />

rather pleased Zimmermann.<br />

Now in its second year, the mentoring<br />

program has been extended to 17 pairings.<br />

Be it in Augsburg, Zurich, Oberhausen, Berlin,<br />

Copenhagen, Dubai or India—mentors<br />

are meeting with their mentees from a variety<br />

of departments. The objectives here<br />

are as varied as the individual personalities.<br />

“With one pairing, the emphasis will<br />

be on management issues, while another<br />

might focus on how to position oneself<br />

during an international assignment in such<br />

a way that headquarters will also notice,”<br />

relates Zimmermann. In addition, she says,<br />

the mentoring program encourages knowledge<br />

transfer and cooperation between departments<br />

and across national boundaries.<br />

These cross-corporate exchanges are<br />

also important to Bernhard Frey. As head of<br />

Personnel Marketing at <strong>MAN</strong> Truck & Bus in<br />

Munich, he is responsible for its Graduate<br />

Program, where he himself serves as a mentor.<br />

While it began at the national level back<br />

in 2003, the program has been expanded to<br />

cover 40 locations worldwide. Supported by<br />

an experienced executive from their main<br />

department who acts as a mentor, trainees<br />

pass through a series of company postings<br />

over the course of 15 months—including<br />

some abroad—to become better qualified<br />

for their future professional responsibilities.<br />

The prospect of jumping on her career<br />

ladder with an overall view was particularly<br />

attractive, says his trainee Antje Bolenz.<br />

Alongside her work in the HR division, the<br />

business administration graduate has had<br />

placements in communication, management<br />

support and production—enabling<br />

her to not only broaden her expertise, but<br />

also to establish valuable contacts within<br />

the company. “Moving from one office to<br />

another and assuming new responsibilities<br />

all the time isn’t easy. I need to adapt rapidly,”<br />

reports the 27-year-old. “It is our goal<br />

that trainees will network together and cooperate<br />

in an interdisciplinary way,” says<br />

her mentor, Frey. “We want engineers working<br />

with controllers, and developers with<br />

HR managers—that is precisely what the<br />

company needs.”<br />

open to feedback<br />

<strong>MAN</strong> expects its trainees to meet the highest<br />

standards in this regard. “We want the<br />

very best graduates in all sectors: engineers,<br />

marketing specialists, HR officers,<br />

technicians, production technicians,” says<br />

Frey. “They must deliver performance, be<br />

willing to learn, cope with conflicts and remain<br />

open to feedback.” Bolenz not only<br />

appreciates that her mentor tells her about<br />

her strengths, but also values his pointing<br />

out what she still needs to work at. No matter<br />

what challenges she is encountering,<br />

important issues with him, and he takes<br />

the time to listen. “I have the feeling that he<br />

always drops everything he’s doing whenever<br />

I should need his help.”<br />

Mutual benefit<br />

Still, not only does the generation of upand-coming<br />

executive staff stand to benefit<br />

from mentoring—mentors in turn can<br />

profit from this intensive dialog with the<br />

young. “Mentors experience a real sense of<br />

appreciation by their company that they<br />

can pass on their experience,” explains<br />

Martina Zimmermann.<br />

In addition, mentors can share their<br />

experiences with others in their position at<br />

<strong>MAN</strong> networking meetings. The process of<br />

helping and advising another person is also<br />

a personal discovery, says mentor Sven<br />

Eisenbach, describing his own experience.<br />

Mentoring made him reflect on what he<br />

himself did upon first finishing his degree<br />

and at changing situations at the beginning<br />

of his professional career. Considering<br />

his past motivation, he says, has helped<br />

him to develop further. And it actually<br />

happens quite often that old hands can<br />

learn something from these whippersnappers.<br />

Mentor Wolfgang Weiss compliments<br />

his mentee Tanja Reissenweber: “I admire<br />

the ease with which she reconciles family<br />

and a career. I would never have managed<br />

that feat myself. She has actually taught<br />

me: Yes, it’s possible.”<br />

During the ongoing contest for the<br />

top talents, mentors also serve as figureheads<br />

for the company. “Well-qualified individuals<br />

are needed at every level,” points<br />

out Eisenbach. “The intensive support program<br />

offers the opportunity to recruit a<br />

truly outstanding staff member.” As witnessed<br />

by Thomas Grimm, a designer in the<br />

truck product management department of<br />

<strong>MAN</strong> Truck & Bus: His mentee is now working<br />

at the same company. <<br />

her mentor is involved. She discusses all Photo: Gallerystock/Mark Laita

“Mentoring isn’t a<br />

monologue, but rather<br />

an exchange.”<br />

Fernanda Kleffmann, Logistics Project Manager,<br />

<strong>MAN</strong> Truck & Bus, Dachau<br />

“The intensive support program offers<br />

the opportunity to recruit a<br />

truly outstanding staff member.”<br />

No mentoring sans controlling: Upon conclusion of frequently long-term support, the mentees’ development process is jointly discussed.<br />

<strong>foru</strong>m 03/2011 25<br />

Sven Eisenbach, computational engineer,<br />

<strong>MAN</strong> Diesel & Turbo, Augsburg

Powerful all-rounder<br />

A newly developed gas turbine from <strong>MAN</strong> Diesel & Turbo can generate<br />

an output of six megawatts of electricity—sufficient power to supply<br />

a small town of 13,000 households. One outstanding feature is the turbine’s<br />

economical size: It could easily fit into a double garage.<br />

oIl Cooler<br />

Keeps the lubricating oil for<br />

the gas turbine system<br />

at the right temperature.<br />

Input aIr fIlter<br />

makes sure that only filtered air<br />

enters the gas turbine, without any<br />

particles or foreign matter.<br />

Control system<br />

this electronically controlled and<br />

computer-monitored communication<br />

unit links the entire package<br />

with the customer’s control room.

Infographics: Horst Kolodziejczyk/Hokolo 3D<br />

Chimney<br />

Power-heat cogeneration<br />

utilizes fuel twice as effectively—producing<br />

both<br />

electricity and heat, which<br />

would escape through the<br />

chimney in other systems.<br />

This allows for actually<br />

utilizing about 80 percent<br />

of the applied energy.<br />

auxiliary Gear uniT<br />

links the starter motor as a<br />

drive with the gas turbine.<br />

heaT exChanGer<br />

here the exhaust heat from the<br />

turbine turns water into hot<br />

steam that can be used for other<br />

applications, such as drying<br />

or melting a variety of products.<br />

Gas Turbine<br />

The system’s centerpiece. newly<br />

developed by man Diesel & Turbo,<br />

it features a high degree of efficiency,<br />

low emission levels and low maintenance<br />

requirements.<br />

GeneraTor<br />

The gas turbine<br />

drives a generator<br />

and thus supplies<br />

electricity.<br />

Power Gear uniT<br />

Converts the rotary speed of the gas turbine<br />

to the required generator speed. For powergeneration<br />

purposes, this amounts to 50 hertz<br />

in europe and 60 hertz in the us.

28<br />

>>> Shimmering like silver, the metal piece<br />

rests on your skin, nestling into the palm,<br />

smooth and cool. Merely the size of a<br />

thumbnail, the object has the ideal dimensions<br />

and design of a mislaid earring. Far<br />

from it, though. This tiny thing measuring<br />

just 17 millimeters actually turns out to be a<br />

compressor blade in the original format. It is<br />

part of the 11th and smallest compression<br />

unit of the new gas turbine made by <strong>MAN</strong><br />

Diesel & Turbo.<br />

The new member of <strong>MAN</strong>’s gas turbine<br />

family is designed to tap additional market<br />

potential, especially in the field of decentralized<br />

energy production. Such applications,<br />

which must work quickly, reliably and independently<br />

of the rest of the power grid, require<br />

machines of the six-megawatt class—<br />

previously missing from the company’s<br />

portfolio. To close the gap, the smaller drive<br />

designed at the Oberhausen plant now supplements<br />

the more powerful THM turbines<br />

from <strong>MAN</strong> Diesel & Turbo, which work as<br />

heavy-duty turbines with an output of more<br />

than 10 megawatts.<br />

> Six-megawatt gaS turbine<br />

Compact size, efficient energy yield<br />

Similar to a car engine, the gas turbine is a drive machine comprising several components.<br />

the power unit owes its name to the hot gas generated in the combustion<br />

chambers, 01 causing the turbine blades 02 to turn. thus, thermal energy is converted<br />

to mechanical energy, which initially drives 03 the compressor. in the twinshaft<br />

design represented here, the compressor and the gas generator turbine 04<br />

form a single unit. the same housing contains the effective power turbine 05 , which<br />

is also used as a mechanical drive in gas or oil pipelines, or else serves to produce<br />

power through a generator. in order to initiate the overall process, ambient air is first<br />

sucked into the system through the inlet housing 06 . the adjoining compressor is<br />

equipped with 11 rows of blades of varying sizes. the largest blade is about the size<br />

of a slice of toast; the smallest is about as large as a dime. Step by step, the air is increasingly<br />

compressed and driven into the combustion chambers at high pressure.<br />

Here the air blends with a gaseous or liquid fuel, ignites and combusts. One part of<br />

the air intake is diverted from the combustion chambers and serves to cool the surrounding<br />

environment, which can reach a temperature of<br />

up to 1,200 degrees Celsius.<br />

3D<br />

Kolodziejczyk/Hokolo Horst Infographics:<br />

Thorough markeT analysis<br />

Kicked off six years ago, the development required<br />

a substantial specification document:<br />

The resulting product needed to be long-lasting,<br />

robust, easy to maintain, low in emissions<br />

and versatile. In addition, it required a<br />

high degree of efficiency when working at<br />

less than full capacity. Due to experience<br />

06<br />

03<br />

04<br />

gathered in recent years with the technology explains Volker Langusch, project manager test center developed specifically in Ober-<br />

to improve the output and efficiency of the for Sales in the Process Industry Gas Turhausen, the complete system—comprising<br />

THM series, the development team found it bines sector. Take the test compressor, for in- the compressor, the turbines and peripheral<br />

easier to achieve these ambitious targets. In stance: Fitted with blades in the original size, units—underwent its first performance tri-<br />

addition, setting up a comprehensive net- it passed all tests perfectly.<br />

al from November 2010 to February 2011.<br />

work of partnerships with universities, re- Tested at another institute, the com- The outcome was satisfactory: Hundreds of<br />

search institutes and other companies bustion chamber proved its functionality measurement devices proved that the new<br />

proved extremely useful. “This way we could with regard to the desired emission levels gas turbine remained within the desired<br />

test the functionality of many individual for nitric oxide and CO2, as well as the unit’s limits in all segments. “Starting with the<br />

components in advance, which accelerated stability and cooling of hot components. first ignition, we went from zero to a<br />

the development of the overall system,” This cleared the way to a prototype. At the 100-percent performance in just a week,”<br />

01<br />

02<br />

02<br />

05

lauds Sven-Hendrik Wiers, head of Gas Turbine<br />

Development at <strong>MAN</strong> Diesel & Turbo<br />

in Oberhausen. Nothing remained to hinder<br />

a market launch in December 2010.<br />

Based on a detailed analysis of customer requirements,<br />

the turbine will become available<br />

in either a single-shaft or a twin-shaft<br />

version in the future. The difference: The<br />

two-shaft machine serves as a mechanical<br />

drive, such as for compressors in the oil and<br />

gas industry. In this design, the turbine part<br />

is divided up into a gas generator turbine<br />

and a power turbine, with independent rotary<br />

speeds. In the single-shaft design, all<br />

the compressor and turbine systems are<br />

lined up on the same shaft.<br />

used in mini power stations<br />

Due to its compact size—about four meters<br />

high, three meters wide and eight meters<br />

long— the gas turbine can be used wherever<br />

electrical energy is needed: in remote<br />

locations like an oil platform, for instance,<br />

or as a mini power plant for residential areas.<br />

After all, the turbine’s six-megawatt<br />

output can provide power for a small town<br />

of around 13,000 households. <strong>MAN</strong>’s developers<br />

are talking about a “world-class” machine<br />

that is so economical of space that it<br />

would fit into a double garage. Another<br />

market for the gas turbine is in the field of<br />

regenerative energy, as sun and wind do not<br />

always deliver power consistently. What to<br />

do in the case of light rain, overcast skies<br />

and no wind? For a reliable source of power,<br />

a regenerative energy supply needs backup<br />

power plants to balance these fluctuations.<br />

To this end, gas turbines can be expected to<br />

also play an increasingly important part in<br />

future energy production.<br />

Last but not least, there is also increasing<br />

demand for gas turbines in power stations<br />

that work according to the power-heat<br />

cogeneration principle. This technology results<br />

in a more efficient use of energy than<br />

when heat and power are produced separately.<br />

In combined gas turbine and steam<br />

turbine systems, for example, the exhaust<br />

gases from the turbine can be directed to a<br />

waste heat boiler that produces steam. This<br />

drives a downstream steam turbine that<br />

yields additional electricity. The steam’s residual<br />

energy content at the turbine outlet<br />

can be condensed in a cooling tower or used<br />

to generate more heat. In comparison with<br />

pure gas turbine operations, this results in<br />

a significantly higher degree of efficiency:<br />

Just in terms of electricity production, the<br />

efficiency gain is well above 30 percent. In<br />

coupled operations, a fuel utilization level<br />

of around 80 percent is also achievable,<br />

which in turn helps to improve the system’s<br />

environmental balance.<br />

In addition to eco-friendliness, the developers<br />

also focused on the economic aspects<br />

of the new product. “With a projected<br />

life cycle of 30 years or more, the initial investment<br />

is negligible,” emphasizes Sven-<br />

<strong>foru</strong>m 03/2011 29<br />

technology<br />

“Starting with the first ignition, we went from<br />

zero to a 100-percent performance in just a week.”<br />

Sven-Hendrik Wiers, head of Gas Turbine Development at <strong>MAN</strong> Diesel & Turbo, Oberhausen<br />

“A comprehensive network of partnerships allowed us<br />

to test the functionality of many individual components in<br />

advance, which accelerated machine development.”<br />

Volker Langusch, project manager for Sales in the Process Industry Gas Turbines sector<br />

Hendrik Wiers. Fuel costs and maintenance<br />

play a decisive role here. Nobody can predict<br />

what the price of natural gas is going to<br />

be in 20 years’ time. Other fuels—such as<br />

synthetic gases, biodiesel and bioalcohol—<br />

are therefore growing increasingly important.<br />

With its six small combustion chambers,<br />

the design of the new gas turbine<br />

makes it easily adaptable for a variety of different<br />

fuels.<br />

easy maintenance<br />

The new gas turbine was also designed with<br />

an advantageous approach to servicing in<br />

mind—an important sales argument for<br />

customers. While a complete turbine replacement<br />

can be carried out within just<br />

72 hours, inspections hardly cause any interruptions<br />

to normal operations. This is<br />

due to a sophisticated maintenance system<br />

developed by <strong>MAN</strong> Diesel & Turbo. It involves<br />

online monitoring that detects abnormalities<br />

and introduces appropriate<br />

measures immediately, as well as a device<br />

known as a borescope. In rather the same<br />

way as an endoscope is used for arthroscopy<br />

of the knee joint, it allows for examining<br />

the interior workings of the turbine without<br />

any disassembly. Another advantage of the<br />

new product from Oberhausen is that all<br />

components of the gas turbine system—<br />

from engineering through to the service<br />

package—are supplied by a single source.<br />

Whether set up as a mini power station<br />

in the neighborhood or used as a backup<br />

system for solar and wind power generators:<br />

The good old gas turbine will continue<br />

its powerful spin, adding to the energy mix<br />

of the future.

30<br />

technology<br />

Surge of SavingS<br />

No less than a revolution in marine engine design: The G-type from <strong>MAN</strong> Diesel & Turbo features a longer piston lift<br />

that reduces engine speed and thus supports the use of ship propellers with an even greater diameter.<br />

>>> The concept is rather straightforward:<br />

Slowly rotating ship propellers with a comparatively<br />

high diameter are considerably<br />

more efficient than smaller ones with<br />

greater rotational speed. When it comes to<br />

large-bore two-stroke engines that require<br />

no gears but are driving the propeller directly,<br />

the outcome is obvious: The larger<br />

the propeller, the lower the speed that the<br />

engine must provide. And precisely this<br />

task was accomplished by <strong>MAN</strong> Diesel &<br />

Turbo’s recently developed ultra-longstroke<br />

engine. Its core characteristics allow<br />

for lower engine speeds, larger propeller diameters,<br />

and thereby significant fuel savings,<br />

and correspondingly reduced carbon<br />

dioxide emissions. According to Ole Grøne,<br />

senior vice president for Low-Speed Sales<br />

and Promotions at <strong>MAN</strong> Diesel & Turbo,<br />

the G-type engine represents “the most<br />

revolutionary development in our engine<br />

portfolio over the last decade, ever since<br />

the successful introduction of the electronically<br />

controlled ME drive.”<br />

New ship desigN waNted<br />

Based on further reductions in the engine’s<br />

rotary speed, the G-type engine supports<br />

the use of propellers that can surpass the<br />

previous diameter by up to a meter. This reduces<br />

consumption by 4 to 7 percent in<br />

comparison with <strong>MAN</strong> Diesel & Turbo’s established<br />

S-ME engine series. These S-type<br />

models with a long piston lift and low en-<br />

the past as the principal drive of tankers and<br />

bulk goods freighters. More often designed<br />

for speed, container ships have generally<br />

been fitted with engines of the K-series,<br />

which have a shorter lift and higher engine<br />

speed. Responding to the economic pressures<br />

of recent years, however, shipping<br />

companies have increasingly been favoring<br />

> PoTeNTiAl sAviNGs<br />

Looking at lower cost<br />

The G-type engine’s fuel consumption<br />

(sFoC) is up to seven percent less than<br />

that of traditional two-stroke engines.<br />

Standard operations (S-type)<br />

Part load operations (g-type)<br />

Low load operations (g-type)<br />

170 SfoC g/kWh<br />

160<br />

the S-models—combined with a bigger propeller—for<br />

these goods carriers as well. “The<br />

time was ready for our even more efficient<br />

G-series,” says Ole Grøne, explaining the decision<br />

to introduce the new model in the fall<br />

of 2010. In order to create space for the bigger<br />

propeller, shipyards must now redesign<br />

the layout of ship sterns. This signals a radical<br />

shift in shipbuilding and engine design.<br />

Optimized eNgiNe cONtrOls<br />

Nowadays, customers are primarily focusing<br />

on their operating costs, as the high fuel<br />