Proportioning - Kremlin Rexson Sames

Proportioning - Kremlin Rexson Sames

Proportioning - Kremlin Rexson Sames

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Experts in Finishing and Dispensing Solutions<br />

Selection Guide<br />

Plural Component<br />

Systems

EXEL North america<br />

EXEL North America, located in Plymouth, Michigan is the<br />

leader of high value added custom and standard solutions for<br />

controlled applications of powders and thick or thin fluids in the<br />

industrial and automotive markets.<br />

Our success is possible because of our strong commitment to<br />

the growth of our employees, who are carefully chosen for their<br />

integrity and mission-to-serve with a sense-of-urgency attitude.<br />

We are committed to complete customer satisfaction! We vow<br />

to develop the latest innovations, maintain close relationships<br />

with key influential’s in the industry and deliver the best solutions<br />

for our customers.<br />

EXEL history dates back to 1925 with the introduction of the first<br />

airspray gun from KREMLIN. SAMES was founded in 1947 and<br />

REXSON in 1954. EXEL expanded into North America in 1978.<br />

EXEL North America consists of over 100 employees with<br />

offices in Plymouth, Michigan; Scarborough, Ontario, Canada;<br />

and Queretaro, QRO, Mexico. We have two distinct sales and<br />

service teams for our Wood & General Industry markets and our<br />

Tier 1 & Automotive markets.<br />

EXEL North America is a wholly owned subsidiary of EXEL<br />

INDUSTRIES, a Global company with 21 manufacturing centers,<br />

two in the US, and 23 subsidiaries, three in North America. For<br />

more information go to www.exel-industries.com.<br />

People:<br />

• Integrity<br />

• Solution<br />

• Service<br />

Products:<br />

• Quality<br />

• Innovation<br />

• Performance<br />

Delivering Controlled Applications<br />

Liquid Finishing - Powder Coating - Sealants - Adhesives<br />

Lubricants - Mold Release Agents - Potting - Plural Component Materials<br />

Experts in Finishing and Dispensing Solutions

Experts in Finishing and Dispensing Solutions<br />

CONTENTS<br />

TABLE OF CONTENTS<br />

Metered Mixing 4<br />

2K or 3K Component 5<br />

PU 2125 F 6<br />

PU 2160 F 7<br />

PU 3000 8 - 9<br />

Cyclomix Features 10<br />

Cyclomix Micro 11<br />

Cyclomix Multi 12<br />

Cyclomix Expert Features 13<br />

Cyclomix Expert 2K & 3K 14<br />

Cyclomix Expert 3K C.A.R.C. 15<br />

Cyclomix Recovery 16<br />

Literature 17<br />

EXEL Industries an International Presence 18<br />

EXEL an North American Presence 19<br />

http://www.kremlinrexson-sames.com/en/usa/

metered mixing<br />

When Production Demands Metered Mixing<br />

Metered Mixing<br />

BEAKER A<br />

Base<br />

Resin<br />

Lacquer<br />

A<br />

B<br />

BEAKER B<br />

Catalyst<br />

Hardener<br />

Accelerator<br />

Activator<br />

Isocyanate<br />

Promoter<br />

As coating or finishing production rises, so does the need to lower the<br />

cost of metering and mixing plural component coatings. The most basic<br />

metering and mixing method is hand mixing or batching.<br />

Once the two components are combined, a reaction between them is<br />

started which is both time and temperature dependant. As time passes,<br />

the viscosity increases and the reaction is accelerated. This can result<br />

in significant labor costs and increased waste, rework and warranty<br />

costs. By utilizing a plural component system, the coating is mixed as<br />

it is used and greatly reduces the amount of wasted material, reworked<br />

parts and equipment damaged by cured coating.<br />

<strong>Kremlin</strong> <strong>Rexson</strong> - Delivering the best solution to fit<br />

your needs.<br />

Specifications<br />

Mechanical<br />

Electronic<br />

Electronic<br />

Mechanical<br />

Custom<br />

PU 2125F<br />

PU 2160F<br />

Cyclomix<br />

Micro<br />

Cyclomix<br />

Multi<br />

Cyclomix<br />

Expert<br />

PU 3000<br />

Cyclomix+<br />

Ratio<br />

1:1, 2:1,<br />

3:1, 4:1,<br />

5:1<br />

1:1, 2:1,<br />

5:1, 10:1<br />

0.6:1 to<br />

20:1<br />

0.6:1 to<br />

0:1<br />

0.6:1 to<br />

20:1<br />

Adjustment Fixed Fixed Variable Variable Variable Variable Variable<br />

Max.<br />

Pressure<br />

Max.<br />

Flow rate<br />

Min.<br />

Flow rate<br />

psi 80 to 140 870 to 1740 2538 2900 2900 As required<br />

bar 5.5 to 9.5 60 to 120 175 200 200 5 to 350 As required<br />

gpm 0.5 to 0.9 0.1 to 0.21 0.52 0.52 0.52 1.04<br />

l/min 2 to 3.4 0.4 to 0.8 2 2 2 2 4<br />

oz/min 1.1 to 2.8 0.33 to 6.3 1.7 1.7 1.7 1.7<br />

cc/min 51 to 85 10 to 19 50 50 50 5 50<br />

Accuracy ± 5% ± 5% ± 1% ± 1% ± 1% ± 1% ± 1%<br />

Max. Viscosity (cps) 400 400 5,000 5,000 5,000 10,000 25,000<br />

Construction SS SS SS SS SS SS SS<br />

Volume of 2K<br />

Flush Waste<br />

1:1 to<br />

20:1<br />

Moderate Moderate Low Low Low Low Low<br />

Flush Time Moderate Moderate Quick Quick Quick Quick Quick<br />

No. of Components 2 2 1 or 2 1 or 2 1, 2 or 3 1 or 2 1, 2 or 3<br />

1:1 to<br />

35:1<br />

Reporting Capability Optional Optional<br />

Printer or<br />

on Screen<br />

Printer or<br />

on Screen<br />

On Screen,<br />

USB or Ethernet<br />

Printer or<br />

on Screen<br />

On Screen,<br />

USB or Ethernet<br />

No. of Colors<br />

Controlled by Unit<br />

No. of Catalysts<br />

Controlled by Unit<br />

Pot Life & Ratio<br />

Alarm<br />

1 1 1 or 3 1 to 7 1 to 49 1 99<br />

1 1 1 1 to 3 1 to 22 1 As Required<br />

Optional Optional Yes Yes Yes Yes Yes<br />

Integrated Gun<br />

Flush Controls<br />

No No Yes Yes<br />

Yes<br />

2 Guns<br />

Yes<br />

Yes<br />

Multiple<br />

Acid Catalyst<br />

Compatible<br />

No<br />

Yes<br />

10:1 only<br />

Yes<br />

PH Units<br />

Yes<br />

PH Units<br />

Yes<br />

PH Units<br />

Yes<br />

PH Units<br />

Yes<br />

PH Units<br />

- - Depending on ratio<br />

4

2K or 3K COMPONENT<br />

Type of materials used<br />

■ SOLVENT OR WATER<br />

baseD materials<br />

■ Polyurethanes<br />

■ MS Polymers<br />

■ primerS<br />

■ Silicon<br />

A large range of high performance<br />

equipment to meet your needs...<br />

■ lacquers<br />

■ epoxy<br />

■ PVC<br />

■ glues<br />

■ ZINC<br />

PU 3000<br />

2K or 3K Component<br />

Specifications<br />

Mechanical<br />

Electronic<br />

Electromechanical<br />

PU 2125F PU 2160F Cyclomix<br />

Micro+<br />

Cyclomix<br />

Multi<br />

Cyclomix<br />

Expert<br />

PU 3000<br />

Nb of bases (A) max 1 1 3 7 22 1<br />

Nb of catalysts (B) max 1 1 1 3 22 1<br />

Nb of components (C) - - - - 1 -<br />

Nb of solvents max 1 1 2 4 22 1<br />

Flushing Type Manual Manual Auto Auto Auto Semi<br />

Mixing accuracy ± 4% ± 4% ± 1% ± 1% ± 1% ± 1%<br />

Max pressure<br />

145 psi<br />

(10 bar)<br />

1740 psi<br />

(120 bar)<br />

2538 psi<br />

(175 bar)<br />

2900 psi<br />

(200 bar)<br />

2900 psi<br />

(200 bar)<br />

5076 psi<br />

(350 bar)<br />

Max output per minute<br />

0.92 gal<br />

(3.5 liter)<br />

0.26 gal<br />

(1 liter)<br />

0.52 gal<br />

(2 liter)<br />

0.52 gal<br />

(2 liter)<br />

0.79 gal<br />

(3 liter)<br />

0.52 gal<br />

(2 liter)<br />

Fixed or variable ratio Fixed Fixed Variable Variable Variable Variable<br />

Ratio range 1:1 to 5:1 1:1 to 10:1 0.6:1 to 20:1 0.6:1 to 20:1 0.6:1 to 20:1 1:1 to 20:1<br />

Application equipment for a very high quality finish<br />

manual<br />

automatic<br />

HTI / HPA / HTV AIRMIX ® AIRLESS<br />

SPRAYMIUM ®<br />

ELECTROSTATIC<br />

HTI/HPA AIRMIX ® AIRLESS ®<br />

5

pu 2125 F<br />

Mechanical Metering<br />

The PU 2125 F pump is a fixed ratio two-component pump for low pressure<br />

applications, such as conventional or HVLP spray guns.<br />

The proportioning pump is mounted on a cart and consists of :<br />

- Mixer<br />

- MATERIAL/SOLVENT selection assembly<br />

- Suction rod and a drain rod for the BASE<br />

- Suction rod for the solvent<br />

- Gravity container and a hose for the CATALYST.<br />

Features<br />

Compact mobile cart<br />

Tamper proof fixed ratio design<br />

CheckFlush <br />

No feed pumps or pressure pots<br />

required to feed the A and B materials<br />

Benefits<br />

Easy to install and start-up, portable<br />

Eliminate risk of unwanted ratio<br />

changes during production<br />

The solvent flush that removes the mixed material<br />

flows across the check valves.<br />

This assures a consistent ratio metering<br />

Simple to install and maintain<br />

SPECIFICATIONS - PU 2125 F<br />

Air supply pressure: 43.5 - 87 psi (3-6 bar)<br />

<strong>Proportioning</strong> pump air<br />

consumption<br />

(Nm3/h)<br />

Wetted<br />

parts:<br />

Fittings:<br />

Dimensions:<br />

Max. Temperature:<br />

Noise level (at 1 m)<br />

Weight:<br />

1.2 x (mixed fluid output in l/mn) x pump ratio x (motor air<br />

pressure + 1 bar) x 60/1000<br />

BASE and CATA fluid section : stainless steel<br />

CATA circuit : stainless steel<br />

Mixer : stainless steel, treated steel, polyethylene<br />

Bellows : PTFE<br />

Air inlet : F 3/8 BSP<br />

Spraying air : M 1/4 NPS<br />

Fluid outlet (manifold) : M 1/2 JIC<br />

43″ x 22″ x 20″ / 110 x 55 x 50 cm<br />

122º F / 50º C<br />

80 dB A (depending upon ISO 3746 standard)<br />

110 lbs / (50 kg)<br />

AVAILABLE CONFIGURATIONS - PU 2125 F<br />

Mix<br />

Ratio<br />

Delivery Per<br />

Cycle (cm3)<br />

A<br />

Delivery Per<br />

Cycle (cm3)<br />

B<br />

Output @ 20 cycles<br />

per minute<br />

US Gal<br />

per min.<br />

Liters per<br />

min.<br />

Pressure<br />

Ratio<br />

Part<br />

Number<br />

1:1 85 85 0.9 3.4 0.92:1 151-586-100<br />

2:1 85 45 0.69 2.6 1.25:1 151-586-110<br />

3:1 85 30 0.61 2.3 1.41:1 151-586-120<br />

4:1 85 21 0.56 2.12 1.51:1 151-586-130<br />

5:1 85 17 0.54 2.04 1.58:1 151-586-140<br />

6

pu 2160 F<br />

The PU 2160 F is a complete two component metering and mixing system<br />

designed to provide small and medium shops the ability to spray two component<br />

coatings at Airmix ® pressures.<br />

The PU 2160 F fixed ratio pump is used for applying two component<br />

material with one Airmix ® gun.<br />

The proportioning pump is mounted on a cart and composed of :<br />

- Mixer<br />

- PRODUCT/SOLVENT selection assembly<br />

- Suction rod and a drain rod for BASE<br />

- Suction rod for the solvent<br />

- Gravity container and a hose for CATALYST<br />

Features<br />

Compact mobile cart<br />

Tamper proof fixed ratio design<br />

CheckFlush <br />

No feed pumps or pressure pots<br />

required to feed the A and B materials<br />

Benefits<br />

Easy to install and start-up, portable<br />

Eliminate risk of unwanted ratio<br />

changes during production<br />

The solvent flush that removes the mixed<br />

material flows across the check valves.<br />

This assures a consistent ratio metering<br />

Simple to install and maintain<br />

Mechanical Metering<br />

SPECIFICATIONS - PU 2160 F<br />

Technology supplied:<br />

Airmix ® / Air Assisted Airless<br />

Air supply pressure: 43.5 - 87 psi (3-6 bar)<br />

<strong>Proportioning</strong> pump air<br />

consumption<br />

(Nm3/h)<br />

Wetted parts<br />

Fittings:<br />

Dimensions:<br />

Max. Temperature:<br />

Noise level (to 1m)<br />

Weight:<br />

1.2 x (mixed fluid flow rate in l/mn) x pump ratio x (motor air<br />

pressure + 1 bar) x 60/1000<br />

PU with 1/1, 2/1 & 5/1 ratio<br />

- BASE and CATA fluid section :stainless steel<br />

- CATA circuit : stainless steel<br />

- Mixer : stainless steel, treated steel and polyethylene<br />

PU with 10/1 ratio<br />

- BASE fluid section : stainless steel<br />

- CATA fluid section : 316L stainless steel<br />

- CATA circuit : 316L stainless steel<br />

- Mixer : 316L stainless steel and polyethylene<br />

Bellows : PTFE<br />

Air inlet : F 3/8 BSP<br />

Spraying air : M 1/4 NPS<br />

Fluid outlet (manifold) : M 1/2 JIC<br />

43″ x 22″ x 20″ / 110 x 55 x 50 cm<br />

122º F / 50º C<br />

80 dB A (depending upon ISO 3746 standard)<br />

132 lbs / 60 kg<br />

AVAILABLE CONFIGURATIONS - PU 2160 F<br />

Mix<br />

Ratio<br />

Delivery Per<br />

Cycle (cm3)<br />

A<br />

Delivery Per<br />

Cycle (cm3)<br />

B<br />

Output @ 20 cycles per<br />

minute<br />

US Gals per<br />

min.<br />

Liters per<br />

min.<br />

Pressure<br />

Ratio<br />

Part<br />

Number<br />

1:1 19 19 0.21 0.8 10:1 151-586-690<br />

2:1 19 9.5 0.16 0.6 15:1 151-586-695<br />

5:1 19 3.8 0.13 0.5 18:1 151-586-710<br />

10:1 19 1.9 0.10 0.4 20:1 151-586-700<br />

7

pu 3000<br />

Electronic control & mechanical metering<br />

SPECIFICATIONS<br />

Technology supplied:<br />

Mixing ratio: 0.6:1 to 20:1<br />

Mixing accuracy: ± 1%<br />

Input fluid viscosity range:<br />

Fluid pressure:<br />

Inlet air pressure:<br />

Fluid output flow rate:<br />

Wetted parts:<br />

Air inlet fitting:<br />

Air outlet fitting:<br />

Fluid outlet fitting:<br />

Weight:<br />

Dimensions:<br />

Input voltage:<br />

Number of bases: 1<br />

Number of catalysts: 1<br />

FLUID PRESSURE RATIO<br />

Airspray<br />

Fluid Pressure<br />

Ratio<br />

Airspray, Airmix ® & Airless<br />

30 to 8000 cps (20,000 cps Airless)<br />

30 to 2900 psi / 2 to 200 bar<br />

30 to 87 psi / 2 to 6 bar<br />

2 to 50 oz/min / 50 to 1500 cc/min<br />

Stainless Steel & HDPE<br />

F 1/4″ BSP<br />

F 1/4″ BSP<br />

F #8 JIC<br />

• Pulse-Free Electronic Control ®<br />

• Constant Metering Control<br />

143 lbs / 65 kg<br />

54″ x 25″ x 19″ / 138 x 64 x 48 cm<br />

110V / 220V AC - 75W<br />

Maximum Fluid<br />

Pressure<br />

1:1 1:1 - 87 psi (6 bar)<br />

7:1 580 psi (40 bar)<br />

Airmix ® 30:1 2900 psi (200 bar)<br />

Airless 53:1 5075 psi (350 bar)<br />

• Data Storage of Material Consumption + VOC’s<br />

• Auto Maintenance Reminder<br />

AVAILABLE CONFIGURATIONS<br />

System Description<br />

Part Number<br />

Low Pressure, HVLP, Conventional 668-681-300<br />

Airmix ® 668-681-200<br />

Airless 668-681-100<br />

8

pu 3000<br />

The PU 3000 is an innovative, economical and patent pending solution that<br />

combines electronic control and mechanical metering. The PU 3000 is easy<br />

to operate and easy to install. The control box is user friendly and allows the<br />

operator to intuitively learn how to operate the machine.<br />

Pulse-Free Electronic (PFE) relates to the control of pump change over and<br />

the elimination of material pulsation during pump change over. The PFE<br />

features a constant output and a +/- 1 % metering accuracy for an outstanding<br />

finish. Electronic dosing constantly monitors the actual material consumption<br />

of products and calculates the VOC’s. The machine can be installed in the<br />

spray zone to be in close proximity to the operator.<br />

The PU 3000 is available in low pressure, AIRMIX ® and airless versions<br />

to meet most market requirements.<br />

FEATURES<br />

Plug & Spray<br />

KREMLIN REXSON patent pending :<br />

Pulse-Free Electronic control (PFE)<br />

Innovative control system of pump<br />

change-over<br />

Direct injection in the high performance<br />

static mixer<br />

Recording of fluid consumptions and VOC<br />

Ability to print records<br />

Automatic component management : base,<br />

catalyst and solvent<br />

Programmable flushing priming &<br />

regeneration<br />

User-friendly control panel<br />

Preventive maintenance alarm<br />

Continuous ratio checking and alarm<br />

Low level drum alarm<br />

reduced rejects & rework from poorly<br />

mixed material<br />

Ratio check kit is standard with 2 liter<br />

test tubes<br />

Filter and drain assembly is standard<br />

Sealing done by a FLOWMAX ® bellows on<br />

the catalyst side<br />

Wide range of ratio from 0.6:1 to 20:1<br />

Suitable for Low pressure, AIRMIX ® ,<br />

airless spraying technologies<br />

Possibility of very low flow rate: from 10cc<br />

BENEFITS<br />

Quick start-up<br />

Constant fluid flow rate<br />

Unsurpassed +/-1 % mixing accuracy<br />

+/-1 % repeatability<br />

Perfect mixing<br />

Fluid and solvent consumptions stored<br />

in memory<br />

User friendly<br />

User-friendly and easy programming<br />

for the operator<br />

Safe operation<br />

Visual control of mixing accuracy<br />

No product loss<br />

High reliability<br />

Total sealing between pump and its<br />

environment, ideal for work with<br />

moisture sensitive catalysts<br />

Suitable for use in a wide range of<br />

markets<br />

Electronic control & mechanical metering<br />

9

cyclomix features<br />

Features & Benefits<br />

accurate mixing for two component materials<br />

Electronic proportioning and mixing often has very short payback periods because they deliver significant<br />

benefits compared to other methods:<br />

Type of Mixing<br />

Manual<br />

(Hot Potting)<br />

Mechanical<br />

Electronic<br />

Cyclomix <br />

Mixing Accuracy +/- 10% +/- 4% +/- 1%<br />

Ratio Control Poor Good Excellent<br />

Mixed Material Quality Poor Good Excellent<br />

Unused Mixed Material High Moderate Very Low<br />

Traceability Poor Good Excellent<br />

Risk of Rework High Moderate Very Low<br />

Fluid Handling Labor Costs High Moderate Very Low<br />

Safety Poor Good Excellent<br />

Ease of Color Change Poor Moderate Excellent<br />

the unique proportioning technique used by cyclomix<br />

The Cyclomix line of plural component systems is based on 25 successful years of <strong>Kremlin</strong> experience in<br />

manufacturing and delivering two component solutions to the finishing industry. It uses our unique proportioning<br />

technique of delivering a constant flow of base material and injecting the pressure regulated catalyst to maintain<br />

ratio control. This maintains extreme mixing accuracy and minimizes dead zones and flush waste. Constant<br />

Flow Meter Mix is an EXEL exclusive feature.<br />

Base/ Solvent<br />

Catalyst/ Solvent<br />

Mixed<br />

material<br />

Proven Technology<br />

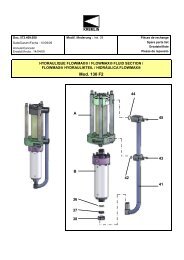

The fluid network features a special design to minimize the<br />

amount of flushing solvents used (less than 2 oz. or 50 cc).<br />

Accurate Mixing +/- 1%<br />

Efficient Flushing<br />

TYPES OF FLUIDS HANDLED<br />

TYPICAL Cyclomix INSTALLATION (Manual Installation)<br />

Bases<br />

Epoxy<br />

Lacquers<br />

Primers<br />

Solvent-based paint<br />

Water-based paint<br />

Polyurethanes<br />

Varnish<br />

10<br />

BASE<br />

FLUSH<br />

COATING<br />

BASE<br />

CATALYST COATING<br />

FLUSH CATALYST

cyclomix micro<br />

The Cyclomix micro machine parameters are easily set-up to suit almost any<br />

application. Operator training is in simple and easy steps that allows for quick<br />

start-up and operation. Cyclomix Micro PH versions are also available for<br />

acid catalyzed coatings.<br />

FEATURES<br />

Precision control with alarm<br />

Ability to use up to 3 bases (colors) with a<br />

single catalyst<br />

Spray booth controls can be operated inside<br />

or outside of the booth<br />

Spray single-component materials<br />

Compatible with Low pressure, Airmix ® and<br />

electrostatic * spray guns<br />

(*) minimum paint resistivity: 5 M<br />

Mixing Ratio 0.6:1 to 20:1<br />

SPECIFICATIONS<br />

Notification in event of a fault<br />

Flexibility with number of bases<br />

Allows the operator the flexibility to control the<br />

device either inside or outside of the spray<br />

booth<br />

The paint applied on parts always conforms<br />

to specifications<br />

Handles a wide range of spray technologies<br />

Accurate Mixing +/- 1%<br />

BENEFITS<br />

Repeatability +/- 0.5%<br />

Construction - two parts:<br />

Electrical control cabinet and Mixing panel<br />

Number of colors:<br />

(depending on version selected)<br />

One to Three<br />

Number of catalyst:<br />

One<br />

Mixed material output: 1.7 to 67.6 oz/min (50-2000 cm 3 /min<br />

Minimum air pressure: 58 psi / (4 bar)<br />

Recommended material viscosity range: 30-5000 cps<br />

Working data storage<br />

Base, Catalyst, Solvent and VOC<br />

Wetted parts construction:<br />

Stainless Steel as Standard<br />

RS 232:<br />

Data transfer option<br />

Built-in function:<br />

Material ratio checking<br />

Solvent flow<br />

7000 cm3/mn<br />

Wetted parts:<br />

Chemically inert materials<br />

Weight: 55 lb / 25kg<br />

Voltage:<br />

230V / 115V - 75W<br />

Entry level electronic 2K metering system<br />

System Description Number of bases Number of catalyst Part Number<br />

Cyclomix Micro W/O Catalyst Flush 1 1 155-660-900<br />

Cyclomix Micro W/O Catalyst Flush 3 1 155-660-930<br />

Cyclomix Micro Catalyst Flush 1 1 155-660-911<br />

Cyclomix Micro Catalyst Flush 3 1 155-660-933<br />

Cyclomix Micro PH Catalyst Flush 1 1 997-108-000<br />

Cyclomix Micro PH Catalyst Flush 3 1 997-108-100<br />

Cyclomix Micro Options<br />

Part Number<br />

RS232 communication kit 155-660-935<br />

Spray booth mounting kit 155-660-340<br />

7m extension cable between control cabinet and mixing panel 901-250-216<br />

11

cyclomix multi<br />

Electronic metering for multiple colors<br />

PH version<br />

available for acid<br />

catalyzed coatings<br />

Autowash<br />

panel for<br />

automatic<br />

flushing<br />

of mixed<br />

material<br />

The Cyclomix MULTI system was designed for production shops that<br />

require accurate mixing and a small number of color changes. This system<br />

provides easy control and outstanding performance in one package.<br />

The Cyclomix MULTI system is also available in a PH version for acid<br />

catalyzed coatings.<br />

FEATURES<br />

Adaptable programming for each color<br />

Pneumatic emergency flush<br />

System interface<br />

Separate control box from the mixing unit<br />

Multiple flushing sequences available<br />

SPECIFICATIONS<br />

Number of bases: 1 to 7<br />

Number of catalysts: 1, 2 or 3<br />

Technology supplied:<br />

Airspray, Airmix ® , Air Assisted Airless & Airless<br />

Mixing ratio: 0.6:1 to 20:1 (166% to 5%)<br />

Mixing accuracy: ± 1%<br />

Input fluid viscosity range:<br />

Inlet fluid pressure:<br />

Inlet air pressure:<br />

Fluid output flow rate:<br />

Wetted metal parts:<br />

Air inlet fitting:<br />

Air outlet fitting:<br />

Fluid inlet fitting:<br />

Fluid outlet fitting:<br />

Weight:<br />

Dimensions (control cabinet):<br />

Dimensions (mixing unit):<br />

Voltage:<br />

Allows for flexibility with each coating recipe<br />

Provides a complete system flush in case of<br />

power failure<br />

Connects easily to automated systems for<br />

triggering and flushing<br />

Allows for Class 1 Division 1 rating so the<br />

mixing unit can be located inside the booth<br />

Provides flexibility for shift changes and<br />

shutdowns while saving material and solvent<br />

20 to 5000 cps<br />

30 to 2900 psi / 2 to 200 bar<br />

60 to 87 psi / 4 to 6 bar<br />

2 to 50 oz/min / 50 to 1500 cc/min<br />

Stainless Steel and HDPE<br />

F 1/4″ BSP<br />

F 1/4″ BSP<br />

#5 JIC filter inlet<br />

F 1/4″ BSP<br />

143 lbs / 65 kg<br />

24″ x 24″ x 16″ / 60 x 60 x 40 cm<br />

31″ x 24″ x 24″ / 77 x 60 x 60 cm<br />

230V / 115V - 75W<br />

BENEFITS<br />

AVAILABLE CONFIGURATIONS<br />

Number<br />

of Bases<br />

Number<br />

of Catalysts<br />

Standard System<br />

Part Number<br />

PH Model System<br />

Part Number<br />

3 1 155-660-813 668-660-413<br />

5 1 155-660-815 668-660-415<br />

7 1 155-660-817 668-660-417<br />

3 2 155-660-823 668-660-423<br />

5 2 155-660-825 668-660-425<br />

3 3 155-660-833 668-660-433<br />

Optional Autowash Panel 155-660-300<br />

12

cyclomix Expert Features<br />

Features<br />

Control<br />

Control<br />

Electronics<br />

Panel<br />

Inlet Pressure Inlet Pressure<br />

Base<br />

Solvent<br />

Hardener<br />

Electro-pneumatic Valves<br />

Flowmeter<br />

Flowmeter with<br />

High Frequency Electric Valve<br />

Electronic Security<br />

Quick Disconnect<br />

Cyclomix SYSTEM FLOW CHART<br />

The Cyclomix system is designed with the operator in mind.<br />

The goal is to provide the most efficient plural component system<br />

in the market, provide flexibility to adapt the system to any<br />

possible system requirements, make it easy to operate and easy<br />

to maintain. The diagram to the left shows just how simple the<br />

fluid manifold is to understand, and it’s just as easy to maintain.<br />

Static<br />

Mixing Head<br />

Mix Control for Sampling<br />

To Application<br />

OPTIONAL: REMOTE CONTROL PANELS<br />

The Cyclomix systems offer OPTIONAL remote control panels which allow<br />

the operator to change colors, perform a flush sequence or turn the system on<br />

or off while in the booth. This reduces the amount of travel an operator needs<br />

to make and allows for more production time. The panels provide the security<br />

of immediately flushing the system when the pot life alarm is activated and<br />

allows the operator to place the system in material ready mode so it maintains<br />

fresh material in the hoses, even when the operator is not using the gun.<br />

OPTIONAL: AUTOMATIC GUN FLUSH BOX<br />

The automatic gun flush box is a must-have accessory for any company<br />

performing color changes with plural component systems. The box allows the<br />

operator to simply insert the gun, close the lid and walk away. The system will<br />

automatically pull the trigger, perform the flush, and be ready for the next color<br />

without the operator being present. The gun flush box works together with the<br />

Cyclomix system to properly flush the system when needed and to also keep<br />

the fresh material in the hoses if the system is in material ready mode.<br />

Cyclomix SERIES INJECTION SYSTEM<br />

The system uses only one injector instead of two. This design allows<br />

the base to continuously flow while the catalyst is injected into the flow at<br />

precise moments and amounts. This allows for a highly accurate mix ratio<br />

without holding high amounts of material in the system. The injector is a<br />

packing free magnetic design which reduces wear and maintenance.<br />

Cyclomix SERIES FLOW METERS<br />

The Cyclomix flow meters utilize ball bearings instead of bushings to provide<br />

less resistance and improve metering capabilities for low viscosity materials.<br />

Cyclomix SERIES FLUID MANIFOLD<br />

The Cyclomix provide extreme savings with the specially designed fluid manifold and<br />

injector design. Both the base and catalyst sides of the panel hold less than two ounces (60<br />

cc) of material in the system. This requires less material to fill the system and less solvent/<br />

material needed to flush the entire system. This can create significant cost savings in<br />

applications that change colors frequently.<br />

13

cyclomix Expert 2k & 3K<br />

Electronic Metering for advanced applications<br />

PH version<br />

available for acid<br />

The Cyclomix Expert is an innovative, industrial solution that is configured<br />

to meet the needs of the customer. This new innovative product can<br />

be upgraded over time while still delivering excellent product quality.<br />

The Cyclomix Expert is available in Airspray, Airmix ® , and Airless (up to<br />

200 bar) configurations to meet the needs of our customers.<br />

FEATURES<br />

Automatic component management up<br />

to 24 products in 1K, 2K or 3K mode of<br />

operation<br />

Real time display of instant real ratio and<br />

flow rate<br />

No pre-mixing chamber : optimized fluid<br />

passages w/o retention zones<br />

All stainless steel construction<br />

BENEFITS<br />

Innumerable possibilities<br />

Flexibility when changing materials<br />

Continuous process control<br />

Perfect flushing<br />

Reduced fluid waste<br />

Compatible with water-based materials<br />

GENERAL FEATURES<br />

sPECIFICATION<br />

Description<br />

Fluid pressure<br />

Min 2 bar / 29 psi - Max 200 bar / 2900.6<br />

psi<br />

Compressed air<br />

Min 3.5 bar / 50.7 psi - Max 6 bar / 87 psi<br />

Voltage<br />

115V / 230V - 75W<br />

Frequency<br />

50 - 60 Hz<br />

Ratio percentage A to B min/max 0.6:1 to 20:1 - 166% to 5%<br />

Ratio tolerance 1%<br />

Particle size<br />

Max 5 micron<br />

Noise level (at 1m) 70 dB A (depending upon Norm ISO 3746)<br />

Viscosity range<br />

min/max 30 to 5000 cps<br />

Moisture (compressed air)<br />

Max 10 ppm<br />

COMPONENTS<br />

catalyzed coating Component<br />

Description<br />

Number of products Max 24<br />

Number of A components Min/Max 1 to 22 (total 24)<br />

Number of B components Min/Max 1 to 22 (total 24)<br />

Number of C components Min/Max 1<br />

Number of A component solvents Min/Max 1 to 22 (total 24)<br />

Number of b component solvents Min/Max 1 to 21 (total 24)<br />

Material compatibility<br />

Solvent and water-based paints<br />

WEIGHT AND DIMENSIONS<br />

Component<br />

Description<br />

2K Version 105 lbs / (48 kg) 1000 mm x 865 mm x 200 mm<br />

3K Version 145 lbs / (66 kg) 1200 mm x 965 mm x 200 mm<br />

Control Panel 75 lbs / 34 kg 600 mm x 600 mm x 225 mm<br />

AVAILABLE CONFIGURATIONS<br />

Call for more information<br />

14

cyclomix expert 3k C.A.R.C.<br />

The Cyclomix Expert 3K electronic meter- mix system is specially designed<br />

for C.A.R.C. coatings. The Cyclomix Expert meter-mix machine is a proven<br />

system in the C.A.R.C. market with installations throughout the US<br />

that deliver outstanding reliability and are extremely accurate. The specially<br />

designed mix manifold provides substantial material savings. We have<br />

numerous, proven installations operating in production for over 5 years.<br />

3K C.A.R.C.<br />

<strong>Kremlin</strong> <strong>Rexson</strong> supplies the complete integrated system. The fluid delivery<br />

pumps are specially designed to deliver the base C.A.R.C. material, moisture<br />

sensitive (solvent based) catalyst and the DI water. From paint kitchen to metermix<br />

and application equipment – <strong>Kremlin</strong> is the answer. The control panel is<br />

supplied<br />

with an Allen Bradley PLC and an easy-to-use operator interface with a color<br />

touch-screen panel.<br />

The <strong>Kremlin</strong> 3K meter-mix system utilizes a dual static mixer design to<br />

provide a complete and thorough mixing of all three components<br />

(base, catalyst & DI water).<br />

SPECIFICATIONS<br />

Component Description Specification<br />

Ratio:<br />

1K A only 1:0 (0%”<br />

2K A to B 0.6:1 or 20:1; 166% to 5%<br />

3K A to C 0.6:1 or 20:1; 166% to 5%<br />

Flow Rate: Min/Max 50 to 2000 cc’s/min<br />

Viscosity Range: Min/Max 30 to 5000 cps<br />

Percent Accuracy: 1%<br />

Number of Products: Max 24<br />

No. of A Products: Min/Max 1 to 22 (24 total)<br />

No. of B Products: Min/Max 1 to 22 (24 total)<br />

No. of A Comp. Solvents: Min/Max 1 to 22 (24 total)<br />

No. of B Comp. Solvents: Min/Max 1 to 21 (24 total)<br />

No. of C Products: Min/Max 1<br />

Material Compatibility: Solvent & Water-based Paints, Acid Catalyst (SS316 Option)<br />

Voltage: 230V/115V -75W<br />

Compressed Air: Min/Max 80/90 psi<br />

Min/Max<br />

(5.5 / 6 bar)<br />

Particle size: Max 5 micron<br />

Moisture Max 10 ppm<br />

Fluid Pressure Min 30 psi (2 bar)<br />

Max 2900 psi (200 bar)<br />

Weight 2K 105 lbs (48kg)<br />

3K 145 lbs (66kg)<br />

Control Panel<br />

Dimensions: Outer Panel 23.6” x 23.6” x 9.25”<br />

600 x 600 x 225mm<br />

Weight: 75 lbs (34kg)<br />

Screen from Cyclomix C.A.R.C.<br />

AVAILABLE CONFIGURATIONS<br />

Call for more information<br />

15

cyclomix recovery<br />

Electronic metering for recovery systems<br />

Cyclomix Recovery ACA<br />

The ACA has been designed for<br />

catalyzed coatings and has the<br />

ability to adapt to future green<br />

coatings.<br />

Recovers belt waste automatically<br />

and pumps it to the mix chamber<br />

where it is filtered and adjusted to<br />

the coatings desired density.<br />

Recovered and densitized material<br />

is introduced into a 3K mixing<br />

system where it is blended with the<br />

virgin coating and catalyst.<br />

When recovered material is unavailable,<br />

the system will automatically<br />

revert back to the original 2K virgin<br />

material and catalyst.<br />

Cyclomix Recovery ACM<br />

The ACM has been designed for<br />

catalyzed coatings and has the<br />

ability to adapt to future green<br />

coatings.<br />

Belt waste is manually recovered<br />

and densitized.<br />

The densitized material is brought to<br />

the machine where it is pumped and<br />

introduced into a 3K mixing system<br />

where it is blended with the virgin<br />

coating and catalyst.<br />

When recovered material is unavailable,<br />

the system will automatically<br />

revert back to the original 2K virgin<br />

material and catalyst.<br />

Cyclomix Recovery UV<br />

The UV system has been designed<br />

for water reducible green UV cure<br />

coatings and has the ability to adapt<br />

to future green coatings.<br />

Recovers belt waste automatically<br />

and pumps it to the mix chamber<br />

where the material is filtered and<br />

adjusted to the coatings desired<br />

density.<br />

Recovered and densitized<br />

material is introduced into a<br />

2K mixing system where it is<br />

blended with the virgin UV<br />

coating.<br />

• Fast return on investment<br />

• Belt waste generation reduced by up to 90%<br />

• Automatic accuracy with precision metering<br />

• Built in fail-safes: fill it and let it perform<br />

• Repeatable quality<br />

• Report generation<br />

• The density tank has been shaped to assure<br />

quick and efficient flushing<br />

• All waste and flushing material is deposited in a<br />

waste recovery drum for easy removal from the area<br />

• The reclaim and density adjustment clean up will be<br />

done with a combination of solvent and compressed air<br />

• Reduces toxic waste generation<br />

• Converts easily to future green coatings<br />

• Fast system shut down<br />

• Stainless steel wetted parts for all materials<br />

• Visual monitors and audible alarms<br />

Mix Chamber<br />

16

literature<br />

Propane Tank Market<br />

Chemical Agent<br />

Resistant Coating<br />

Steel Door Market<br />

Wind Energy Market<br />

Color Changer Family<br />

Horizontal Line<br />

Bell Finishing<br />

6X-CTE-<br />

Vertical Finishing System<br />

Linear Flat-Line<br />

Cyclomix Recovery<br />

Series<br />

17

EXEL Industries...<br />

An International Presence<br />

Canada<br />

EXEL North America, consisting of our American, Canadian and Mexican subsidiaries, is a wholly owned subsidiary of<br />

EXEL Industries. They bring four finishing, fluid handling and dispensing brands under one company banner.<br />

The four brands offer the widest range of controlled application equipment for finishing and dispensing in the world.<br />

Our Vision<br />

To remain the global leader in high value added custom and standard solutions for controlled applications of<br />

powders and fluids, thick or thin, in the industrial and automotive markets.<br />

Our Values<br />

We are a team of people with integrity that have a mission-to-serve with a sense of urgency<br />

in delivering the right solution and service through our network of distributors.<br />

Our Mission<br />

Experts in Finishing and Dispensing Solutions<br />

18

EXEL A north american Presence<br />

Precision Finishing, Fluid Handling and Dispensing Brands<br />

Non-electrostatic guns, pumps and<br />

accessories for thin fluids<br />

Electrostatic application equipment<br />

for liquid and powder<br />

Dispense heads, pumps<br />

and accessories for thick fluids<br />

Full Range of Equipment<br />

Manual<br />

Airspray<br />

Manual<br />

Airmix ®<br />

Manual<br />

Liquid<br />

Electrostatic<br />

Manual<br />

Powder<br />

Automatic<br />

Non-Electrostatic<br />

Automatic<br />

Liquid<br />

Electrostatic<br />

Automatic<br />

Powder<br />

Fluid Delivery<br />

Pumps &<br />

Accessories<br />

Dispensing<br />

(RAM) Pumps<br />

& Accessories<br />

Plural Component<br />

Systems &<br />

Accessories<br />

Wood<br />

Manufacturing Markets Served<br />

Industrial<br />

Feeder<br />

Plants<br />

Automotive<br />

Plymouth, Michigan<br />

Scarborough, Ontario<br />

Queretaro, Mexico<br />

Plymouth, Michigan<br />

Scarborough, Ontario<br />

Queretaro, Mexico<br />

Plymouth, Michigan<br />

Scarborough, Ontario<br />

Queretaro, Mexico<br />

Plymouth, Michigan<br />

Scarborough, Ontario<br />

Queretaro, Mexico<br />

EXEL R&D, Testing, Training, Distribution and Manufacturing Locations<br />

Over 100 North American<br />

Distributors for Customer Sales and Service<br />

19

Experts in Finishing and Dispensing Solutions<br />

KREMLIN REXSON offers a wide range of pumps and equipment for the protection of materials<br />

and application of paints, sealants and adhesives in many different markets such as:<br />

• Rolling equipment<br />

• Plastic industries<br />

• Wood (kitchens, bathrooms, furniture<br />

and joineries)<br />

• Leather<br />

• Renewable energies (windmills, solar)<br />

• Aeronautics<br />

• Construction equipment<br />

• Packaging (drums and containers, etc...)<br />

• Appliances<br />

• Consumer goods<br />

• Glass coating<br />

• Cycles and motorcycles<br />

EXEL North America, Inc.<br />

North American Headquarters<br />

45001 5 Mile Road<br />

Plymouth, MI 48170<br />

Toll Free: (800) 573-5554<br />

Phone: (734) 979-0100<br />

Fax: (734) 927-0064<br />

http://www.kremlinrexson-sames.com/en/usa/<br />

EXEL North America, Inc.<br />

Canadian Branch<br />

931 Progress Ave., Unit 7<br />

Scarborough, Ontario M1G 3V5<br />

Toll Free: (800) 450-0655<br />

Phone: (416) 431-5017<br />

Fax: (416) 431-9171<br />

<strong>Kremlin</strong> <strong>Rexson</strong><br />

EXEL-NA, S.A. de C.V.<br />

Acceso III N°16A Int 15A<br />

Conjunto Quadrum<br />

Parque Industrial Benito Juárez<br />

Santiago de Querétaro, Qro.<br />

México, C.P. 76120<br />

+52 (442) 209-5027 /161-2595 Ext 170 Oficina<br />

+52 (81) 1811-0955 Nextel ID: 92*898188*2<br />

LT 999-100-207<br />

© 2012 EXEL North America, Inc. reserves the right to modify the characteristics of its equipment. © Pictures : ynamaku, Roy L., cornelius.