PROGRESSING CAVITY PUMP SYSTEMS - National Oilwell Varco

PROGRESSING CAVITY PUMP SYSTEMS - National Oilwell Varco

PROGRESSING CAVITY PUMP SYSTEMS - National Oilwell Varco

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>PROGRESSING</strong> <strong>CAVITY</strong> <strong>PUMP</strong> <strong>SYSTEMS</strong>

<strong>PROGRESSING</strong> <strong>CAVITY</strong> <strong>PUMP</strong> <strong>SYSTEMS</strong><br />

One Company, Unlimited Solutions<br />

Since 1841, <strong>National</strong> <strong>Oilwell</strong> <strong>Varco</strong>® has been dedicated to ensuring customers receive the highest quality oilfield<br />

products and services. <strong>National</strong> <strong>Oilwell</strong> <strong>Varco</strong> is a worldwide leader in the design, manufacture and sale of equipment<br />

and components used in oil and gas drilling and production operations, the provision of oilfield services, and supply<br />

chain integration services to the upstream oil and gas industry. NOV® also provides supply chain services through its<br />

network of more than 200 distribution service centers located near major drilling and production activity worldwide.<br />

We continue to build upon our unlimited, customer-focused solutions and are proud to deliver our Artificial Lift Systems<br />

through the NOV Monoflo division.<br />

NOV Monoflo<br />

Artificial Lift Systems<br />

Coverage<br />

The NOV Monoflo division is a true partner and worldwide source for complete Artificial Lift equipment and packaged<br />

solutions. Our Artificial Lift professionals collaborate with you to properly evaluate well conditions and provide customized<br />

artificial lift solutions that will optimize your production.<br />

• Professional Well Evaluation<br />

• Surface and Subsurface Equipment<br />

• Controllers and Production Automation<br />

• All Production Accessories and Expendables<br />

• Global Supply Chain and Service Solutions<br />

LLOYDMINSTER, CANADA HOUSTON, TEXAS

Progressing Cavity Pump Systems<br />

NOV Monoflo is a leader in the design, manufacture and<br />

supply of progressing cavity pumps (PC Pumps) and artificial<br />

lift solutions worldwide. With over 75 years of experience, 8<br />

international sites and global distribution network, we provide<br />

a range of PC Pump solutions that fulfill many oilfield production<br />

needs. Our line of downhole PC Pumps are designed for use<br />

in both oil production and dewatering applications where the<br />

economics of production demand efficiency, reliability and low<br />

life-cycle cost from the production equipment.<br />

Common Applications<br />

• Heavy Crude (aggressive geometry)<br />

• Medium Crude<br />

• Coal Bed Methane – CBM (specialized elastomers)<br />

• Shale Oil and Water<br />

• High GOR Wells<br />

Features and Benefits<br />

• Lower Capital Cost<br />

The lack of expensive foundations, simple construction<br />

and the compact surface drive units reduce start-up costs<br />

which allow for more pumps to be installed and more oil<br />

recovered.<br />

• Lower Running Cost<br />

Typically, a PC pump has an overall efficiency rating of 70%<br />

which is significantly higher than alternative lift methods<br />

and lowers the cost per barrel of recovered fluid.<br />

• Reliable<br />

The simple construction consists of only one moving part<br />

downhole and has no standing or traveling valves to block.<br />

The pump handles gas and solids without blocking and is<br />

more resistant to abrasive wear.<br />

• Environmentally Acceptable Profile<br />

The low, unobtrusive profile of the quiet running surface<br />

drivehead makes the PC pump ideal for environmentally<br />

sensitive areas. Also, state of the art Leak Detection<br />

Stuffing Boxes help protect the environment from spills.<br />

www.nov.com/ArtificialLift<br />

MonofloALS@nov.com

<strong>PROGRESSING</strong> <strong>CAVITY</strong> <strong>PUMP</strong> <strong>SYSTEMS</strong><br />

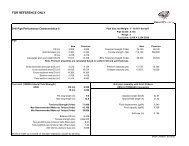

Progressing Cavity Pump Specifications<br />

<strong>PUMP</strong> STATOR ROTOR INSERTABLE SLIMHOLED STATOR<br />

PC Pump Series Displacement Lift Capacities Top Connection EUE Max O.D. Length Top Connector Pin Max O.D. Length Tubing Sizes Max O.D. Length<br />

Metric Imperial Bbl/Day/100 RPM psi ft in in in in in in 2⅞” 3½” 4½” 5½” in in<br />

2-1000 13-3300 13 1400 3300<br />

49<br />

64<br />

2-2000 13-6550 13 2800 6550 1.9" Box 2.25 98 ¾ API Pin 1.04 113 • • • •<br />

2-3000 13-9850 13 4200 9850 147 162<br />

4-600 25-2000 25 852 2000<br />

48<br />

63<br />

4-1200 25-4100 25 1704 4100 2⅞" Pin 3.1 98 ¾ API Pin 1.368 110 • • •<br />

4-1800 25-6000 25 2556 6000 147 158<br />

5-3000 28-9800 28 4200 9800 1.9" Box 2.25 98 ¾ API Pin 1.04 113 • • • •<br />

7-1050 44-3450 44 1491 3450<br />

147<br />

162<br />

7-1400<br />

7-1750<br />

44-4600<br />

44-5750<br />

44<br />

44<br />

1988<br />

2485<br />

4600<br />

5750<br />

1.9" Box 2.25<br />

196<br />

245<br />

¾ API Pin 1.08<br />

211<br />

260<br />

• • • •<br />

7-2100 44-6900 44 2982 6900 294 309<br />

9-1000 56-3300 56 1400 3300<br />

98<br />

113<br />

9-1500<br />

9-2000<br />

56-4900<br />

56-6550<br />

56<br />

56<br />

2130<br />

2800<br />

4900<br />

6550<br />

2⅜" Box 2.76<br />

147<br />

196<br />

⅞ API Pin 1.39<br />

162<br />

211<br />

• • •<br />

9-2500 56-8200 56 3550 8200 245 260<br />

10-600<br />

10-1200<br />

10-1800<br />

60-2000<br />

60-4100<br />

60-6000<br />

60<br />

60<br />

60<br />

852<br />

1704<br />

2556<br />

2000<br />

4100<br />

6000<br />

2⅞" Box<br />

or 3½" Box<br />

3.5<br />

66<br />

131<br />

196<br />

⅞ API Pin 1.677<br />

80<br />

146<br />

211<br />

• •<br />

13-1500 82-5000 82 2130 5000 3½" Box 4.2 131 1 API Pin 2.450 146 •<br />

15-1400<br />

15-1800<br />

95-4600<br />

95-600<br />

95<br />

95<br />

1988<br />

2556<br />

4600<br />

6000<br />

2⅞ Box or 3½" Box 3.5<br />

172<br />

222<br />

⅞ API Pin 1.925<br />

187<br />

237<br />

• •<br />

16-840 100-2750 100 1192 2750<br />

147<br />

162<br />

16-1120<br />

16-1400<br />

100-3650<br />

100-4600<br />

100<br />

100<br />

1590<br />

1988<br />

3650<br />

4600<br />

2⅜" Box 2.76<br />

196<br />

245<br />

⅞ API Pin 1.39<br />

211<br />

260<br />

• • •<br />

16-1680 100-5650 100 2385 5500 294 309<br />

21-660 131-2150 131 937 2150<br />

147<br />

162<br />

21-880<br />

21-1100<br />

131-2900<br />

131-3600<br />

131<br />

131<br />

1249<br />

1562<br />

2900<br />

3600<br />

2⅜" Box 2.76<br />

196<br />

245<br />

⅞ API Pin 1.39<br />

211<br />

260<br />

• • •<br />

21-1320 131-4350 131 1874 4350 294 309<br />

24-900<br />

24-1500<br />

24-1800<br />

24-3000<br />

150-4100<br />

150-5000<br />

150-6000<br />

150-10000<br />

150<br />

150<br />

150<br />

150<br />

1278<br />

2130<br />

2556<br />

4260<br />

3100<br />

5000<br />

6000<br />

10000<br />

2⅞" Box<br />

or<br />

3½" Box<br />

3.5<br />

158<br />

262<br />

316<br />

527<br />

⅞ API Pin 1.790<br />

173<br />

277<br />

331<br />

542<br />

• •<br />

32-1500<br />

32-1800<br />

32-2700<br />

200-5000<br />

200-6000<br />

200-8850<br />

200<br />

200<br />

200<br />

2130<br />

2556<br />

3834<br />

5000<br />

3½" Box x 2’ Weld Ext. or<br />

6000<br />

8850<br />

4½" LTC Pin x 2’ Weld Ext.<br />

4.5<br />

292<br />

346<br />

507<br />

1 API Pin 2.272<br />

284<br />

337<br />

498<br />

• 3.820<br />

337*<br />

390*<br />

527*<br />

40-750<br />

40-1125<br />

40-1500<br />

250-2500<br />

250-3750<br />

250-5000<br />

250<br />

250<br />

250<br />

1065<br />

1597<br />

2130<br />

2500<br />

3750<br />

5000<br />

2⅞ Box<br />

or 3½ Box<br />

3.5<br />

172<br />

258<br />

344<br />

1 API Pin 1.810<br />

187<br />

273<br />

359<br />

• •<br />

44-900<br />

44-1400<br />

44-1800<br />

280-3100<br />

280-4600<br />

280-6000<br />

280<br />

280<br />

280<br />

1278<br />

1988<br />

2556<br />

3100<br />

3½" Box x 2’ Weld Ext. or<br />

4600<br />

6000<br />

4½" LTC Pin x 2’ Weld Ext.<br />

4.5<br />

175<br />

274<br />

326<br />

1 API Pin 2.200<br />

166<br />

265<br />

317<br />

• 3.820<br />

219*<br />

303*<br />

370*<br />

54-900 340-3100 340 1278 3100<br />

266<br />

257<br />

310*<br />

54-1200<br />

54-1500<br />

340-4100<br />

340-5000<br />

340<br />

340<br />

1704<br />

2130<br />

4100<br />

5000<br />

3½ Box x 2’ Weld Ext. or<br />

4½ LTC Pin x 2’ Weld Ext.<br />

4.5<br />

346<br />

427<br />

1 API Pin 2.272<br />

337<br />

418<br />

• 3.820<br />

390*<br />

471*<br />

54-1800 340-6000 340 2556 6000 507 498 551*<br />

64-520 400-1750 400 738 1750<br />

185<br />

176<br />

229*<br />

64-800<br />

64-1040<br />

400-2650<br />

400-3450<br />

400<br />

400<br />

1136<br />

1476<br />

2650 3½" Box x 2’ Weld Ext. or<br />

3450 4½" LTC Pin x 2’ Weld Ext.<br />

4.5<br />

266<br />

346<br />

1 API Pin 2.259<br />

257<br />

337<br />

• 3.820<br />

316*<br />

390*<br />

64-1300 400-4350 400 1846 4350 427 418 471*<br />

70-900<br />

70-1350<br />

70-1800<br />

500-2700<br />

500-4100<br />

500-5300<br />

440<br />

440<br />

440<br />

1278<br />

1917<br />

2556<br />

2700<br />

3½" Box x 2’ Weld Ext. or<br />

4100<br />

6000<br />

4½" LTC Pin x 4’ Weld Ext.<br />

4.5<br />

201<br />

290<br />

378<br />

1⅛ API Pin 2.638<br />

192<br />

281<br />

369<br />

•<br />

80-800 500-2700 500 1136 2700<br />

201<br />

192<br />

80-1200<br />

80-1600<br />

500-4100<br />

500-5300<br />

500<br />

500<br />

1704<br />

2272<br />

4100 3½" Box x 2’ Weld Ext. or<br />

5300 4½" LTC Pin x 2’ Weld Ext.<br />

4.5<br />

290<br />

378<br />

1⅛ API Pin 2.580<br />

281<br />

369<br />

•<br />

80-1800 500-6000 500 2556 6000 423 414<br />

96-520 600-1750 605 738 1750<br />

201<br />

192<br />

245*<br />

96-800<br />

96-1040<br />

96-1300<br />

600-2650<br />

600-3500<br />

600-4350<br />

605<br />

605<br />

605<br />

1136<br />

1476<br />

1846<br />

2650<br />

3½" Box x 2’ Weld Ext. or<br />

3450<br />

4350<br />

4½" LTC Pin x 2’ Weld Ext.<br />

4.5<br />

290<br />

378<br />

467<br />

1 API Pin 2.286<br />

281<br />

369<br />

458<br />

• 3.820<br />

341*<br />

378*<br />

511*<br />

96-1560 600-5350 605 2215 5100 555 546 599*<br />

98-1200<br />

98-1580<br />

98-1800<br />

615-4100<br />

615-5200<br />

615-6000<br />

615<br />

615<br />

615<br />

1704<br />

2243<br />

2556<br />

4100<br />

5200<br />

6000<br />

5½" LTC Pin<br />

or 4½" Box<br />

5.5<br />

263<br />

350<br />

399<br />

2⅜ PAC Pin 2.965<br />

285<br />

372<br />

421<br />

110-1600<br />

110-1800<br />

690-5300<br />

690-6000<br />

690<br />

690<br />

2272<br />

2556<br />

5300<br />

6000<br />

5½" LTC Pin<br />

or 4½" Box<br />

5.5<br />

350<br />

399<br />

2⅜ PAC Pin 2.970<br />

372<br />

421<br />

120-400<br />

120-800<br />

120-1000<br />

120-1200<br />

755-1350<br />

755-2650<br />

755-3400<br />

755-4100<br />

755<br />

755<br />

755<br />

755<br />

568<br />

1136<br />

1420<br />

1704<br />

1350<br />

2650<br />

3400<br />

4100<br />

3½" Box x 2’ Weld Ext.<br />

also has optional<br />

4 1/2" LTC Pin x 2' Weld Ext.<br />

4.5<br />

201<br />

378<br />

467<br />

555<br />

1 API Pin 2.275<br />

192<br />

369<br />

458<br />

546<br />

• 3.820<br />

245*<br />

422*<br />

511*<br />

599*<br />

130-1300<br />

130-1625<br />

820-4400<br />

820-5380<br />

820<br />

820<br />

1846<br />

2307<br />

4400<br />

5380<br />

5½" LTC Pin<br />

or 4½" Box<br />

5.5<br />

350<br />

438<br />

2⅜ PAC Pin 2.913<br />

372<br />

460<br />

150-600 940-2000 940 852 2000<br />

378<br />

369<br />

422*<br />

150-750<br />

150-900<br />

940-2500<br />

940-3100<br />

940<br />

940<br />

1065<br />

1278<br />

2500 3½" Box x 2’ Weld Ext. or<br />

3100 4½" LTC Pin x 2’ Weld Ext.<br />

4.5<br />

467<br />

555<br />

1 API Pin 2.264<br />

458<br />

546<br />

• 3.820<br />

511*<br />

599*<br />

150-1200 940-4000 940 1704 4000 732 723 776*<br />

165-1200<br />

165-1800<br />

1030-4100<br />

1030-6000<br />

1030<br />

1030<br />

1704<br />

2556<br />

4100<br />

6000<br />

6⅝" BTC Pin 6.6<br />

301<br />

402<br />

2⅞ PAC Pin 3.990<br />

322<br />

428<br />

200-1200<br />

200-1800<br />

1260-4100<br />

1260-6000<br />

1260<br />

1260<br />

1704<br />

2556<br />

4100<br />

6000<br />

7" LTC Pin 7.0<br />

301<br />

402<br />

2⅞ PAC Pin 4.330<br />

322<br />

428<br />

1<br />

*Slimholed stators are only 4" longer than standard stators due to a welded on collar at the bottom. 1 All 3.82" OD slimholed stators will have 2 7/8" Box connections.

Rotors, Stators and Elastomers<br />

Performance by Design<br />

Rotors are available in alloy steel (4140) with hard chrome plating which provides resistance<br />

to abrasion and wear. All pumps have 1:2 ratio lobe geometry and rotor chrome thickness<br />

within 0.010 and 0.020 inches.<br />

Through the use of advanced manufacturing technology and modern production techniques,<br />

finite machining and plating of the rotor profile is maintained, ensuring that the design<br />

performance is always achieved.<br />

Elastomers<br />

A range of stator elastomers is available allowing the pump to be selected for many<br />

downhole fluid conditions as described below.<br />

Rotors and Stators<br />

Elastomer Type General Description and Application Temperature Limit Tensile Strength Tear Strength Abrasion Resistance H 2 S Resistance CO 2 Resistance Hardness (IRHD)<br />

QS<br />

(Soft Nitrile)<br />

OD<br />

(Soft Nitrile - Buna L)<br />

RR<br />

(Nitrile)<br />

OBX<br />

(High Nitrile)<br />

OC<br />

(Hydrogenated Nitrile)<br />

• Very soft medium acrylonitrile content with good<br />

oil and solvent resistance and excellent abrasion<br />

resistance<br />

• Typically used in very abrasive and high water cut<br />

applications with low aromatic content fluids<br />

• Soft medium acrylonitrile content with good oil<br />

and solvent resistance and excellent abrasion<br />

resistance<br />

• Typically used in medium abrasive and high water<br />

cut applications with low aromatic content fluids<br />

• Medium acrylonitrile content with good oil and<br />

solvent resistance<br />

• Excellent abrasion resistance and mechanical<br />

properties<br />

• Typically used in abrasive and high water cut<br />

applications with low to medium aromatic content<br />

• High acrylonitrile content with improved oil and<br />

solvent resistance and excellent mechanical<br />

properties<br />

• Higher acrylonitrile content provides extra<br />

resistance to oils with medium to high aromatic<br />

content<br />

• High acrylonitrile content with similar properties<br />

to OB but with improved resistance to hydrogen<br />

sulfide (H S) and high temperature capability<br />

2<br />

80°C Good Good Excellent Good Poor 48-53<br />

90°C Good Excellent Excellent Good Fair 60-65<br />

100°C Good Excellent Excellent Good Good 68-72<br />

100°C Excellent Excellent Excellent Good Fair 70-75<br />

150°C Excellent Good Excellent Excellent Fair 69-75<br />

www.nov.com/ArtificialLift<br />

MonofloALS@nov.com

<strong>PROGRESSING</strong> <strong>CAVITY</strong> <strong>PUMP</strong> <strong>SYSTEMS</strong><br />

Two Run Insertable PC Pump<br />

NOV Monoflo has an innovative, new insertable progressing cavity pump design that allows the<br />

customer to insert a pc pump inside the production tubing and pressure test the tubing string with<br />

one easy to use tool.<br />

Features and Benefits<br />

• There is no need for a service rig to<br />

pull the production tubing to change a<br />

downhole pump<br />

• Pump changes can be done with a flushby<br />

equipped for rod handling<br />

• The unit minimizes the need to remove<br />

production tubing, reducing the cost of<br />

downhole gauge installations<br />

• Allows for pressure testing the<br />

production tubing as well as the primary<br />

seal, while inserting the stator.<br />

• The system has the ability to use any<br />

progressing cavity pump without<br />

performing any modifications.<br />

• The system can pull the rotor out of the<br />

well bore without unseating the primary<br />

seal.<br />

Mechanically Bonded Stator<br />

Well temperatures can increase due to natural conditions and the use of<br />

thermal stimulation techniques. These conditions challenge the viability of<br />

the traditional chemically bonded pc pump stator.<br />

One way to address this challenge is through new methods of anchoring the<br />

elastomers into the stator tube. NOV Monoflo has developed elastomeric<br />

stator technology to meet demands of high temperature wells.<br />

The mechanically bonded stator is comprised of 3 main components (not<br />

including the elastomer):<br />

• Stator Tube<br />

• Mechanical Bond Inserts<br />

• End Caps<br />

Available in two elastomer grades:<br />

• OBX suitable for temperatures up to 110° C<br />

• OC suitable for temperatures up to 150° C<br />

Available sizes:<br />

D32-900 (1 raw) D96-1040 (2 raw) D54-1800 (3 raw)<br />

D44-900 (1 raw) D150-300 (1 raw) D64-1560 (3 raw)<br />

D54-1200 (2 raw) D32-1800 (2 raw) D96-1560 (3 raw)<br />

D64-1040 (2 raw) D44-1800 (2 raw) D150-600 (2 raw)<br />

Rotor<br />

Operating<br />

Position<br />

Insert Tool<br />

Seating Nipple<br />

Insert<br />

Position<br />

Stator<br />

Tag-Bar<br />

Torque Anchor<br />

Seating Mandrel<br />

with Primary Seal

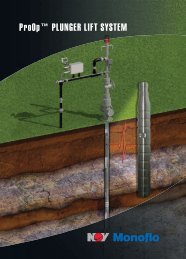

NO-GO Tag Progressing Cavity Pumps<br />

The NO-GO Tag system is a new advanced generation tool for rotor placement in progressing cavity<br />

pumps. It provides all the functionality of a traditional bottom tag bar system with the following<br />

advantages.<br />

Features and Benefits<br />

• Tags within the stator, leaving intake free of obstruction, allowing rotor to agitate solids<br />

• Coilable through the pump by only pulling up polish rod<br />

• Protects top end of stator elastomer by guiding coil entry through the pump<br />

• Positive tag for proper rotor placement by guiding rotor through timed helical tag passage into<br />

stator elastomer<br />

• Unique integrated design eliminates flow losses and extra connections<br />

• Tags using a conventional rod box<br />

• Ability to land pump lower in well<br />

• Eliminates costly mechanical tools below the pump while maintaining circulation clean-out<br />

capabilities<br />

Application<br />

• Medium to heavy oil<br />

• Wells producing solids (sand, coal fines, pyrite, etc.)<br />

• Wells with history of intake plugging<br />

• Wells with minimal cellar<br />

Charge Pumps<br />

Problem wells that produce slug sand, water, and/or gas can benefit from the use of a Charge Pump. These<br />

pumps have 3 main parts:<br />

• Production Pump - determines your lift capacity and final volume.<br />

• Pup Joint - usually located between the two pumps and has additional holes or slots depending on the<br />

application.<br />

• Charge Pump - higher volume, lower pressure pump that maintains consistent wellbore fluid by mixing it<br />

before entering the production pump.<br />

Charge Pumps<br />

Production Pump 10 15 24 32 40 44 54 64 70 80 96 120 150<br />

Charge Pump 10 40 or 24 40 96 40 96 150<br />

Specialty Components<br />

• Perforated Stator - High Gas Rate Applications<br />

• Hollow Rotor - Breaking up solids at intake<br />

NO-GO Tag Insert<br />

Bottom or Top View<br />

www.nov.com/ArtificialLift<br />

MonofloALS@nov.com

<strong>PROGRESSING</strong> <strong>CAVITY</strong> <strong>PUMP</strong> <strong>SYSTEMS</strong><br />

Hydraulic Driveheads<br />

HTD<br />

NOV Monoflo’s HTD hydraulic drivehead utilizes a bent axis motor that is<br />

coupled to a hollow shaft bearing box by a belt and pulley system, which<br />

transfers torque to the polished rod. Backspin is controlled through the<br />

hydraulic system. The motors are available in a variety of displacements to<br />

accommodate a wide variety of speeds and torques.<br />

Features and Benefits of the HTD Hydraulic Drivehead<br />

• Motor is available in various displacements<br />

• Standard synchronous belt and sheave system<br />

• Fully enclosed hinged belt guard<br />

CG-33<br />

Each model of the NOV Monoflo CG-33 hydraulic drivehead is a beltless top drive using<br />

gears to transfer torque to the polished rod. The precision ground gears reduce<br />

noise levels by up to five times in comparison to conventional belt drives,<br />

making the CG-33 drivehead an ideal solution for use in populated areas. Each<br />

CG-33 drive utilizes a radial piston motor designed to reduce internal friction<br />

and run efficiently. These driveheads are fitted with a hydraulically activated<br />

stuffing box that can withstand any progressing cavity pumping application.<br />

Features and Benefits of the CG-33 Hydraulic Drivehead<br />

• Enclosed gear housing eliminates need for belts, thus reducing field<br />

maintenance<br />

• Case hardened and precision ground gears drastically reduce noise levels.<br />

• Gear drive utilizes a radial piston motor connected to the input gear, and<br />

is available in various displacements<br />

• Pressurized stuffing box prevents fluid from entering the seal chamber<br />

extending the life of the seals<br />

• Built in polished rod vise allows stuffing box seal change without removal of<br />

drivehead or flush-by rig<br />

Technical Specifications<br />

Model HTD CG-33<br />

Max. System Pressure 3600 psi (245 kPa) 3500 psi (24,132 kPa)<br />

Max. System Temperature¹ 175 °F/ 80 °C 176 °F/80 °C<br />

Polish Rod Size 1¼" (32 mm) 1¼" (32 mm)<br />

Wellhead Connection 2d” EUE Pin or 38-3000<br />

psi-R31 Flange<br />

Thrust Bearing² Ca90-25,000 lbs /<br />

ISO-96,300 lbs<br />

Backspin Control Check valve on pressure side of<br />

the motor.<br />

Torque Control Adjustable pressure<br />

compensator on pump.<br />

38”-3000 psi-R31 Flange<br />

Ca90-33,500 lbs /<br />

ISO-129,000 lbs<br />

Check valve on pressure side of<br />

the motor.<br />

Adjustable pressure<br />

compensator on pump.<br />

Model HTD CG-33<br />

Variable Speed Control Adjustment knob on the pump. Adjustment knob on the pump.<br />

Height Integral 31" (787 mm) 31" (787 mm)<br />

Height Retrofit 47" (1194 mm) N/A<br />

Width 29" (737 mm) 24" (610 mm)<br />

Weight Integral 400 lbs (181 kg) 240 lbs (109 kg)<br />

Weight Retrofit 450 lbs (204 kg) N/A<br />

HTD Hydraulic Drivehead<br />

CG-33 Hydraulic Drivehead<br />

Bearing Box Grease Chevron Delo Grease EP NLGi2 1 tube (Chevron Ulti-Plex<br />

Synthetic Grease)<br />

¹ Maximum operating temperature may be limited by hydraulic oil. ² Ca90 load rating is for 90 million revolutions at 500 rpm. Reducing load by 50% increases life 10 times. Reducing speed by 50% doubles hours of life.

Electric Driveheads<br />

NOV Monoflo provides a complete line of Electric Driveheads for all your production<br />

needs.<br />

Features and Benefits<br />

• Robust frame<br />

• Detachable stuffing box<br />

• Operator-friendly guards and motor adjustments<br />

• Easy-to-adjust door for simple belt tightening<br />

• Accessible fill/drain spouts for easy oil changes<br />

• Bearing box is designed with a three-bearing system (Models C-50, C-60, C-80,<br />

and C-33M)<br />

• Hollow shaft bearing box (Model N-25)<br />

• Hydrodynamic brake (Models C-50, C-60, C-80, and C-33M)<br />

• Hydraulically actuated caliper disc braking system (Model N-25)<br />

• Brake reservoir for heat dissipation (Models C-50, C-60, C-80, and C-33M<br />

• Service and technical support<br />

Technical Specifications<br />

Model C-50 C-60 C-80 C-33M N-25<br />

Drive Type Direct Direct Direct Direct Direct<br />

Shaft Type Hollow Hollow Hollow Hollow Hollow<br />

Drive Style Bearing Box Bearing Box Bearing Box Bearing Bearing Box<br />

Input Style Vertical Vertical Vertical Vertical Vertical<br />

Drive Ratio 1:1 1:1 1:1 1:1 1:1<br />

Backspin Control<br />

Ratings<br />

Hydrodynamic Hydrodynamic Hydrodynamic Hydrodynamic Caliper Disc<br />

Max. Output Torque 2000 ft-lbs (2712 Nm) 2500 ft-lbs (3390 Nm) 3500 ft-lbs (4745 Nm) 1575 ft-lbs (2135 Nm) 600 ft-lbs (813 Nm)<br />

Thrust Bearing 195,000 ISO lbf 227,000 ISO lbf 310,000 ISO lbf 45,100 ISO lbf 96,300 ISO lbf<br />

Thrust Bearing¹ 50,500 Ca90 lbf 59,000 Ca90 lbf 80,400 Ca90 lbf 33,000 Ca90 lbf 25,000 Ca90 lbf<br />

Maximum Speed 600 rpm 600 rpm 600 rpm 600 rpm 500 rpm<br />

Horsepower Rating² 20 - 100 80 - 150 120 - 300 10 - 60 10 - 20<br />

Frame Type Single Motor Dual Motor Dual Motor Single Motor Single<br />

Polish Rod Size<br />

1¼” or 1½”<br />

(32mm or 38 mm)<br />

1½” (38 mm)<br />

1¼” or 2”<br />

(38 mm or 51mm)<br />

1¼” (32 mm) 1¼” (32 mm)<br />

Max. Operating Temp. 212°F / 100°C 212°F / 100°C 212°F / 100°C 428°F / 220°C 180°F / 80°C<br />

Dimensions<br />

Height with Retro. Stuffing Box 50” (1270mm) 55” (1397mm) 64” (1626mm) 44” (1118mm) 34” (864mm)<br />

Width 35” (889mm) 41” (1041mm) 42” (1067mm) 35” (889mm) 30” (762mm)<br />

Input Shaft Size 3¼” (83 mm) 3¼” (83 mm) 4¼” (108mm) 3¼” (83 mm) 2½” (64 mm)<br />

Weight 1350 lbs (612kg) 1700 lbs (771kg) 2100 lbs (953kg) 1350 lbs (612kg) 600 lbs (272kg)<br />

¹ Ca90 load rating is for 90 million revolutions. Reducing load one half increases life 10 times. Reducing rpm by one half doubles hours of life.<br />

² Maximum HP rating based on frame size only. Care must be taken in selecting motor and sheave combinations to ensure input rod torque is not exceeded.<br />

N-25 Electric Drivehead<br />

C-33M Electric Drivehead<br />

C-50 Electric Drivehead<br />

C-60 Electric Drivehead<br />

C-80 Electric Drivehead<br />

www.nov.com/ArtificialLift<br />

MonofloALS@nov.com

<strong>PROGRESSING</strong> <strong>CAVITY</strong> <strong>PUMP</strong> <strong>SYSTEMS</strong><br />

Leak Free Stuffing Box<br />

The NOV Monoflo Leak Free (LF) stuffing box is a pre-built assembly that has been exclusively<br />

designed to simplify monitoring seal wear. It consists of a double mechanical seal supplied<br />

in a single sealed cartridge.<br />

Features and Benefits<br />

• Designed with a two bearing system consisting of seal bearings designed to be<br />

in one cartridge for easy replacement which results in less downtime during<br />

maintenance<br />

• Can be mounted directly on drivehead with or without a booth<br />

• Utilizes a double mechanical seal supplied as a sealed cartridge, to deliver extended periods of leak free<br />

operation and contains any leaked fluid inside the unit<br />

• Double sealing mechanism performs an improved sealing function.<br />

• Easy fitting of the cartridge arrangement with no setting requirement normally associated with conventional<br />

mechanical seals; seal abuts bearing to set working length<br />

• Positive drive from the spindle via key through sleeve of the mechanical seal<br />

• All sealing faces are made from solid material for increased pressure and thermal stability<br />

• Equipped with a leakage detection unit which provides a visible indication to any breach of the primary seal<br />

and also ensures barrier fluid lubrication of the seal faces for maximum durability<br />

• The leakage detection unit can be reset after seal replacement<br />

Hydrodynamic Brake<br />

The Hydrodynamic Brake consists of a stationary half (stator) and<br />

a rotary half (rotor). The stator is bolted into the housing and the<br />

rotor is coupled to the shaft. During normal operation the rotor spins<br />

freely. When the unit goes into backspin, the rotor begins to rotate<br />

in the counter clockwise direction. The working fluid is then forced<br />

to the outside of the rotor and creates a circular flow path inside the<br />

brake cavity. As the energized fluid from the rotor comes into contact<br />

with the stationary fins of the stator, the energy is transferred to the<br />

stator and then back to the working fluid as heat. A small amount of<br />

working fluid is continually removed from the system and replaced<br />

with new fluid. The working fluid contained in the drivehead reservoir<br />

is used as the braking medium, which allows the energy stored in the<br />

fluid column and rod string to safely dissipate without the drivehead<br />

reaching excessive backspin speeds.<br />

Features and Benefits<br />

• Non-friction brake eliminates wear on brake components<br />

• Brake capable of 2000 ft-lbs resisting torque at 250 hp<br />

• Reliable and repeatable braking<br />

• Backspin energy is absorbed by the working fluid<br />

• Heat generated by braking is dissipated by the fluid reservoir<br />

• Consistent braking with minimal maintenance throughout the<br />

drivehead’s life<br />

Brake Stator<br />

Brake Rotor<br />

Hydrodynamic Brake Curves

VFD Controller<br />

The NOV Monoflo Progressing Cavity Pump Controller provides a<br />

number of features specifically designed for operation of progressing<br />

cavity pumps. The drive combines motor and pump control into a<br />

single, compact package that increases production, improves energy<br />

efficiency and enhances the reliability of both new and existing<br />

pumping systems.<br />

Multiple Constraint Optimization<br />

At any instant during the life of a well, there is a single constraint<br />

that limits production. Production can be maximized without<br />

compromising efficiency or reliability by forcing the system to<br />

operate at the constraint limiting production at each instant of time.<br />

Determining the applicable limits and moving smoothly between<br />

them in real time is a key advantage of the system. Models of all<br />

the system elements are run in real time at the wellhead to detect<br />

appropriate limits and enforce associated control strategies. At<br />

different points in time, the system may be limited by motor voltage,<br />

motor current, motor speed, motor torque, motor thermal capacity,<br />

power demand, rod string torque, flow line pressure, fluid level, or<br />

well inflow. Multiple constraint optimization is particularly beneficial<br />

in applications with variable inflow conditions, such as those found in<br />

coal-bed methane, high gas/oil ratio, and thermally stimulated wells.<br />

Sensorless Operation<br />

The drive uses a number of unique methods for precisely determining<br />

performance parameters from models of the pumping system<br />

elements without requiring external surface or downhole sensors.<br />

Sensorless system variables including rod speed, rod torque, pump<br />

speed, pump torque, fluid flow, fluid level, suction pressure, discharge pressure, and differential pressure can be<br />

observed through the drive keypad/display or recorded as circle charts and time-based plots. Fluid level, pump flow,<br />

and total production are displayed in selectable engineering units.<br />

Sophisticated Modeling<br />

Embedded mathematical models of the drive, motor, drive head, rod string, pump, flow line, tubing, casing, fluid, and<br />

reservoir use component specifications and well completion information along with field setup parameters to monitor<br />

pumping system operation. Identification routines automatically determine installation-dependent system parameters<br />

including those of the motor, rod string, and pump. The models capture the thermal, mechanical, electrical, and<br />

hydraulic behavior of the system to control the pumping process with greater precision than ever before.<br />

Pump Speed Control<br />

The drive provides a number of options for manual, remote, and automatic control of pump speed. Speed commands<br />

can be selected from a number of sources including potentiometer adjustments, keypad presets, serial data<br />

communications, and internal optimization controllers. The motor can be operated up to twice base speed at constant<br />

power. This allows the overall gear ratio to be increased, thereby providing increased low-speed torque without loss<br />

of maximum pump speed. Dual motors can be controlled from a single drive for operation of large pumps. The system<br />

can be configured for optimization of fluid production, gas production, energy efficiency, and/or power flow.<br />

www.nov.com/ArtificialLift<br />

MonofloALS@nov.com

Corporate<br />

Headquarters<br />

7909 Parkwood Circle Drive<br />

Houston, Texas 77036<br />

United States<br />

Phone: 713 375 3700<br />

Fax: 713 346 7687<br />

Sales<br />

8708 West Little York Road<br />

Suite 100<br />

Houston, Texas 77040<br />

United States<br />

Phone: 281 854 0300<br />

Fax: 281 854 0301<br />

<strong>National</strong> <strong>Oilwell</strong> <strong>Varco</strong> has produced this brochure for general information only, and it is not<br />

intended for design purposes. Although every effort has been made to maintain the accuracy and<br />

reliability of its contents, <strong>National</strong> <strong>Oilwell</strong> <strong>Varco</strong> in no way assumes responsibility for liability for any<br />

loss, damage or injury resulting from the use of information and data herein. All applications for the<br />

material described are at the user’s risk and are the user’s responsibility.<br />

All brands listed are trademarks of <strong>National</strong> <strong>Oilwell</strong> <strong>Varco</strong>.<br />

One Company . . . Unlimited Solutions<br />

Downhole Solutions<br />

Drilling Solutions<br />

Engineering and Project Management Solutions<br />

Industrial Solutions<br />

Lifting and Handling Solutions<br />

Production Solutions<br />

Supply Chain Solutions<br />

Tubular and Corrosion Control Solutions<br />

Well Service and Completion Solutions<br />

MonofloALS@nov.com www.nov.com<br />

© 2012 <strong>National</strong> <strong>Oilwell</strong> <strong>Varco</strong><br />

D392004432-MKT-001 Rev. 02