Annual Report 2014

This is the 2014 annual report of Etex Group

This is the 2014 annual report of Etex Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Environmental report<br />

Protecting our planet<br />

3.1<br />

Protecting our planet<br />

As a leader in sustainable<br />

building solutions,<br />

limiting our impact on the<br />

planet is important for<br />

Etex. In <strong>2014</strong>, we stayed<br />

true to our two-pronged<br />

strategy: minimising<br />

our use of energy and<br />

natural resources by<br />

manufacturing more<br />

efficiently, and helping<br />

our customers reduce<br />

their carbon footprint<br />

through our products and<br />

solutions.<br />

Building technology plays a critical role<br />

in addressing global climate challenges.<br />

That is why we incorporate environmental<br />

considerations into every aspect of our<br />

business: our affordable and sustainable<br />

products allow customers to create spaces<br />

that are both comfortable and energy<br />

efficient, while our sites are geared towards<br />

the reduction of our own environmental<br />

impact.<br />

Energy consumption and<br />

CO2 emissions<br />

Many of our processes require heating to<br />

guarantee the final product quality. This<br />

makes reducing our energy consumption<br />

a complex and ongoing challenge.<br />

Nevertheless, lowering our carbon footprint<br />

is an important part of our environmental<br />

efforts. Of course, striving to reduce energy<br />

consumption is inextricably linked with<br />

business objectives, such as reducing<br />

production costs and safeguarding our<br />

competitive position by using less energy.<br />

Our manufacturing and engineering<br />

departments continue to focus on<br />

initiatives such as cogeneration to enable<br />

further progress.<br />

The attached charts show the percentages<br />

of energy used from different sources. In<br />

<strong>2014</strong>, we used 2% more energy than the<br />

year before.<br />

The consumption of energy per tonne<br />

of material produced increased by over<br />

2%, reaching 671 kWh. Meanwhile,<br />

CO2 emissions per tonne produced<br />

rose from 113 to 114.<br />

More energy, less waste: how<br />

we recover and reuse heat<br />

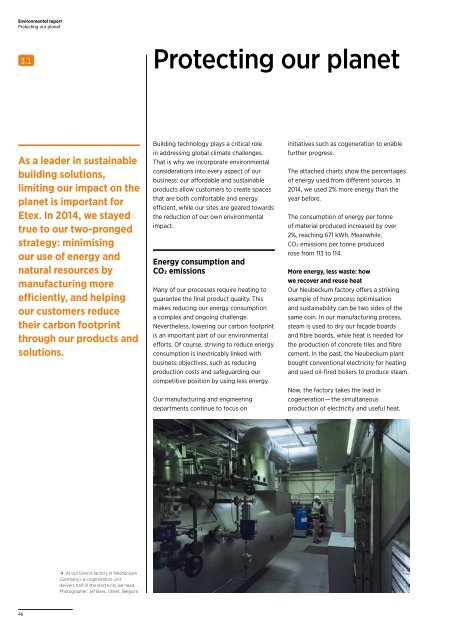

Our Neubeckum factory offers a striking<br />

example of how process optimisation<br />

and sustainability can be two sides of the<br />

same coin. In our manufacturing process,<br />

steam is used to dry our façade boards<br />

and fibre boards, while heat is needed for<br />

the production of concrete tiles and fibre<br />

cement. In the past, the Neubeckum plant<br />

bought conventional electricity for heating<br />

and used oil-fired boilers to produce steam.<br />

Now, the factory takes the lead in<br />

cogeneration — the simultaneous<br />

production of electricity and useful heat.<br />

ppAt our Eternit factory in Neubeckum<br />

(Germany), a cogeneration unit<br />

delivers half of the electricity we need.<br />

Photographer: Jef Boes, Ghent, Belgium.<br />

46