Section D â Hollow Cone Spray Nozzles - Spraying Systems Co.

Section D â Hollow Cone Spray Nozzles - Spraying Systems Co.

Section D â Hollow Cone Spray Nozzles - Spraying Systems Co.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

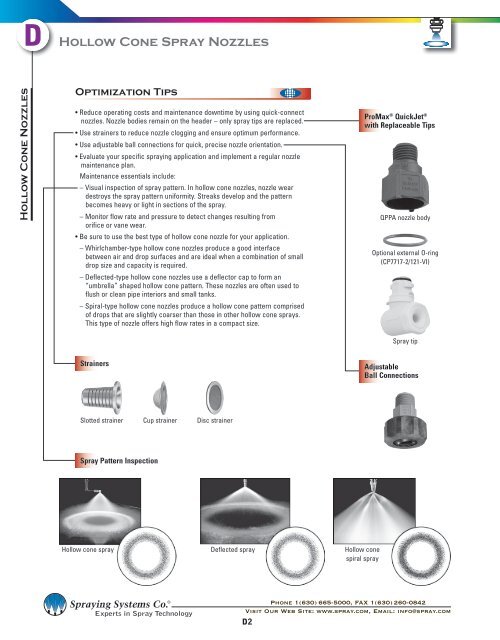

<strong>Hollow</strong> <strong><strong>Co</strong>ne</strong> <strong>Spray</strong> <strong>Nozzles</strong><br />

<strong>Hollow</strong> <strong><strong>Co</strong>ne</strong> <strong>Nozzles</strong><br />

Optimization Tips<br />

• Reduce operating costs and maintenance downtime by using quick-connect<br />

nozzles. Nozzle bodies remain on the header – only spray tips are replaced.<br />

• Use strainers to reduce nozzle clogging and ensure optimum performance.<br />

• Use adjustable ball connections for quick, precise nozzle orientation.<br />

• Evaluate your specific spraying application and implement a regular nozzle<br />

maintenance plan.<br />

Maintenance essentials include:<br />

– Visual inspection of spray pattern. In hollow cone nozzles, nozzle wear<br />

destroys the spray pattern uniformity. Streaks develop and the pattern<br />

becomes heavy or light in sections of the spray.<br />

– Monitor flow rate and pressure to detect changes resulting from<br />

orifice or vane wear.<br />

• Be sure to use the best type of hollow cone nozzle for your application.<br />

– Whirlchamber-type hollow cone nozzles produce a good interface<br />

between air and drop surfaces and are ideal when a combination of small<br />

drop size and capacity is required.<br />

– Deflected-type hollow cone nozzles use a deflector cap to form an<br />

“umbrella” shaped hollow cone pattern. These nozzles are often used to<br />

flush or clean pipe interiors and small tanks.<br />

– Spiral-type hollow cone nozzles produce a hollow cone pattern comprised<br />

of drops that are slightly coarser than those in other hollow cone sprays.<br />

This type of nozzle offers high flow rates in a compact size.<br />

ProMax ® QuickJet ®<br />

with Replaceable Tips<br />

QPPA nozzle body<br />

Optional external O-ring<br />

(CP7717-2/121-VI)<br />

<strong>Spray</strong> tip<br />

Strainers<br />

Adjustable<br />

Ball <strong>Co</strong>nnections<br />

Slotted strainer<br />

Cup strainer<br />

Disc strainer<br />

<strong>Spray</strong> Pattern Inspection<br />

<strong>Hollow</strong> cone spray<br />

Deflected spray<br />

<strong>Hollow</strong> cone<br />

spiral spray<br />

Phone 1(630) 665-5000, FAX 1(630) 260-0842<br />

Visit Our Web Site: www.spray.com, Email: info@spray.com<br />

D2