Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Table of Contents<br />

Overview<br />

Sponsors & Supporters..............................................................2<br />

Committees...............................................................................3<br />

Staff.............................................................................................4<br />

Symposium Map.......................................................................5<br />

Week-At-A-Glance..................................................................6<br />

Tutorials & Workshops-At-A-Glance.......................................8<br />

Sunday, 24 June 2012<br />

Detailed Agenda<br />

Pre-Registration.............................................................................10<br />

Monday, 25 June 2012<br />

Tutorials & Workshops...................................................................10<br />

Small Business Forum.....................................................................11<br />

Welcome Reception and Exhibit & Poster Kick-Off.........................11<br />

Tuesday, 26 June 2012<br />

Plenary Session..............................................................................12<br />

Hypersonics Session (Track 1)......................................................13<br />

Breakthrough Innovations Session (Track 2)................................14<br />

Wednesday, 27 June 2012<br />

Hypersonics Session (Track 1)......................................................15<br />

Poster Session & Caribbean Reception.....................................17<br />

Space Materials Experiments & Environmental Effects<br />

Simulation Session (Track 2).........................................................18<br />

Space Exploration Session (Track 3)...........................................20<br />

Thursday, 28 June 2012<br />

Missiles & Missile Defense Session (Track 1)................................22<br />

Space Exploration Session (Track 2)...........................................24<br />

Orbital Technologies & Operations Session (Track 2)...............25<br />

Grand Prize Give-Away................................................................26<br />

Poster Session..........................................................................26<br />

NSMMS Exhibit Map................................................................30<br />

NSMMS Exhibitors....................................................................31<br />

Notes........................................................................................39<br />

1

Sponsors & Supporters<br />

Lead Industry Sponsor<br />

General Dynamics Information Technology<br />

Additional Industry Sponsors<br />

ATK<br />

The Boeing Company<br />

Plasma Processes, LLC<br />

Pratt & Whitney Rocketdyne<br />

Scot Forge Company<br />

Ultramet Corporation<br />

Supporters<br />

Aerojet<br />

Aerospace Corporation<br />

Air Force Research Laboratory<br />

Air Force Office of Scientific Research<br />

Army Aviation & Missile Research Development & Engineering Center<br />

Army Space & Missile Defense Command<br />

Arnold Engineering Development Center<br />

Ball Aerospace and Technologies Corporation<br />

Defense Advanced Research Projects Agency<br />

Lockheed Martin Space Systems<br />

Materials Research & Design, Inc.<br />

Missile Defense Agency<br />

NASA Ames Research Center<br />

NASA Headquarters<br />

NASA Johnson Space Center<br />

NASA Langley Research Center<br />

NASA Marshall Space Flight Center<br />

Naval Surface Warfare Center Carderock Division<br />

Northrop Grumman Aerospace Systems<br />

Oak Ridge National Laboratory<br />

Rice University<br />

Southern Research Institute<br />

USEC, Inc.<br />

2

Planning & Steering Committees<br />

Core Planning Team<br />

Advisor: Mr. Eric Becker, AFRL<br />

Advisor: Mr. Shane Juhl, AFRL<br />

Advisor: Mr. Patrick Sisson, GDIT<br />

Advisor: Dr. Monica Stucke, AFRL<br />

Advisor: Dr. Andy Swanson, AFRL<br />

Symposium Coordinator: Ms. Michelle Williams, GDIT<br />

Steering Committee<br />

Government<br />

Mr. David Brewer, NASA LaRC<br />

Dr. Anthony Calomino, NASA LaRC<br />

Dr. Charles Camarda, NASA HQ<br />

Dr. Douglas Deason, MDA<br />

Mr. Derek Doyle, AFRL<br />

Dr. Brian Holloway, DARPA<br />

Mr. Michael Huggins, AFRL<br />

Dr. Sylvia Johnson, NASA ARC<br />

Ms. Fabiola Lopez, USASMDC<br />

Mr. Curtis Martin, NSWCCD<br />

Dr. John Rivard, ORNL<br />

Dr. Gerald Russell, U.S. Army RDECOM<br />

Mr. Wesley Sanderson, MDA<br />

Dr. John Schmisseur, AFOSR<br />

Mr. Mark Smith, AEDC<br />

Mr. John Vickers, NASA MSFC<br />

Mr. Richard Wegrich, NASA MSFC<br />

Dr. Eric Wuchina, NSWC<br />

Industry & University<br />

Dr. Jack Agee, Rice University<br />

Mr. Jerry Brockmeyer, Ultramet Corporation<br />

Mr. Alan Brown, Pratt & Whitney Rocketdyne<br />

Mr. Charles Frohlich, The Boeing Company<br />

Mr. Michael Fuller, ATK Launch Systems<br />

Mr. Kon Haake, Pratt & Whitney Rocketdyne<br />

Mr. Andrew Haaland, ATK Launch Systems<br />

Mr. Brian Hill, Northrop Grumman Aerospace Systems<br />

Ms. Beth Kelsic, Ball Aerospace & Technology Corp.<br />

Mr. John Koenig, Southern Research Institute<br />

Dr. Russell Lipeles, The Aerospace Corporation<br />

Mr. Paul Marchol, Aerojet<br />

Mr. Timothy McKechnie, Plasma Processes, LLC<br />

Mr. Ronald Ooten, USEC, Inc.<br />

Mr. Mitch Petervary, The Boeing Company Phantom Works<br />

3

Steering Committee & Staff<br />

Steering Committee, cont’d<br />

Dr. Suraj Rawal, Lockheed Martin Space Systems<br />

Dr. Brian Sullivan, Materials Research & Design, Inc.<br />

Dr. Dianne Wiley, Consultant<br />

Behind the Scenes & On-site Staff<br />

Ms. Tina Barnhill, MDA (Staff)<br />

Ms. Jennie Hempstead, GDIT (Webmaster & Graphics)<br />

Ms. Nancy Johnson, GDIT (Registrar)<br />

Ms. Sherry Johnson, GDIT (Registrar)<br />

Ms. Susie Sanford, GDIT (Webmaster & Graphics)<br />

4

Symposium Map<br />

Tampa Marriott Waterside Hotel<br />

Registration<br />

Exhibits &<br />

Posters<br />

Technical<br />

Sessions,<br />

Tutorials,<br />

Workshops,<br />

and Small<br />

Business<br />

Forum<br />

Speaker<br />

Breakfast<br />

5

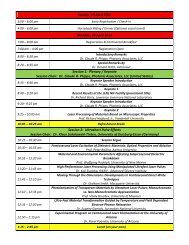

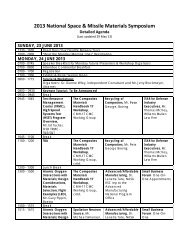

Week-At-A-Glance<br />

Monday,<br />

25 June<br />

Tuesday,<br />

26 June<br />

AM<br />

Tutorials &<br />

Workshops<br />

Small<br />

Business<br />

Forum<br />

Plenary Session<br />

(Florida Ballroom 1-4)<br />

BREAK<br />

(Grand Ballroom Foyer)<br />

BREAK<br />

(Grand Ballroom Foyer)<br />

Tutorials &<br />

Workshops<br />

Small<br />

Business<br />

Forum<br />

Plenary Session<br />

(Florida Ballroom 1-4)<br />

LUNCH BREAK<br />

(On Your Own)<br />

LUNCH BREAK<br />

(On Your Own)<br />

PM<br />

Tutorials &<br />

Workshops<br />

Small<br />

Business<br />

Forum One-<br />

On-Ones<br />

Hypersonics<br />

Session<br />

(Florida Ballroom<br />

1-4)<br />

Breakthrough<br />

Innovations<br />

Session<br />

(Florida<br />

Ballroom 5-6)<br />

BREAK<br />

(Grand Ballroom Foyer)<br />

Tutorials &<br />

Workshops<br />

Small<br />

Business<br />

Forum One-<br />

On-Ones<br />

Welcome Reception and<br />

Exhibit & Poster Kick-Off<br />

Sponsored by The Boeing<br />

Company<br />

(Grand Ballroom)<br />

BREAK<br />

Sponsored by Plasma Processes<br />

(Grand Ballroom)<br />

Hypersonics<br />

Session<br />

(Florida Ballroom<br />

1-4)<br />

Breakthrough<br />

Innovations<br />

Session<br />

(Florida<br />

Ballroom 5-6)<br />

See Pages 8 & 9 for Tutorials, Workshops, and Small Business Forum Locations<br />

6

Week-At-A-Glance<br />

Hypersonics<br />

Session<br />

(Florida<br />

Ballroom<br />

1-4)<br />

Wednesday,<br />

27 June<br />

Space Materials<br />

Experiments and<br />

Environmental<br />

Effects Simulation<br />

Session<br />

(Florida Ballroom 5)<br />

BREAK<br />

(Grand Ballroom)<br />

Space<br />

Exploration<br />

Session<br />

(Florida<br />

Ballroom 6)<br />

Missiles &<br />

Missile<br />

Defense<br />

Session<br />

(Florida<br />

Ballroom<br />

1-4)<br />

Thursday,<br />

28 June<br />

Space<br />

Exploration<br />

Session<br />

(Florida<br />

Ballroom 5)<br />

BREAK<br />

(Grand Ballroom Foyer)<br />

Hypersonics<br />

Session<br />

(Florida<br />

Ballroom<br />

1-4)<br />

Space Materials<br />

Experiments and<br />

Environmental<br />

Effects Simulation<br />

Session<br />

(Florida Ballroom 5)<br />

Space<br />

Exploration<br />

Session<br />

(Florida<br />

Ballroom 6)<br />

Missiles &<br />

Missile<br />

Defense<br />

Session<br />

(Florida<br />

Ballroom<br />

1-4)<br />

Space<br />

Exploration<br />

Session<br />

(Florida<br />

Ballroom 5)<br />

LUNCH BREAK<br />

(On Your Own)<br />

LUNCH BREAK<br />

(On Your Own)<br />

Hypersonics<br />

Session<br />

(Florida<br />

Ballroom<br />

1-4)<br />

Hypersonics<br />

Session<br />

(Florida<br />

Ballroom<br />

1-4)<br />

Space Materials<br />

Experiments and<br />

Environmental<br />

Effects Simulation<br />

Session<br />

(Florida Ballroom 5)<br />

BREAK<br />

Sponsored by Scot Forge<br />

(Grand Ballroom)<br />

Space Materials<br />

Experiments and<br />

Environmental<br />

Effects Simulation<br />

Session<br />

(Florida Ballroom 5)<br />

Poster Session & Caribbean<br />

Reception<br />

Sponsored by Pratt & Whitney<br />

Rocketdyne<br />

(Grand Ballroom)<br />

Space<br />

Exploration<br />

Session<br />

(Florida<br />

Ballroom 6)<br />

Space<br />

Exploration<br />

Session<br />

(Florida<br />

Ballroom 6)<br />

Missiles &<br />

Missile<br />

Defense<br />

Session<br />

(Florida<br />

Ballroom<br />

1-4)<br />

Orbital<br />

Technologies<br />

& Operations<br />

Session<br />

(Florida<br />

Ballroom 5)<br />

BREAK<br />

(Grand Ballroom Foyer)<br />

Missiles &<br />

Missile<br />

Defense<br />

Session<br />

(Florida<br />

Ballroom<br />

1-4)<br />

Orbital<br />

Technologies<br />

& Operations<br />

Session<br />

(Florida<br />

Ballroom 5)<br />

Grand Prize Give-Away<br />

Sponsored by GDIT<br />

(Florida Ballroom 1-4)<br />

7

Tutorials-At-A-Glance<br />

Monday, 25 June<br />

0800 - 0930<br />

0930 - 0945<br />

0945 - 1115<br />

1115 - 1200<br />

Keynote: Materials in NASA’s Space<br />

Launch System: The Stuff Dreams Are Made Of<br />

Mr. Todd May, NASA MSFC (Florida Ballroom 4)<br />

TRACK 1:<br />

TUTORIALS<br />

(Florida Ballroom 4)<br />

Columbia Lessons<br />

Learned<br />

Mr. Matt Melis, NASA GRC<br />

The Mighty F-1 Engine<br />

Mr. John Halchak, Pratt &<br />

Whitney Rocketdyne<br />

BREAK (Grand Ballroom Foyer)<br />

TRACK 2:<br />

WORKSHOPS<br />

(Florida Ballroom 5)<br />

What’s It Gonna Take to Fly<br />

Ceramic Matrix Composites<br />

(CMCs) Part 2: Materials<br />

Properties, Testing Methods<br />

and Databasing Workshop<br />

Dr. Anthony Calomino, NASA<br />

LaRC and Dr. David Glass,<br />

NASA ARC<br />

1200 - 1300<br />

1300 - 1345<br />

LUNCH BREAK (On Your Own)<br />

125 Years of Carbon and<br />

Graphite Science: From<br />

Arc Carbons to Smart<br />

Phones<br />

Dr. Julian Norley, GrafTech<br />

Intl Holdings, Inc.<br />

The Composites<br />

Materials Handbook<br />

17 Workshop<br />

CMH-17 CMC Working<br />

Group<br />

1345 - 1430<br />

Overview of Foreign<br />

Efforts in Materials and<br />

Manufacturing<br />

Dr. Chris Davis, Missile and<br />

Space Intelligence Center<br />

The Composites<br />

Materials Handbook<br />

17 Workshop, cont’d<br />

CMH-17 CMC Working<br />

Group<br />

1430 - 1515 Mach 3 Legend: Design<br />

& Development of the<br />

Lockheed Blackbird<br />

Mr. Peter Merlin, Tybrin<br />

Corporation<br />

1515 - 1530<br />

BREAK (Grand Ballroom Foyer)<br />

1530 - 1615<br />

1615 - 1700<br />

1700 - 1830<br />

Space Weather<br />

Dr. Dale Ferguson, AFRL<br />

The Holloman High Speed<br />

Test Track: Rocket Sled<br />

Testing 101<br />

Mr. Clinton Hooser, High<br />

Speed Test Track<br />

The Composites<br />

Materials Handbook<br />

17 Workshop, cont’d<br />

CMH-17 CMC Working<br />

Group<br />

Welcome Reception and Exhibit & Poster Kick-Off -<br />

Sponsored by The Boeing Company (Grand Ballroom)<br />

8

Workshops-At-A-Glance<br />

TRACK 3:<br />

WORKSHOPS<br />

Advanced Hypersonic Weapon<br />

TPS Technology Development<br />

Workshop<br />

Dr. Gerald Russell, U.S. Army<br />

AMRDEC; Mr. Bruce Moylan, U.S.<br />

Army AMRDEC; and Mr. Forrest<br />

Strobel, ITT AES<br />

TRACK 4: SMALL<br />

BUSINESS FORUM<br />

(Florida Ballroom 6) (Florida Ballroom 1-3)<br />

Small Business Forum:<br />

Government SBIR Agency<br />

and Prime Panels<br />

Advanced Hypersonic Weapon<br />

TPS Technology Development<br />

Workshop, cont’d<br />

Dr. Gerald Russell, U.S. Army AMRDEC;<br />

Mr. Bruce Moylan, U.S. Army AMRDEC;<br />

and Mr. Forrest Strobel, ITT AES<br />

Small Business Forum One-<br />

On-Ones with the Primes<br />

Composite Manufacturing<br />

Challenges Using Out-of-<br />

Autoclave Technologies<br />

Workshop<br />

Mr. Dawson Vincent, NASA MSFC;<br />

Ms. Tara Storage, AFRL; and Dr.<br />

Jim Sutter, NASA GRC<br />

Additive Manufacturing<br />

Workshop<br />

Mr. Craig Brice, NASA LaRC; Mr.<br />

Francisco Mendina, University of<br />

Texas; and Dr. Ian Harris, Edison<br />

Welding Institute<br />

Small Business Forum One-<br />

On-Ones with the Primes<br />

9

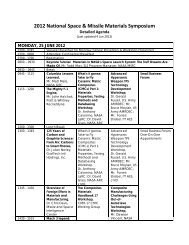

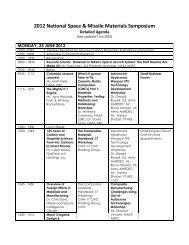

SUN, 24 & MON, 25 June 2012<br />

Sunday, 24 June<br />

1500 - 1800 Pre-Registration (Tampa Marriott Waterside Lobby)<br />

Monday, 25 June<br />

0700 - 0745 Speaker Breakfast for Tutorial Speakers and Workshop<br />

Organizers (Meeting Room 4)<br />

0700 - 0800 Attendee Continental Breakfast (Grand Ballroom Foyer)<br />

0700 - 1700 Registration (Grand Ballroom Foyer)<br />

1700 - 1830 Welcome Reception and Exhibit & Poster Kick-Off -<br />

Sponsored by The Boeing Company (Grand Ballroom)<br />

Tutorials, Workshops, & Small<br />

Business Forum<br />

(See pages 8 & 9 for locations)<br />

Tutorial & Workshop Chairs:<br />

Dr. Dianne Wiley, Consultant & Mr. Jerry Brockmeyer, Ultramet<br />

0800 - 0930 Keynote Tutorial: Materials in NASA’s Space<br />

Launch System: The Stuff Dreams Are Made Of<br />

Mr. Todd May, SLS Program Manager, NASA MSFC<br />

0930 - 0945 BREAK (Grand Ballroom Foyer)<br />

0945 - 1115 Columbia Lessons Learned<br />

Mr. Matt Melis, NASA GRC<br />

0945 - 1200<br />

0945 - 1345<br />

What’s It Gonna Take to Fly Ceramic Matrix<br />

Composites (CMCs) Part 2: Materials Properties,<br />

Testing Methods, and Databasing Workshop<br />

Dr. Anthony Calomino, NASA LaRC and Dr. David<br />

Glass, NASA ARC<br />

Advanced Hypersonic Weapon TPS Technology<br />

Development Workshop<br />

Dr. Gerald Russell, U.S. Army AMRDEC; Mr. Bruce<br />

Moylan, U.S. Army AMRDEC; and Mr. Forrest Strobel,<br />

ITT AES<br />

10

Monday, 25 June 2012<br />

0945 - 1700<br />

1115 - 1200<br />

Small Business Forum<br />

Dr. Doug Deason, MDA and Mr. Kent Buesking, MR&D<br />

0945 - 0950 Welcome & One-On-One Instructions<br />

by Dr. Douglas Deason, MDA<br />

0950 - 1050 Government SBIR Agency Introductions<br />

& Panel<br />

1100 - 1200 Industry Prime Introductions and Panel<br />

1300 - 1700 One-On-Ones Meetings with the Primes<br />

The Mighty F-1 Engine<br />

Mr. John Halchak, Pratt & Whitney Rocketdyne<br />

1200 - 1300 LUNCH BREAK (On-Your-Own)<br />

1300 - 1345 125 Years of Carbon and Graphite Science: From<br />

Arc Carbons to Smart Phones<br />

Dr. Julian Norley, GrafTech Intl Holdings, Inc.<br />

1300 - 1700<br />

1345 - 1430<br />

1345 - 1515<br />

1430 - 1515<br />

The Composites Materials Handbook 17<br />

Workshop<br />

CMH-17 CMC Working Group<br />

Overview of Foreign Efforts in Materials and<br />

Manufacturing<br />

Dr. Chris Davis, Missile and Space Intelligence Center<br />

Composite Manufacturing Challenges Using Outof-Autoclave<br />

Technologies Workshop<br />

Mr. Dawson Vincent, NASA MSFC; Ms. Tara Storage,<br />

AFRL; and Dr. Jim Sutter, NASA GRC<br />

Mach 3 Legend: Design & Development of the<br />

Lockheed Blackbird<br />

Mr. Peter Merlin, Tybrin Corporation<br />

1515 - 1530 BREAK (Grand Ballroom Foyer)<br />

1530 - 1615<br />

1530 - 1700<br />

1615 - 1700<br />

Space Weather<br />

Dr. Dale Ferguson, AFRL<br />

Additive Manufacturing Workshop<br />

Mr. Craig Brice, NASA LaRC; Mr. Francisco Mendina,<br />

University of Texas; and Dr. Ian Harris, Edison Welding<br />

Institute<br />

The Holloman High Speed Test Track: Rocket<br />

Sled Testing 101<br />

Mr. Clinton Hooser, High Speed Test Track<br />

1700 - 1830 WELCOME RECEPTION AND EXHIBIT & POSTER<br />

KICK-OFF - Sponsored by Boeing (Grand Ballroom)<br />

11

Tuesday, 26 June 2012<br />

0700 - 0745 Speaker Breakfast for Tuesday Presenters<br />

(Meeting Room 4)<br />

0700 - 0800 Attendee Continental Breakfast - Sponsored by<br />

ATK (Grand Ballroom Foyer)<br />

0700 - 1700 Registration (Grand Ballroom Foyer)<br />

1330 - 1730 Exhibits & Posters Open (Grand Ballroom)<br />

Plenary Session<br />

(Florida Ballroom 1-4)<br />

Plenary Chair:<br />

Dr. Monica Stucke, Air Force Research Laboratory<br />

0800 - 0820 Opening Remarks & National Anthem<br />

0820 - 0830 Welcome<br />

Mr. Joe Sciabica, Executive Director, Air Force Research<br />

Laboratory<br />

0830 - 0900 Mr. Joe Sciabica<br />

Executive Director, Air Force Research Laboratory<br />

0900 - 0930 Mr. Stephen Welby<br />

Deputy Assistant Secretary of Defense for Systems Engineering<br />

0930 - 1000 Mr. Greg Hulcher<br />

Director for Strategic Warfare, Office of the Under Secretary of<br />

Defense Acquisition, Technology & Logistics<br />

1000 - 1030 BREAK (Grand Ballroom Foyer)<br />

1030 - 1100 Mr. Steve Gaddis<br />

Program Manager, Game Changing Technology<br />

Development Office, NASA LaRC<br />

1100 - 1200 Plenary Session “Fireside Chat”<br />

1200 - 1330 LUNCH BREAK (ON YOUR OWN)<br />

12

Tuesday, 26 June 2012<br />

Track 1: Hypersonics Session<br />

(Florida Ballroom 1-4)<br />

Session Chairs:<br />

Dr. Paul Jero, AFRL; Dr. Artie Mabbett, DARPA; and<br />

Mr. Craig Stephens, NASA DFRC<br />

Session Organizers:<br />

Mr. Kon Haake, Pratt & Whitney Rocketdyne; Mr. Mitch Petervary, The<br />

Boeing Company; Mr. Brian Sullivan, Materials Research & Design, Inc.;<br />

Mr. David Brewer, NASA LaRC; Dr. Monica Stucke, AFRL; and<br />

Mr. Andy Swanson, AFRL<br />

1330 - 1335 Session Introduction:<br />

Overview of AFRL Thermal Protection System<br />

Development Programs<br />

Dr. Paul Jero, AFRL<br />

1335 - 1400 Durability Assessment of CMCs for Air Force TPS<br />

Applications<br />

Mr. Larry Zawada, AFRL<br />

1400 - 1425 Innovative Materials & Processes Development<br />

for Structurally Integrated Thermal Protection<br />

Systems<br />

Mrs. Kerry Hopp, Materials Research & Design, Inc.<br />

1425 - 1450 Thermo-Photo-Shielding for Next Generation<br />

Thermal Protection System<br />

Dr. Tao Deng, GE Global Research Center<br />

1450 - 1515 Development of Ceramic Micro-Truss as a Panel<br />

Core Structure for Thermal Protection Systems<br />

Dr. Daniel Driemeyer, The Boeing Company<br />

1515 - 1545 ROOT BEER FLOAT BREAK - Sponsored by<br />

Plasma Processes (Grand Ballroom)<br />

1545 - 1610 C/SiC Truss Core for PGS<br />

Ms. Leanne Lehman, The Boeing Company<br />

1610 - 1635 Integral SiC-SiC Structures for Thermal<br />

Protection<br />

Dr. Oliver Sudre, Teledyne Scientific<br />

13

Tuesday, 26 June 2012<br />

1635 - 1700 Materials Characterization and Optimization of<br />

Carbon-Carbon<br />

Mr. Venkatakrishnan Raj Narayanan, Carbon Carbon<br />

Advanced Technologies, Inc.<br />

1700 - 1725 Ceramic Matrix Composites for Thermal<br />

Protection Systems<br />

Mr. Randy Batzer, Lockheed Martin Aeronautics<br />

Track 2: Breakthrough<br />

Innovations Session<br />

(Florida Ballroom 5-6)<br />

Session Chair:<br />

Dr. Jim Sutter, NASA GRC<br />

Session Organizers:<br />

Dr. John Rivard, ONRL; Dr. Russ Lipeles, The Aerospace Corporation;<br />

Dr. Sylvia Johnson, NASA ARC; and Dr. Brian Holloway, DARPA<br />

1330 - 1335 Session Introduction<br />

Dr. Jim Sutter, NASA GRC<br />

1335 - 1400 Advanced Carbon Fiber<br />

Mr. Cliff Eberle, ORNL<br />

1400 - 1425 Carbon Nanotubes for Space Applications<br />

Mr. Matthew Gross, Ball Aerospace & Technologies<br />

Corporation<br />

1425 - 1450 Practical Use of Multivariate Statistical Methods<br />

for Rapid Qualification of New Materials<br />

Dr. Vanessa Oklejas, The Aerospace Corporation<br />

1450 - 1515 New High-Performance, Lower-Cost Alloys:<br />

Ferrium ® M54, Ultra-High Strength, Ultra-High<br />

Toughness Steel, and High-Strength, High-<br />

Toughness Castable Titanium<br />

Mr. Rich Kooy, QuesTek Innovations, Inc.<br />

1515 - 1545 ROOT BEER FLOAT BREAK - Sponsored by<br />

Plasma Processes (Grand Ballroom)<br />

14

Tuesday, 26 June 2012<br />

1545 - 1610 Synthesis and Consolidation of Boride-<br />

Carbide Composites with Submicron Scale<br />

Microstructure<br />

Dr. E.G. Baburaj, Clarkson Aerospace Corporation<br />

1610 - 1635 Liquid Precursor Systems of Ultrahigh<br />

Temperature Ceramics (UHTC) HfB2 and ZrB2 by<br />

Rapid Sol-Gel Processing<br />

Mr. Luke Walker, The University of Arizona<br />

1635 - 1700 Ionic Liquids: Lubricants for the Future<br />

Dr. Jenny Devaud, Ball Aerospace and Technology<br />

Corporation<br />

1700 - 1725 Charge Dissipating Transparent Conformal<br />

Coatings for Spacecraft Electronics<br />

Mr. Adam Goff, Luna Innovations, Inc.<br />

Wednesday, 27 June<br />

0700 - 0745 Speaker Breakfast for Wednesday Presenters -<br />

Sponsored by Ultramet (Meeting Room 4)<br />

0700 - 0800 Attendee Continental Breakfast - Sponsored by<br />

ATK (Grand Ballroom Foyer)<br />

0700 - 1700 Registration (Grand Ballroom Foyer)<br />

0945 - 1830 Exhibits & Posters Open (Grand Ballroom)<br />

1650 - 1830 Poster Session & Caribbean Reception - Sponsored<br />

by Pratt & Whitney Rocketdyne (Grand Ballroom)<br />

Track 1: Hypersonics Session<br />

(Grand Ballroom 1-4)<br />

Session Chairs:<br />

Dr. Paul Jero, AFRL; Dr. Artie Mabbett, DARPA; and<br />

Mr. Craig Stephens, NASA DFRC<br />

Session Organizers:<br />

Mr. Kon Haake, Pratt & Whitney Rocketdyne; Mr. Mitch Petervary, The<br />

Boeing Company; Mr. Brian Sullivan, Materials Research & Design, Inc.;<br />

Mr. David Brewer, NASA LaRC; Dr. Monica Stucke, AFRL; and<br />

Mr. Andy Swanson, AFRL<br />

15

Wednesday, 27 June 2012<br />

0800 - 0805 Session Introduction<br />

Dr. Artie Mabbett, DARPA<br />

0805 - 0830 CPGS: A Year in Review<br />

Mr. Greg Hulcher, OSD<br />

0830 - 0855 Development of High Temperature Materials for<br />

Hypersonic Vehicles in China<br />

Mr. James Shircliffe, National Intelligence Council/<br />

Science and Technology Intelligence Committee<br />

0855 - 0920 Carbon-Carbon Composite Laminates<br />

Mechanical Properties Characterization<br />

Dr. Dragos-Stefan Dancila, The University<br />

of Texas at Arlington<br />

0920 - 0945 X-Ray CT-Scan-Based Characterization of<br />

Arc-Jet and Laser Heating Induced Damage in<br />

Carbon-Carbon Composites<br />

Dr. Dragos-Stefan Dancila, The University<br />

of Texas at Arlington<br />

0945 - 1015 BREAK (Grand Ballroom)<br />

1015 - 1040 Ultra High Temperature Mechanical Testing of<br />

ZrB2 Based Ceramics<br />

Mr. Eric Neuman, Missouri University of Science &<br />

Technology<br />

1040 - 1105 Structural Performance of Continuous Core<br />

Structurally Integrated Thermal Protection<br />

System<br />

Mr. Carl Poteet, NASA LaRC<br />

1105 - 1130 Energy Conversion Capabilities in Scramjet<br />

Vehicles Using Thermoelectrics<br />

Mr. Kevin Yost, AFRL<br />

1130 - 1155 Overview of TRL Developments for Large-<br />

Scale, Atmospheric, Hypersonic, Inflatable,<br />

Aerodynamic Decelerators<br />

Dr. Anthony Calomino, NASA LaRC<br />

1155 - 1300 LUNCH BREAK (ON YOUR OWN)<br />

1300 - 1325 NASA Fundamental Aeronautics Hypersonics<br />

Project Overview<br />

Mr. Craig Stephens, NASA DFRC<br />

1325 - 1350 Low Cost Lightweight High-Speed Structures<br />

Dr. Bill Garver, Lockheed Martin Aeronautics<br />

16

Wednesday, 27 June 2012<br />

1350 - 1415 Results of Trade Study Design Analyses<br />

for Selection and Fabrication of Candidate<br />

Structurally Integrated Thermal Protection<br />

System Joint Subelement Test Articles<br />

Mr. Daniel Howren, Materials Research & Design, Inc.<br />

1415 - 1440 Experimental Evaluation of Gap Thermal<br />

Resistance in a Hot Composite Structure<br />

Mr. Brett Hauber, AFRL<br />

1440 - 1510 BREAK - Sponsored by Scot Forge<br />

(Grand Ballroom)<br />

1510 - 1535 Innovative Core Development for Structurally<br />

Integrated Thermal Protection Systems<br />

Mr. Craig Iwano, Materials Research & Design, Inc.<br />

1535 - 1600 Ground Test Studies in the LENS Hypervelocity<br />

Tunnels of Missile and Re-Entry Vehicles at<br />

Duplicated Flight Conditions<br />

Dr. Michael Holden, CUBRC<br />

1600 - 1625 Updating the Hypersonic Weather Encounter<br />

Ground Testing Capability of AEDC Range G<br />

Mr. Richard Rushing, AEDC<br />

1625 - 1650 Manufacture and Testing of Niobium Alloy/<br />

Lithium Heat Pipes for Wing Leading Edges<br />

Mr. John Rosenfeld, Thermacore, Inc.<br />

1650 - 1830 POSTER SESSION & CARIBBEAN RECEPTION -<br />

Sponsored by Pratt & Whitney Rocketdyne<br />

(Grand Ballroom)<br />

17

Wednesday, 27 June 2012<br />

Track 2: Space Materials<br />

Experiments & Environmental<br />

Effects Simulation Session<br />

(Grand Ballroom 5)<br />

Session Chair:<br />

Mr. John Vasquez, NRL<br />

Session Organizers:<br />

Mr. Chip Frohlich, The Boeing Company; Mr. Shane Juhl, AFRL;<br />

and Dr. Suraj Rawal, Lockheed Martin Space Systems<br />

0800 - 0805 Session Introduction<br />

Mr. John Vasquez, NRL<br />

0805 - 0830 Estimated Environmental Exposures for MISSE-<br />

7B<br />

Mrs. Miria Finckenor, NASA MSFC<br />

0830 - 0855 Measurements of the Ionosp<strong>here</strong> Using<br />

Miniaturized Electrostatic Analyzer on MISSE-7<br />

Dr. Richard Balthazor, USAF Academy/Space<br />

Scientific Instruments, Inc.<br />

0855 - 0920 Post-Flight Characterization of Optical Samples<br />

Flown on ORMatE-2/MISSE-7<br />

Mr. Christopher Panetta, The Aerospace Corporation<br />

0920 - 0945 Post Flight Analysis of Optical Specimens from<br />

MISSE-7<br />

Dr. Alan Stewart, The Boeing Company<br />

0945 - 1015 BREAK (Grand Ballroom)<br />

1015 - 1040 Coverglasses for Advanced Photovoltaics<br />

Mr. James Belcher, Infoscitex Corporation<br />

1040 - 1105 Mechanical Testing of Silicon Carbide Specimens<br />

on MISSE-7<br />

Dr. David Witkin, The Aerospace Corporation<br />

1105 - 1130 Results of International Space Station Vehicle<br />

Materials Exposed on MISSE-7B<br />

Mrs. Miria Finckenor, NASA MSFC<br />

18

Wednesday, 27 June 2012<br />

1130 - 1155 Space Environmental Analysis, Deposition<br />

Analysis and Resistivity Analysis of Z-93C55<br />

White Conductive Thermal Control Material<br />

System (TCMS)<br />

Mr. Michael Kenny, Alion Science & Technology<br />

1155 - 1300 LUNCH BREAK (ON YOUR OWN)<br />

1300 - 1325 Boeing / MISSE-8 On-Orbit Data First Results<br />

Dr. Mark Clemen, Boeing Research & Technology<br />

1325 - 1350 Energy Considerations and Reaction Rates for<br />

Atomic Oxygen-Surface Collisions<br />

Dr. Gary Pippin, The Boeing Company<br />

1350 - 1415 Application of Classical Surface Energy Theory<br />

to Quantify Rubber Surface Conditions to<br />

Support Adhesive Bonding Processes<br />

Mr. Emmanuel Cua, Aerojet<br />

1415 - 1440 Comparison of Leak Rates of In-Flight and<br />

Ground Based Exposed Silicone Elastomer Seals<br />

Ms. Janice Wasowski, The University of Akron<br />

1440 - 1510 BREAK - Sponsored by Scot Forge<br />

(Grand Ballroom)<br />

1510 - 1535 A Computational Leak Rate Prediction Method<br />

for Elastomer Space Seals<br />

Dr. Nicholas Garafolo, The University of Akron<br />

1535 - 1600 Preparation and Testing of Transparent<br />

Hyperbranched Polyhedral Oligomeric<br />

Silsesquioxane (HB-POSS) Nanostructured<br />

Protective Coatings and Adhesives for Space<br />

Applications<br />

Dr. Clare Hartmann-Thompson, Michigan Molecular<br />

Institute<br />

1600 - 1625 Material Classification and Damage Assessment<br />

Using Laser Polarimetry<br />

Dr. Brian Hoover, Advanced Optical Technologies<br />

1625 - 1650 Damage Tolerance Behavior of Friction Stir<br />

Welds in Aluminum Alloys<br />

Dr. Preston McGill, NASA MSFC<br />

1650 - 1830 POSTER SESSION & CARIBBEAN RECEPTION -<br />

Sponsored by Pratt & Whitney Rocketdyne<br />

(Grand Ballroom)<br />

19

Wednesday, 27 June 2012<br />

Track 3: Space Exploration<br />

Session<br />

(Grand Ballroom 6)<br />

Session Chair:<br />

Mr. Wendell Colberg, NASA MSFC<br />

Session Organizers:<br />

Mr. Rich Wegrich, NASA MSFC; Mr. John Vickers, NASA MSFC;<br />

Mr. Mike Fuller, ATK; Mr. Charlie Camarda, NASA HQ; and<br />

Mr. Alan Brown, Pratt & Whitney Rocketdyne<br />

0800 - 0805 Session Introduction<br />

Mr. Wendell Colberg, NASA MSFC<br />

0805 - 0830 NASA Space Exploration<br />

Mr. Chris Singer, NASA MSFC<br />

0830 - 0855 Global Commercial Space Transportation<br />

Industry<br />

Mr. Ken Gidlow, FAA Commercial Space<br />

Transportation Office<br />

0855 - 0920 Design of Large Composite Cryotanks for CCTD<br />

Mr. Michael Robinson and Mr. Michael Hand, The<br />

Boeing Company<br />

0920 - 0945 Hydrogen Permeation Testing and Analysis for<br />

Composite Cryotanks<br />

Mr. Michael Robinson, The Boeing Company and Mr.<br />

Justin Jackson, NASA MSFC<br />

0945 - 1015 BREAK (Grand Ballroom)<br />

1015 - 1040 Composite Cryotank Technologies and<br />

Development Phase 2<br />

Mr. Dan Rivera, The Boeing Company<br />

1040 - 1105 Test Approach to CCTD<br />

Mr. Cataldo Mazzola, The Boeing Company<br />

1105 - 1130 C-C Nozzle Extension Designs and Analyses<br />

in Support of J-2X Nozzle Extension Risk<br />

Reduction Effort<br />

Ms. Leslie Weller, Materials Research & Design, Inc.<br />

20

Wednesday, 27 June 2012<br />

1130 - 1155 Digital Material Skins: A Reversible, Reusable,<br />

Recyclable Pressure Vessel<br />

Ms. Sarah Hovsepian, The Massachusetts Institute<br />

of Technology, NASA Space Technology Research<br />

Fellowship<br />

1155 - 1300 LUNCH BREAK (OWN YOUR OWN)<br />

1300 - 1325 NASA Composite Crew Module Manufacturing<br />

Mr. Dawson Vincent, The Geocent Company<br />

1325 - 1350 Hydrocarbon Boost Technology Demonstration<br />

Program<br />

Mr. Jamie Cleland, Aerojet<br />

1350 - 1415 LE-X Nozzle Liner Prototype Development<br />

Mr. Guido Canzona, Pratt & Whitney Rocketdyne<br />

1415 - 1440 HIAD Application Technology Benefits and<br />

Requirements for Future Space Mission<br />

Exploration Overview of TRL Development for<br />

Inflatable EDL Decelerators<br />

Dr. Anthony Calomino, NASA LaRC<br />

1440 - 1510 BREAK - Sponsored by Scot Forge<br />

(Grand Ballroom)<br />

1510 - 1535 Evaluation of Lightweight Radiator Fin<br />

Construction for High-Temperature Nuclear<br />

Electric Powered Spacecraft<br />

Ms. Briana Tomboulian, University of Massachusetts<br />

Amherst<br />

1535 - 1600 Lightweight Nanomaterial Shielded Cables and<br />

Harnesses for Space and Missile Applications<br />

Mrs. Megan Caprio, San Diego Composites, Inc.<br />

1600 - 1625 Remote UV Fluorescence Lifetime Imaging<br />

Spectrometer (RUVPhase) for the Scientific<br />

Investigation of Planetary Surface and<br />

Subsurface Geophysical Terrain<br />

Dr. Edgar Mendoza, Redondo Optics, Inc.<br />

1625 - 1650 Reducing Costs and Weight of Ablative<br />

Composites<br />

Dr. John Shigley, ATK<br />

1650 - 1830 POSTER SESSION & CARIBBEAN RECEPTION -<br />

Sponsored by Pratt & Whitney Rocketdyne<br />

(Grand Ballroom)<br />

21

Thursday, 28 June 2012<br />

0700 - 0745 Speaker Breakfast for Thursday Presenters<br />

(Meeting Room 4)<br />

0700 - 0800 Attendee Continental Breakfast (Grand Ballroom<br />

Foyer)<br />

0700 - 1530 Registration (Grand Ballroom Foyer)<br />

1650 - 1700 Grand Prize Give-Away - Sponsored by GDIT<br />

(Grand Ballroom 1-4)<br />

Track 1: Missiles & Missile<br />

Defense Session<br />

(Grand Ballroom 1-4)<br />

Session Chair:<br />

Dr. Douglas Deason, MDA<br />

Session Organizers:<br />

Mr. Wes Sanderson, MDA; Dr. Gerald Russell, U.S. Army RDECOM;<br />

Mr. Mark Smith, AEDC; Mr. Paul Marchol, Aerojet; Ms. Fabiola Lopez,<br />

SMDC, Mr. Curtis Martin, NSWCCD; and Mr. Jerry Brockmeyer,<br />

Ultramet<br />

0800 - 0805 Session Introduction<br />

Dr. Douglas Deason, MDA<br />

0805 - 0830 HWTPS Overview<br />

Dr. Gerald Russell, U.S. Army RDECOM<br />

0830 - 0855 Low Erosion, Light-Weight Composites for Hot<br />

Gas Valve Components<br />

Dr. Daniel Butts, Plasma Processes, LLC<br />

0855 - 0920 Survivable Mirrors and Coatings for the Ballistic<br />

Missile Defense System<br />

Dr. William Goodman, Trex Enterprises Corporation<br />

0920 - 0945 Fabrication of Single-Piece 2D Carbon-Carbon<br />

Aeroshell<br />

Dr. John Shigley, ATK Aerospace Systems<br />

22

Thursday, 28 June 2012<br />

0945 - 1015 BREAK (Grand Ballroom Foyer)<br />

1015 - 1040 Oxide Ceramic Matrix Composite (CMC) for<br />

Missile Radomes<br />

Mr. Steve Atmur, ATK – COI Ceramics, Inc.<br />

1040 - 1105 Development of Structural Insulators for MDA<br />

Applications<br />

Mr. Kent Buesking, Materials Research & Design, Inc.<br />

1105 - 1130 Integration of Thermal Interface Materials into<br />

Missile Airframe Structures<br />

Mrs. Carissa Russell, U.S. Army AMRDEC<br />

1130 - 1155 Non-Eroding Ceramic Nozzle Throat Insert<br />

Designs for Aluminized Propellant Solid Rocket<br />

Motor Applications<br />

Mr. Mike Fuller, ATK Aerospace Systems and<br />

Mr. Joseph Pluscauskis, Materials Research & Design,<br />

Inc.<br />

1155 - 1300 LUNCH BREAK (ON YOUR OWN)<br />

1300 - 1325 Ballistic Missile Defense Interceptor System<br />

Innovation Concepts and Strategy<br />

Mr. Andrew Facciano, Raytheon Missile Systems<br />

1325 - 1350 Determination of Design Allowables for Novoltex<br />

C-SiC<br />

Mr. Paul Marchol, Aerojet<br />

1350 - 1415 Comparison of GE 2D and 3D C-SiC Materials:<br />

Properties, Processing and Microstructure<br />

Mr. Randall Jenkins, Southern Research Institute<br />

1415 - 1440 Thermostructural Analysis of LHMEL Phenolic,<br />

Mr. Hans Jensen, Materials Research & Design, Inc.<br />

1440 - 1510 BREAK (Grand Ballroom Foyer)<br />

1510 - 1535 Demonstration of Segmented Heater Operation at<br />

Glide Vehicle Conditions<br />

Dr. Joseph Sheeley, ATA-AEDC<br />

1535 - 1600 NDE Methods for Filament Wound Aluminum<br />

Metal Matrix Composites<br />

Dr. Eric Johnson, The Aerospace Corporation<br />

1600 - 1625 Characterization of the Artificial Rain Environment<br />

at the Holloman High Speed Test Track<br />

Dr. Michelle Zeisset, 846th TS<br />

23

Thursday, 28 June 2012<br />

1625 - 1650 Computed Tomography Processing for Non-<br />

Routine Inspection of Solid Rocket Motor Defects<br />

Dr. Timothy Holmes, Lickenbrock Technologies, LLC<br />

1650 - 1700 Grand Prize Give-Away - Sponsored by GDIT<br />

(Florida Ballroom 1-4)<br />

1700 ADJOURN<br />

Track 2: Space Exploration<br />

Session<br />

(Florida Ballroom 5)<br />

Session Chair:<br />

Mr. Wendell Colberg, NASA MSFC<br />

Session Organizers:<br />

Mr. Rich Wegrich, NASA MSFC; Mr. John Vickers, NASA MSFC;<br />

Mr. Mike Fuller, ATK; Mr. Charlie Camarda, NASA HQ; and<br />

Mr. Alan Brown, Pratt & Whitney Rocketdyne<br />

0800 - 0805 Session Introduction<br />

Mr. Wendell Colberg, NASA MSFC<br />

0805 - 0830 Out of Autoclave Fabrication of Fluted Core<br />

for Composite Cryotank Technologies and<br />

Development Project<br />

Mr. Michael Hand, The Boeing Company<br />

0830 - 0855 Aerogel Modified Structural Thermal Protection<br />

System<br />

Mr. Mark Grogan, Powdermet, Inc.<br />

0855 - 0920 Thermally Insulated Structural Aerogel<br />

Composites for Satellites<br />

Dr. Nicholas Zafiropoulous, Aspen Aerogels, Inc.<br />

0920 - 0945 Lightweight Hybrid Ablator Incorporating Aerogel-<br />

Filled Open Cell Foam for Mars Return Missions<br />

Mr. Scott Brown, Brown Research & Technology<br />

24

Thursday, 28 June 2012<br />

0945 - 1015 BREAK (Grand Ballroom Foyer)<br />

1015 - 1040 Woven TPS - A New Approach to TPS Design and<br />

Manufacturing<br />

Dr. Mairead Stackpoole, NASA ARC<br />

1040 - 1105 Development of an Analysis Tool for the<br />

Evaluation of Thermal and Structural Performance<br />

of Ablative TPS Materials<br />

Mr. John Podhiny, Materials Research & Design, Inc.<br />

1105 - 1300 LUNCH BREAK (ON YOUR OWN)<br />

Track 2: Orbital Technologies &<br />

Operations Session<br />

(Florida Ballroom 5)<br />

Session Chair:<br />

Dr. Jim Riker, AFRL<br />

Session Organizers:<br />

Ms. Beth Kelsic, Ball Aerospace; Mr. Eric Becker, AFRL; Mr. Derek<br />

Doyle, AFRL; Mr. Brian Hill, Northrop Grumman; Mr. Tim McKechnie,<br />

Plasma Processes; and Mr. Patrick Sisson, GDIT<br />

1300 - 1325 AFRL Space Research and Material Innovation<br />

Dr. Jim Riker, AFRL<br />

1325 - 1350 SHM for Improved Situational Awareness<br />

Mr. Derek Doyle, AFRL<br />

1350 - 1415 Radhard Optical Patchcords and Packaging for<br />

Satellites Using Liquid Crystal Polymers<br />

Dr. Amaresh Mahapatra, Linden Photonics, Inc.<br />

1415 - 1440 Development of Aerogel-Impregnated Ceramic<br />

Papers and Felts for Multilayer Insulation (MLI)<br />

and Thermoelectric Applications<br />

Dr. Frances Hurwitz, NASA GRC<br />

1440 - 1510 BREAK (Grand Ballroom Foyer)<br />

25

Thursday, 28 June 2012<br />

1510 - 1535 Development of Thermal Control Blanket Using<br />

Flexible Thermal Control Material Systems on<br />

Gold and Black Kapton<br />

Mr. Michael Kenny, Alion Science & Technology<br />

1535 - 1600 Overview of Basic Science Program for Materials<br />

for Protection of Space Systems<br />

Dr. Calvin Shipbaugh, Defense Threat Reduction<br />

Agency<br />

1600 - 1625 Low Temperature Superplastic Forming of Fine<br />

Grained Ti Rocket Nozzle Liners and Jackets<br />

Dr. Sion Pickard, Aerojet<br />

1625 - 1650 New High Power Conformal Lithium Reserve<br />

Battery with Weight Reduction<br />

Dr. William Smith, LithChem Energy<br />

1650 - 1700 Grand Prize Give-Away - Sponsored by GDIT<br />

(Florida Ballroom 1-4)<br />

1700 ADJOURN<br />

Poster Session<br />

Session Organizers: Mr. Shane Juhl, AFRL; Dr. Todd Steyer, The Boeing<br />

Company; and 2dLt Kelli Walker, AFRL<br />

Breakthrough Innovations<br />

• CONTACT – Enhancing Optical Absorption in Polymer Solar<br />

Cells with Plasmonic Nanostructures, Dr. Forrest Agee, Rice<br />

University<br />

• Carbon Nanotube Composite Components for JUNO<br />

Spacecraft, Mr. Nick Altobelli, Lockheed Martin Space<br />

Systems<br />

• Increasing Through-Thickness Thermal Conductivity in<br />

Composites: Engineered Carbon Nanotube-Carbon Fiber/<br />

Epoxy Prepregs, Mr. John Craddock, University of Kentucky,<br />

Center for Applied Energy Research<br />

• Dry-Epitaxial Lift-Off, Integration, Interconnect and<br />

Encapsulation of Foldable/Rollable High Efficiency Solar<br />

Cell Modules, Dr. John Farah, OptiCOMP Networks<br />

26

Poster Papers<br />

• Nanoinfusion Processing for Energetic Materials,<br />

Mr. Michael Fisher, Cornerstone Research Group<br />

• Electron Beam Melting of Gamma TiAl, Mr. Robert Hayes,<br />

MTI<br />

• Conductive and Transparent Graphene Coatings via a Non-<br />

Surfactant, Aqueous Route, Dr. David Irvin, Systems and<br />

Materials Research Corporation<br />

• User Defined Material Model for Explicit Analysis of<br />

Ceramic Matrix Composite Damage Progression During<br />

Low Speed Impact, Mr. Edward Klock-McCook, Materials<br />

Research & Design, Inc.<br />

• The US Army’s 100kW One Micron Laser Facility: A Unique<br />

Materials Test Capability, Dr. Michael Lavan, U.S. Army<br />

Space and Missile Defense Command/ARSTRAT<br />

• Demonstrating Ablation Thermometry, Mr. Joseph Lloyd,<br />

Industrial Measurement Systems, Inc.<br />

• On the Benefits of In-Line Coating of Silicon Carbide<br />

Fibers, Dr. Joseph Pegna, Free Form Fibers, LLC<br />

• Experimental Studies of Carbon Nanotube Materials for<br />

Space Radiators, Mr. Michael SanSoucie, NASA MSFC<br />

• Manufacturing Development for Large Unitized Out-of-<br />

Autoclave Composite Sandwich Structures and Support<br />

of NASA’s Shell Buckling Knockdown Factor Project,<br />

Mr. Dawson Vincent, Northrop Grumman<br />

• Brazing Alloys for High Temperature Performance,<br />

Mr. Michael Weinstein, Wall Colmonoy Corporation<br />

Hypersonics<br />

• Innovative 2D Carbon-Carbon Substrates for Refractory<br />

Coated/Lined Low Density Structures, Mr. Dan Hladio,<br />

Materials Research & Design, Inc.<br />

• Thermostructural Analysis and Design Support for<br />

Low-Cost, Light-Weight, High-Speed Structures,<br />

Mr. Daniel Howren, Materials Research & Design, Inc.<br />

• Neutron Imaging of a High Temperature Lithium-<br />

Molybdenum Heat Pipe, Mr. Eric Kirchoff, The University of<br />

Tennessee Knoxville<br />

27

Poster Papers<br />

• Experimental Methods for Dynamic Non-Equilibrium In-<br />

Situ Oxidation Measurements of Ultra-High Temperature<br />

Ceramics up to 1600°C, Ms. Melia Miller-Oana, University of<br />

Arizona<br />

• Emerging Silicon Carbide Pressure Sensors Embedded in<br />

Ceramic Matrix Composites, Dr. Robert Okojie, NASA GRC<br />

• Modeling Thermal Loading and Response of Hybrid TPS<br />

During Laser Based Tests, Dr. Triplicane Parthasarathy,<br />

UES, Inc.<br />

• Ceramic Matrix Composite Thermal Protection System<br />

Concepts, Mr. James Riedell, ATK - COI Ceramics, Inc.<br />

• SITPS Joint Trade Study Investigation, Ms. Leslie Weller,<br />

Materials Research & Design, Inc.<br />

Missiles & Missile Defense<br />

• Non-Eroding Boost Nozzles for Advanced Ballistic Missile<br />

Interceptors, Mr. Daniel Butts, Plasma Processes, LLC<br />

• Ultrahigh Yield Strength Rhenium for High-Performance<br />

Combustion Chambers, Dr. Art Fortini, Ultramet<br />

• Evaluation of TaC-Based Materials & Nozzle Concepts<br />

for Aluminized Solid Rocket Motors: Design, Analysis,<br />

and Testing, Mr. Joseph Pluscauskis, Materials Research &<br />

Design, Inc.<br />

• UHT CMCs for Missile Propulsion and Non-Ablative TPS<br />

Applications, Dr. Edward Pope, MATECH<br />

• Laser-Assisted Machining for Advanced Radome<br />

Manufacturing, Mr. Jay Rozzi, Creare Incorporated<br />

• Performance of Conformable Phenolic Impregnated<br />

Carbon Ablator in Aerothermal Environments,<br />

Mr. Jeremy Thornton, ERC, Inc.<br />

Orbital Technologies & Operations<br />

• Variable Conductance Heat Pipes Without Compensation<br />

Chambers, Mr. John Rosenfeld, Thermacore, Inc.<br />

28

Space Exploration<br />

Poster Papers<br />

• Evaluation of SOFI for Surface Treated Aluminum<br />

Cryogenic Propellant Tanks, Mr. Keith Chong, The Boeing<br />

Company<br />

• Ceramic Bracket for Load Bearing Panel, Mr. Daniel Moan,<br />

Northern Arizona University<br />

• Contamination Control and Hardware Processing Solutions<br />

at the Marshall Space Flight Center, Mr. Howard DeWitt<br />

Burns, NASA MSFC<br />

• Development of an Undergraduate Degree in Commercial<br />

Space Operations, Mr. Lance Erickson, Embry-Riddle<br />

Aeronautical University<br />

• Modeling of the Time-Temperature-Stress Profile During<br />

Fabrication of 238 PuO2 Fuel Pellets Employed in<br />

Radioisotope Space Power Systems, Dr. Daniel Kramer,<br />

University of Dayton Research Institute<br />

• Development of High Temperature Catalysts and Bed<br />

Plates Based on Metal Foam, Dr. Anatoliy Shchetkovskiy,<br />

Plasma Processes, LLC<br />

• Aerothermal Testing of Woven TPS Ablative Materials,<br />

Dr. Mairead Stackpoole, ERC, Inc. at NASA ARC<br />

Space Materials Experiments &<br />

Environmental Effects Simulation<br />

• Space Environmental Effects Testing Capability at the<br />

Marshall Space Flight Center, Mr. Howard DeWitt Burns,<br />

NASA MSFC<br />

• Opening of MISSE-6 & MISSE-7, Mr. Chip Frohlich, The<br />

Boeing Company<br />

• Multi-Use Coating for Abrasion Prevention, Wear<br />

Protection and Dust Removal, Mr. Timothy McKechnie,<br />

Plasma Processes, LLC<br />

• Weather Effects Testing in the AEDC RANGE G,<br />

Mr. Marshall Polk, ATA/AEDC<br />

29

NSMMS Exhibit Show<br />

NSMMS Exhibit Map<br />

(Grand Ballroom)<br />

Chairs:<br />

Mr. Ron Ooten, USEC, Inc. and Mr. Chip Frohlich, The Boeing Company<br />

30

NSMMS Exhibitors<br />

846 TS Holloman Test Track (Booth 31)<br />

www.846ts.info@holloman.af.mil<br />

The Holloman High Speed Test Track is an aerospace ground test facility<br />

that provides testers with a unique environment to study the erosive effects<br />

of simulated rain droplet impacts during supersonic or hypersonic flight.<br />

The facility can also be used to study aerodynamic heating phenomena and<br />

airflow patterns under conditions of high Mach number flow at low altitudes.<br />

Air Force Research Laboratory (Booth 26)<br />

www.wpafb.af.mil/afrl<br />

The Air Force Research Laboratory is the Air Force’s only organization<br />

wholly dedicated to leading the discovery, development, and integration of<br />

warfighting technologies for our air, space and cyberspace forces. We trace<br />

our roots to the vision of airpower pioneers who understood science as key<br />

to air supremacy. The passionate commitment of AFRL people to realize this<br />

vision has helped create the world’s best air, space and cyberspace force.<br />

ATA/AEDC (Booth 28)<br />

www.arnold.af.mil<br />

Arnold Engineering Development Center (AEDC) is the most advanced and<br />

largest complex of flight simulation test facilities in the world. The center<br />

operates aerodynamic and propulsion wind tunnels, rocket and turbine<br />

engine test cells, space environmental chambers, arc heaters, ballistic ranges<br />

and other specialized units.<br />

ATK/ATK COI (Booth 42 & 43)<br />

www.atk.com<br />

ATK is a premier advanced weapon and space systems company producing<br />

composite structures, propulsion systems, munitions, and defense<br />

integration solutions. ATK is a world-class supplier of launch vehicle solid<br />

propulsion systems and a leader in the development and production of<br />

composite optical benches and dimensionally stable assemblies for satellites<br />

and propulsion products.<br />

Barrday Composite Solutions (Booth 15)<br />

www.barrday.com<br />

Barrday Composite Solutions supplies a wide array of thermoset and<br />

thermoplastic prepregs reinforced with carbon, aramid or glass fibers.<br />

Prepregs can be supplied at widths up to 86” (218 cm) and at a wide range<br />

of fiber areal weights and resin contents. Resin/polymer systems include:<br />

phenolic, epoxy, polyester, BMI, PPS, PEEK, & PEKK, among others. A wide<br />

range of engineered fabrics, adhesive films, etc., are also available. Barrday is<br />

AS9100C and ISO9001 certified.<br />

31

NSMMS Exhibitors<br />

Barrday supplies materials to a variety of demanding applications in the<br />

military/defense (ablatives, carbon/carbon, radomes/antennas, lighter than<br />

air ships, armor/protective, etc.), commercial aerospace (interiors, structures,<br />

et al.) and industrial (automotive, wind blades, filtration, electrical, and<br />

sports/recreation, among others) markets. Barrday focuses on FR, snap<br />

curing, toughened, & low temperature cure resin systems. Barrday supplies<br />

its ablative materials (rayon replacement, graphite, silica, and glass) in<br />

broadgoods, bias tapes, and molding compounds.<br />

The Boeing Company (Booth 6 & 7)<br />

www.boeing.com<br />

Boeing is the world’s leading aerospace company and the largest<br />

manufacturer of commercial jetliners and military aircraft combined.<br />

Additionally, Boeing designs and manufactures rotorcraft, electronic<br />

and defense systems, missiles, satellites, launch vehicles and advanced<br />

information and communication systems. As a major service provider to<br />

NASA, Boeing operates the Space Shuttle and International Space Station.<br />

The company also provides numerous military and commercial airline<br />

support services. Boeing has customers in more than 90 countries around<br />

the world and is one of the largest U.S. exporters in terms of sales. Boeing<br />

has a long tradition of aerospace leadership and innovation. We continue to<br />

expand our product line and services to meet emerging customer needs. Our<br />

broad range of capabilities includes creating new, more efficient members<br />

of our commercial airplane family; integrating military platforms, defense<br />

systems and the warfighter through network-centric operations; creating<br />

advanced technology solutions that reach across business units; e-enabling<br />

airplanes and providing connectivity on moving platforms; and arranging<br />

financing solutions for our customers. Headquartered in Chicago, Boeing<br />

employs more than 157,000 people across the United States and in 70<br />

countries. This represents one of the most diverse, talented and innovative<br />

workforces anyw<strong>here</strong>. More than 90,000 of our people hold college degrees-<br />

-including nearly 29,000 advanced degrees--in virtually every business and<br />

technical field from approximately 2,700 colleges and universities worldwide.<br />

Our enterprise also leverages the talents of hundreds of thousands more<br />

skilled people working for Boeing suppliers worldwide.<br />

BryCoat, Inc. (Booth 37)<br />

www.brycoat.com<br />

BryCoat applies surface engineered coatings to improve performance<br />

of precision components for improved wear resistance, temperature<br />

resistance, anti-friction, non-stick, plus elimination of galling. BryCoat<br />

applies coatings of ceramics, carbides, and metal alloys by PVD vacuum<br />

coating such as Titanium Nitride & Chrome Nitride or Thermal Spray<br />

coatings by HVOF and Plasma.<br />

32

NSMMS Exhibitors<br />

CONTACT Program - Rice University (Booth 16)<br />

www.contact.rice.edu<br />

The Consortium for Nanomaterials for Aerospace Commerce and<br />

Technology or CONTACT is a research consortium including Rice, Air<br />

Force Research Laboratory, and six other Texas universities (UT Austin, UT<br />

Dallas, UT Brownsville, UT Pan American, UT Arlington, and University of<br />

Houston). The Consortium is focused on developing and commercializing<br />

new nanomaterials for the defense aerospace industry. CONTACT offers the<br />

basis for cooperative nanotechnology research in Texas and in the Air Force<br />

Research Laboratory to provide breakthrough technological solutions. It is<br />

strengthened by cross-cutting intellectual collaborations and the availability of<br />

state-of-the-art equipment. The Program focuses on technology transfer to<br />

aerospace, commercial, and defense sectors. CONTACT is a critical part of<br />

the Richard E. Smalley Institute for Nanoscale Science and Technology.<br />

DARPA SBIR (Booth 20)<br />

www.darpa.mil<br />

DARPA’s mission is to prevent technological surprise for the United States<br />

and to create technological surprise for its adversaries. The DARPA Small<br />

Business Innovation Research (SBIR) and Small Business Technology<br />

Transfer (STTR) Programs are designed to provide small, high-tech<br />

businesses and academic institutions the opportunity to propose radical,<br />

innovative, high-risk approaches to address existing and emerging national<br />

security threats; t<strong>here</strong>by supporting DARPA’s overall strategy to bridge the<br />

gap between fundamental discoveries and the provision of new military<br />

capabilities. The DARPA Small Business Programs Office is responsible for<br />

implementing DARPA’s SBIR and STTR Programs.<br />

Eclipse Energy Systems, Inc. (Booth 13)<br />

www.eclipsethinfilms.com<br />

Eclipse Energy Systems, Inc.,is a world leader in thin films processing for<br />

nano-based optical materials and nanotechnology systems. Eclipse has built<br />

off this expertise and capability to design, fabricate, and assemble working<br />

novel systems which incorporate metamaterials phenomenon, one of which<br />

is currently flying in space.<br />

Free Form Fibers (Booth 30)<br />

www.fffibers.com<br />

Free Form Fibers is an early stage company that has developed the<br />

technology of Laser-assisted Chemical Vapor Deposition to create low-cost<br />

inorganic high performance fibers, including:<br />

• Stoichiometric Silicon Carbide fibers (10-15 microns, 40 filaments/tow<br />

– 2012, 360 filaments/tow – 2013 projection)<br />

• Amorphous boron fibers (10-15 microns, 40 filaments/tow)<br />

33

NSMMS Exhibitors<br />

• Other specialty fibers: If material can be deposited by CVD, it can be<br />

made into fibers<br />

FFF’s silicon carbide fibers features benefits<br />

• U.S. technology domestic source of fibers<br />

• Non-polymeric-based<br />

• Oxygen-free production process<br />

• Oxygen-free silicon carbide fibers<br />

• Adjustable stoichiometry, stoichiometric, Si-rich, or C-rich fibers<br />

• Adjustable microstructure, glassy SiC or 100 nm grain Beta-SiC<br />

• Adjustable fiber diameter, dimensionally stable<br />

• Single step energy efficient process<br />

• Low-cost, low environmental impact<br />

IBC Engineered Materials Corporation (Booth 21 & 22)<br />

www.ibcadvancedalloys.com<br />

IBC Engineered Materials Corporation provides high-precision investment<br />

castings for a broad spectrum of applications within the aerospace and<br />

defense market segments. These lightweight, high-stiffness castings are<br />

derived from an alloy of beryllium and aluminum and offer distinct advantages<br />

over conventional lightweight metals and alloys such as aluminum,<br />

magnesium and titanium. This family of alloy, called Beralcast, is 22% less<br />

dense than Al-356 with an equivalent yield strength, is 350% stiffer with a<br />

superior damping coefficient and a lower CTE(14.2 vs. 21.5).<br />

Linden Photonics, Inc. (Booth 3)<br />

www.LindenPhotonics.com<br />

Miniature, high strength optical fiber cables, cable coatings and specialized<br />

optoelectronic packaging. Radiation resistant fiber optic patchcords.<br />

Linden’s fiber optic cables are optimized for such harsh environments as<br />

space, aerospace and underwater use, as well as use in larger umbilicals.<br />

Combining high strength, low weight and small size, we produce the ideal<br />

optical cable. High strength, buoyant designs also available.<br />

Materials, Research & Design (Booth 40)<br />

www.m-r-d.com<br />

Materials Research & Design (MR&D) is a small business that provides<br />

research and design services to the aerospace materials community. Typical<br />

programs at MR&D focus on the simultaneous design of material and<br />

structure to optimize component cost, weight, or structural performance.<br />

Additional areas of interest focus upon research into the behavior of<br />

composite materials and the development of micromechanical models<br />

to analyze and understand observed properties. The analytical approach<br />

employed by MR&D is based upon a practical understanding of engineering<br />

issues founded upon a strong background of theoretical mechanics.<br />

34

NSMMS Exhibitors<br />

MATECH (Booth 5)<br />

www.matechgsm.com<br />

MATECH specializes in exotic, high performance advanced ceramics.<br />

MATECH has emerged as the world’s premier developer of high temperature<br />

and ultra-high-temperature (UHT) ceramic fibers. These fibers include silicon<br />

nitride/carbide (SiNC-1400X), stoichiometric silicon carbide (SiC-1900X),<br />

hafnium carbide (HfC-2000X), tantalum carbide (TaC-1600X), silicon<br />

oxycarbide (SiOC). In addition, MATECH has developed HT and UHT CMC<br />

components for emerging UHT turbine and missile applications.<br />

MDA SBIR/STTR (Booth 23)<br />

www.mdasbir.com; www.mdatechnology.net<br />

MDA’s goal is to realize a return on investment by acquiring technology that<br />

can be transitioned into the Ballistic Missile Defense System (BMDS); MDA<br />

currently focuses the efforts of the program around the needs of the BMDS.<br />

NASA (Booths 32-35 & 38-39)<br />

www.nasa.gov<br />

Since its inception in 1958, NASA has accomplished many great scientific<br />

and technological feats in air and space. NASA technology also has been<br />

adapted for many non-aerospace uses by the private sector. NASA remains<br />

a leading force in scientific research and in stimulating public interest in<br />

aerospace exploration, as well as science and technology in general.<br />

Perhaps more importantly, our exploration of space has taught us to view<br />

Earth, ourselves, and the universe in a new way.<br />

NASA’s mission is to pioneer the future in space exploration, scientific<br />

discovery, and aeronautics research and conducts its work through four<br />

mission directorates:<br />

• Aeronautics: pioneers and proves new flight technologies that<br />

improve our ability to explore and which have practical applications<br />

on Earth.<br />

• Exploration Systems: creates new capabilities and spacecraft for<br />

affordable, sustainable human and robotic exploration.<br />

• Science: explores the Earth, Moon, Mars and beyond; charts the<br />

best route of discovery; and reaps the benefits of Earth and space<br />

exploration for society.<br />

• Space Operations provides critical enabling technologies for much of<br />

the rest of NASA through the space shuttle, the International Space<br />

Station and flight support.<br />

35

NSMMS Exhibitors<br />

In the next 20 years, NASA will be laying the groundwork for sending humans<br />

not only beyond Earth’s orbit, but further into space than they’ve ever been.<br />

Though nearly 50 years old, NASA is only beginning the most exciting part of<br />

its existence.<br />

PLANSEE USA (Booth 8)<br />

www.plansee-usa.com<br />

PLANSEE USA is the worldwide leader in the supply, machining and<br />

fabrication of high performance materials (Molybdenum, Tungsten, Tantalum,<br />

Niobium, Tungsten Heavy Metals, Super Alloys, Titanium). PLANSEE<br />

USA’s state-of-the-art facility provides innovative and effective solutions<br />

in engineering, high precision machining, fabrication, thermal processing,<br />

brazing and cleanroom operations. PLANSEE USA offers a portfolio of<br />

components for space, civil, and military aerospace applications. We are<br />

AS9100 Certified and ITAR Registered.<br />

Plasma Processes, LLC (Booth 44)<br />

www.plasmapros.com<br />

Plasma Processes is an ISO 9001:2008 certified small business specializing<br />

in the development and manufacture of high temperature materials, coatings,<br />

net-shape structures, and powder processing services. Plasma develops,<br />

applies and validates coating solutions for thermal protection, electrical<br />

isolation, wear and corrosion resistance and dimensional restoration, in<br />

addition to the manufacture of net-shape components by vacuum plasma<br />

and EL-Form® deposition processes. Plasma serves customers in the<br />

government, aerospace/defense and commercial sectors.<br />

Pratt & Whitney Rocketdyne (Booth 25 & 27)<br />

www.pw.utc.com<br />

Pratt & Whitney Rocketdyne, a recognized leader in propulsion for more than<br />

80 years, is proud to exhibit many of its innovative products and services.<br />

Pushing beyond the boundaries of Earth, we are working with NASA, DOD,<br />

and ULA with new technologies and solutions for planetary exploration and<br />

reliable space access. Pratt & Whitney Rocketdyne offers propulsion and<br />

power solutions for launch vehicles, spacecraft, satellites, missiles, aircraft,<br />

hypersonic and combined-cycle propulsion and power generation systems.<br />

QuesTek Innovations, LLC (Booth 19)<br />

www.questek.com<br />

QuesTek is a global leader in Integrated Computational Materials Engineering<br />

(ICME), using its advanced Materials By Design® technology and expertise<br />

to rapidly design, invent, develop and qualify new materials; QuesTek<br />

licenses its intellectual property to proven third-party producers, processors<br />

or OEMs. Four new QuesTek-designed Ferrium® VIM/VAR steels are<br />

commercially-available: M54 (AMS 6516) is an economical, SSC-resistant,<br />

36

NSMMS Exhibitors<br />

ultra-strong and –tough steel that provides superior fatigue resistance,<br />

SCC resistance and economy vs. AerMet® 100 (AMS 6532); S53® (AMS<br />

5922; MMPDS-05) provides superior resistance to general corrosion, SCC,<br />

fatigue, corrosion fatigue and high temperature exposure than 300M; and<br />

carburizing grades C61 (AMS 6517) and C64 offer superior mechanical<br />

properties, thermal resistance, fatigue resistance and hardness or toughness<br />

vs. 9310 or Pyrowear® 53. QuesTek is computationally designing 10+ other<br />

Al-, Ti-, Fe-, Ni-, Cu-, Mo-, Co- and Nb-based alloys; those alloys nearing<br />

commercialization include new castable, high-strength, high-toughness<br />

titanium and stainless steel alloys, and new high-strength aluminum alloys<br />

resistant to SCC and high temperature exposure. Potential applications<br />

include housings, armor, penetrator assemblies, structural components, drive<br />

shafts and other parts of missiles and spacecraft.<br />

Rapid Composites, LLC (Booth 45)<br />

website under construction<br />

Rapid Composites is an established provider of engineering services with<br />

the skill, training, expertise and resources to take projects from concept<br />

through production. We work on time, on budget and within the most<br />

exacting standards of precision and performance. Rapid Composites offers<br />

a wide array of in-house services including; industrial design, mechanical<br />

engineering, electrical engineering, software engineering, prototyping, tooling,<br />

carbon fiber molding and production. Our team specialize in developing both<br />

thermoplastic and thermoset, continuous fiber, composite product solutions<br />

from the ground up. Rapid Composites is capable of executing a “start to<br />

finish” process entirely under one roof.<br />

Reinhold Industries, Inc. (Booth 24)<br />

www.reinhold-ind.com<br />

Reinhold Industries is a leading manufacturer of composite and metallic<br />

structures for the Aerospace Defense, Aircraft and Industrial market. The<br />

Aerospace Product Line specializes in the manufacturing of composite and<br />

ablative components for use in space and military requirements. Providing<br />

solutions for 75 years, Reinhold is a privately-owned, certified small business<br />

with 185 employees and $50M in annual sales.<br />

Scot Forge (Booth 41)<br />

www.scotforge.com<br />

Scot Forge is a 100% employee-owned, AS9100C certified manufacturer of<br />

custom open die and rolled ring forgings. Scot Forge has over 100 years of<br />

experience, leading the industry as one of the most modern and respected<br />

forging companies in the world. More than 650 employees operate within<br />

1,000,000 square feet of manufacturing space in five plants. Output of these<br />

facilities is greater than 250 million pounds of material annually. Our 3,600<br />

ton ring expander compliments a large Wagner ring roller and drop-bottom<br />

37

NSMMS Exhibitors<br />

furnace. These assets work in tandem to provide large ring forgings for<br />

aircraft, missile and space applications. With the capability to form aluminum,<br />

magnesium and titanium rings up to 252” diameter and over 42” tall, Scot<br />

Forge is a member an extremely small community of domestic corporations<br />

with these capabilities.<br />

Thermacore, Inc. (Booth 29)<br />

www.thermacore.com<br />

Founded in 1970, Thermacore specializes in the custom design,<br />

development, and manufacturing of highly engineered thermal management<br />

systems and components such as heat pipe/vapor chamber assemblies,<br />

loop heat pipe assemblies, k-Core® APG based advanced solid conduction<br />

assemblies and active pumped liquid thermal management systems for a<br />

variety of OEM applications across a diversified set of global markets that<br />

includes Military/Aerospace, Computer, Communication, Energy Conversion,<br />

Medical and Test Equipment.<br />

Ultramet - (Booth 10)<br />

www.ultramet.com<br />

Ultramet is an ISO 9001:2008-certified producer of flight-qualified<br />

components, comprised of engineers, scientists, and support personnel,<br />

production and R&D facilities particularly suited to the research, development<br />

and production of advanced materials including high temperature capability,<br />

corrosion- and erosion-resistant materials. Ultramet personnel will be<br />

available to discuss your specific materials-related applications.<br />

U.S. Army Space and Missile Defense Command/Army Forces Strategic<br />

Command (SMDC/ARSTRAT) (Booth 17 & 18)<br />

www.army.mil/smdc<br />

The U.S. Army Space and Missile Defense Command/Army Forces Strategic<br />

Command (SMDC/ARSTRAT) Technical Center (TC) develops, tests and<br />

transitions space, missile defense, and other related technologies. The TC<br />

manages the Missile Defense Materials and Manufacturing Technology<br />

Program which is developing technologies for near and mid-term insertion.<br />

Supporting programs include Ultra-high Temperature Propulsion Materials.<br />

WKU/NOVA Center (Booth 36)<br />

www.largechamber.com<br />

We have established the Nondestructive Analysis (NOVA) Center at Western<br />

Kentucky University (WKU). The acquisition of the Large Chamber Scanning<br />

Electron Microscope (LC-SEM) has positioned WKU as the only university<br />

in North America with an instrument of this type. As envisioned, the NOVA<br />

Center will be a national focal point for nondestructive measurements.<br />

38

Notes<br />

Unclassified Notes<br />

(No ITAR or Military Critical Data Allowed)<br />

39

Notes<br />

Unclassified Notes<br />

(No ITAR or Military Critical Data Allowed)<br />

40