ASTM

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Influence”<br />

37<br />

A<br />

<strong>ASTM</strong> STANDARDS IN NEW INDUSTRIES<br />

In the early 1920s, <strong>ASTM</strong>’s main activities still focused<br />

on the steel, railroad, and cement industries, and<br />

most of its members were based in the Northeastern<br />

part of the country. In the four decades after World<br />

War I, <strong>ASTM</strong><br />

evolved into<br />

a truly<br />

national<br />

organization<br />

whose more<br />

than 100<br />

technical<br />

committees<br />

formed an<br />

integral part<br />

of America’s maturing economic base, contributing to<br />

the rise of new industries in strategic areas such as<br />

highway transportation, petrochemicals, electronics,<br />

and aerospace technology, to name only a few.<br />

<strong>ASTM</strong>’s development from the 1920s to the 1960s<br />

helped facilitate the nation’s rise to economic and<br />

military superpower status.<br />

The period between the two world wars witnessed<br />

a phenomenal growth of<br />

mass-production industries,<br />

which formed the backbone<br />

of American<br />

economic strength for<br />

decades to come. Mass<br />

production, which<br />

involved interchangeable<br />

parts and manufacturing<br />

methods based on<br />

the<br />

assembly-line<br />

system, had<br />

been pioneered<br />

by Eli Whitney<br />

in small arms<br />

manufacture,<br />

Isaac Singer in<br />

sewing machine<br />

production, and<br />

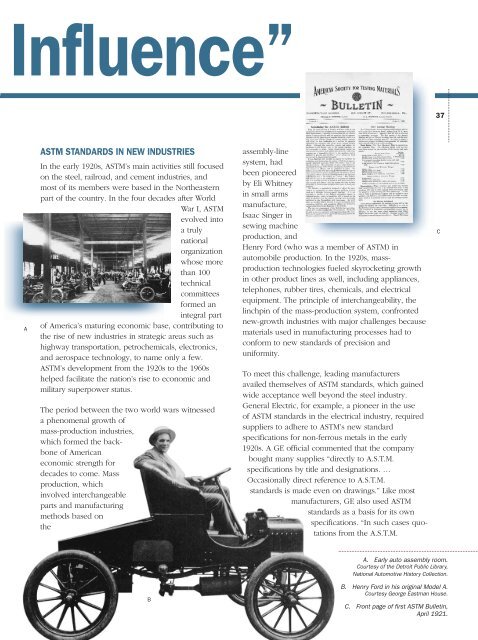

Henry Ford (who was a member of <strong>ASTM</strong>) in<br />

automobile production. In the 1920s, massproduction<br />

technologies fueled skyrocketing growth<br />

in other product lines as well, including appliances,<br />

telephones, rubber tires, chemicals, and electrical<br />

equipment. The principle of interchangeability, the<br />

linchpin of the mass-production system, confronted<br />

new-growth industries with major challenges because<br />

materials used in manufacturing processes had to<br />

conform to new standards of precision and<br />

uniformity.<br />

To meet this challenge, leading manufacturers<br />

availed themselves of <strong>ASTM</strong> standards, which gained<br />

wide acceptance well beyond the steel industry.<br />

General Electric, for example, a pioneer in the use<br />

of <strong>ASTM</strong> standards in the electrical industry, required<br />

suppliers to adhere to <strong>ASTM</strong>’s new standard<br />

specifications for non-ferrous metals in the early<br />

1920s. A GE official commented that the company<br />

bought many supplies “directly to A.S.T.M.<br />

specifications by title and designations. …<br />

Occasionally direct reference to A.S.T.M.<br />

standards is made even on drawings.” Like most<br />

manufacturers, GE also used <strong>ASTM</strong><br />

standards as a basis for its own<br />

specifications. “In such cases quotations<br />

from the A.S.T.M.<br />

C<br />

A. Early auto assembly room.<br />

Courtesy of the Detroit Public Library,<br />

National Automotive History Collection.<br />

B<br />

B. Henry Ford in his original Model A.<br />

Courtesy George Eastman House.<br />

C. Front page of first <strong>ASTM</strong> Bulletin,<br />

April 1921.