oliver valves power industry

oliver valves power industry

oliver valves power industry

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Oliver Valves Power Br NEW.qx 12/5/2004 12:45 PM Page 6<br />

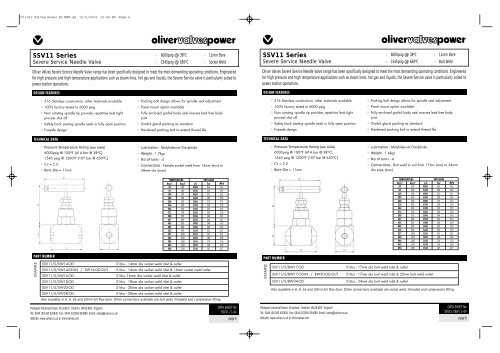

SSV11 Series<br />

Severe Service Needle Valve<br />

• 6000psig @ 38 o C • 11mm Bore<br />

• 1545psig @ 650 o C • Socket Weld<br />

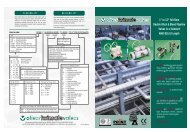

SSV11 Series<br />

Severe Service Needle Valve<br />

• 6000psig @ 38 o C • 11mm Bore<br />

• 1545psig @ 650 o C • Butt Weld<br />

Oliver Valves Severe Service Needle Valve range has been specifically designed to meet the most demanding operating conditions. Engineered<br />

for high pressure and high temperature applications such as steam lines, hot gas and liquids, the Severe Service valve is particularly suited to<br />

<strong>power</strong> station operations.<br />

DESIGN FEATURES<br />

Oliver Valves Severe Service Needle Valve range has been specifically designed to meet the most demanding operating conditions. Engineered<br />

for high pressure and high temperature applications such as steam lines, hot gas and liquids, the Severe Service valve is particularly suited to<br />

<strong>power</strong> station operations.<br />

DESIGN FEATURES<br />

• 316 Stainless construction, other materials available<br />

• 100% factory tested to 6000 psig<br />

• Non rotating spindle tip provides repetitive leak tight<br />

process shut off<br />

• Safety back seating spindle seals in fully open position<br />

• Firesafe design<br />

• Packing bolt design allows for spindle seal adjustment<br />

• Panel mount option available<br />

• Fully enclosed grafoil body seal ensures leak free body<br />

joint<br />

• Grafoil gland packing as standard<br />

• Hardened packing bolt to extend thread life<br />

• 316 Stainless construction, other materials available<br />

• 100% factory tested to 6000 psig<br />

• Non rotating spindle tip provides repetitive leak tight<br />

process shut off<br />

• Safety back seating spindle seals in fully open position<br />

• Firesafe design<br />

• Packing bolt design allows for spindle seal adjustment<br />

• Panel mount option available<br />

• Fully enclosed grafoil body seal ensures leak free body<br />

joint<br />

• Grafoil gland packing as standard<br />

• Hardened packing bolt to extend thread life<br />

TECHNICAL DATA<br />

TECHNICAL DATA<br />

• Pressure-Temperature Rating (see table)<br />

6000psig @ 100 o F (414 bar @ 38 o C)<br />

1545 psig @ 1200 o F (107 bar @ 650 o C)<br />

• Cv = 2.2<br />

• Bore Dia = 11mm<br />

• Lubrication - Molybdenum Disulphide<br />

• Weight - 1.7kgs<br />

• No of turns - 4<br />

• Connections - Female socket weld from 14mm (min) to<br />

28mm dia (max)<br />

• Pressure-Temperature Rating (see table)<br />

6000psig @ 100 o F (414 bar @ 38 o C)<br />

1545 psig @ 1200 o F (107 bar @ 650 o C)<br />

• Cv = 2.2<br />

• Bore Dia = 11mm<br />

• Lubrication - Molybdenum Disulphide<br />

• Weight - 1.6kgs<br />

• No of turns - 4<br />

• Connections - Butt weld to suit from 17mm (min) to 34mm<br />

dia pipe (max).<br />

TEMPERATURE<br />

PRESSURE<br />

deg C deg F psi bar MPa<br />

38 100 6000 414 41.4<br />

93 200 5160 356 35.6<br />

149 300 4660 321 32.1<br />

205 400 4280 295 29.5<br />

260 500 3980 274 27.4<br />

316 600 3760 259 25.9<br />

344 650 3700 255 25.5<br />

371 700 3620 250 25.0<br />

399 750 3560 246 24.5<br />

427 800 3520 243 24.3<br />

455 850 3480 240 24.0<br />

483 900 3460 239 23.9<br />

510 950 3220 222 22.2<br />

537 1000 2915 201 20.1<br />

566 1050 2865 198 19.8<br />

594 1100 2545 176 17.6<br />

622 1150 1970 136 13.6<br />

650 1200 1545 107 10.7<br />

TEMPERATURE<br />

PRESSURE<br />

deg C deg F psi bar MPa<br />

38 100 6000 414 41.4<br />

93 200 5160 356 35.6<br />

149 300 4660 321 32.1<br />

205 400 4280 295 29.5<br />

260 500 3980 274 27.4<br />

316 600 3760 259 25.9<br />

344 650 3700 255 25.5<br />

371 700 3620 250 25.0<br />

399 750 3560 246 24.5<br />

427 800 3520 243 24.3<br />

455 850 3480 240 24.0<br />

483 900 3460 239 23.9<br />

510 950 3220 222 22.2<br />

537 1000 2915 201 20.1<br />

566 1050 2865 198 19.8<br />

594 1100 2545 176 17.6<br />

622 1150 1970 136 13.6<br />

650 1200 1545 107 10.7<br />

PART NUMBER<br />

EXAMPLE<br />

SSV11/S/SW14-OD<br />

316ss - 14mm dia socket weld inlet & outlet<br />

SSV11/S/SW14-OD-IN / SW16-OD-OUT 316ss - 14mm dia socket weld inlet & 16mm socket weld outlet<br />

SSV11/S/SW16-OD<br />

316ss -16mm dia socket weld inlet & outlet<br />

SSV11/S/SW18-OD<br />

316ss - 18mm dia socket weld inlet & outlet<br />

SSV11/S/SW20-OD<br />

316ss - 20mm dia socket weld inlet & outlet<br />

SSV11/S/SW28-OD<br />

316ss - 28mm dia socket weld inlet & outlet<br />

Also available in 6, 9, 16 and 20mm full flow bore. Other connections available are butt weld, threaded and compression fitting.<br />

PART NUMBER<br />

EXAMPLE<br />

SSV11/S/BW17-OD<br />

316ss - 17mm dia butt weld inlet & outlet<br />

SSV11/S/BW17-OD-IN / BW20-OD-OUT 316ss - 17mm dia butt weld inlet & 20mm butt weld outlet<br />

SSV11/S/BW34-OD<br />

316ss - 34mm dia butt weld inlet & outlet<br />

Also available in 6, 9, 16 and 20mm full flow bore. Other connections available are socket weld, threaded and compression fitting.<br />

Parkgate Industrial Estate Knutsford Cheshire WA16 8DX England<br />

Tel: 0044 (0)1565 632636 Fax: 0044 (0)1565 654089 Email: sales@<strong>valves</strong>.co.uk<br />

Website: www.<strong>valves</strong>.co.uk or <strong>oliver</strong><strong>valves</strong>.com<br />

DATA SHEET No<br />

SSV11 / 1-04<br />

page 5<br />

Parkgate Industrial Estate Knutsford Cheshire WA16 8DX England<br />

Tel: 0044 (0)1565 632636 Fax: 0044 (0)1565 654089 Email: sales@<strong>valves</strong>.co.uk<br />

Website: www.<strong>valves</strong>.co.uk or <strong>oliver</strong><strong>valves</strong>.com<br />

DATA SHEET No<br />

SSV11 / BW / 1-04<br />

page 6