Nufarmer 2006 Autumn - Pest Genie

Nufarmer 2006 Autumn - Pest Genie

Nufarmer 2006 Autumn - Pest Genie

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

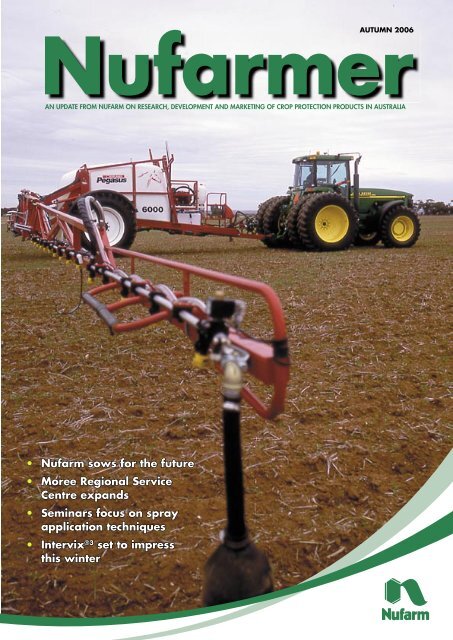

AUTUMN <strong>2006</strong><br />

<strong>Nufarmer</strong><br />

AN UPDATE FROM NUFARM ON RESEARCH, DEVELOPMENT AND MARKETING OF CROP PROTECTION PRODUCTS IN AUSTRALIA<br />

• Nufarm sows for the future<br />

• Moree Regional Service<br />

Centre expands<br />

• Seminars focus on spray<br />

application techniques<br />

• Intervix ®3 set to impress<br />

this winter<br />

<strong>Nufarmer</strong> <strong>Autumn</strong> <strong>2006</strong><br />

1

Welcome<br />

Contents<br />

For more than 50 years Nufarm has<br />

been supporting Australian agriculture<br />

by developing new products and uses<br />

and expanding our service network.<br />

Nufarm is an Australian-owned<br />

company, committed to quality products<br />

designed for and tested in Australian<br />

conditions. No other supplier of crop<br />

production products can claim this fact.<br />

In this issue we reinforce the messages<br />

outlined in the current advertising<br />

campaign. In this campaign, Nufarm<br />

reminds growers of the value we deliver,<br />

ensuring farmers get the best outcomes<br />

when they choose Nufarm products.<br />

When you’re farming, timing is<br />

everything. When the spray window is<br />

open, farmers need to work quickly to<br />

maximise cropping yields. To help farmers<br />

get products delivered quickly, Nufarm has<br />

made significant investments in its service<br />

network. The latest expansion is at the<br />

Moree Regional Service Centre (see page<br />

5). Crop protection products stored closer<br />

to the paddock ensure rapid delivery times.<br />

Nufarm provides so much more than a<br />

drum of chemical. Nufarm is committed to<br />

efficacious spray application and holds<br />

regular demonstrations and workshops for<br />

our re-sellers, farmers and agronomists<br />

(see page 4/5).<br />

Seeds are quickly being regarded as the<br />

engine room of agricultural production.<br />

Nufarm has an expanding seeds division<br />

that is bringing exciting new varieties to<br />

market for better yields and greater returns<br />

for farmers.<br />

Nufarm develops new products for the<br />

market every year. In this issue are details<br />

of the new Intervix ®3 herbicide and new<br />

uses for Penncozeb ®5 420SC fungicide.<br />

This season, more than ever, farmers<br />

should insist on Nufarm. Anything else is<br />

just UnAustralian.<br />

Darren Thomas<br />

Brand Manager<br />

Nufarm Australia Limited<br />

3 Nufarm sows for the future<br />

4 Why farmers should insist on Nufarm<br />

5 Upgrade for Moree Regional Service Centre<br />

6-7 News from Croplands, your crop protection<br />

equipment specialists<br />

8 Opus 125 gives the best stripe rust control in<br />

dryland wheat<br />

9 Monza: your flexible choice for brome<br />

and barley grass control<br />

10 Herbicide mixtures effective against resistant<br />

annual ryegrass<br />

11 News in horticulture<br />

®/ Registered/trademarks of Nufarm Australia Limited<br />

® 1 Registered trademark of Nufarm Technology USA Pty Ltd.<br />

® 2 Registered trademarks of Monsanto Technologies LLC, used under<br />

license by Nufarm Australia Limited.<br />

® 3 Registered trademarks of BASF, used under licence by Nufarm<br />

Australia Limited<br />

® 4 Registered trademark of Spraying Systems Co, USA.<br />

® 5 Registered trademark of Cerexagri SA.<br />

® 6 Registered trademark of Syngenta.<br />

Cover: Croplands’ 6000 L Pegasus Sprayer is purpose-built for easy and efficient broadacre spraying.<br />

2 <strong>Nufarmer</strong> <strong>Autumn</strong> <strong>2006</strong>

Nufarm Plant Science<br />

– sowing for the future<br />

Nufarm has a highly skilled domestic and international plant breeding and field operations team, based in Horsham, Finley and Yarck in<br />

Victoria and offshore. This aerial photograph shows the plant breeding operation on Dahlen Quarry Road near Horsham, Victoria.<br />

In the past 12 months Nufarm has<br />

consolidated its interests in plant<br />

breeding and development with the<br />

acquisition of Victorian canola breeder,<br />

Ag-Seed Research Pty Ltd.<br />

Nufarm, under the banner of Nufarm<br />

Plant Science, now owns three plant<br />

breeding and development businesses -<br />

Nugrain Pty Ltd, Ag-Seed Research Pty<br />

Ltd and Access Genetics Pty Ltd.<br />

The company and its partners are<br />

involved in breeding and developing<br />

new wheat, barley, canola, oats and<br />

field pea varieties. Nufarm now has a<br />

significant germplasm base and a highly<br />

skilled domestic and international plant<br />

breeding and field operations team,<br />

based in Horsham, Finley, Yarck and<br />

offshore.<br />

“This is an exciting move for Nufarm in<br />

delivering the biology and chemistry to<br />

Australian farmers and in the mediumterm<br />

progressing developments<br />

internationally,” said Barry Cox, General<br />

Manager of Nufarm Plant Science.<br />

“Nufarm, through its subsidiary<br />

companies and licensing arrangements,<br />

is actively involved in the development<br />

and release of many of the new, elite<br />

canola varieties now available to<br />

Australian growers,” he said.<br />

“These include ATR Banjo ,<br />

ATR-Summitt , Bravo TT and Warrior<br />

CL .<br />

“Nufarm plans to continue to release<br />

new canola varieties.”<br />

Through Access Genetics Pty Ltd,<br />

Nufarm has established relationships<br />

with SW Seeds and World Wide Wheat.<br />

Both companies have access to new and<br />

diverse germplasm pools not previously<br />

available to Australian growers.<br />

After five years of breeding and<br />

development work with these partners,<br />

Access Genetics Pty Ltd will offer a<br />

range of new plant varieties to Australian<br />

growers in <strong>2006</strong>/2007.<br />

This will include a range of high<br />

yielding, high quality field peas and new<br />

wheat, barley and oat varieties. Many of<br />

these varieties are already in public trials<br />

and showing excellent results.<br />

<strong>2006</strong> varieties<br />

Variety Description Marketed by<br />

ATR Banjo<br />

A new early maturity, TT canola<br />

with very high oil yields and a<br />

blackleg rating of 7<br />

ATR-Summitt New mid maturity TT canola Dovuro<br />

Ag-Seed Research<br />

Bravo TT New mid TT canola PlantTech<br />

SW Odiel Wheat<br />

Tickit Triticale<br />

Warrior CL<br />

Early maturity, strong rust<br />

resistant wheat<br />

Tahara replacement with<br />

excellent rust and CCN<br />

resistance<br />

New mid-late maturity IMI<br />

variety<br />

“Nufarm is always seeking ways to do<br />

things better,” said Mr Cox.<br />

“The way new plant varieties have<br />

historically been delivered to farmers can<br />

and will change over time,” he said.<br />

“Nufarm expects to be at the forefront<br />

of these changes.”<br />

The products denoted by this symbol<br />

are registered under Plant Breeders Rights<br />

(PBR) in Australia. Unauthorised commercial<br />

propagation or any sale, conditioning, export,<br />

import or stocking of propagating material is an<br />

infringement under the Plant Breeders Rights Act<br />

(1994). Any breach of this legislation will leave<br />

the grower liable for prosecution.<br />

Access Genetics<br />

Nugrain<br />

PlantTech<br />

Seeds of these varieties should be available through major distribution outlets,<br />

however, some stocks are limited.<br />

Enquiries can be directed to Barry Cox on mobile: 0409 374 383.<br />

<strong>Nufarmer</strong> <strong>Autumn</strong> <strong>2006</strong><br />

3

Nufarm committed to local<br />

R&D and manufacturing<br />

“Good advice is just as important as<br />

the product in getting the job done right<br />

the first time. Nufarm has a support<br />

network of 29 Territory Managers and<br />

five Horticulture Managers based in key<br />

crop protection zones in five states to<br />

support farmers’ decisions in the<br />

paddock. We’ve got the resources to get<br />

the job done and done well.”<br />

Darren Thomas, Brand Manager, said<br />

research had shown a groundswell of<br />

consumer support for Australian-made<br />

products and services.<br />

“Consumers are keen to support<br />

Australian products, particularly if they<br />

are high quality and available at the<br />

right price,” said Mr Thomas.<br />

Nufarm has stressed its commitment to investing in local research and development in current<br />

press and television advertisements featuring the slogan: “Insist on Nufarm. Anything else is<br />

just UnAustralian.”<br />

Farmers who want to choose quality<br />

Australian crop protection products<br />

and services need look no further<br />

than Nufarm.<br />

Nufarm supports Australian farmers<br />

through local manufacturing and<br />

infrastructure investment, timely product<br />

supply and local research and<br />

development into new products and uses.<br />

That’s the theme of the current Nufarm<br />

advertising campaign launched in<br />

February.<br />

According to National Marketing<br />

Manager, Peter Crock, Australian-owned<br />

Nufarm continues to invest heavily in its<br />

own backyard with:<br />

• four major Australian<br />

manufacturing facilities – in<br />

Laverton, Kwinana, Welshpool and<br />

Brendale, employing more than<br />

300 people,<br />

• nine Regional Service Centres<br />

situated in prime farming areas<br />

across the country, and<br />

• more than $10 million spent<br />

annually on research and<br />

development in the laboratory and<br />

in field trials on Australian farms.<br />

“Nufarm is proudly Australian. For<br />

more than 50 years we’ve worked with<br />

Australian farmers to provide a wide<br />

range of top quality crop protection<br />

products,” said Mr Crock.<br />

“Australians are regarded as<br />

resourceful, hardworking, loyal and<br />

trustworthy. Nufarm also holds these<br />

values which ref lect the service<br />

philosophies and successes of our<br />

founder, Max Fremder,” he said.<br />

“Nufarm has done the hard yards in<br />

the paddock, running extensive field<br />

trials to develop new products and uses<br />

for tough Australian conditions in<br />

recognition that imported formulations<br />

are often designed for European<br />

conditions.<br />

“No other crop protection company in<br />

Australia has the manufacturing<br />

capability of Nufarm to back up our<br />

research. We’re proud to keep<br />

manufacturing jobs and profits in<br />

Australia.<br />

“We’re able to respond more rapidly<br />

than other companies to peak farming<br />

demand by building our Regional<br />

Service Centres in the best places to<br />

serve agriculture. Our expansion<br />

program continues.<br />

“We know Australian farmers want to<br />

support local industry because together<br />

we’re creating a better future for<br />

agriculture in this country. Choosing<br />

products from overseas companies would<br />

be just unAustralian.”<br />

Spraywise semi<br />

More than 700 farmers and<br />

agronomic advisors have<br />

heard and seen ways to<br />

reduce off-target spray drift at 19<br />

spray application workshops held by<br />

Nufarm in the past four months.<br />

The workshops were conducted as<br />

part of the company’s Spraywise ®<br />

program and were well received,<br />

according to the co-ordinator, Jorg Kitt.<br />

Nufarm introduced the Spraywise<br />

program last year to significantly<br />

reduce the incidence and risk of spray<br />

drift damage to a diversity of crops<br />

without compromising spraying efficacy.<br />

The workshops were designed to<br />

look at the drift problem from all<br />

angles – the role of chemicals used,<br />

inf luence of nozzle choice and<br />

set-up of machinery, impact of<br />

weather and governing legislation.<br />

4 <strong>Nufarmer</strong> <strong>Autumn</strong> <strong>2006</strong>

Moree Regional<br />

Service Centre<br />

upgraded<br />

Nufarm is in a strong position to<br />

meet expected growth in<br />

demand for its range of preemergent<br />

crop protection products in<br />

<strong>2006</strong>, following further investment in its<br />

Regional Service Centre network.<br />

A new 1,000 square metre warehouse<br />

has been completed at the Moree<br />

Regional Service Centre, bringing the<br />

number of warehouses on site to three.<br />

In addition, three new 30,000 litre onsite<br />

bulk tanks will offer refills of Roundup<br />

PowerMAX ®2 and Roundup ®2 CT.<br />

The upgrade anticipates increased<br />

demand for f lagship pre-emergent<br />

brands – Roundup PowerMAX, Avadex ®1<br />

Xtra and Trif lurX ® – in the run-up to the<br />

winter broadacre cropping season.<br />

Moree is the latest in a series of<br />

upgrades that has seen expanded<br />

facilities at the Wagga Wagga and<br />

Dubbo Regional Service Centres.<br />

A brand new facility also opened at<br />

Geraldton in WA last year. More<br />

Regional Service Centres are planned as<br />

Nufarm continues to invest in Australian<br />

agriculture by providing up-to-date<br />

facilities offering the full Nufarm product<br />

range at shorter delivery times.<br />

Nufarm now has nine state-of-the-art<br />

Regional Service Centres in prime<br />

farming districts throughout Australia to<br />

serve its resellers, reinforcing its position<br />

as the only Australian-owned<br />

manufacturer with an extensive service<br />

network in rural Australia.<br />

“The company’s goal is to supply our<br />

products to resellers in a turnaround time<br />

unmatched by any other crop protection<br />

supplier,” said Matt Sargent, Commercial<br />

Development Manager.<br />

Bruce McGowan of Nufarm stores pallets<br />

inside the new warehouse in readiness for<br />

the <strong>2006</strong> winter cropping season.<br />

“No other agricultural chemicals<br />

supplier in Australia has as broad a<br />

network of Regional Service Centres as<br />

Nufarm. We are proud to be Australianowned<br />

and to serve Australian<br />

agriculture as efficiently as possible,”<br />

said Mr Sargent.<br />

nars – managing spray drift<br />

Consultant for weather services,<br />

Graeme Tepper, presented informative<br />

insights into the complexity of local<br />

weather predictions.<br />

“Mr Teppert explained<br />

microclimates at ground level<br />

and how inversion layers form<br />

and how they can affect<br />

spraying operations,” said Mr<br />

Kitt.<br />

Richard Warner and Frank<br />

Taylor from the R&D team at<br />

Nufarm, differentiated phenoxy Jorg Kitt<br />

products according to their<br />

volatility and explained differences<br />

between vapour drift and physical<br />

droplet drift.<br />

“A very popular part of the workshop<br />

was the hands-on demonstration<br />

provided by spray application consultant,<br />

Bill Gordon,” said Mr Kitt.<br />

“He demonstrated visually how<br />

nozzles producing a coarser spray<br />

quality were less affected by drift.”<br />

Senior Chemical Standards<br />

Officers presented at the<br />

workshops and discussed new<br />

legislation such as the<br />

extension to chemical control<br />

areas in Victoria and new<br />

legislation stipulating phenoxy<br />

products must be sprayed with<br />

nozzles that produce a<br />

COARSE to VERY COARSE<br />

spray quality.<br />

“The Spraywise workshops were an<br />

excellent example of how Nufarm can<br />

pull industry resources together and<br />

apply its knowledge to provide viable<br />

information and a service of relevance<br />

to the farming community,” said Mr Kitt.<br />

• Nozzles producing a FINE spray<br />

quality such as the TeeJet ®4 XR11002<br />

markedly increase drift potential<br />

compared to a COARSE spray<br />

quality.<br />

• Most spray operations in the field<br />

allow a change to nozzles that provide<br />

a coarser spray quality without the<br />

risk of losing efficacy.<br />

• Highly volatile phenoxy formulations<br />

such as Estercide ® 800 should<br />

mainly be used in colder winter<br />

months and not in proximity to<br />

sensitive crops.<br />

• Only non-volatile phenoxy products<br />

such as Surpass ® 300 should be<br />

used in warmer spring and summer<br />

months or in close proximity to<br />

sensitive crops.<br />

• New legislation requires all phenoxy<br />

herbicides to be applied with<br />

nozzles producing a COARSE to<br />

VERY COARSE spray quality.<br />

<strong>Nufarmer</strong> <strong>Autumn</strong> <strong>2006</strong><br />

5

CROPLANDS<br />

YOUR CROP PROT<br />

Spra-Coupe responds to customers<br />

with bigger, better 7000 series<br />

Bigger fields, longer rows and a<br />

need for increased productivity<br />

have driven Spra-Coupe customers<br />

to desire bigger, high-profile, selfpropelled<br />

machines. As a result, Spra-<br />

Coupe has introduced the 7000 series<br />

Spra-Coupe with the largest engine and<br />

largest capacity spray tanks available.<br />

“Croplands has responded to customer<br />

needs from the beginning, and those<br />

needs have changed significantly over<br />

the past years,” says Brendan Deck,<br />

General Manager, Croplands Equipment.<br />

“They imagined a new kind of Spra-<br />

Coupe, and with the 7000 series, we<br />

have a sprayer to meet their needs.<br />

These new models offer more power,<br />

more traction, more comfort and more<br />

tank capacity. The spray system is more<br />

stable and more durable with the<br />

traditional reliability and accuracy that<br />

our customers expect.”<br />

“The very efficient, electronically<br />

controlled engine reaches peak torque of<br />

645 Nm at 1400 rpm, plenty of power<br />

to muscle the 7000 Series payloads<br />

across soft soils and steep slopes,”<br />

reports Malcolm Reck, Service Manager,<br />

Croplands Equipment.<br />

Speed and traction match need on the<br />

7000 Series with the new electronic<br />

power shift transmission and optional<br />

front-wheel assist. The transmission offers<br />

six forward and two reverse gears with<br />

four selections under 29.5 km/h and top<br />

speed of up to 44.3 km/h. Torque also<br />

matches need with the integral torque<br />

converter.<br />

Like the engine, transmission and cab,<br />

the 7000 Series Spra-Coupe spray<br />

system is also bigger and better. Built for<br />

greater capacity, the new Spra-Coupe<br />

can be outfitted with either 2,750 L poly<br />

or 2,500 L stainless steel spray tanks.<br />

The centrifugal hydraulic-driven pump<br />

has a maximum output of 320 L/min with<br />

rates as low as 26 L/min to match<br />

product and field condition requirements.<br />

In the best Spra-Coupe tradition, the<br />

7000 Series is designed to match the<br />

crop and the field. The boom on the<br />

Spra-Coupe has introduced the 7000 series Spra-Coupe with the largest engine and largest<br />

capacity spray tanks available.<br />

7650 with its 1.2 metre clearance can be<br />

dropped as low as 58.4 cm in the lowest<br />

setting and raised as high as 243.8 cm<br />

above the ground in the highest setting.<br />

Tracking width easily adjusts to row or<br />

bed width. The electro-hydraulic controls<br />

adjust tracking in 5 cm increments. The<br />

7000 series has a model that is suitable<br />

for the two metre row crop farmer and a<br />

model suitable for the three metre<br />

broadacre farmer.<br />

The new 24 metre boom is engineered<br />

for increased stability and durability with<br />

full boom and tip breakaways and<br />

retractable fold over tips. The five section<br />

shutoffs and independent left/right boom<br />

folds allow the operator to quickly and<br />

easily adjust spray swaths at field edges<br />

and reduce overlaps.<br />

“Increased power and increased<br />

capacity make the 7000 series perfectly<br />

suited to today’s bigger farms and bigger<br />

fields,” said Mr Deck.<br />

“The improved spray system and<br />

features, like the optional eductor, make<br />

the 7000 Series an efficient and<br />

productive machine, just a few of the<br />

great qualities Spra-Coupe customers<br />

have come to expect from Croplands.”<br />

New air induction<br />

provides excellen<br />

The new Turbo TeeJet Induction (TTI)<br />

spray tip from Croplands<br />

Equipment is ideal for use when<br />

off-target drift is a concern and<br />

excellent overlap distribution is<br />

required. Using a unique pre-orifice<br />

design, the smaller droplets in the<br />

spectrum are eliminated and large, airfilled,<br />

drift-resistant droplets are<br />

produced.<br />

“If a grower is spraying near sensitive<br />

areas such as residential areas, open<br />

water or near susceptible plants, the TTI<br />

is the best nozzle to help control drift<br />

without compromising spray pattern<br />

distribution,” said Brendan Deck,<br />

General Manager, Croplands<br />

Equipment.<br />

“That’s because this tip produces very<br />

few small, drift-prone droplets.<br />

“The TTI is ideal for use with preemergent<br />

herbicides, post-emergent<br />

6 <strong>Nufarmer</strong> <strong>Autumn</strong> <strong>2006</strong>

ECTION EQUIPMENT SPECIALISTS<br />

Increased profit, even in uncertain times<br />

Western Australian wheat<br />

grower, Romolo Patroni,<br />

recently upgraded his<br />

OutbackS lightbar guidance unit on his<br />

sprayer to incorporate a mapping unit.<br />

The upgrade will assist Mr Patroni in<br />

achieving greater spraying accuracy,<br />

reducing overspray and saving money<br />

on chemical wastage.<br />

“We need to ensure we’re not<br />

overlapping,” Mr Patroni said.<br />

Romolo, who has a 10,000 hectare<br />

property 40 km south of Southern Cross,<br />

purchased an OutbackS guidance<br />

system for his sprayer last year from local<br />

dealer, Southern Cross Traders.<br />

“I like to support local agencies and<br />

Southern Cross provides excellent service<br />

and back-up. John Griffiths from<br />

Croplands has also offered great support<br />

in the past with our old Croplands<br />

spray tip<br />

t drift resistance<br />

systemic herbicides and systemic<br />

fungicides because of its unique<br />

performance,” he said.<br />

Based on the patented design of the<br />

original Turbo TeeJet spray nozzle, the<br />

TTI offers many of the same benefits: a<br />

wide angle flat spray pattern, excellent<br />

spray pattern distribution and an<br />

economical polymer construction.<br />

Other TTI features include easy preorifice<br />

removal for cleaning/inspection,<br />

a choice of six capacities ranging from<br />

0.56 to 1.9 L/min at 2.75 bar, colorcoding<br />

in compliance with the ISO<br />

standard for easy capacity<br />

identification and easy installation/<br />

alignment via Quick TeeJet caps.<br />

The TeeJet product range includes<br />

spray nozzles, boom components, line<br />

strainers, electric shut-off valves and<br />

hand spray guns.<br />

Romolo Patroni and Southern Cross Service Manager, Bryan Close examine Romolo’s new<br />

Pegasus Trailed Sprayer.<br />

Stallion spray unit. Anytime we had a<br />

problem, John could fix it.”<br />

Mr Patroni added the Outback 360<br />

Mapping Unit when he purchased a new<br />

sprayer.<br />

“The light-bar system on the GPS unit<br />

was good, but I found that as I sprayed<br />

closer to the inside of the paddock,<br />

overlapping became more of a problem.<br />

I couldn’t believe the accuracy of the<br />

guidance system and by adding the<br />

mapping unit I can reduce overspray and<br />

achieve the cost savings I’m after.”<br />

When he bought the mapping unit<br />

Romolo also traded in his Croplands<br />

Stallion sprayer for a new 5000 L<br />

Croplands Pegasus Trailed Sprayer with<br />

30 metre boom.<br />

“The Pegasus has a lot of<br />

improvements over the old Croplands<br />

Stallion. In particular the plumbing, ease<br />

of use and the strength of the boom. The<br />

floating boom with airbag suspension<br />

and the long drawbar offers a much<br />

smoother ride,” he said.<br />

The Pegasus Trailed Sprayer range is<br />

purpose built for broadacre spraying<br />

and is available in a 4000 L, 5000 L<br />

and 6000 L tank.<br />

Fitted with 18.4 x 38” tyres on single<br />

wheels, the Pegasus provides excellent<br />

flotation and a huge rolling radius. A<br />

load-sensitive self-adjusting air-ride<br />

system is available as an option for<br />

rougher conditions.<br />

A choice of 21, 24, 28, 30, 33 and 36<br />

metre hydraulic folding booms with winglift<br />

option and individual fold option are<br />

offered.<br />

“We had a better than average year<br />

last year, but with the price of wheat at<br />

the moment the margins aren’t always<br />

there and there’s a degree of uncertainty.<br />

The new sprayer and mapping unit will<br />

save us money and help make things<br />

easier,” he said.<br />

Croplands Equipment is currently<br />

offering a 6.5% finance offer on Pegasus<br />

Trailed Sprayers through their Finance<br />

division, Croplands Credit. Conditions<br />

apply.<br />

For further information about this offer,<br />

contact Croplands on 1800 999 162.<br />

<strong>Nufarmer</strong> <strong>Autumn</strong> <strong>2006</strong><br />

7

Trial shows yield<br />

bonus in wheat<br />

In a demonstration trial of fungicide<br />

effectiveness on stripe rust and<br />

other fungal diseases in dryland<br />

wheat at Warren, in western New<br />

South Wales, wheat treated with<br />

Opus ® 125 out-performed Tilt ®7<br />

and Bayleton ®6 by an increased<br />

0.4 tonne/ha yield.<br />

Nathan Soulsby of Landmark<br />

Warren, who conducted the trial<br />

on the farming property ‘The<br />

Overf low’, said the Drysdale wheat<br />

was sprayed at full f lag emergence<br />

with experimental rates of Opus 125<br />

and Bayleton. These were compared<br />

to 250 mL/ha of Tilt.<br />

“Seven days after application, the<br />

Opus 125 treated plot had reduced<br />

the number of active spores on the<br />

leaf surface significantly and after<br />

14 days was the only one where the<br />

stripe rust was no longer active,” he<br />

said.<br />

“The way Opus 125 works also<br />

kept the plot greener for longer and it<br />

was able to take advantage of an<br />

extra rain event.<br />

“In conditions where two tonnes/ha<br />

is considered a good average yield,<br />

a bonus of 0.4 tonne/ha is worth<br />

pursuing. It well and truly paid for<br />

any extra expense in using Opus 125<br />

over the cheaper alternatives.<br />

“In the right season, many growers<br />

could benefit from a timely<br />

application of Opus 125 as a stripe<br />

rust preventative.”<br />

Temora district farmer Phil Reid examines H45 wheat successfully treated for stripe rust with<br />

Opus 125 last year.<br />

Successful stripe rust<br />

control with<br />

Following the 2005 harvest, Temora<br />

wheat grower Phil Reid has<br />

concluded one thing about stripe<br />

rust control – he doesn’t have time for<br />

repeated foliar fungicide applications.<br />

“Come the end of winter, we’re into<br />

shearing – there’s all sorts of things<br />

happening,” he said. “I don’t have time<br />

to check every day for signs of stripe rust<br />

in each crop.”<br />

Growing more than 1000 hectares of<br />

wheat in 2005 on his property,<br />

‘Maylands’ south of Temora, NSW, Phil<br />

found the best results were achieved in<br />

stripe rust control when applying Opus<br />

125 once at the recommended rate of<br />

500 mL/ha as opposed to two<br />

applications of Bayleton.<br />

“One hit of Opus 125 on H45 was far<br />

more beneficial than two hits of<br />

Bayleton,” he said.<br />

“A paddock that was treated with<br />

Bayleton yielded three tonne to the<br />

hectare and the grain was shrivelled up<br />

rubbish, whereas just half a kilometre<br />

away a paddock that was treated with<br />

Opus 125 went five tonne to the hectare<br />

and there were minimal screenings.<br />

“Any crop around here that was<br />

untreated just turned into shrivelled up<br />

little grains – it was bloody shocking.”<br />

As with many farming decisions, Phil<br />

works on the principle that time is money<br />

and he would rather invest in doing a job<br />

properly first time round.<br />

“You need to consider the length of<br />

coverage of a treatment and if it is going<br />

to get you through the risk period then it<br />

has to be of greater value. It will take the<br />

stress out of what is normally a busy time<br />

of year because you know it will be<br />

protected.”<br />

In the 2004 season, Phil waited for<br />

stripe rust to appear before having to<br />

spray foliar fungicides by air. These<br />

experiences taught Phil to take a more<br />

pro-active approach in 2005 by<br />

spraying before the disease had taken<br />

hold. The strategy paid dividends and<br />

removed the stress and time constraints<br />

experienced in 2004.<br />

“If I grow any susceptible wheats in<br />

<strong>2006</strong>, like H45, the only fungicide I’ll use<br />

will be Opus 125 and I’ll try and apply it<br />

so it gives the maximum length of<br />

protection in that high pressure period.”<br />

8 <strong>Nufarmer</strong> <strong>Autumn</strong> <strong>2006</strong>

Monza: the flexible choice for<br />

brome and barley grass<br />

L<br />

ate seasonal starts in the drought<br />

conditions of the past few years<br />

have seen many grain growers<br />

unable to utilise a knockdown phase for<br />

weed control prior to sowing, increasing<br />

their reliance back on pre-emergent and<br />

post-emergent herbicides.<br />

In addition, many farmers in the<br />

southern and western wheat belts have<br />

dropped pulse and canola crops from<br />

their rotations to grow cereals on cereals.<br />

This has ruled out the option of using<br />

triazine herbicides (Group C) in the<br />

break crops for weed control.<br />

As a result, infestations of brome and<br />

barley grass are becoming a serious<br />

problem in wheat crops where farmers<br />

are not utilising the best available tools<br />

to control them early.<br />

“Controlling brome and barley grass<br />

weed burdens is essential to avoid<br />

significant yield losses in wheat and<br />

triticale,” said Damien Deckert, Business<br />

Manager.<br />

“These weeds are noted for their<br />

aggressive competitiveness and prolific<br />

seed production. Taking steps to avoid<br />

them ‘getting away’ by treating them<br />

early before sowing or at the 1-4 leaf<br />

stage can mean the difference between<br />

sowing or not sowing a profitable crop.”<br />

Mr Deckert said that fortunately in the<br />

past eight years growers have been able<br />

to choose the proven performance of the<br />

selective Group B herbicide, Monza ®2 .<br />

“Monza offers growers the f lexibility<br />

of both pre-emergent and post-emergent<br />

application and is an effective and<br />

reliable herbicide for the selective<br />

suppression of brome and barley grass<br />

in wheat and triticale,” said Mr Deckert.<br />

“It works by being absorbed by the<br />

foliage and roots and moved through the<br />

plant. As Monza is a Sulfonylurea, it<br />

blocks the production of essential amino<br />

acids required for production of proteins<br />

used in root and shoot growth.<br />

“Monza gives farmers the ability to<br />

sow on time and to finish the season with<br />

cleaner grain samples, minimal grading<br />

losses and improved returns from<br />

significantly increased yields.<br />

“Monza also has good activity on a<br />

number of other troublesome weeds<br />

including wild oats, wild radish, wild<br />

turnip, silver grass and mustard species.”<br />

Treatments with Monza significantly<br />

reduce populations of brome and barley<br />

grass in crop with remaining plants<br />

showing reduced panicle size and<br />

numbers, plant height, tiller numbers and<br />

seed production.<br />

“Nufarm is committed to providing<br />

products of superior quality that add<br />

significant value,” said Mr Deckert.<br />

“The research and development team at<br />

Nufarm is continuing the necessary trial<br />

work to expand the number of compatible<br />

herbicides listed on the label and to<br />

provide in-field advice so that weed<br />

efficacy and yield responses are<br />

maximised,” he said.<br />

Calculate the benefits with the<br />

Monza wheel<br />

Now, growers and agronomists have an<br />

easy to use calculator to demonstrate the<br />

financial advantages of using Monza.<br />

Intervix set to impress<br />

Nufarm is set to launch an<br />

exciting new product for the<br />

winter cropping season.<br />

Intervix is a new generation herbicide<br />

developed for CLEARFIELD ®3 canola<br />

that was previously trialled under the<br />

code name ‘Euro Lightning’.<br />

“The launch of Intervix has been<br />

eagerly awaited by growers who want<br />

to take advantage of the benefits of<br />

CLEARFIELD canola with increased<br />

f lexibility,” said Business Manager for<br />

CLEARFIELD crops, Damien Deckert.<br />

“Intervix is a Group B herbicide so it<br />

can be used strategically in rotation to<br />

prolong the effectiveness of other<br />

herbicides.”<br />

Mr Deckert said that Intervix offered<br />

growers of CLEARFIELD canola<br />

significant benefits over standard weed<br />

control treatments.<br />

Agronomist Richard Stecher (left) uses the<br />

Monza wheel to calculate the benefits of<br />

weed control for farmer, James Castles.<br />

The Monza wheel calculates<br />

the potential grain yield saved by<br />

controlling weeds early with Monza,<br />

using data provided by the South<br />

Australian Research and Development<br />

Institute (SARDI).<br />

Growers can obtain their calculator by<br />

contacting their local Nufarm reseller.<br />

“If you’re planning to use Monza this<br />

season, grab a calculator to see the<br />

benefits in terms of crop yields and<br />

improved returns,” said Mr Deckert.<br />

“Intervix will offer safer plantback<br />

intervals compared to OnDuty ®3 and<br />

Clearsol ®3 , providing growers with<br />

greater confidence that crops following<br />

CLEARFIELD canola will reach their full<br />

yield potential,” he said.<br />

“The extensive local research and<br />

development trial program at Nufarm<br />

has confirmed that Intervix provides<br />

more powerful weed control compared<br />

to OnDuty, especially on key grass<br />

weeds.<br />

“This means that growers can expect<br />

even higher levels of performance on<br />

yield robbing weeds, which means<br />

cleaner crops and higher financial<br />

returns,” said Mr Deckert.<br />

Intervix will be distributed via Nufarm<br />

AgriCentres ®3 and will be available in<br />

limited quantities this year packed in 10<br />

litre containers.<br />

<strong>Nufarmer</strong> <strong>Autumn</strong> <strong>2006</strong><br />

9

Herbicide mixture is vital in<br />

battle against resistant ARG<br />

When it comes to resistant<br />

annual ryegrass, throw<br />

everything you’ve got at it,<br />

advises Bill Long, Private Consultant,<br />

Ag Consulting Co. on the Yorke<br />

Peninsula.<br />

Bill Long is someone who knows.<br />

Over the past 10 years, he and his<br />

staff have battled increasing annual<br />

ryegrass resistance on his customers’<br />

farms on the Peninsula and in the mid<br />

and lower north of South Australia.<br />

“We’re still growing profitable crops.<br />

But it’s a numbers game. We’re still<br />

winning on farms where we are best<br />

able to combine the available herbicide<br />

and cultural methods.”<br />

Mr Long said farms were now very<br />

reliant on pre-emergent herbicides,<br />

particularly mixtures like Avadex Xtra<br />

and Trif lurX, to allow the crop to establish<br />

and get away without excessive ryegrass<br />

pressure.<br />

Research has found mixtures that<br />

include active ingredients giving high<br />

levels of control of a weed species and<br />

including active ingredients from different<br />

mode of action groups, such as Group E<br />

(Avadex Xtra) and Group D (Trif lurX), are<br />

a useful tool in managing or preventing<br />

the establishment of resistant weeds.<br />

And by using pre-emergent herbicides,<br />

non-selective herbicides and cultural<br />

practices can be given the chance to<br />

work later in the season to control weed<br />

escapes.<br />

Mr Long said the big change in the<br />

past few years had been the recognition<br />

of the excellent performance of Avadex<br />

Xtra against annual ryegrass.<br />

“People think of Avadex Xtra as a wild<br />

oat control herbicide, but we’re now<br />

recommending Avadex Xtra mixed with<br />

Trif lurX as a resistant ryegrass control<br />

measure. Wild oats control is really a<br />

secondary bonus.”<br />

Mr Long said that Trif lurX provided<br />

some valuable control of annual ryegrass<br />

and excellent broad leaf weed control of<br />

pests such as wireweed. But the mixture<br />

of Avadex Xtra and Trif lurX combined<br />

provided increased ryegrass control.<br />

“The anecdotal results we’ve found in<br />

the paddock were confirmed in Ag<br />

Consulting Co. pot trials conducted by<br />

Peter Boutsalis, Plant Science Consulting<br />

at the Adelaide University in 2004 and<br />

by a number of field trials conducted by<br />

our group and other research<br />

organisations over the past few years.<br />

“The control achieved by the mixture<br />

was compared with other chemicals such<br />

as metolachlor and several older<br />

compounds. The mixture performed very<br />

well against resistant annual ryegrass<br />

and is well worth using, particularly<br />

when numbers are high,” he said.<br />

Mr Long said that the other big change<br />

was that Avadex Xtra could also be used<br />

in pulse crops, particularly lentils.<br />

“Many people still think Avadex Xtra<br />

can only be used in cereals.<br />

“Lentils are very uncompetitive against<br />

ryegrass. By using the mixture, we can<br />

get adequate ryegrass control to allow<br />

lentil crops to get away and not suffer<br />

from ryegrass competition. Then we can<br />

use selective DIM-based grass products<br />

such as clethodim for ryegrass control<br />

later in the season.”<br />

Mr Long said selective Group A<br />

herbicides were no longer working<br />

against annual ryegrass, particularly in<br />

cereals.<br />

“We rarely mention Group A<br />

chemicals in cereals any more,” he said.<br />

“However, we have a raft of cultural<br />

methods we recommend. Sequencing<br />

crops to allow a range of herbicides to<br />

be used, high seeding rates, careful<br />

selection of crop varieties that provide<br />

competition against ryegrass, spray<br />

topping, weed wiping, stubble burning<br />

and, where possible, using pastures and<br />

grazing, all contribute to lower ryegrass<br />

populations.<br />

“If you can combine as many methods<br />

as you have available, you can win the<br />

game against ryegrass and grow crops<br />

profitably,” he said.<br />

Farmers should consider an Avadex<br />

Xtra and Trif lurX mixture as a worthwhile<br />

part of the battle strategy.<br />

Private agronomic consultant, Bill Long (right), chats with farmer, Doug Smith, at Petersville,<br />

South Australia, about controlling resistant annual ryegrass.<br />

10 <strong>Nufarmer</strong> <strong>Autumn</strong> <strong>2006</strong>

Highlights from the<br />

horticulture range at Nufarm<br />

Nufarm is well placed to help<br />

farmers harvest the growing<br />

opportunities in horticulture with<br />

our comprehensive range of products,<br />

says Guy Perriman, Australian<br />

Horticulture Manager.<br />

Here is the latest news about<br />

Nufarm horticultural products.<br />

Downy mildew gets the<br />

high jump with Acrobat ®3<br />

The 2005 season caused<br />

many cucurbit, lettuce and<br />

onion growers across Australia<br />

to turn to Acrobat ®3 to combat<br />

high levels of downy mildew<br />

infection. Acrobat contains<br />

500 g/kg dimethomorph and is a Group<br />

X fungicide. Acrobat is ideal for inclusion<br />

in disease control programs in rotation<br />

with other chemical groups in order to<br />

eliminate or delay the onset of disease<br />

resistance.<br />

Acrobat has a unique mode of action;<br />

disrupting the fungal cell wall formation<br />

which enables it to control strains of<br />

fungi that have become resistant to other<br />

chemical groups, e.g. the phenylamides.<br />

With no reported cases of resistance to<br />

dimethomorpth in Australia, Acrobat has<br />

a valuable position to play in disease<br />

control programs.<br />

Acrobat has performed best when<br />

applied prior to weather conditions that<br />

resulted in high levels of disease<br />

pressure. It is this strong protectant<br />

activity of Acrobat that enables the<br />

production of quality vegetables under<br />

testing environmental conditions.<br />

Acrobat has strong residual activity<br />

and is rainfast within 2 hours.<br />

Acrobat is a valuable fungicide for<br />

potato growers risking late blight<br />

Guy Perriman<br />

(Phytophthora infestans) infection. This<br />

devastating disease occurs under<br />

conditions of high humidity (>90%) and<br />

when temperatures are cool at night<br />

(around 12 o C) and warm during the day<br />

(around 21 o C). Acrobat is an ideal<br />

protectant fungicide for use<br />

when the late blight infection<br />

risk is high.<br />

Acrobat must be applied in<br />

a tank mixture with either<br />

Polyram ®3 DF (containing<br />

700 g/kg metiram) or<br />

Penncozeb 750DF (containing<br />

750 g/kg mancozeb) and a<br />

non-ionic surfactant. This is<br />

part of an anti-resistance<br />

strategy for the compound.<br />

Label expansion for Penncozeb<br />

420SC in key crops<br />

Penncozeb 420SC is a popular, liquid<br />

mancozeb sold by Nufarm. Widely used<br />

by Australian banana, potato and poppy<br />

growers. Penncozeb 420SC has recently<br />

had its label extended to include a<br />

number of other key crop registrations.<br />

Penncozeb 420SC is now registered in<br />

almonds, cucurbits, tomatoes and for the<br />

control of phomopsis in grapes, both<br />

wine and table. In tomatoes, Penncozeb<br />

420SC is the only mancozeb formulation<br />

with a powdery mildew suppression<br />

claim. Penncozeb 420SC also controls<br />

early blight (Alternaria solani).<br />

Penncozeb 420SC is a suspo-emulsion<br />

formulation (oil emulsion in water)<br />

containing 420 g/L mancozeb. With the<br />

fine particle size formed as a result of the<br />

formulation, the oil allows better<br />

coverage and adhesion to the plant<br />

surface, Penncozeb 420SC offers<br />

improved rainfastness and effective<br />

protectant activity.<br />

Growers have been impressed with<br />

Penncozeb 420SC as the liquid<br />

alternative to traditional DF mancozeb<br />

formulations. The ease of handling,<br />

simplicity of measuring, lack of dust issues<br />

and the formulation quality all combine to<br />

provide growers with real benefits.<br />

Mancozeb remains a valuable fungicide<br />

for disease prevention and management.<br />

Emergency use permits for Filan ®3<br />

Filan ®3 has provided many vegetable<br />

growers with a new fungicide option<br />

following the granting of a series of<br />

emergency use permits by the Australian<br />

<strong>Pest</strong>icides and Veterinary Medicines<br />

Authority (APVMA).<br />

Permit 8819, effective from 10 October<br />

2005 until 31 October 2007 will allow<br />

growers of brassicas, brassica leafy<br />

vegetables, lettuce, beans – green pods<br />

and immature beans (phaseolus spp) to<br />

apply Filan for the control of Sclerotinia<br />

disease. Permit 8819 is available from<br />

the APVMA website<br />

(www.apvma.gov.au) or the Nufarm<br />

Horticulture website<br />

(www.nufarmhorticulture.com.au).<br />

Emergency use permits for Filan were<br />

issued following the withdrawal of the<br />

registration for procymidione in these<br />

crops. Nufarm and Horticulture Australia<br />

Limited are supporting an extensive<br />

research and development program with<br />

Filan to ensure registrations for these and<br />

other crops in the years ahead.<br />

Filan is a Group G fungicide,<br />

containing 500 g/kg boscalid, a new<br />

and unique compound for vegetable<br />

growers. The initial Filan registration was<br />

for the control of Botrytis in grapes. Filan<br />

has excellent crop safety, is non-toxic to<br />

bees and is classified as a “reduced risk”<br />

compound by the EPA in America.<br />

<strong>Nufarmer</strong> <strong>Autumn</strong> <strong>2006</strong><br />

11

Nufarm contacts<br />

TERRITORY MANAGERS<br />

Customer Service<br />

Coastal/Central Regions 1800 267 612<br />

Southern New South Wales 1800 033 038<br />

Victoria/Tasmania 1800 033 038<br />

South Australia/Sunraysia 1800 131 964<br />

Western Australia 1800 131 964<br />

Coastal<br />

NSW North Coast/<br />

New England Matt Moyle 0400 811 796<br />

Wide Bay/Burnett/<br />

Callide/Dawson Jamie Cox 0427 100 065<br />

Far North Queensland Eddie Hayes 0409 200 993<br />

Central Queensland/<br />

Burdekin Mandy Jeppesen 0428 192 001<br />

South East Queensland Stewart Frankling 0419 558 219<br />

Central<br />

Goondiwindi Lachlan Carrigan 0428 715 955<br />

Gunnedah Phillippa Fleming 0428 710 298<br />

Moree Daniel Guest 0428 529 549<br />

Toowoomba Ed Redfern 0439 798 970<br />

Southern NSW<br />

Griffith Mathew Taylor 0429 398 854<br />

Dubbo David Wood 0407 450 174<br />

Tablelands/Hunter Valley Sean Richardson 0438 985 785<br />

Greater Central West Rupert Backus 0428 285 865<br />

Wagga Wagga Stuart Blair 0418 504 114<br />

Victoria/Tasmania<br />

Western District Philip Jobling 0409 807 160<br />

Gippsland Rafe Bell 0409 424 716<br />

Wimmera Gerard Bardell 0419 561 016<br />

North East Matthew Hincks 0429 708 808<br />

Mallee Ben Coombe 0427 806 635<br />

Tasmania Peter Wilkinson 0418 132 087<br />

South Australia/Sunraysia<br />

Mid North/<br />

Yorke Peninsula Tony Button 0418 637 310<br />

Riverland/Sunraysia Nick Hall 0429 434 217<br />

South East c/- Adelaide Office 1800 131 964<br />

Eyre Peninsula Ken Webber 0428 828 410<br />

Mallee/Adelaide Plains Russell Meade 0418 818 570<br />

Western Australia<br />

Albany David Cunningham 0428 340 825<br />

Geraldton Bill Campbell 0427 545 553<br />

Merredin Keith Perry 0429 413 200<br />

Northam Matt Beckett 0427 928 230<br />

HORTICULTURE MANAGERS<br />

QLD Stewart Frankling 0419 558 219<br />

Sthn NSW Sean Richardson 0438 985 785<br />

Vic/Tas Paul Geister 0438 382 672<br />

SA/Sunraysia Adam Phelan 0417 498 428<br />

WA David Buckley 0427 100 026<br />

RESEARCH & DEVELOPMENT OFFICERS<br />

Coastal Andrew Horsfield 0427 012 815<br />

Central Frank Taylor 0438 092 972<br />

Sthn NSW Angus MacLennan 0408 358 024<br />

Vic/Tas Gereon Schnippenkoetter 0438 862 896<br />

Vic/Tas Mark Slatter 0438 064 845<br />

SA/Sunraysia John Both 0418 803 055<br />

WA Mike Jackson 0427 527 975<br />

WA Scott Paton 0427 692 319<br />

REGIONAL OFFICES<br />

Coastal<br />

Unit 13/16 Metroplex Ave,<br />

Murarrie QLD 4172<br />

Regional Manager Mark Dawson 0428 106 090<br />

Bus. Support & Develop. Shane Rudd 0417 213 833<br />

Central<br />

Unit 13/16 Metroplex Ave,<br />

Murarrie QLD 4172<br />

Regional Manager Paul Smith 0419 033 841<br />

Bus. Support & Develop. Amanda Marwood 0437 082 620<br />

Southern NSW<br />

Lot 1 Lewington St,<br />

Wagga Wagga NSW 2650<br />

Regional Manager Owen Williams 0417 459 471<br />

Bus. Support & Develop. Angela Armytage 0429 009 716<br />

Victoria/Tasmania<br />

103-105 Pipe Rd<br />

Laverton North Vic 3026<br />

Regional Manager Paul White 0419 306 983<br />

Bus. Support & Develop. Michael Reese 0408 510 064<br />

South Australia/Sunraysia<br />

190 Cormack Rd<br />

Wingfield SA 5013<br />

Regional Manager Warren Ramsey 0419 526 389<br />

Bus. Support & Develop. Aaron Edmunds 0409 184 188<br />

Western Australia<br />

Lot 51, Mason Rd<br />

Kwinana WA 6167<br />

Regional Manager Chris Ryan 0418 692 319<br />

Bus. Support & Develop. Steve Lacy 0407 542 448<br />

CROPLANDS<br />

50 Cavan Rd,<br />

Dry Creek SA 5094 1800 999 162<br />

Nufarm Australia Limited<br />

HEAD OFFICE<br />

103-105 Pipe Rd, Laverton North, Vic 3026<br />

Ph: 03 9282 1000 Fax: 03 9282 1001<br />

Internet: www.nufarm.com.au<br />

Region Contact Phone Based<br />

Nthn Qld/NT Bruce Henningsen 0409 899 491 Townsville<br />

Nthn NSW/Sthn Qld Jeremy Rennick 0407 485 569 Toowoomba<br />

Central NSW Dave Farmer 0427 651 971 Orange<br />

Sthn NSW David Hamilton 0427 975 072 Junee<br />

Victoria/Tasmania Toby Brown 0417 832 784 Melbourne<br />

South Australia Jason Sims 0418 819 350 Adelaide<br />

Nthn WA Kevin Kentish 0428 940 822 Perth<br />

Sthn WA John Griffiths 0407 132 746 Perth<br />

This publication is a guide only and no substitute for professional or expert advice. The product label should be consulted before use of any of the<br />

products referred to in this publication. Nufarm Australia Limited shall not be liable for any results, loss or damage whatsoever, whether consequential<br />

or otherwise through the use or application of products and/or materials referred to herein.<br />

© Copyright <strong>2006</strong> Nufarm Australia Limited A.C.N. 004 377 780