Scientific Molding, In-Cavity Sensors, and Data Management - MAPP

Scientific Molding, In-Cavity Sensors, and Data Management - MAPP

Scientific Molding, In-Cavity Sensors, and Data Management - MAPP

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Scientific</strong> <strong>Molding</strong>,<br />

<strong>In</strong>-<strong>Cavity</strong> <strong>Sensors</strong>,<br />

<strong>and</strong> <strong>Data</strong> <strong>Management</strong><br />

<strong>MAPP</strong> Webinar<br />

August 19, 2009<br />

Presented by:<br />

Ken Fassett<br />

RJG, <strong>In</strong>c.<br />

1

What is <strong>Scientific</strong> <strong>Molding</strong>?<br />

You can know the name of a bird in all the<br />

languages of the world, but when you’re<br />

finished, you’ll know absolutely nothing whatever<br />

about the bird… So let’s look at the bird <strong>and</strong> see<br />

what it’s doing - - that’s what counts…<br />

Richard Feynman<br />

US Educator & Physicist<br />

2

Why is<br />

<strong>Scientific</strong> <strong>Molding</strong><br />

Important?<br />

3

One Word<br />

Competition<br />

4

Knowledge is the Only<br />

Sustainable Competitive Advantage<br />

5

Patents Are NOT!<br />

The best offence is a good defense, right<br />

…where could gas assist technology be today?<br />

6

Closed Borders are NOT!<br />

Ask me about a certain injection<br />

molding industry in Europe…<br />

7

Technology is NOT!<br />

Utilization of technology may be…<br />

which is knowledge based!<br />

8

The best technology in the world,<br />

whether from Germany, or Japan, or the US,<br />

is available for purchase in low-cost labor countries<br />

AND THEY CAN AFFORD IT!<br />

9

“Is it better for the trained people to leave<br />

or the untrained people to stay?”<br />

10

Therefore, their cost of quality is HUGE!<br />

11

Knowledge is OUR only<br />

Sustainable Competitive Advantage<br />

12

<strong>Scientific</strong> <strong>Molding</strong><br />

•>2,500 people from the US IM industry have gone through<br />

an RJG 3 day <strong>Scientific</strong> <strong>Molding</strong> seminar since 1991<br />

•>1200 people from the US IM industry have gone through<br />

an RJG 10 day <strong>Scientific</strong> <strong>Molding</strong> h<strong>and</strong>s-on course since<br />

1999<br />

13

Knowledge<br />

• A Constant Pursuit<br />

• Buy it, or <strong>In</strong>vest in it<br />

14

Why is<br />

<strong>Scientific</strong> <strong>Molding</strong><br />

Important?<br />

15

The Wall of Shame<br />

‣ Short Shots<br />

‣ Sink <strong>and</strong> voids<br />

‣ Dimensional Variations<br />

‣ Warp<br />

‣ Flash<br />

Cosmetic rejects like:<br />

Splay<br />

Specs<br />

Off color<br />

Are not generally process control related problems<br />

16

Not So <strong>In</strong>dependent Variables in <strong>In</strong>jection <strong>Molding</strong><br />

Screw<br />

Run Time<br />

Material<br />

Properties<br />

Backpressure<br />

Drying<br />

Material<br />

Supplied<br />

Colorant or<br />

other additives<br />

Shot Size<br />

Items in rounded rectangles are<br />

equipment setup parameters<br />

Transfer Position or<br />

<strong>Cavity</strong> Pr. Setpoint<br />

Fill ->Pack Position<br />

Pack Speed<br />

Hold Pressure<br />

Plastication Rate<br />

(i.e. screw RPM)<br />

Melt<br />

Temperature<br />

Viscosity<br />

Pressure<br />

Profile<br />

Barrel<br />

Temperatures<br />

Hot Runner<br />

Variation<br />

Flow Rate<br />

Coolant<br />

<strong>In</strong>let<br />

Pressure<br />

Cooling<br />

Channel<br />

Condition<br />

Coolant<br />

Outlet<br />

Pressure<br />

Melt temperature affects<br />

both cooling rate <strong>and</strong> mold<br />

surface temperature<br />

Coolant<br />

Flow Rate<br />

Coolant<br />

Delta<br />

Pressure<br />

Check Ring<br />

Performance<br />

Cooling<br />

Mold<br />

Temperature<br />

Speed<br />

Settings<br />

Coolant<br />

Temperature<br />

Cooling Time<br />

(Mold Clamped time)<br />

Times: Cycle,<br />

Mold Open etc.<br />

<strong>Cavity</strong><br />

Shape<br />

(deflection)<br />

9/5/07<br />

Art Schubert<br />

© 2007 RJG <strong>In</strong>c.<br />

17

• Material Viscosity Variation<br />

– Velocity induced<br />

– <strong>In</strong>herent<br />

• Imbalance<br />

• Pressure Loss<br />

• Machine (IN)Dependence<br />

– Pressure vs. <strong>In</strong>tensification Ratios<br />

– Linear Shot Measurement vs. cavity volume<br />

18

Material Variation Over Time<br />

Expect at Least a<br />

20% viscosity Variation<br />

This Is Normal<br />

19

If You have:<br />

Hold On Tight<br />

• New Machines<br />

• New Molds<br />

• Virgin Plastic (with a 20% normal<br />

viscosity variation over time)<br />

• Automatic Cycle<br />

• Air Conditioned <strong>Molding</strong> Rooms<br />

The best you can expect is that<br />

cavity pressure will vary just<br />

under ________%???<br />

Underst<strong>and</strong>ing why is key to<br />

developing a robust Automated<br />

process control strategy!<br />

20

What is <strong>Scientific</strong> <strong>Molding</strong>?<br />

You can know the name of a bird in all the<br />

languages of the world, but when you’re<br />

finished, you’ll know absolutely nothing whatever<br />

about the bird… So let’s look at the bird <strong>and</strong><br />

see what it’s doing - - that’s what counts…<br />

Richard Feynman<br />

US Educator & Physicist<br />

22

A Strategy Based on the<br />

4 Plastics’ Variables<br />

“Helps <strong>In</strong>jection Molders Succeed”<br />

<br />

Temperature<br />

<br />

Flow Rate<br />

<br />

Pressure<br />

<br />

Cooling<br />

23

A Concept - Using <strong>Data</strong> to Verify<br />

Process Parameter<br />

Shot<br />

Fill Time<br />

Plastic<br />

Pressure<br />

1/t<br />

Effective<br />

Viscosity<br />

30000<br />

1 0.20 8720<br />

5.0 1,744<br />

27000<br />

10<br />

2 0.22 8160<br />

4.55 1,795<br />

24000<br />

3 0.30 5440<br />

4 0.62 4640<br />

3.33 1,632<br />

1.61 2,877<br />

21000<br />

9<br />

5 1.47 2969<br />

.68 4,364<br />

18000<br />

8<br />

6 1.52 2960<br />

7 1.92 6260<br />

.65 4,499<br />

.52 12,019<br />

15000<br />

8 2.13 8160<br />

.47 17,381<br />

12000<br />

7<br />

9 2.52 8560<br />

10 3.31 8360<br />

.40 21,571<br />

.30 27,672<br />

9000<br />

6000<br />

6<br />

5<br />

3000<br />

4<br />

3<br />

2<br />

1<br />

5.0<br />

4.5<br />

4.0<br />

3.5<br />

3.0<br />

2.5<br />

2.0<br />

1.5<br />

1.0<br />

.50<br />

24

Analyzing Plastic Viscosity<br />

<strong>In</strong>tegral data can be broken down into fundamental parts such as the<br />

integral during fill.<br />

The area under the hydraulic pressure curve during fill represents the<br />

sum of the resistance to flow during fill <strong>and</strong>, therefore, represents the<br />

viscosity of the plastic.<br />

Effective Viscosity or Fill <strong>In</strong>tegral<br />

PRESSURE (PSI)<br />

Fill<br />

Plastic<br />

<strong>In</strong>jection<br />

Pressure<br />

Pack & Hold<br />

0<br />

Start Mold<br />

Fill Time<br />

TIME (SECONDS) 16<br />

25

Systematic Approach<br />

26<br />

1.Part Design<br />

2.Gate & Runner Balance<br />

3.Press Selection<br />

4.Process Development

Part Design<br />

High Risk Part Design<br />

Square corners equals risk of 5<br />

Additions to walls equals risk of 5<br />

Change in wall thickness equals risk of 5 if<br />

gate location is on opposing end of part<br />

Low Risk Part Design<br />

Square corners equals risk of 2<br />

Additions to walls equals risk of 5<br />

Change in wall thickness equals risk of 3<br />

27

Part of process control involves knowing if <strong>and</strong> when gate<br />

seal occurs on all cavities for all molds.<br />

Without <strong>In</strong>strumentation<br />

we use part weight study<br />

With instrumentation we use post<br />

gate psi curve including hold time<br />

Gate Seal = Best Dimensional Control<br />

Allowing discharge or backflow out of the gate after a set period of time:<br />

‣ Can reduce compressive stresses near the gate<br />

‣ Can affect pressure gradient caused warpage<br />

28

Pressure Loss Study<br />

15,256 ppsi<br />

9,628 ppsi<br />

8,343 ppsi<br />

What happens if the<br />

viscosity changes?<br />

5,245ppsi<br />

29

<strong>In</strong>tensification Ratio<br />

Not Enough<br />

Pressure<br />

30

Mold Transfer<br />

Machine A<br />

Machine B<br />

220 ton clamp force<br />

‣ 2600 psi hydraulic pump<br />

‣ General Purpose Screw<br />

‣ 12 inch linear shot capability<br />

‣ Maximum <strong>In</strong>jection Speed 10.2 in/sec<br />

‣ Tie Bar Spacing is 17in x 17in<br />

‣ 1.78 in diameter screw<br />

‣ 12.2:1 <strong>In</strong>tensification Ratio<br />

220 ton clamp force<br />

‣ 2600 psi hydraulic pump<br />

‣ General Purpose Screw<br />

‣ 12 inch linear shot capability<br />

‣ Maximum <strong>In</strong>jection Speed 10.2 in/sec<br />

‣ Tie Bar Spacing is 17in x 17in<br />

‣ 2.25 in diameter screw<br />

‣ 9.85:1 <strong>In</strong>tensification Ratio<br />

31

Machine Dependent<br />

Machine A<br />

750 psih<br />

Machine B<br />

32

Machine Dependent<br />

9,150 ppsi<br />

Machine A<br />

750 psih<br />

7,388 ppsi<br />

Machine B<br />

33

Machine INDEPENDENT<br />

Hold Pressure<br />

Machine A Plastic Machine B<br />

750 psi h<br />

9,150 ppsi 929 psi h<br />

Settings<br />

R I : 9.85:1<br />

Screw Dia: 2.25”<br />

R I : 12.2:1<br />

Screw Dia: 1.78”<br />

34

<strong>In</strong>tensification Ratio<br />

Machine A<br />

750 psih<br />

9,150 ppsi<br />

Machine B<br />

929 psih<br />

35

What about VOLUME of Plastic?<br />

Machine A<br />

R I : 12.2:1<br />

Screw Dia: 1.78”<br />

Plastic<br />

Settings<br />

Machine B<br />

R I : 9.85:1<br />

Screw Dia: 2.25”<br />

Transfer Position<br />

1.855 in.<br />

4.617 in 3<br />

1.161 in.<br />

36

Plastic Temperature<br />

Plastic Temp<br />

Machine A<br />

Barrel Temp<br />

Zone 1-4<br />

475<br />

Plastic<br />

Settings<br />

Melt Temp<br />

460<br />

Machine B<br />

Barrel Temp<br />

Zone 1-4<br />

482<br />

37

Cooling<br />

Mold Surface Temp<br />

Machine A<br />

Thermolator<br />

Setting<br />

148<br />

Plastic<br />

Settings<br />

Steel Surface<br />

145<br />

Machine B<br />

Thermolator<br />

Setting<br />

150<br />

38

Matching Using <strong>Data</strong><br />

39

And for the Toughest Jobs...<br />

<strong>Cavity</strong><br />

Pressure<br />

Probably no more than 20% of molds<br />

40

Monitoring <strong>and</strong> Containment<br />

For Process Control<br />

The Goal:<br />

‣ No escapes of bad parts to the<br />

downstream customer<br />

41

Successful Molders<br />

Now Realize That:<br />

What Happens in the <strong>Cavity</strong><br />

Stays in the Part<br />

42

The Problem<br />

“Bad” parts get sent downstream<br />

to the customer:<br />

‣ Short Shots<br />

‣ Sink <strong>and</strong> voids<br />

‣ Dimensional Variations<br />

‣ Warp<br />

‣ Flash<br />

Bad = Other than Normal<br />

43

Critical Containment Applications<br />

Here’s the 20%<br />

‣ Monitor <strong>Cavity</strong> Pressure on high volume <strong>and</strong> high<br />

problem jobs<br />

• End of <strong>Cavity</strong> to detect <strong>and</strong> contain short shots <strong>and</strong> observe<br />

variation<br />

• Gate end to detect gate seal <strong>and</strong> detect variation over the<br />

entire part<br />

Use Alarm light tree or Alert to warn of problems<br />

Contain abnormal parts<br />

This is the start of Process Monitoring <strong>and</strong><br />

Control from the Plastics’ Point of View<br />

44

Abnormal Part Containment<br />

45

You Can’t Manually Sort Your Way To<br />

World Class<br />

‣ 4 sigma companies can produce 6 sigma products<br />

through enormous amounts of rework<br />

‣ They can’t raise their prices to recapture their costs<br />

because they must price their products<br />

competitively<br />

‣ Business quality is highest when cost is at its<br />

absolute lowest for both the producer <strong>and</strong> the<br />

consumer<br />

46

Constant Machine Conditions:<br />

Are the parts the same?<br />

REMEMBER: What happens in the cavity stays in the part!<br />

47

Which Do We Watch?<br />

‣ <strong>Cavity</strong> Pressures:<br />

• <strong>In</strong>tegrals are usually best<br />

‣ Mold Surface Temperatures Semi-Crystalline Aps<br />

• Cooling temperature <strong>and</strong> time<br />

• Effective Melt Temp<br />

• Can be used for full cavity monitoring in<br />

high cavitation mold<br />

‣ Material Condition:<br />

• Effective Viscosity<br />

This is Process Control from the<br />

Plastic’s Point of View using containment<br />

It’s The Best!<br />

48

<strong>In</strong> Mold Gate End Pressure<br />

20,000<br />

PRESSURE (PSI)<br />

Peak PSI<br />

• Fill Dynamics<br />

• Correct Transfer<br />

• Pack Rate/Time<br />

• Peak PSI<br />

• Static Pressure Gradient<br />

• Cooling<br />

• Gate Seal<br />

• Best For Control<br />

Pack Rate<br />

Cooling Rate<br />

Area or<br />

<strong>In</strong>tegral<br />

Reduction due<br />

to Discharge<br />

0<br />

Full<br />

Packed<br />

TIME (SECONDS) 15<br />

49

<strong>In</strong> Mold End of <strong>Cavity</strong> Pressure<br />

20,000<br />

PRESSURE (PSI)<br />

Peak PSI<br />

• Full Part<br />

• Pack Rate/Time<br />

• Peak PSI<br />

• Cooling<br />

• Most Variable<br />

• Best For Monitoring<br />

No Dynamic PSI<br />

Pack Rate<br />

Cooling Rate<br />

0<br />

TIME (SECONDS) 15<br />

50

The Opportunity<br />

51

Relate Directly to Pressure Variation<br />

in the <strong>Cavity</strong>!<br />

‣ Short Shots<br />

‣ Sink <strong>and</strong> voids<br />

‣ Dimensional Variations<br />

‣ Warp<br />

‣ Flash<br />

52

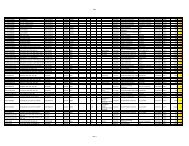

Correlate Your <strong>Data</strong> To Part Quality<br />

29,341<br />

29,723<br />

30,642<br />

31,325<br />

32,445<br />

32,889<br />

33,021<br />

34,555<br />

<strong>Cavity</strong> Pressure<br />

Cycle <strong>In</strong>tegral<br />

48.010<br />

48.025<br />

48.040<br />

48.055<br />

48.070<br />

48.085<br />

48.100<br />

48.115<br />

Dimensions<br />

Looks<br />

Good<br />

53

Auto Alarm Capability<br />

Sample groups can be collected<br />

in the eDART TM Software.<br />

54

Auto Alarm Capability<br />

Automatically correlate data collected by the<br />

eDART System TM to your critical part attributes<br />

55

Close the Loop<br />

56

The Value of <strong>Data</strong><br />

Viscosity<br />

<strong>Cavity</strong><br />

pressure<br />

Can SQC find the 4 bad parts??<br />

57

<strong>Data</strong> Taken Over Time is effective for<br />

Process Monitoring / Abnormal<br />

Cycle Detection<br />

Know<br />

Immediately<br />

when<br />

something<br />

has changed<br />

58

<strong>Data</strong> <strong>Management</strong><br />

59

This?<br />

Or this?<br />

60

Why would we want to guess what is going<br />

on when we can see – with data?…<br />

61

Which Machine Process<br />

is Set-up Correctly?<br />

62

Which Machine Process<br />

is Set-up Correctly?<br />

Correct Set-Up<br />

<strong>In</strong>correct Set-Up<br />

63

The Match Meter<br />

‣ <strong>In</strong> a glance see if the process is set up correctly<br />

‣ See if the viscosity has changed<br />

64

How do you determine whether<br />

ALL OF YOUR MACHINES AND<br />

PROCESSES<br />

are set up correctly?<br />

65

All the Machine Meters<br />

on One page<br />

66

Advanced System Overview<br />

67

How was your plant running<br />

LAST NIGHT?<br />

68

ASO History<br />

69

Check out the problem with a press<br />

without leaving your desk!<br />

70

ASO Process Viewer<br />

71

But what did the data look like back<br />

when the Machine Match went into the red?<br />

72

Analyzer Mode<br />

73

When problems occur,<br />

how do you know what happened?<br />

The data is stored on the eDART!<br />

74

What is Your<br />

Quality Accountability?<br />

75

So, when you want to know how<br />

your plant is running,<br />

what data do you want to rely on?<br />

76

This?<br />

Or this?<br />

77

<strong>Data</strong> <strong>Management</strong>: The Goal<br />

‣ To Know What You Don’t Know<br />

• <strong>In</strong>termittent Process Variation<br />

• Breakdowns<br />

• Bad set ups<br />

• Bad material<br />

<br />

<br />

Dryness<br />

Viscosity<br />

78

Systematic Approach<br />

79<br />

1.<strong>Scientific</strong> <strong>Molding</strong><br />

2.<strong>Cavity</strong> Pressure Technology<br />

3.<strong>Data</strong> <strong>Management</strong>

How RJG Can Help<br />

Full Service Provider for <strong>In</strong>jection Molders<br />

Training<br />

‣Seminars<br />

‣Master Molder Certification<br />

‣H<strong>and</strong>s On Workshops<br />

Process Monitoring/Control<br />

‣ Machine<br />

‣ <strong>Cavity</strong> Pressure<br />

80

Make It Happen!<br />

The greatest difference between those that have<br />

done a lot <strong>and</strong> those that accomplish little:<br />

High achievers set specific timetables to accomplish<br />

seemingly impossible tasks <strong>and</strong> routinely meet or<br />

exceeded them.<br />

81<br />

July 20, 1969

Let us help you in your<br />

Transformation Process!<br />

82

At RJG,<br />

in all that we teach <strong>and</strong><br />

in all that we do,<br />

our mission is..<br />

Helping<br />

<strong>In</strong>jection Molders<br />

Succeed<br />

www.rjginc.com<br />

83