to download brochure - Microntesa.co.za

to download brochure - Microntesa.co.za

to download brochure - Microntesa.co.za

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

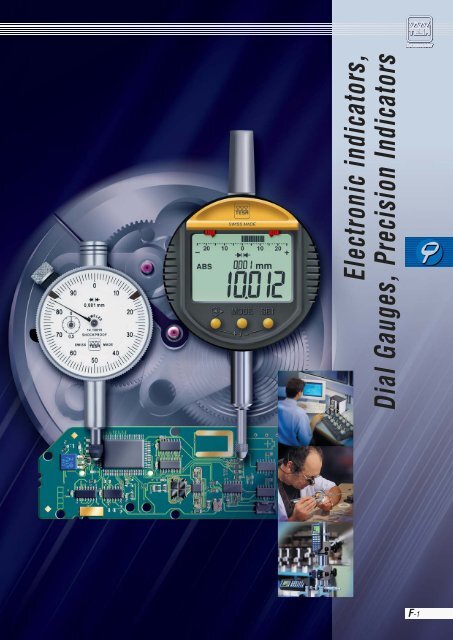

Electronic indica<strong>to</strong>rs,<br />

Dial Gauges, Precision Indica<strong>to</strong>rs<br />

F-1

E LECTRONIC I NDICATORS AND D IAL G AUGES<br />

EASY-TO-USE AND VERSATILE<br />

As manufacturer of a full range of precision dial gauges for more than 50 years, we are able <strong>to</strong> provide you with<br />

a wide variety of models.<br />

• Electronic indica<strong>to</strong>rs featuring a <strong>co</strong>mbined analogue/digital indication with the most up-<strong>to</strong>-date technology.<br />

• Mechanical dial gauges with high-precision movement and smooth pointer revolution, doublF-action shockproof<br />

mechanisms as well as measuring spans up <strong>to</strong> 100 mm.<br />

Which Style Do you Need?<br />

• Digital indication provides error-free readout of the measured values as the fractions of the scale divisions need<br />

not be estimated, visually.<br />

• Analogue indication has the advantage <strong>to</strong> change smoothly ac<strong>co</strong>rding <strong>to</strong> the size of the workpiece feature <strong>to</strong> be<br />

measured. This type of indication is best suited for dynamic measurements, e.g. when determining axial and<br />

radial runout errors.<br />

• Electronic indica<strong>to</strong>rs provide many additional functions <strong>co</strong>mpared <strong>to</strong> the mechanical models. For more information,<br />

also read the pages F-4 <strong>to</strong> F-11.<br />

• Electronic indica<strong>to</strong>rs, precision dial gauges as well as dial test indica<strong>to</strong>rs have the capability <strong>to</strong> measure with<br />

the lowest possible hysteresis. Therefore, they are ideally suited for runout inspection where this capability is<br />

required.<br />

• In order <strong>to</strong> significantly reduce the effects of the systematic errors, we re<strong>co</strong>mmend <strong>to</strong> carry out a number of<br />

<strong>co</strong>mparative measurements because only the actual size of each related nominal length will be read out.<br />

This means that electronic indica<strong>to</strong>rs, dial gauges with limited range of indication and precision indica<strong>to</strong>rs are<br />

best suited for this purpose.<br />

• These hand-held <strong>to</strong>ols also permit <strong>to</strong> avoid rough reading errors of the metric range.<br />

Standards and Definitions<br />

From now on, the international ISO 463:2006 standard replaces the national ones dealing with dial gauges. Newly<br />

applicable definitions and requirements also imply some changes of the so-called design and metrological characteristics,<br />

which <strong>co</strong>uld no be entirely reported in this issue.<br />

This standard, which is part of the matrix «Product Specification (GPS) – Dimensional measuring equipment»,<br />

states the requirements that affect the most significant characteristics mentioned above. Therefore, all values<br />

indicated in this catalogue as limit values for the metrological characteristics only are based on internal<br />

standards proper <strong>to</strong> our fac<strong>to</strong>ry.<br />

Electronic indica<strong>to</strong>rs<br />

Precision indica<strong>to</strong>rs<br />

Definitions used in this section:<br />

Max. perm. errors in one measuring direction<br />

over the whole measuring range<br />

within the local measuring range<br />

in both measuring directions<br />

Repeatability limit<br />

Max. hysteresis<br />

Mechanical dial gauges<br />

Definitions used in this section for the maximum permissible<br />

errors of a metrological characteristic (MPE):<br />

Deviation span<br />

(Error of indication within the measuring range)<br />

Deviation span (error of indication) within<br />

the local measuring span<br />

Total deviation span<br />

(Error of indication within the measuring range)<br />

Repeatability limit of indication<br />

Hysteresis of indication<br />

20<br />

20<br />

Error of measurement, µm<br />

15<br />

10<br />

5<br />

0<br />

-5<br />

-10<br />

-15<br />

Hysteresis<br />

Local measuring<br />

span<br />

Downward plunger movement<br />

Upward plunger movement<br />

Max. error of measurement<br />

Limits of the permissible error<br />

Error of measurement, µm<br />

15<br />

10<br />

5<br />

0<br />

-5<br />

-10<br />

-15<br />

Hysteresis<br />

Deviation span<br />

Local deviation<br />

span<br />

Downward plunger movement<br />

Upward plunger movement<br />

Total<br />

deviation span<br />

-20<br />

-20<br />

F-2<br />

0 1 2 3 4 5 6 7 8 9 10<br />

Given length, mm<br />

0 1 2 3 4 5 6 7 8 9 10<br />

Given length, mm

D IAL G AUGES<br />

INDICATORS<br />

NUMERICAL<br />

Digi<strong>co</strong> 200 - 300 - 400 -<br />

500 - 600 - 700<br />

mm<br />

mm / in<br />

12,5 ÷ 25 F-4 - F-7<br />

Digi<strong>co</strong> 1 30 ÷ 60 F-8 - F-9<br />

Digi<strong>co</strong> 12 5 ÷ 12,5 F-10 - F-11<br />

ANALOGUE, TYPE HI-FI<br />

0,001 0,1 F-12 - F-13<br />

mm / in mm mm / in<br />

ANALOGUE<br />

mm 0,1 40 ÷ 58 ÷ 80 10 ÷ 20 ÷ 30 F-14<br />

0,01 40 0,4 ÷ 3 ÷ 5 F-15 - F-17<br />

58 0,8 ÷ 1 ÷ 10 ÷ 30 ÷ 50 ÷ 100 F-18 - F-23<br />

82 10 ÷ 30 ÷ 50 ÷ 100 F-24 - F-26<br />

0,002 40 0,16 ÷ 3 F-27<br />

58 0,16 ÷ 5 F-28<br />

0,001 40 0,08 ÷ 1 F-29 - F-30<br />

58 1 ÷ 5 F-31 - F-33<br />

82 1 ÷ 5 F-34<br />

in 0.001 40 ÷ 58 0.2 ÷ 0.4 ÷ 1 F-35<br />

0.0005 40 ÷ 58 0.2 ÷ 0.4 ÷ 1 F-36<br />

0.0001 40 ÷ 58 0.12 ÷ 0.2 F-37<br />

ANALOGUE<br />

with small bezel (mm/inch)<br />

ANALOGUE<br />

with back mounted plunger<br />

29 mm – 1 1 /8 in 0,2 ÷ 1 mm - 0.01 ÷ 0.04 in F-38<br />

38 ÷ 40 ÷ 58 0,16 ÷ 0,8 ÷ 1 ÷ 3 mm F-39 - F-41<br />

0.05 in<br />

ACCESSORIES<br />

Measuring inserts<br />

Retraction devices<br />

Backs for precision dial gauges<br />

F-42 - F-44<br />

F-45<br />

F-46<br />

A-3F-3

E LECTRONIC I NDICATORS<br />

TESA DIGICO 205 and 305<br />

• Dual LC Display.<br />

• Mechanical <strong>to</strong>lerance marks.<br />

• Dimensions ac<strong>co</strong>rding <strong>to</strong> DIN 878.<br />

Main functions<br />

ON/Au<strong>to</strong> OFF – Data output – Counting sense reversal – Keypad lock.<br />

✓<br />

Combined<br />

analogue and<br />

numerical display<br />

6-decade LC<br />

display field plus<br />

minus sign<br />

10 x 5 mm<br />

Digit size (H x L)<br />

Resolution <strong>to</strong><br />

0,01 mm =<br />

±0,25 mm<br />

Resolution <strong>to</strong> 0,001 mm =<br />

±0,025 mm<br />

MI or MIE type:<br />

metric/inch<br />

<strong>co</strong>nversion<br />

Glass scale with<br />

incremental divisions,<br />

capacitive<br />

≤ 2 m/s<br />

Full-metal housing<br />

with front face in<br />

polyamide.<br />

Stainless steel plunger.<br />

M2,5 mounting thread for<br />

the measuring insert.<br />

≤ 2N<br />

RS232,<br />

op<strong>to</strong>-<strong>co</strong>upled<br />

3V lithium battery,<br />

type CR2032<br />

1 year <strong>to</strong> 2 years<br />

TESA DIGICO 205<br />

mm / in mm / in µm µm<br />

01910230 DIGICO 205 M 12,5 / – 0,01 / – 20 10<br />

01930230 DIGICO 205 MI 12,5 / 0.5 0,01 / 0.0005 20 10<br />

TESA DIGICO 305<br />

01910231 DIGICO 305 M 12,5 / – 0,001 / – 8 2<br />

01930231 DIGICO 305 MI 12,5 / 0.5 0,001 / 0.00005 8 2<br />

TESA DIGICO 305 IP54<br />

01930232 DIGICO 305 MIE 12,5 / 0.5 0,001 / 0.00005 8 2<br />

10 °C <strong>to</strong> 40 °C<br />

–10 °C <strong>to</strong> 60 °C<br />

80%<br />

EN 50081-1<br />

EN 50082-1<br />

150 g<br />

7<br />

7<br />

Shipping case<br />

including a<br />

lithium battery<br />

01961000<br />

53,1<br />

121,5<br />

ø57,1<br />

134,4<br />

ø57,1<br />

Identification<br />

number<br />

Inspection report<br />

with a declaration<br />

of <strong>co</strong>nformity<br />

28,5<br />

18,4<br />

ø8 h6<br />

68,4<br />

ø4<br />

27<br />

Dimensions fully meet DIN 878<br />

27<br />

F-4

E LECTRONIC I NDICATORS<br />

✓<br />

Combined<br />

analogue and<br />

numerical display<br />

6-decade LC<br />

display field plus<br />

minus sign<br />

10 x 5 mm<br />

Digit size (H x L)<br />

Resolution <strong>to</strong><br />

0,01 mm =<br />

±0,25 mm<br />

Resolution <strong>to</strong> 0,001 mm =<br />

±0,025 mm<br />

MI or MIE type:<br />

metric/inch<br />

<strong>co</strong>nversion<br />

Glass scale with<br />

incremental divisions,<br />

capacitive<br />

TESA DIGICO 400 and 500<br />

• Measuring modes ABS/REL.<br />

• Dual LC Display.<br />

• Display rotation through 270°. Same goes for the key functions.<br />

• Mechanical <strong>to</strong>lerance marks.<br />

• Symbols for both limit values.<br />

Measuring functions and modes<br />

ON – Au<strong>to</strong> OFF – PRESET mode – Tolerance mode – Data output – Counting<br />

sense reversal – Keypad lock – Metric/Inch units – Full RESET.<br />

≤ 2 m/s<br />

Full-metal housing<br />

with front face in<br />

polyamide.<br />

Stainless steel plunger.<br />

M2,5 mounting thread for<br />

the measuring insert.<br />

RS232,<br />

op<strong>to</strong>-<strong>co</strong>upled<br />

3V lithium battery,<br />

type CR2032<br />

1 year <strong>to</strong> 2 years<br />

10 °C <strong>to</strong> 40 °C<br />

–10 °C <strong>to</strong> 60 °C<br />

80%<br />

EN 50081-1<br />

EN 50082-1<br />

Shipping case<br />

including one<br />

lithium battery<br />

01961000<br />

Identification<br />

number<br />

Inspection report<br />

with a declaration<br />

of <strong>co</strong>nformity<br />

TESA DIGICO 400<br />

mm / in mm / in µm µm N g<br />

01930240 Digi<strong>co</strong> 405 MI 12,5 / 0.5 0,01 / 0.0005 20 10 < 2 150<br />

01930241 Digi<strong>co</strong> 410 MI 25 / 1 0,01 / 0.0005 20 10 < 2 162<br />

TESA DIGICO 500<br />

01930250 Digi<strong>co</strong> 505 MI 12,5 / 0.5 0,001 / 0.00005 4 2 < 2 150<br />

01930251 Digi<strong>co</strong> 510 MI 25 / 1 0,001 / 0.00005 5 2 < 2 162<br />

TESA DIGICO 505 IP54<br />

01930255 Digi<strong>co</strong> 505 MIE 12,5 / 0.5 0,001 / 0.00005 4 2 < 2 150<br />

7<br />

7<br />

28,5<br />

18,4<br />

121,5<br />

ø57,1<br />

134,4<br />

ø57,1<br />

53,1<br />

ø8 h6<br />

68,4<br />

ø4<br />

27<br />

Dimensions fully meet DIN 878<br />

27<br />

F-5

E LECTRONIC I NDICATORS<br />

TESA DIGICO 600<br />

• Measuring modes ABS/REL.<br />

• Dual LC Display.<br />

• Display rotation through 270°. Same goes for the key functions.<br />

• Mechanical <strong>to</strong>lerance marks.<br />

• Symbols for both limit values.<br />

Measuring functions and modes<br />

ON – Au<strong>to</strong> OFF – PRESET mode – Tolerance mode – Value s<strong>to</strong>rage mode<br />

• Max • Min • Max-Min (TIR) – Data output – Counting sense reversal –<br />

Keypad lock – Metric/Inch units – Full RESET.<br />

✓<br />

Combined<br />

analogue and<br />

numerical display<br />

6-decade LC<br />

display field plus<br />

minus sign<br />

10 x 5 mm<br />

Digit size (H x L)<br />

Resolution <strong>to</strong><br />

0,01 mm =<br />

± 0,25 mm<br />

Resolution <strong>to</strong> 0,001 mm =<br />

± 0,025 mm<br />

MI or MIE type<br />

with metric/inch<br />

<strong>co</strong>nversion<br />

Glass scale with<br />

incremental divisions,<br />

capacitive<br />

≤ 2 m/s<br />

Full-metal housing<br />

with front face in<br />

polyamide.<br />

Stainless steel plunger.<br />

M2,5 mounting thread for<br />

the measuring insert.<br />

RS232,<br />

op<strong>to</strong>-<strong>co</strong>upled<br />

3V lithium battery,<br />

type CR2032<br />

1 year <strong>to</strong> 2 years<br />

7<br />

10 °C <strong>to</strong> 40 °C<br />

–10 °C <strong>to</strong> 60 °C<br />

80%<br />

52,5<br />

15,3<br />

Ø8 h6<br />

106,5 70<br />

176,5<br />

Ø57,1<br />

EN 50081-1<br />

EN 50082-1<br />

Shipping case<br />

including a<br />

lithium battery<br />

01961000<br />

Identification<br />

number<br />

Inspection report<br />

with a declaration<br />

of <strong>co</strong>nformity<br />

Ø4<br />

Dimensions fully meet DIN 878<br />

33,4<br />

TESA DIGICO 600<br />

mm / in mm / in µm µm N g<br />

01930256 Digi<strong>co</strong> 605 MI 12,5 / 0.5 0,001 / 0.00005 4 2 < 2 150<br />

01930257 Digi<strong>co</strong> 610 MI 25 / 1 0,001 / 0.00005 5 2 < 2 162<br />

F-6

E LECTRONIC I NDICATORS<br />

✓<br />

Combined<br />

analogue and<br />

numerical display<br />

6-decade LC<br />

display field plus<br />

minus sign<br />

TESA DIGICO 705<br />

Use in <strong>co</strong>njunction with bore gauges with 2-point <strong>co</strong>ntact. Allows setting<br />

of the dial gauge on the smallest setting ring value.<br />

• Same functions as DIGICO 600.<br />

10 x 5 mm<br />

Digit size (H x L)<br />

Resolution <strong>to</strong><br />

0,01 mm =<br />

± 0,25 mm<br />

Resolution <strong>to</strong> 0,001 mm =<br />

± 0,025 mm<br />

MI or MIE type<br />

with metric/inch<br />

<strong>co</strong>nversion<br />

Glass scale with<br />

incremental divisions,<br />

capacitive<br />

≤ 2 m/s<br />

Full-metal housing<br />

with front face in<br />

polyamide.<br />

Stainless steel plunger.<br />

M2,5 mounting thread for<br />

the measuring insert.<br />

RS232,<br />

op<strong>to</strong>-<strong>co</strong>upled<br />

3V lithium battery,<br />

type CR2032<br />

1 year <strong>to</strong> 2 years<br />

10 °C <strong>to</strong> 40 °C<br />

–10 °C <strong>to</strong> 60 °C<br />

80%<br />

TESA DIGICO 705<br />

mm / in mm / in µm µm N g<br />

01930258 Digi<strong>co</strong> 705 MI 12,5 / 0.5 0,001 / 0.00005 4 2 < 2 150<br />

Optional accessories available for all<br />

TESA DIGICO 200 <strong>to</strong> 700<br />

EN 50081-1<br />

EN 50082-1<br />

Shipping case<br />

including a<br />

lithium battery<br />

01961000<br />

Identification<br />

number<br />

Inspection report<br />

with a declaration<br />

of <strong>co</strong>nformity<br />

01961000<br />

01962002<br />

04761054<br />

04761055<br />

04761056<br />

Lithium battery, type CR2032, 3V, 190 mAh<br />

External power supply<br />

Mains adapter<br />

Cable EU for mains adapter<br />

Cable US for mains adapter<br />

Measuring inserts listed on page F-42<br />

Backs and retraction devices detailed on page F-45<br />

For information on <strong>co</strong>nnecting cables, refer <strong>to</strong> chapter A<br />

Digi<strong>co</strong> 01962002 04761054<br />

F-7

E LECTRONIC I NDICATORS<br />

TESA DIGICO 1 and 2<br />

Both models are remarkable for their versatile functions, long measuring<br />

travel, high accuracy.<br />

• Analogue and digital display; the latter can be displaced for easy<br />

reading in any position.<br />

• Zero setting at any point within the measuring span.<br />

• Data input through the keyboard.<br />

• Counting sense reversal.<br />

• Entry of limit values for classification through displayed symbols.<br />

Additional green, red or amber <strong>co</strong>loured background whenever the <strong>to</strong>ol<br />

is <strong>co</strong>nnected <strong>to</strong> the mains.<br />

• Value s<strong>to</strong>rage through the functions «Highest value», «Lowest value»<br />

or «Highest value minus lowest value».<br />

✓<br />

LC display<br />

with <strong>co</strong>loured<br />

background<br />

6 decades plus<br />

minus sign<br />

9 x 4,5 mm digit<br />

size (H x W)<br />

See table<br />

opposite<br />

Metric/inch<br />

<strong>co</strong>nversion<br />

40 mm<br />

scale length<br />

25 scale divisions<br />

Ac<strong>co</strong>rding<br />

<strong>to</strong> selected<br />

<strong>to</strong>lerances<br />

30,4 mm<br />

(DIGICO 1) or<br />

60,4 mm<br />

(DIGICO 2)<br />

Incremental<br />

glass scale<br />

Max. 1 m/s for<br />

(DIGICO 1) or<br />

max. 2 m/s for<br />

DIGICO 2<br />

Plunger<br />

guided on a<br />

plain bearing<br />

M2,5 mounting thread for<br />

the measuring insert.<br />

2 µm for DIGICO 1<br />

3 µm for DIGICO 2<br />

1 µm<br />

1 µm<br />

See table<br />

on page F-9<br />

RS232<br />

3,6 V<br />

lithium battery<br />

or mains adapter<br />

TESA electronic indica<strong>to</strong>rs<br />

mm mm in in<br />

01930000 DIGICO 1 30 0,001 / 0,01 1.18 0.00005 / 0.0005<br />

01930001 DIGICO 2 60 0,001 / 0,01 3.36 0.00005 / 0.0005<br />

F-8

E LECTRONIC I NDICATORS<br />

≈ 1000 h with<br />

lithium battery<br />

0,002%/ °C<br />

10 °C <strong>to</strong> 40 °C<br />

– 10 °C <strong>to</strong> 50 °C<br />

✓<br />

Measuring force<br />

Measuring force*<br />

close <strong>to</strong> plunger s<strong>to</strong>p<br />

– bot<strong>to</strong>m<br />

– <strong>to</strong>p<br />

Hysteresis*<br />

DIGICO 1 DIGICO 2<br />

0,85 N ± 0,15 N 0,90 N ± 0,20 N<br />

1,10 N ± 0,20 N 1,45 N ± 0,25 N<br />

0,10 N 0,15 N<br />

* Valid with the indica<strong>to</strong>r used vertically, with downward oriented plunger,<br />

or in static measurement.<br />

Dial casing<br />

of regular<br />

models <strong>to</strong><br />

IP54<br />

(IEC 60529)<br />

290 g (DIGICO 1)<br />

310 g (DIGICO 2)<br />

Moved mass<br />

through the plunger:<br />

28 g (DIGICO 1)<br />

27 g (DIGICO 2)<br />

Supplied in a<br />

suited shipping<br />

case including<br />

1 lithium battery<br />

01960007 plus 1 lift lever<br />

01960005<br />

49<br />

29<br />

Identification<br />

number<br />

Inspection report<br />

with a declaration<br />

of <strong>co</strong>nformity<br />

18/17<br />

199 / 233<br />

ø8 h6<br />

20<br />

9<br />

ø4,5<br />

6<br />

30 / 60<br />

57 / 86,5<br />

✓<br />

Accessories for TESA DIGICO 1 and 2<br />

ø3<br />

04761037<br />

04761057<br />

01960007<br />

01960005<br />

01960009<br />

01960008<br />

01960010<br />

01960011<br />

04768000<br />

230 V mains adapter, 50 Hz, 9 V, 200 mA,<br />

1,8 VA<br />

110 V mains adapter<br />

3,6 V lithium battery, LR6, AA<br />

Lever for plunger retraction<br />

Connec<strong>to</strong>r for vacuum plunger lift,<br />

suitable for DIGICO 1<br />

Same as above, but for DIGICO 2<br />

Connec<strong>to</strong>r for pneumatic plunger retraction,<br />

suitable for DIGICO 1 only<br />

Adapter for use of the mains adapter<br />

<strong>to</strong>gether with the switch for triggering<br />

data transfer<br />

Hand switch<br />

for triggering data transfer<br />

For information on <strong>co</strong>nnecting cables, refer <strong>to</strong> chapter A<br />

01960008<br />

ø3<br />

01960009<br />

ø3<br />

01960010<br />

A-9F-9

E LECTRONIC I NDICATORS<br />

TESA DIGICO 12<br />

Made <strong>to</strong> measure in extreme workshop <strong>co</strong>nditions – Water and <strong>co</strong>olant<br />

resistant (IP65) – 44 mm dial diameter – Lets you take advantage of the<br />

mechanics <strong>co</strong>mbined with digital reading.<br />

✓<br />

5-digit LC display<br />

+ sign<br />

6 mm<br />

digit height<br />

Zero-setting<br />

of display<br />

TESA DIGICO 12 – Standard<br />

• 44 mm dial casing diameter.<br />

• Water and <strong>co</strong>olant resistant (IP65).<br />

• RS 232 SIMPLEX data output <strong>co</strong>mbined with<br />

external power supply.<br />

• Inductive measuring system, patented.<br />

• Choice between absolute («ABS») and relative («REL»)<br />

measuring modes.<br />

• Numerical display.<br />

• Possible setting of PRESET value <strong>to</strong> ±130 mm.<br />

• Inverse measuring direction.<br />

• Direct <strong>co</strong>nversion of the metric/inch units.<br />

• Au<strong>to</strong>matic shut down.<br />

20 µm<br />

5 µm<br />

0,5 <strong>to</strong> 0,9 N<br />

(± 0,15 N)<br />

Max. 2 m/s<br />

Number of<br />

measurements<br />

per se<strong>co</strong>nd: 7<br />

Working temper -<br />

ature range:<br />

+ 5 °C <strong>to</strong> + 40 °C<br />

3V lithium battery,<br />

type CR 2032<br />

19.3<br />

5<br />

Battery life<br />

> 3500 hours<br />

101.5<br />

13<br />

Ø 8 h6<br />

Ø 4<br />

Ø 44<br />

42.5<br />

13<br />

13 18 58 12.5<br />

58<br />

18<br />

25.8<br />

101.8<br />

RS232<br />

70 g<br />

EN 61326-1<br />

IP65 (IEC 529)<br />

Shipping case<br />

including<br />

1 lithium battery,<br />

type CR 2032 (order<br />

No. 01961000).<br />

Identification<br />

number<br />

1,65<br />

8,54<br />

6,4<br />

ø 1,5<br />

Declaration<br />

of <strong>co</strong>nformity<br />

Models 0,01 mm<br />

with report.<br />

Models 0,001 mm<br />

without report.<br />

mm/in mm in<br />

Module<br />

IP65 indica<strong>to</strong>rs with electronic module protected against the penetration of liquids<br />

01930130 12,5/0.5 0,01 0.0005 IP65<br />

01930132 12,5/0.5 0,001 / 0,01 0.00005 / 0.0005 IP65<br />

IP65 indica<strong>to</strong>rs with mechanics and electronics protected against the penetration of liquids<br />

01930131 12,5/0.5 0,01 0.0005 IP65<br />

01930133 12,5/0.5 0,001 / 0,01 0.00005 / 0.0005 IP65<br />

F-10

E LECTRONIC I NDICATORS<br />

✓<br />

LCD,<br />

5 digits + sign<br />

6 mm<br />

digit height<br />

Zero-setting<br />

of display<br />

4 µm<br />

TESA DIGICO 12 – HP<br />

• High-precision measuring system.<br />

• Water and <strong>co</strong>olant resistant (IP65).<br />

• Combined analogue/digital display.<br />

• Analogue readout from ±0,025 <strong>to</strong> ±1,25 mm.<br />

• NOR/MIN/MAX/MAX-MIN measuring modes.<br />

• 44 mm dial casing diameter.<br />

• RS232 data output, <strong>co</strong>mbined with external power supply.<br />

• Inductive measuring system, patented.<br />

• Zero-setting of display.<br />

• Direct <strong>co</strong>nversion of the metric/inch units.<br />

• Au<strong>to</strong>matic shut down. Can also be locked.<br />

2 µm<br />

0,4 <strong>to</strong> 0,75 N<br />

(± 0,15 N)<br />

Max. 2 m/s<br />

Number of<br />

measurements<br />

per se<strong>co</strong>nd: 9<br />

Working temperature<br />

range:<br />

+ 5 °C <strong>to</strong> + 40 °C<br />

3V lithium<br />

battery,<br />

type CR 2032<br />

mm/in mm in<br />

IP65 indica<strong>to</strong>r HP with electronic module protected against the penetration of liquids<br />

01930134 5/0.210 0,001 / 0,01 0.00005 / 0.0005 IP65<br />

IP65 indica<strong>to</strong>r HP with mechanics and electronics protected against the penetration of liquids<br />

01930135 5/0.210 0,001 / 0,01 0.00005 / 0.0005 IP65<br />

Battery life<br />

> 4000 hours<br />

RS232<br />

19.3<br />

5<br />

70 g<br />

EN 61326-1<br />

IP65 (IEC 529)<br />

1 lithium battery,<br />

type CR 2032.<br />

Order number:<br />

01961000.<br />

1,65<br />

8,54<br />

6,4<br />

ø 1,5<br />

50.5<br />

18<br />

16.3<br />

84.8<br />

86.5<br />

13<br />

Ø 8 h6<br />

Ø 4<br />

Ø 44<br />

42.5<br />

13<br />

5.5 18 50.5 12.5<br />

Identification<br />

number<br />

Inspection report<br />

with a declaration<br />

of <strong>co</strong>nformity<br />

Accessories<br />

03238013<br />

01961012<br />

01960005<br />

04761060<br />

01961000<br />

Clamping lug<br />

Upper lift lever<br />

Lower lift lever<br />

RS232 <strong>co</strong>nnecting cable along with external power supply<br />

3 V lithium battery, type CR 2032, 190 mAh<br />

For information on <strong>co</strong>nnecting cables, refer <strong>to</strong> chapter A<br />

19,05<br />

9,5<br />

6,4<br />

50<br />

10<br />

ø 6,4<br />

14,3<br />

26,2<br />

24.5<br />

03238013 01961012<br />

A-11 F-11

P RECISION I NDICATORS<br />

TESA CARY Micro<strong>co</strong>mpara<strong>to</strong>rs MCA-8<br />

The absolute high precision<br />

Specially designed for high precision measurement by <strong>co</strong>mparison<br />

(0,8 µm) – Ideal for checking axial and radial runouts with<br />

a very low hysteresis (0,3 µm).<br />

• TESA CARY precision mechanism mounted parallel <strong>to</strong> the measuring<br />

axis in <strong>co</strong>mpliance with the Abbe principle.<br />

• Streamlined steel case for high rigidity.<br />

• High precision throughout the measuring travel.<br />

• Very low measuring force (from 150 mN).<br />

• Non-rotating dial. Quickly set <strong>to</strong> zero by moving the pointer with<br />

just a thumb grip.<br />

• Low sensitivity <strong>to</strong> temperature variations.<br />

✓<br />

DIN 879<br />

Non-rotating dial<br />

Fine setting when<br />

moving the pointer<br />

Full-metal<br />

dial casing.<br />

Stainless steel<br />

plunger, hardened.<br />

Adjustable<br />

<strong>to</strong>lerance marks<br />

M2,5 mounting<br />

thread for the<br />

measuring insert<br />

Mounted insert<br />

with a 3 mm dia.<br />

steel ball tip<br />

110 g<br />

Plastic case<br />

Identification<br />

number<br />

Inspection report<br />

with a declaration<br />

of <strong>co</strong>nformity<br />

Regular models<br />

mm mm mN mm<br />

Range for<br />

zero-setting<br />

mm<br />

01410423 MCA8-2-500 0,001 0,1 3 500 50 ÷ 0 ÷ 50 ± 0,006<br />

01410425 MCA8-2-150 0,001 0,1 3 150 50 ÷ 0 ÷ 50 ± 0,006<br />

01410426 MCA8-2-300 0,001 0,1 3 300 50 ÷ 0 ÷ 50 ± 0,006<br />

Lateral model<br />

01410424 MCA8-2-L 0,001 0,1 3 500 50 ÷ 0 ÷ 50 ± 0,006<br />

Accessory<br />

On request Sealing bellow (<strong>to</strong> be specified when ordering)<br />

62<br />

31<br />

Precision<br />

70<br />

20 31<br />

ø 8 h6<br />

Max. perm. errors, Gges<br />

0,001 mm<br />

0,8 µm<br />

4<br />

ø 4 h5<br />

Repeatability limit, r<br />

0,3 µm<br />

F-12<br />

Max. hysteresis, fu<br />

0,3 µm

P RECISION I NDICATORS<br />

✓<br />

DIN 879-1.<br />

All sizes <strong>to</strong><br />

EN ISO 463<br />

Ball-bearing<br />

plunger<br />

Full-metal<br />

dial<br />

casing.<br />

Stainless steel plunger,<br />

hardened.<br />

Adjustable<br />

<strong>to</strong>lerance<br />

marks.<br />

Coupling thread for the<br />

lifting cable.<br />

M2,5 mounting thread for<br />

the measuring insert.<br />

ETALON Basic Precision Indica<strong>to</strong>rs<br />

The absolute high precision<br />

Remarkably reliable, even when <strong>co</strong>nstantly used for series inspection –<br />

Specially made for <strong>co</strong>mparative measurements demanding a very<br />

low measurement uncertainty – Measure axial and radial runouts with<br />

the lowest hysteresis.<br />

• Shockproof movement with gear-lever transmission and<br />

long dead travel.<br />

• Large, non-dazzling dial for easy readout.<br />

• No <strong>co</strong>arse reading errors as the measuring travel is limited<br />

<strong>to</strong> less than one revolution.<br />

• Fine adjustment and protective knob <strong>to</strong> prevent unintentional<br />

pointer displacement.<br />

≈ 1 N<br />

Mounted insert<br />

with a 3,175 mm<br />

dia. steel ball tip.<br />

Also with lifting<br />

cable.<br />

Suited<br />

plastic case<br />

Declaration<br />

of <strong>co</strong>nformity<br />

mm mm mm mm<br />

Regular model<br />

01419051 0,001 0,1 3,0 62<br />

•<br />

50 ÷ 0 ÷ 50<br />

Model <strong>to</strong> IP54, protected against the penetration of liquids<br />

01419052 0,001 0,1 3,0 62<br />

•<br />

50 ÷ 0 ÷ 50<br />

Precision<br />

23<br />

9<br />

Max. perm. errors<br />

in one direction throughout<br />

the measuring range, Ge<br />

over any local<br />

measuring range including<br />

10 scale divisions, Gt<br />

in both measuring directions<br />

throughout the measuring<br />

range, Gges<br />

0,001 mm<br />

1 µm<br />

0,7 µm<br />

1,2 µm<br />

ø8 h6<br />

R31<br />

18<br />

72,5<br />

108<br />

Repeatability limit, rw<br />

0,5 µm<br />

ø4<br />

Max. hysteresis, fu<br />

0,5 µm<br />

6<br />

A-13 F-13

D IAL G AUGES<br />

Precision Dial Gauges<br />

0,1 mm dial readout / 40, 58 or 80 mm dial diameter<br />

✓<br />

EN ISO 463<br />

Fac<strong>to</strong>ry standard<br />

0,1 mm<br />

1,1 mm (40 mm dia.)<br />

1,5 mm (58 mm dia.)<br />

2,2 mm (80 mm dia.)<br />

Rotating dial<br />

Full-metal<br />

dial casing.<br />

Stainless steel<br />

fixing shank and<br />

plunger, hardened .<br />

Without<br />

shockproof<br />

mechanism<br />

M2,5 mounting<br />

thread for the<br />

measuring insert<br />

mm mm mm mm mm N<br />

ROCH dial gauges<br />

0141760500 40 0,1 10 10,5 – 10 0 ÷ 5 ÷ 10 ≤ 1,0<br />

0141760501 58 0,1 10 10,5 – 10 0 ÷ 5 ÷ 10 ≤ 1,0<br />

0141760502 58 0,1 20 20,5 – 10 0 ÷ 5 ÷ 10 ≤1,0<br />

0141760503 58 0,1 30 30,5 – 10 0 ÷ 5 ÷ 10 ≤1,5<br />

0141760513 80 0,1 30 30,5 – 10 0 ÷ 5 ÷ 10 ≤ 2,0<br />

See table<br />

opposite<br />

Mounted insert<br />

with a 3,175 mm<br />

dia. steel ball tip<br />

Suited<br />

plastic case<br />

Identification<br />

number<br />

Declaration<br />

of <strong>co</strong>nformity<br />

6<br />

7<br />

7<br />

11,5<br />

7,5<br />

7,5<br />

13<br />

7,5<br />

7,5<br />

13 / 23<br />

9,5<br />

7,5<br />

23<br />

7,5<br />

7,5<br />

ø 40<br />

1<br />

11,5<br />

ø 8<br />

ø 37<br />

15,5<br />

83<br />

ø 58<br />

ø 52<br />

(108)<br />

ø 58<br />

ø 52<br />

(118 / 138)<br />

ø 80<br />

7,5<br />

ø 52<br />

26<br />

M 2,5 - 6H<br />

0141760500<br />

ø 4<br />

6 13<br />

1<br />

33<br />

16,5<br />

ø 8<br />

ø 5<br />

M 2,5 - 6H<br />

Maximum permissible<br />

0141760501<br />

errors for a metrological characteristic (MPE)<br />

0,1 mm 10 mm<br />

Deviation span<br />

40 µm<br />

Deviation span within the local<br />

measuring span of 1 mm<br />

25 µm<br />

Total deviation span<br />

55 µm<br />

22<br />

15<br />

6<br />

1<br />

43 / 53<br />

16,5<br />

ø 8<br />

ø 5<br />

M 2,5 - 6H<br />

22<br />

25 / 35<br />

6<br />

0141760503<br />

Similar model:<br />

0141760502<br />

1<br />

57<br />

23,5<br />

ø 8<br />

ø 5<br />

M 2,5 - 6H<br />

6 32<br />

40<br />

(153)<br />

0141760513<br />

Repeatability limit<br />

15 µm<br />

Max. hysteresis<br />

15 µm<br />

F-14

D IAL G AUGES<br />

✓<br />

EN ISO 463<br />

Fac<strong>to</strong>ry standard<br />

0,01 mm<br />

2,2 mm<br />

Rotating<br />

dial.<br />

Regular models<br />

with or without dial lock.<br />

Full-metal<br />

casing.<br />

Fixing shank and<br />

plunger in hardened stainless<br />

steel.<br />

With or without<br />

shockproof<br />

mechanism<br />

Adjustable <strong>to</strong>lerance<br />

marks. M2,5<br />

mounting thread<br />

for the measuring insert.<br />

3 mm dia.<br />

ball tip, already<br />

mounted.<br />

Cardboard box<br />

Precision Dial Gauges<br />

0,01 mm dial readout/ 40 mm dial diameter<br />

These precision dial gauges <strong>co</strong>mbine excellent metrological properties with<br />

extra-long life.<br />

• Smooth full-jewelled movement with rubies.<br />

• Full-metal dial casing and bezel.<br />

• Fully shockproof mechanism.<br />

• Non-dazzling dial.<br />

• Swiss Made.<br />

29<br />

48.4<br />

37<br />

ø37<br />

6<br />

6.5 14.5<br />

ø10<br />

ø8 h6<br />

ø4<br />

ø40<br />

(77.4)<br />

57<br />

37 30<br />

ø37<br />

6.5 14.5<br />

ø10<br />

ø8 h6<br />

ø40<br />

Identification<br />

number<br />

Inspection report<br />

with a declaration<br />

of <strong>co</strong>nformity<br />

ø3<br />

ø5<br />

6<br />

ø3<br />

ø5<br />

TESA dial gauges<br />

mm mm mm mm<br />

01410210 YR 0,01 5 5,4 0,5 0 ÷ 25 ÷ 50 01410211 YR 0,01 5 5,4 0,5 0 ÷ 25 ÷ 0 •<br />

01410212 YR 0,01 5 5,4 0,5 0 ÷ 25 ÷ 50 –<br />

•<br />

01412010 YE 0,01 5 5,4 – 0,5 0 ÷ 25 ÷ 50 –<br />

MERCER dial gauges<br />

01416013 X185-1 0,01 5 5,4 – 0,5 0 ÷ 25 ÷ 0 01416014 186-1 0,01 5 5,4 – 0,5 0 ÷ 25 ÷ 50<br />

•<br />

TESA IP54 dial gauge, protected against the penetration of liquids<br />

01412410 YE 0,01 5 5,4 – 0,5 0 ÷ 25 ÷ 50 –<br />

Permissible limits of a metrological characteristic (MPE/MPL)<br />

Deviation span<br />

Deviation span within the local measuring span 0,10 mm<br />

Total deviation span<br />

Repeatability limit<br />

Max. hysteresis<br />

Measuring force<br />

– Model IP54<br />

0,01 mm0,01 mm<br />

12 µm<br />

6 µm<br />

14 µm<br />

33 µm µm<br />

33 µm µm<br />

≤ 1,4 N<br />

≤ 2 N<br />

A-15 F-15

D IAL G AUGES<br />

Precision Dial Gauges<br />

0,01 mm dial readout / 40 mm dial diameter<br />

Remarkable for their robustness, these precision dial gauges are essential for<br />

the workshop.<br />

• Smooth jewelled movement with rubies.<br />

• Full-metal dial casing.<br />

• Optimum protection against shocks.<br />

• Swiss Made.<br />

✓<br />

EN ISO 463<br />

Fac<strong>to</strong>ry<br />

standard<br />

0,01 mm<br />

2,2 mm<br />

Rotating dial<br />

29<br />

48.4<br />

37<br />

ø37<br />

6<br />

6.5 14.5<br />

ø10<br />

ø8 h6<br />

ø4<br />

ø40<br />

(77.4)<br />

Full-metal<br />

dial casing.<br />

Stainless steel<br />

fixing shank and plunger,<br />

hardened.<br />

Adjustable <strong>to</strong>le -<br />

rance marks. M2,5<br />

mounting thread<br />

for the measuring insert.<br />

3 mm dia.<br />

ball tip, already<br />

mounted<br />

Cardboard box<br />

ø3<br />

ø5<br />

Identification<br />

number<br />

Inspection report<br />

with a declaration<br />

of <strong>co</strong>nformity<br />

mm mm mm mm<br />

COMPAC dial gauge<br />

353 0,01 5 5,4<br />

•<br />

– 0,5 0 ÷ 25 ÷ 50<br />

COMPAC IP54 dial gauge, protected against the penetration of liquids<br />

353E 0,01 5 5,4<br />

•<br />

– 0,5 0 ÷ 25 ÷ 50<br />

COMPAC dial gauge with limited reading range<br />

353S 0,01 ±0,2 3,3<br />

•<br />

– 0,5 20 ÷ 0 ÷ 20<br />

Permissible limits of a metrological characteristic (MPE/MPL)<br />

Deviation span<br />

Deviation span within<br />

the local measuring span 0,10 mm<br />

Total deviation span<br />

Repeatability limit<br />

Max. hysteresis<br />

Measuring force<br />

– Model IP54<br />

± 0,2 mm 5 mm<br />

7 µm 12 µm<br />

5 µm 6 µm<br />

9 µm 14 µm<br />

3 µm 3 µm<br />

3 µm 3 µm<br />

≤ 1,4 N<br />

≤ 1,4 N<br />

– ≤ 2 N<br />

F-16

D IAL G AUGES<br />

✓<br />

EN ISO 463<br />

Fac<strong>to</strong>ry<br />

standard<br />

0,01 mm<br />

Precision Dial Gauges<br />

0,01 mm dial readout / 40 mm dial diameter<br />

The model 0141760560 is specially advantageous whilst the other model<br />

0141760561 is particularly robust.<br />

2,2 mm<br />

Rotating dial<br />

Full-metal<br />

dial casing.<br />

Stainless steel<br />

fixing shank and plunger,<br />

hardened .<br />

With or without<br />

shockproof<br />

mechanism<br />

Adjustable<br />

<strong>to</strong>lerance<br />

marks.<br />

M2,5 mounting thread for<br />

the measuring insert.<br />

See table<br />

opposite<br />

Mounted insert<br />

with a 3,175 mm<br />

dia. steel ball tip<br />

Plastic case or<br />

cardboard box<br />

Identification<br />

number<br />

Declaration<br />

of <strong>co</strong>nformity<br />

ROCH dial gauges<br />

mm mm mm mm N<br />

0141760560 0,01 3 3,4 – 0,5 0 ÷ 25 ÷ 50* ≤1,4<br />

0141760561 0,01 3 3,4 – 0,5 0 ÷ 25 ÷ 50* ≤1,4<br />

ETALON dial gauge<br />

01419047 0,01 5 0,5 0 ÷ 25 ÷ 50 ≈1<br />

•<br />

* With extra red tinted reverse numbering.<br />

6,5<br />

7<br />

7<br />

11,5 / 8<br />

7<br />

20,5<br />

21 1 ø 40<br />

11,5<br />

M 2,5 - 6H<br />

ø 8<br />

ø 4<br />

ø 37<br />

15,5<br />

6 8<br />

(78 / 74,5)<br />

ø8 h6<br />

ø4<br />

6<br />

12 ø40<br />

48<br />

74,5<br />

0141760561 01419047<br />

Maximum permissible errors for a metrological characteristic (MPE)<br />

0,01 mm 3 mm 5 mm<br />

Deviation span<br />

10 µm 12 µm<br />

Deviation span within the local<br />

measuring span of 0,1 mm<br />

5 µm 6 µm<br />

Total deviation span<br />

12 µm –<br />

Repeatability limit<br />

3 µm 3 µm<br />

Max. hysteresis<br />

3 µm –<br />

F-17

6<br />

6<br />

D IAL G AUGES<br />

Precision Dial Gauges<br />

0,01 mm dial readout / 57 or 58 mm dial diameter<br />

✓<br />

EN ISO 463<br />

Fac<strong>to</strong>ry standard<br />

0,01 mm<br />

1,5 mm<br />

TESA dial gauges<br />

mm mm mm mm<br />

01410610 YR 0,01 10 10,5<br />

• •<br />

1 0 ÷ 50 ÷ 100<br />

01410611 YR 0,01 10 10,5<br />

• •<br />

1 0 ÷ 50 ÷ 0<br />

01412310 YE 0,01 10 10,5 – – 1 0 ÷ 50 ÷ 100<br />

MERCER dial gauges<br />

01416020 250-1 0,01 10 10,5 –<br />

•<br />

1 0 ÷ 50 ÷ 0<br />

01416021 251-1 0,01 10 10,5 –<br />

•<br />

1 0 ÷ 50 ÷ 100<br />

TESA IP54 dial gauges, protected against the penetration of liquids<br />

01410721 YR 0,01 10 10,5 – 1 0 ÷ 50 ÷ 0<br />

•<br />

01412411 YE 0,01 10 10,5 – – 1 0 ÷ 50 ÷ 100<br />

TESA dial gauge with limited reading range<br />

01412211 YE 0,01 ± 0,4 4 – 1,27 40 ÷ 0 ÷ 40<br />

•<br />

Rotating<br />

dial.<br />

Regular models<br />

with or without dial lock.<br />

Full-metal<br />

dial casing.<br />

Stainless steel<br />

fixing shank and plunger,<br />

hardened .<br />

With or without<br />

shockproof<br />

mechanism<br />

Adjustable <strong>to</strong>lerance<br />

marks. M2,5<br />

mounting thread<br />

for the measuring insert.<br />

3 mm dia.<br />

ball tip, already<br />

mounted<br />

Cardboard box<br />

Identification<br />

number<br />

Inspection report<br />

with a declaration<br />

of <strong>co</strong>nformity<br />

Permissible limits of a metrological characteristic (MPE/MPL)<br />

15.7<br />

10<br />

± 0,4 10 mm<br />

57.5<br />

Deviation span<br />

Deviation span within<br />

the local measuring span 0,10 mm<br />

Total deviation span<br />

7 µm 15 µm<br />

5 µm 8 µm<br />

9 µm 17 µm<br />

(142.5)<br />

ø58<br />

ø8 h6<br />

ø53<br />

50<br />

85<br />

Repeatability limit<br />

3 µm 3 µm<br />

Max. hysteresis<br />

Measuring force<br />

– Models IP54<br />

3 µm 3 µm<br />

≤ 1 N ≤ 1,5 N<br />

– ≤ 2,2 N<br />

ø5<br />

15.7 9<br />

ø10<br />

ø3<br />

01410721 – 01412411<br />

50<br />

(111)<br />

ø57<br />

ø53<br />

43<br />

ø8 h6<br />

68<br />

ø4.5<br />

F-18<br />

ø5<br />

ø3<br />

01410610 – 01410611

D IAL G AUGES<br />

✓<br />

EN ISO 463<br />

Fac<strong>to</strong>ry<br />

standard<br />

Precision Dial Gauges<br />

0,01 mm dial readout / 58 mm dial diameter<br />

0,01 mm<br />

1,5 mm<br />

Rotating dial<br />

with or without<br />

dial lock<br />

Full-metal<br />

dial casing.<br />

Stainless steel<br />

fixing shank and plunger,<br />

hardened.<br />

Adjustable <strong>to</strong>lerance<br />

marks. M2,5<br />

mounting thread<br />

for the measuring insert.<br />

3 mm dia.<br />

ball tip, already<br />

mounted.<br />

Cardboard box<br />

(111)<br />

ø58<br />

15.7 9<br />

ø10<br />

ø8h6<br />

ø53<br />

50<br />

43<br />

68<br />

(142.5)<br />

ø58<br />

15.7<br />

ø8 h6<br />

10<br />

ø53<br />

50<br />

57.5<br />

85<br />

Identification<br />

number<br />

Inspection report<br />

with a declaration<br />

of <strong>co</strong>nformity<br />

6<br />

ø4.5<br />

ø5<br />

ø3<br />

6<br />

ø5<br />

ø3<br />

COMPAC dial gauges<br />

mm mm mm mm<br />

512K 0,01 10 10,5 – – 1 0 ÷ 50 ÷ 100<br />

532 0,01 10 10,5 – 1 0 ÷ 50 ÷ 100<br />

•<br />

COMPAC IP 54 dial gauge, protected against the penetration of liquids<br />

532E 0,01 10 10,5 – 1 0 ÷ 50 ÷ 100<br />

•<br />

COMPAC dial gauges with limited reading range<br />

532S 0,01 ± 0,4 4<br />

• •<br />

1,27 40 ÷ 0 ÷ 40<br />

533S 0,01 ± 0,5 4<br />

•<br />

– 1,27 50 ÷ 0 ÷ 50<br />

Permissible limits of a metrological characteristic (MPE/MPL)<br />

Deviation span<br />

Deviation span within<br />

the local measuring span 0,10 mm<br />

Total deviation span<br />

Repeatability limit<br />

Max. hysteresis<br />

Measuring force<br />

– Model IP54<br />

±0,4 / ±0,5 mm 10 mm<br />

7 µm 15 µm<br />

5 µm 8 µm<br />

9 µm 17 µm<br />

3 µm 3 µm<br />

3 µm 3 µm<br />

≤ 1 N<br />

≤ 1,5 N<br />

– ≤ 2,2 N<br />

F-19

D IAL G AUGES<br />

E<br />

Long Range Precision Dial Gauges<br />

0,01 mm dial readout / 58 mm dial diameter<br />

✓<br />

EN ISO 463<br />

Fac<strong>to</strong>ry<br />

standard<br />

15.7<br />

D<br />

0,01 mm<br />

1,5 mm<br />

ø58<br />

ø6.4<br />

C<br />

A<br />

Rotating dial<br />

with or without<br />

dial lock<br />

Full-metal<br />

dial casing.<br />

Stainless steel<br />

fixing shank and plunger,<br />

hardened .<br />

Adjustable <strong>to</strong>lerance<br />

marks. M2,5<br />

mounting thread<br />

for the measuring insert.<br />

3 mm dia.<br />

ball tip, already<br />

mounted.<br />

F<br />

B<br />

Cardboard box<br />

M 2,5 - 6H<br />

ø4.5<br />

6<br />

Identification<br />

number<br />

Inspection report<br />

with a declaration<br />

of <strong>co</strong>nformity<br />

ø5<br />

ø3<br />

mm 30 mm 50 mm 100 mm<br />

A 148 228 390<br />

B 88 117,2 211,6<br />

C 50 60 103,6<br />

D 10 9 9<br />

E 20 19 19<br />

F Ø 8h6 Ø 8h6 Ø 8h6<br />

COMPAC dial gauges<br />

mm mm mm mm<br />

712 0,01 30 30,5<br />

•<br />

– 1 0 ÷ 50 ÷ 100<br />

722 0,01 50 50,5<br />

•<br />

– 1 0 ÷ 50 ÷ 100<br />

732 0,01 100 100,5<br />

•<br />

– 1 0 ÷ 50 ÷ 100<br />

MERCER dial gauge<br />

01416039 252-1 0,01 30 30,5<br />

• •<br />

1 0 ÷ 50 ÷ 100<br />

Permissible limits of a metrological characteristic (MPE/MPL)<br />

Deviation span<br />

Total deviation span<br />

30 mm 50 mm 100 mm<br />

20 µm 25 µm 30 µm<br />

25 µm 30 µm 35 µm<br />

Repeatability limit<br />

3 µm 3 µm 3 µm<br />

Max. hysteresis<br />

5 µm 5 µm 8 µm<br />

Measuring force<br />

≤ 2,2 N ≤ 2,5 N ≤ 3,2 N<br />

F-20

D IAL G AUGES<br />

✓<br />

EN ISO 463<br />

Fac<strong>to</strong>ry<br />

standard<br />

Long Range Precision Dial Gauges<br />

0,01 mm dial readout / 58 mm dial diameter<br />

Both models 0141760635 and 0141760636 are particularly profitable.<br />

0,01 mm<br />

1,5 mm<br />

Rotating dial<br />

Full-metal<br />

dial casing.<br />

Stainless steel<br />

fixing shank and plunger,<br />

hardened .<br />

With or without<br />

shockproof<br />

mechanism<br />

Adjustable<br />

<strong>to</strong>lerance<br />

marks.<br />

Model No. 0141760640<br />

with fine adjust mounted<br />

under the protective cap<br />

for dial reading.<br />

M2,5 mounting thread for<br />

the measuring insert.<br />

For accuracy,<br />

see table on<br />

page F-22<br />

See table<br />

opposite<br />

Mounted insert<br />

with a 3,175 mm<br />

dia. steel ball tip.<br />

Exception:<br />

Each model No. 0141760631<br />

has a ruby ball tip.<br />

Plastic case or<br />

cardboard box<br />

Identification<br />

number<br />

Declaration<br />

of <strong>co</strong>nformity<br />

ROCH dial gauges<br />

mm mm mm mm N<br />

0141760631 0,01 10 10,5 – 1 0 ÷ 50 ÷ 100* ≤ 1,4<br />

0141760635 0,01 10 10,5 – 1 0 ÷ 50 ÷ 100* ≤ 1,4<br />

0141760636**** 0,01 10 10,5 – 1 0 ÷ 50 ÷ 100* ≤ 1,4<br />

0141760640 0,01 10 10,5 1 0 ÷ 50 ÷ 100* ≤ 1,4<br />

0141761213*** 0,01 15 15,5 1 0 ÷ 50 ÷ 100* ≤1,6<br />

•<br />

0141760651 0,01 30 30,5 – 1 0 ÷ 50 ÷ 100 ≤1,6<br />

0141760653 0,01 30 30,5 1 0 ÷ 50 ÷ 100 ≤1,6<br />

•<br />

0141760661 0,01 50 51 – 1 0 ÷ 50 ÷ 100 ≤ 2,2<br />

0141760662** 0,01 50 51 – 1 0 ÷ 50 ÷ 100 ≤2,2<br />

0141760663 0,01 50 51 1 0 ÷ 50 ÷ 100 ≤2,2<br />

•<br />

0141760671 0,01 80 81 – 1 0 ÷ 50 ÷ 100 ≤ 3,0<br />

ROCH IP54 dial gauge, protected against the penetration of liquids<br />

0141760624 0,01 10<br />

* With extra red tinted reverse numbering.<br />

10,5<br />

•<br />

1 0 ÷ 50 ÷ 100* ≤ 2<br />

** Counterclockwise numbering.<br />

*** 60,4 mm dial diameter.<br />

**** With mounted central lug back.<br />

7,5<br />

7,5<br />

7,5<br />

7,5<br />

7,5<br />

7,5<br />

10 / 13<br />

ø8<br />

25<br />

ø8<br />

25<br />

7,5<br />

ø 58<br />

1<br />

ø 52<br />

(108 / 105)<br />

ø 58<br />

7,5<br />

ø 52<br />

(120)<br />

ø 58<br />

7,5<br />

ø 52<br />

(127)<br />

16,5<br />

ø 8<br />

22<br />

33<br />

1<br />

1<br />

ø 4<br />

M 2,5 - 6H<br />

15<br />

33<br />

16,5<br />

ø 8<br />

ø 4<br />

22<br />

18<br />

ø 8 h6<br />

22<br />

6<br />

M 2,5 - 6H<br />

15<br />

22<br />

M 2,5<br />

0141760631<br />

0141760635<br />

0141760636 0141760640<br />

0141760624<br />

6<br />

6<br />

F-21

D IAL G AUGES<br />

✓<br />

EN ISO 463<br />

Fac<strong>to</strong>ry standard<br />

0,01 mm<br />

1,5 mm<br />

Rotating dial<br />

40,8<br />

ø 60,4<br />

21,5<br />

24<br />

ø 4<br />

M 2,5 - 6H<br />

0141761213<br />

9<br />

ø 54<br />

116<br />

ø 8 h6<br />

8<br />

ø 58<br />

7,8<br />

ø 11<br />

7,5<br />

7,5<br />

75,5<br />

ø 59<br />

(232)<br />

ø 58<br />

7,8<br />

ø 11<br />

7,5<br />

7,5<br />

105,5<br />

ø 59<br />

(312)<br />

Full-metal<br />

dial casing.<br />

Stainless steel<br />

fixing shank and plunger,<br />

hardened .<br />

With or without<br />

shockproof<br />

mechanism<br />

Adjustable <strong>to</strong>lerance<br />

marks.<br />

M2,5 mounting<br />

thread for the measuring<br />

insert.<br />

In order<br />

<strong>to</strong> eliminate<br />

any hysteresis<br />

when measuring with<br />

the plunger moving<br />

downward, this feature<br />

has <strong>to</strong> be <strong>co</strong>upled on<br />

the measuring points,<br />

directly.<br />

See table<br />

on the previous<br />

page F-21<br />

Mounted insert<br />

with a 3,175 mm<br />

dia. steel ball tip.<br />

Exception:<br />

Each model No. 0141761213<br />

has a ruby ball tip<br />

Plastic case or<br />

cardboard box<br />

35<br />

ø 8<br />

36,5<br />

55<br />

56,5<br />

Identification<br />

number<br />

91,5<br />

ø 5<br />

55<br />

141,5<br />

ø 8<br />

ø 5<br />

Declaration<br />

of <strong>co</strong>nformity<br />

M 2,5 - 6H<br />

M 2,5 - 6H<br />

85<br />

6<br />

6<br />

0141760651<br />

0141760653<br />

0141760661 – 0141760663<br />

0141760662 – 0141760671<br />

Maximum permissible errors for a metrological characteristic (MPE)<br />

0,01 mm 10 mm 15 mm 30 mm 50 mm 80 mm<br />

Deviation span<br />

15 µm 20 µm 20 µm 25 µm 30 µm<br />

Deviation span within the local<br />

measuring span of 0,1 mm<br />

5 µm 5 µm 5 µm 5 µm 5 µm<br />

Repeatability limit<br />

3 µm 3 µm 3 µm 3 µm 3 µm<br />

F-22

6<br />

D IAL G AUGES<br />

✓<br />

EN ISO 463<br />

Fac<strong>to</strong>ry<br />

standard<br />

Precision Dial Gauges<br />

0,01 mm dial readout / 58 mm dial diameter<br />

Regular and long range models<br />

0,01 mm<br />

1,5 mm<br />

Rotating dial<br />

Full-metal<br />

dial casing.<br />

Stainless steel<br />

fixing shank and plunger,<br />

hardened .<br />

With or without<br />

shockproof<br />

mechanism<br />

Adjustable <strong>to</strong>lerance<br />

marks.<br />

M2,5 mounting<br />

thread for the measuring<br />

insert.<br />

See table<br />

opposite<br />

Mounted insert<br />

with a 3,175 mm<br />

dia. steel ball tip<br />

Plastic case or<br />

cardboard box<br />

Identification<br />

number<br />

Declaration<br />

of <strong>co</strong>nformity<br />

mm mm mm mm N<br />

ETALON dial gauges<br />

01419048 0,01 10 58 – 1 0 ÷ 50 ÷ 100 ≈1<br />

01419049 0,01 30 58<br />

•<br />

1 0 ÷ 50 ÷ 100 1,5 ÷ 2<br />

01419050 0,01 50 58<br />

•<br />

1 0 ÷ 50 ÷ 100 1,5 ÷ 2<br />

Plunger retraction device<br />

01462003 Lift lever<br />

Backs with permanent magnet or central lug, see page F-45.<br />

Maximum permissible errors for a metrological characteristic (MPE)<br />

8/11<br />

mm 10 30 50<br />

22,5<br />

Deviation span<br />

Deviation span within the local<br />

measuring span of 0,1 mm<br />

µm 15 20 25<br />

µm 8 9 12<br />

7,5<br />

Repeatability limit<br />

µm 3 3 3<br />

7,5<br />

22,5<br />

ø58<br />

105<br />

ø58<br />

148 / 232<br />

89 / 127<br />

19 / 36<br />

ø8 h6<br />

ø8 h6<br />

18<br />

69<br />

ø5<br />

35 / 55<br />

ø4<br />

6<br />

01419048 01419049 - 01419050<br />

F-23

D IAL G AUGES<br />

Precision Dial Gauges<br />

0,01 mm dial readout / 82 mm dial diameter<br />

✓<br />

EN ISO 463<br />

Fac<strong>to</strong>ry<br />

standard<br />

0,01 mm<br />

19.2<br />

19<br />

2,3 mm<br />

19,2<br />

ø10<br />

9<br />

ø82<br />

15.7<br />

9<br />

390<br />

Rotating dial<br />

with or without<br />

dial lock<br />

Full-metal<br />

dial casing.<br />

Stainless steel<br />

fixing shank and plunger,<br />

hardened.<br />

High perfor mance<br />

shock proof system<br />

in both directions<br />

Adjustable <strong>to</strong>lerance<br />

marks. M2,5<br />

mounting thread<br />

for the measuring insert.<br />

3 mm dia.<br />

ball tip, already<br />

mounted<br />

ø6.4<br />

Cardboard box<br />

(121)<br />

ø82<br />

ø53<br />

60<br />

43<br />

8h6<br />

103,6<br />

211,6<br />

Identification<br />

number<br />

Inspection report<br />

with a declaration<br />

of <strong>co</strong>nformity<br />

ø8 h6<br />

78<br />

ø4.5<br />

ø4.5<br />

M 2,5 - 6H<br />

6<br />

6<br />

ø5<br />

ø3<br />

ø5<br />

ø3<br />

mm mm mm mm<br />

TESA dial gauge with dial lock<br />

01410910 YR 0,01 10 10,5<br />

•<br />

0,1 0 ÷ 50 ÷ 100<br />

TESA dial gauge with a long range<br />

01412014 YE 0,01 100 100,5<br />

•<br />

1 0 ÷ 50 ÷ 100<br />

Permissible limits of a metrological characteristic (MPE/MPL)<br />

Deviation span<br />

Deviation span within<br />

the local measuring span 0,10 mm<br />

Total deviation span<br />

Repeatability limit<br />

Max. hysteresis<br />

10 mm 100 mm<br />

15 µm 30 µm<br />

8 µm –<br />

17 µm 35 µm<br />

3 µm 3 µm<br />

3 µm 8 µm<br />

Measuring force<br />

≤ 1,4 N<br />

≤ 3,2 N<br />

F-24

D IAL G AUGES<br />

✓<br />

Precision Dial Gauges<br />

EN ISO 463<br />

Fac<strong>to</strong>ry<br />

standard<br />

0,01 mm dial readout / 82 mm dial diameter<br />

0,01 mm<br />

19.2<br />

15.7<br />

E<br />

D<br />

2,2 mm<br />

Rotating dial<br />

with or without<br />

dial lock<br />

Full-metal<br />

dial casing.<br />

Stainless steel<br />

fixing shank and plunger,<br />

hardened.<br />

M2,5 thread<br />

for the<br />

measuring insert<br />

3 mm dia.<br />

ball tip, already<br />

mounted.<br />

ø82<br />

A<br />

Cardboard box<br />

C<br />

ø6.4<br />

Identification<br />

number<br />

Inspection report<br />

with a declaration<br />

of <strong>co</strong>nformity<br />

F<br />

B<br />

ø4.5<br />

M 2,5 - 6H<br />

ø5<br />

ø3<br />

6<br />

mm 30 mm 50 mm 100 mm<br />

A 158 228 390<br />

B 98 117,2 211,6<br />

C 60 60 103,6<br />

D 10 9 9<br />

E 20 19 19<br />

F Ø 8h6 Ø 8h6 Ø 8h6<br />

mm mm mm mm<br />

COMPAC dial gauges with a long range<br />

712G 0,01 30 30,5<br />

•<br />

– 1 0 ÷ 50 ÷ 100<br />

722G 0,01 50 50,5<br />

•<br />

– 1 0 ÷ 50 ÷ 100<br />

732G 0,01 100 100,5<br />

•<br />

– 1 0 ÷ 50 ÷ 100<br />

732GB 0,01 100 100,5<br />

• •<br />

1 0 ÷ 50 ÷ 100<br />

Permissible limits of a metrological characteristic (MPE/MPL)<br />

Deviation span<br />

Total deviation span<br />

Repeatability limit<br />

Max. hysteresis<br />

Measuring force<br />

30 mm 50 mm 100 mm<br />

20 µm 25 µm 30 µm<br />

25 µm 30 µm 35 µm<br />

3 µm 3 µm 3 µm<br />

5 µm 5 µm 8 µm<br />

≤ 2,2 N ≤ 2,5 N ≤ 3,2 N<br />

F-25

D IAL G AUGES<br />

Precision Dial Gauges<br />

0,01 mm dial readout / 80 mm dial diameter<br />

✓<br />

EN ISO 463<br />

Fac<strong>to</strong>ry<br />

standard<br />

0,01 mm<br />

2,2 mm<br />

7,5<br />

Rotating dial<br />

9,5<br />

7,5<br />

9,5<br />

ø 13<br />

8,5<br />

128,5<br />

Full-metal<br />

dial casing.<br />

Stainless steel<br />

fixing shank and plunger,<br />

hardened .<br />

With or without<br />

shockproof<br />

mechanism<br />

Adjustable<br />

<strong>to</strong>lerance marks.<br />

M2,5 mounting<br />

thread for the measuring<br />

insert.<br />

ø 80<br />

13<br />

7,5<br />

51<br />

ø 80<br />

71<br />

(382)<br />

See in the<br />

table opposite<br />

Mounted insert<br />

with a 3,175 mm<br />

dia. steel ball tip<br />

Cardboard box<br />

30<br />

17<br />

ø 8<br />

ø 4<br />

26<br />

20<br />

12<br />

(128)<br />

172<br />

64,5<br />

ø 10<br />

ø 6<br />

M 2,5 - 6H<br />

70,5<br />

106<br />

Identification<br />

number<br />

Declaration<br />

of <strong>co</strong>nformity<br />

M 2,5 - 6H<br />

6<br />

6<br />

0141761221<br />

0141761224<br />

mm mm mm mm N<br />

ROCH dial gauges<br />

0141761221 0,01 10 10,4 – 1 0 ÷ 50 ÷ 100* ≤1,4<br />

0141761224 0,01 100 100,5 – 1 0 ÷ 50 ÷ 100 ≤ 3,5<br />

* With extra red tinted reverse numbering.<br />

Maximum permissible errors for a metrological characteristic (MPE)<br />

Deviation span<br />

Deviation span within the local<br />

measuring span of 0,1 mm<br />

Total deviation span<br />

10 mm 100 mm<br />

15 µm 35 µm<br />

5 µm 8 µm<br />

19 µm –<br />

Repeatability limit<br />

3 µm 8 µm<br />

Max. hysteresis<br />

3 µm –<br />

F-26

D IAL G AUGES<br />

✓<br />

EN ISO 463<br />

Fac<strong>to</strong>ry<br />

standard<br />

Precision Dial Gauges<br />

0,002 mm dial readout / 40 mm dial diameter<br />

0,002 mm<br />

1,1 mm<br />

Rotating dial<br />

Full-metal<br />

dial casing.<br />

Stainless steel<br />

fixing shank and plunger,<br />

hardened .<br />

Adjustable <strong>to</strong>lerance<br />

marks. M2,5<br />

mounting thread<br />

for the measuring insert.<br />

3 mm dia.<br />

ball tip, already<br />

mounted<br />

6.5 14.5<br />

ø10<br />

6.5 14.5<br />

ø10<br />

Cardboard box<br />

Identification<br />

number<br />

Inspection report<br />

with a declaration<br />

of <strong>co</strong>nformity<br />

57<br />

37 30<br />

ø37<br />

ø8 h6<br />

ø40<br />

29<br />

48.4<br />

37<br />

ø37<br />

ø8 h6<br />

ø40<br />

ø4<br />

6<br />

(77.4)<br />

6<br />

ø3<br />

ø5<br />

ø3<br />

ø5<br />

mm mm mm mm<br />

COMPAC dial gauge<br />

355 0,002 3 3,3<br />

•<br />

– 0,2 0 ÷ 10 ÷ 20<br />

COMPAC dial gauge IP54, protected against the penetration of liquids<br />

355E 0,002 3 3,3<br />

•<br />

– 0,2 0 ÷ 10 ÷ 20<br />

COMPAC dial gauge with limited reading range<br />

365S 0,002 ±0,08 1,5<br />

•<br />

– 0,2 8 ÷ 0 ÷ 8<br />

Permissible limits of a metrological characteristic (MPE/MPL)<br />

Deviation span<br />

Deviation span within<br />

the local measuring span 0,10 mm<br />

Total deviation span<br />

Repeatability limit<br />

Max. hysteresis<br />

Measuring force<br />

– Model IP54<br />

±0,08 mm 3 mm<br />

2 µm 10 µm<br />

2 µm 6 µm<br />

4 µm 12 µm<br />

1 µm 1,5 µm<br />

1 µm 2 µm<br />

≤ 1,4 N<br />

≤ 1,4 N<br />

– ≤ 1,7 N<br />

F-27

D IAL G AUGES<br />

Precision Dial Gauges<br />

0,002 mm dial readout / 58 mm dial diameter<br />

✓<br />

EN ISO 463<br />

Fac<strong>to</strong>ry<br />

standard<br />

0,002 mm<br />

1,5 mm<br />

15.7<br />

ø10<br />

9<br />

15.7<br />

ø10<br />

9<br />

15.7<br />

10<br />

Rotating dial<br />

with or without<br />

dial lock<br />

Full-metal<br />

dial casing.<br />

Stainless steel<br />

fixing shank and plunger,<br />

hardened .<br />

Adjustable <strong>to</strong>lerance<br />

marks. M2,5<br />

mounting thread<br />

for the measuring insert.<br />

3 mm dia.<br />

ball tip, already<br />

mounted.<br />

57.5<br />

Cardboard box<br />

(105)<br />

ø58<br />

43<br />

ø8 h6<br />

ø53<br />

50<br />

62<br />

(105)<br />

ø58<br />

ø53<br />

ø8 h6<br />

50<br />

62<br />

(129)<br />

ø58<br />

ø4.5<br />

6<br />

43<br />

ø8 h6<br />

ø53<br />

50<br />

71.5<br />

Identification<br />

number<br />

Inspection report<br />

with a declaration<br />

of <strong>co</strong>nformity<br />

ø4.5<br />

6<br />

ø5<br />

ø3<br />

ø5<br />

ø3<br />

6<br />

ø5<br />

ø3<br />

MERCER dial gauges<br />

mm mm mm mm<br />

01416034 253-1 0,002 5 5,3 –<br />

•<br />

0,2 0 ÷ 10 ÷ 0<br />

01416035 254-1 0,002 5 5,3 –<br />

•<br />

0,2 0 ÷ 10 ÷ 20<br />

COMPAC dial gauge<br />

555 0,002 5 5,3<br />

•<br />

– 0,2 0 ÷ 10 ÷ 20<br />

COMPAC dial gauge IP54, protected against the penetration of liquids<br />

555E 0,002 5 5,3<br />

•<br />

– 0,2 0 ÷ 10 ÷ 20<br />

COMPAC dial gauge with limited reading range<br />

565S 0,002 ±0,08 3,3<br />

•<br />

– 0,2 8 ÷ 0 ÷ 8<br />

Permissible limits of a metrological characteristic (MPE/MPL)<br />

Deviation span<br />

Total deviation span<br />

Repeatability limit<br />

Max. hysteresis<br />

Measuring force<br />

– Model IP54<br />

±0,08 mm 5 mm<br />

4 µm 12 µm<br />

4 µm 14 µm<br />

1 µm 2 µm<br />

1 µm 2 µm<br />

≤ 1,5 N<br />

≤ 1,5 N<br />

– ≤ 1,7 N<br />

F-28

D IAL G AUGES<br />

✓<br />

EN ISO 463<br />

Fac<strong>to</strong>ry<br />

standard<br />

Precision Dial Gauges<br />

0,001 mm dial readout / 40 mm dial diameter<br />

0,001 mm<br />

1,1 mm<br />

Rotating dial,<br />

With or without<br />

dial lock.<br />

Full-metal<br />

dial casing.<br />

Stainless steel<br />

fixing shank and plunger,<br />

hardened.<br />

High perfor mance<br />

shock proof system<br />

in both directions<br />

Adjustable <strong>to</strong>lerance<br />

marks. M2,5<br />

mounting thread<br />

for the measuring insert.<br />

3 mm dia.<br />

ball tip, already<br />

mounted.<br />

Cardboard box<br />

Identification<br />

number<br />

Inspection report<br />

with a declaration<br />

of <strong>co</strong>nformity<br />

TESA dial gauges<br />

mm mm mm mm<br />

01410010 YR 0,001 1 1,5<br />

• •<br />

0,1 0 ÷ 50 ÷ 100<br />

01410011 YR 0,001 1 1,5<br />

• •<br />

0,1 0 ÷ 50 ÷ 0<br />

01412510 YE 0,001 1 1,5<br />

•<br />

– 0,1 0 ÷ 50 ÷ 100<br />

TESA dial gauges IP54, protected against the penetration of liquids<br />

01410120 YR 0,001 1 1,5<br />

•<br />

– 0,1 0 ÷ 50 ÷ 100<br />

01410121 YR 0,001 1 1,5<br />

•<br />

– 0,1 0 ÷ 50 ÷ 0<br />

01412710 YE 0,001 1 1,5<br />

•<br />

– 0,1 0 ÷ 50 ÷ 100<br />

COMPAC dial gauge<br />

367 0,001 1 1,5 – 0,1 0 ÷ 5 ÷ 10<br />

•<br />

COMPAC dial gauge IP54, protected against the penetration of liquids<br />

367E 0,001 1 1,5 – 0,1 0 ÷ 5 ÷ 10<br />

•<br />

COMPAC dial gauge with limited reading range<br />

367S 0,001 ±0,04 1,5<br />

•<br />

– 0,1 4 ÷ 0 ÷ 4<br />

6.5 14.5<br />

ø10<br />

37<br />

29<br />

ø37<br />

ø40<br />

(77.4)<br />

Permissible limits of a metrological characteristic (MPE/MPL)<br />

48.4<br />

6<br />

ø3<br />

ø8 h6<br />

ø4<br />

ø5<br />

6.5 14.5<br />

ø10<br />

Deviation span<br />

Deviation span within<br />

the local measuring span 0,10 mm<br />

Total deviation span<br />

±0,04 mm 1 mm<br />

2 µm 4 µm<br />

2 µm 4 µm<br />

4 µm 5 µm<br />

57<br />

37 30<br />

ø37<br />

ø8 h6<br />

ø40<br />

Repeatability limit<br />

Max. hysteresis<br />

Measuring force<br />

– Models IP54<br />

1 µm 1 µm<br />

1 µm 1 µm<br />

≤ 1,4 N ≤ 1,7 N<br />

– ≤ 2 N<br />

6<br />

ø3<br />

F-29<br />

ø5

D IAL G AUGES<br />

Precision Dial Gauges<br />

0,001 mm dial reading / 40 mm dial diameter<br />

✓<br />

EN ISO 463<br />

Fac<strong>to</strong>ry<br />

standard<br />

7<br />

7<br />

0,001 mm<br />

21 1 ø 40<br />

11,5<br />

6,5<br />

ø8<br />

M 2,5 - 6H<br />

ø 8<br />

ø 4<br />

7<br />

6 8 15,5 ø 37 13,5<br />

(80)<br />

21 1 ø 40<br />

11,5<br />

ø9<br />

6,5<br />

7<br />

M 2,5 - 6H<br />

ø 8<br />

ø 4<br />

6 8 15,5 ø 37 10,5<br />

(77)<br />

1,1 mm<br />

(0141761261)<br />

2,2 mm<br />

(0141761262)<br />

Rotating dial<br />

Full-metal<br />

dial casing.<br />

Stainless steel<br />

fixing shank and plunger,<br />

hardened .<br />

With shockproof<br />

mechanism<br />

Adjustable<br />

<strong>to</strong>lerance marks.<br />

M2,5 mounting<br />

thread for the measuring<br />

insert.<br />

mm mm mm mm N<br />

ROCH dial gauges<br />

0141761261 0,001 1 1,1 0,2 0 ÷ 100/0 ÷ 100* ≤ 1,5<br />

0141761262 0,001 1 1,1 0,1 0 ÷ 50 ÷ 100* ≤ 1,2<br />

•<br />

* With extra red tinted reverse numbering.<br />

Maximum permissible errors<br />

for a metrological characteristic (MPE)<br />

See table<br />

opposite<br />

Mounted insert<br />

with a 3,175 mm<br />

dia. steel ball tip<br />

Suited<br />

plastic case<br />

Identification<br />

number<br />

Declaration<br />

of <strong>co</strong>nformity<br />

0,001 mm 1 mm<br />

Deviation span<br />

5 µm<br />

Deviation span within the local<br />

measuring span of 0,01 mm<br />

3 µm<br />

Total deviation span<br />

7 µm<br />

Repeatability limit<br />

3 µm<br />

Max. hysteresis max.<br />

3 µm<br />

F-30

D IAL G AUGES<br />

✓<br />

EN ISO 463<br />

Fac<strong>to</strong>ry<br />

standard<br />

Precision Dial Gauges<br />

0,001 mm dial readout / 58 mm dial diameter<br />

0,001 mm<br />

1,5 mm<br />

Full-metal<br />

dial casing.<br />

Stainless steel<br />

fixing shank and plunger,<br />

hardened .<br />

High perfor mance<br />

shockproof system<br />

in both directions<br />

Adjustable <strong>to</strong>lerance<br />

marks. M2,5<br />

mounting thread<br />

for the measuring insert.<br />

3 mm dia.<br />

ball tip, already<br />

mounted<br />

Cardboard box<br />

Identification<br />

number<br />

Inspection report<br />

with a declaration<br />

of <strong>co</strong>nformity<br />

TESA dial gauges<br />

mm mm mm mm<br />

01412511 YE 0,001 1 1,5<br />

•<br />

– 0,1 0 ÷ 50 ÷ 100<br />

01410410 YR 0,001 1 3,3<br />

•<br />

– 0,1 0 ÷ 50 ÷ 100<br />

01410411 YR 0,001 1 3,3<br />

•<br />

– 0,1 0 ÷ 50 ÷ 0<br />

01412611 YE 0,001 5 5,3<br />

•<br />

– 0,2 0 ÷ 100 ÷ 200<br />

COMPAC dial gauges IP54, protected against the penetration of liquids<br />

01412711 YE 0,001 1 1,5<br />

•<br />

– 0,1 0 ÷ 50 ÷ 100<br />

01410520 YR 0,001 1 3,3<br />

•<br />

– 0,1 0 ÷ 50 ÷ 100<br />

Permissible limits of a metrological characteristic (MPE/MPL)<br />

1 mm 5 mm<br />

Deviation span<br />

Deviation span within<br />

the local measuring span 0,10 mm<br />

Total deviation span<br />

Repeatability limit<br />

Max. hysteresis<br />

Measuring force<br />

– Models IP54<br />

4 µm 12 µm<br />

4 µm<br />

5 µm 14 µm<br />

1 µm 2 µm<br />

1 µm 2 µm<br />

≤ 1,7 N<br />

≤ 1,5 N<br />

– ≤ 1,7 N<br />

15.7<br />

10<br />

15.7<br />

9<br />

ø10<br />

50<br />

43<br />

ø8 h6<br />

ø4.5<br />

6<br />

50<br />

(105)<br />

ø58<br />

62<br />

ø53<br />

(129)<br />

ø58<br />

ø53<br />

57.5<br />

ø8 h6<br />

71.5<br />

ø5<br />

ø3<br />

6<br />

ø5<br />

ø3<br />

A-31 F-31

D IAL G AUGES<br />

Precision Dial Gauges<br />

0,001 mm dial readout / 58 mm dial diameter<br />

✓<br />

EN ISO 463<br />

Fac<strong>to</strong>ry<br />

standard<br />

0,001 mm<br />

1,5 mm<br />

Rotating dial<br />

ø58<br />

15.7<br />

ø10<br />

9<br />

ø53<br />

43<br />

(129)<br />

ø58<br />

15.7<br />

10<br />

ø53<br />

57.5<br />

Full-metal<br />

dial casing.<br />

Stainless steel<br />

fixing shank and plunger,<br />

hardened.<br />

Adjustable <strong>to</strong>lerance<br />

marks. M2,5<br />

mounting thread<br />

for the measuring insert.<br />

3 mm dia.<br />

ball tip, already<br />

mounted.<br />

(105)<br />

50<br />

Cardboard box<br />

6<br />

50<br />

ø4.5<br />

ø5<br />

ø3<br />

ø8 h6<br />

62<br />

6<br />

ø8 h6<br />

ø5<br />

ø3<br />

71.5<br />

Identification<br />

number<br />

Inspection report<br />

with a declaration<br />

of <strong>co</strong>nformity<br />

mm mm mm mm<br />

COMPAC dial gauges<br />

556 0,001 5 5,3<br />

•<br />

– 0,2 0 ÷ 10 ÷ 20<br />

567 0,001 1 3,3<br />

•<br />

– 0,1 0 ÷ 5 ÷ 10<br />

COMPAC dial gauges IP54, protected against the penetration of liquids<br />

556E 0,001 5 5,3<br />

•<br />

– 0,2 0 ÷ 10 ÷ 20<br />

567E 0,001 1 3,3<br />

•<br />

– 0,1 0 ÷ 5 ÷ 10<br />

Permissible limits of a metrological characteristic (MPE/MPL)<br />

Deviation span<br />

Total deviation span<br />

Repeatability limit<br />

Max. hysteresis<br />

Measuring force<br />

– Models IP54<br />

1 mm 5 mm<br />

4 µm 12 µm<br />

5 µm 14 µm<br />

1 µm 2 µm<br />

1 µm 2 µm<br />

≤ 1,5 N<br />

≤ 1,5 N<br />

≤ 1,7 N<br />

≤ 1,7 N<br />

F-32

D IAL G AUGES<br />

✓<br />

EN ISO 463<br />

Fac<strong>to</strong>ry<br />

standard<br />

Precision Dial Gauges<br />

0,001 mm dial readout / 58 mm dial diameter<br />

0,001 mm<br />

0,8 mm<br />