REGENERATOR REACTOR HEAD Cutting T

REGENERATOR REACTOR HEAD Cutting T

REGENERATOR REACTOR HEAD Cutting T

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

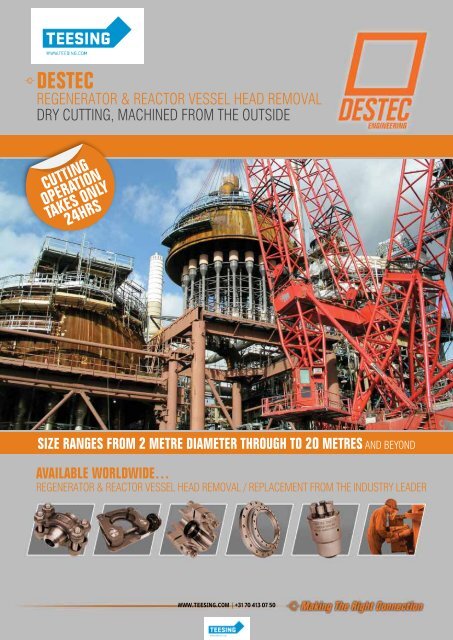

DESTEC PROCEDURE1. Bottom rail showingsecure welds2. Bottom rail with toprail mounting bracketsin position3. Rail positions and brackets 4. Rail positions showingnon-removable obstructions5. Top and bottom rails readyfor dressing6. ‘C’ plate brackets tackedover cut line area7. ‘C’ plate brackets fullywelded and settingmachine on the rail8. Initial cut 9. Finished prep showingrefractory wall10. <strong>Cutting</strong> the refractory11. Grinding frame 12. Re-gen head with‘C’ plates andwedges positioned13. Re-gen head with‘C’ plates andwedges fitted14. Prep completed.‘C’ plates andalignment plates fitted15. Re-gen head lift(Refractory lining of ceramic capable of resisting & maintaining high temperatures).WWW.TEESING.COM | +31 70 413 07 50www.destec.co.uk DESTEC <strong>REGENERATOR</strong> & <strong>REACTOR</strong> VESSEL <strong>HEAD</strong> REMOVAL 03

<strong>REGENERATOR</strong> / <strong>REACTOR</strong> VESSEL <strong>HEAD</strong> REMOVALUSER LISTClient SitePlantShutdownDateVessel DataShell <strong>Cutting</strong>MethodInternalRefractoryLiningRefractory <strong>Cutting</strong>MethodGeneral InformationMOBIL Coryton RefineryEngland, UKFebruary1996Diameter: 9.4 m.Wall Thickness: 26mm.Material: C.S.Type PM6Milling M/c.100mm thickElectric cutters withdiamond & abrasive disc.Head re-used. Angle prep.machined to top and bottom.BP Grangemouth RefineryScotland, UKSeptember1996Diameter: 8.4 m.Wall Thickness: 16mm.Material: C.S.Purpose built V8electric grinderCutter.Abrasive disc.125mm thickElectric cutters withabrasive disc.Head replaced with new one.Straight cut only.TOTAL Lindsey Oil RefineryEngland, UK(Mitsui Babcock)October1996Diameter: 8.3 m.Wall Thickness: 20mm.Material: C.S.Type PM7Milling M/c.125mm thickElectric cutters withdiamond & abrasive disc.Head re-used. Angle prep.machined to top and bottom.Netherlands Refinery Co.(NEREFCO / BP)Rotterdam, HollandMarch1998Diameter: 9.4 m.Wall Thickness: 22mm.Material: C.S.Type PM7Milling M/c.100mm thickAir power cutter withdiamond & abrasive disc.Head replaced with new one.Angle prep (10°) machined tobottom side only.Yambu RefineryArabian C.B.I.Saudi Arabia(ARAMCO)April1998Diameter: 13.6 m.Wall Thickness: 26mm.Material: C.S.Type PM8Milling M/c.100mm thickElectric cutters withdiamond & abrasive disc.Head re-used. Angle prep.machined to top and bottom.TEXACO Milford Haven RefineryWales, UK(Ledwood)September1999Diameter: 13.3 m.Wall Thickness: 28mm.Material: C.S.Type PM8Milling M/c.102mm thick(Gunite)Electric cutters withdiamond & abrasive disc.Head replaced with new one.Straight cut only.ESSO RefineryRotterdam, Holland(Stork)October1999Diameter: 11.5 m.Wall Thickness: 19mm.Material: C.S.Type PM8Milling M/c.127mm thick(3BF with S.S.needles)Electric and air cutterswith diamond andabrasive discs.Head replaced with new one.Straight cut only.CONOCO Humber RefineryEngland, UK(Mitsui Babcock)April2001Diameter: 8.1 m.Wall Thickness: 20mm.Material: C.S.Type PM8Milling M/c.100mm thickElectric cutters withdiamond & abrasive disc.Head replaced with new one.Angle prep (15°) machined tobottom side only.SHELL PernisRotterdam, HollandApril2002Diameter: 12.75 m.Wall Thickness: 25mm.Material: C.S.Type PM8Milling M/c.150mm thickElectric and air cutterswith diamond andabrasive discs.Head re-used. Preps machined15° bottom45° topNetherlands Refinery Co.(NEREFCO / BP)Rotterdam, HollandOctober2002Diameter: 9.4 m.Wall Thickness: 22mm.Material: C.S.Type PM8Milling M/c.100mm thickElectric cutters withdiamond & abrasive disc.Head re-used. Preps machined15° bottom45° topBP Coryton RefineryEngland, UKFebruary2005Diameter: 9.4 m.Wall Thickness: 26mm.Material: C.S.Type PM8Milling M/c.100mm thickAir powered cutters withdiamond & abrasivediscs.Head re-used. Angle prep machinedtop & bottom. Original rails re-usedas basis for new type tracks.TOTAL Lindsey Oil RefineryEngland, UK(Mitsui Babcock)September2005Diameter: 8.3 m.Wall Thickness: 20mm.Material: C.SType PM8Milling M/c.100mm thickElectric powered cutterswith diamond & abrasivediscs.Head replaced with new one.Angle prep (15°). Machined tobottom side only.ESSO Fawley RefineryEngland, UKOctober2006Diameter: 17 m.Wall Thickness: 22mm.Material: C.SType PM8Milling M/c.125mm thickElectric & Air poweredcutters with diamond &abrasive discs.Head replaced with new one.Angle prep (10°). Machined tobottom side only.STATOIL Mongstad RefineryNorway(Ledwood)September2008Diameter: 11.65 m.Wall Thickness 25mm Material:C.S.Type PM8Milling M/c.100mm thickElectric & Air poweredcutters with diamond &abrasive discs.Head replaced with new one.Angle prep (10°) Machined tobottom side only.ESSO Italiana Augusta RefinerySicilyMarch2009Diameter: 6.93 m.Wall Thickness: 11mm.Material: C.S.Type PM8Milling M/c.102mm thickElectric & Air poweredcutters with diamond &abrasive discs.Head re-used. Angle prep machinedtop & bottom. Original rails re-usedas basis for new type tracks.PETROPLUS Coryton RefineryEngland, UK(Vessels & columns only)October2009Diameter: 1 m - 4 m.Wall Thickness: 20mm - 43mm.Material: C.S.Type PM8 & RingMilling M/c.25mm Hexmesh100mm RescoElectric powered cutterswith diamond & abrasivediscs.Variety of straight cut only andsingle angle weld preps machinedas required.EXXON MOBILRotterdam, Holland(ERMO GmbH)January2010Diameter: 11.5 m.Wall Thickness: 22mm.Material: C.SType PM8Milling M/c.127mm thickElectric & Air poweredcutters with diamond &abrasive discs.Reactor vessel head reused.Preps machined 15° bottom45° top.NOTE: In most cases the overhead lines were also cut by Destec Engineering LtdMaterial: C.S - Carbon SteelPM6/7/8 - Portable Milling MachinesWWW.TEESING.COM | +31 70 413 07 50