Transactions

Transactions

Transactions

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

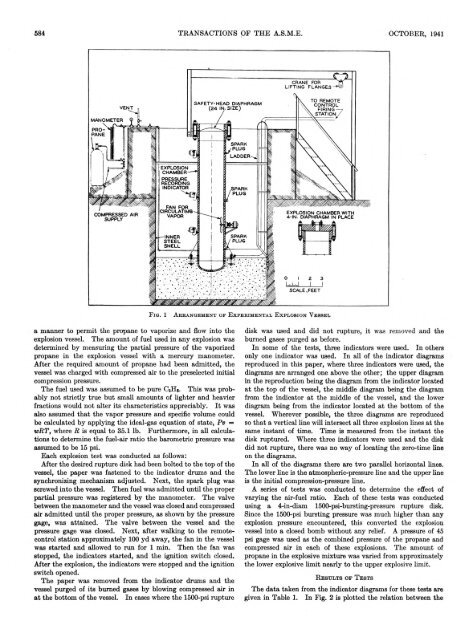

584 TRANSACTIONS OF THE A.S.M.E. OCTOBER, 1941F ig . 1A r r a n g e m e n t o f E x p e r im e n t a l E x p l o s io n V e s s e la manner to permit the propane to vaporize and flow into theexplosion vessel. The amount of fuel used in any explosion wasdetermined by measuring the partial pressure of the vaporizedpropane in the explosion vessel with a mercury manometer.After the required amount of propane had been admitted, thevessel was charged with compressed air to the preselected initialcompression pressure.The fuel used was assumed to be pure C8H8. This was probablynot strictly true but small amounts of lighter and heavierfractions would not alter its characteristics appreciably. It wasalso assumed that the vapor pressure and specific volume couldbe calculated by applying the ideal-gas equation of state, Pv —wRT, where R is equal to 35.1 lb. Furthermore, in all calculationsto determine the fuel-air ratio the barometric pressure wasassumed to be 15 psi.Each explosion test was conducted as follows:After the desired rupture disk had been bolted to the top of thevessel, the paper was fastened to the indicator drums and thesynchronizing mechanism adjusted. Next, the spark plug wasscrewed into the vessel. Then fuel was admitted until the properpartial pressure was registered by the manometer. The valvebetween the manometer and the vessel was closed and compressedair admitted until the proper pressure, as shown by the pressuregage, was attained. The valve between the vessel and thepressure gage was closed. Next, after walking to the remotecontrolstation approximately 100 yd away, the fan in the vesselwas started and allowed to run for 1 min. Then the fan wasstopped, the indicators started, and the ignition switch closed.After the explosion, the indicators were stopped and the ignitionswitch opened.The paper was removed from the indicator drums and thevessel purged of its burned gases by blowing compressed air inat the bottom of the vessel. In cases where the 1500-psi rupturedisk was used and did not rupture, it was removed and theburned gases purged as before.In some of the tests, three indicators were used. In othersonly one indicator was used. In all of the indicator diagramsreproduced in this paper, where three indicators were used, thediagrams are arranged one above the other; the upper diagramin the reproduction being the diagram from the indicator locatedat the top of the vessel, the middle diagram being the diagramfrom the indicator at the middle of the vessel, and the lowerdiagram being from the indicator located at the bottom of thevessel. Wherever possible, the three diagrams are reproducedso that a vertical line will intersect all three explosion lines at thesame instant of time. Time is measured from the instant thedisk ruptured. Where three indicators were used and the diskdid not rupture, there was no way of locating the zero-time lineon the diagrams.In all of the diagrams there are two parallel horizontal lines.The lower fine is the atmospheric-pressure line and the upper lineis the initial compression-pressure line.A series of tests was conducted to determine the effect ofvarying the air-fuel ratio. Each of these tests was conductedusing a 4-in-diam 1500-psi-bursting-pressure rupture disk.Since the 1500-psi bursting pressure was much higher than anyexplosion pressure encountered, this converted the explosionvessel into a closed bomb without any relief. A pressure of 45psi gage was used as the combined pressure of the propane andcompressed air in each of these explosions. The amount ofpropane in the explosive mixture was varied from approximatelythe lower explosive limit nearly to the upper explosive limit.R e s u l t s o f T e s t sThe data taken from the indicator diagrams for these tests aregiven in Table 1. In Fig. 2 is plotted the relation between the