2007 Issue 2 - Raytheon

2007 Issue 2 - Raytheon

2007 Issue 2 - Raytheon

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

R F S Y S T E M S<br />

Continued from page 27<br />

completed, affirming <strong>Raytheon</strong>’s leadership<br />

position in the development of this technology.<br />

This testing was done at elevated temperatures<br />

and operating conditions to simulate<br />

performance over a much longer period<br />

of time. Three temperature DC Arrhenius<br />

tests of <strong>Raytheon</strong>’s 28V GaN have also been<br />

completed, and the results predict a mean<br />

time to failure (MTTF) of greater than 1 million<br />

hours at a standard transistor channel<br />

temperature of 150 Celsius. These test<br />

results have given <strong>Raytheon</strong> customers confidence<br />

in the use of <strong>Raytheon</strong>’s GaN for<br />

future defense systems.<br />

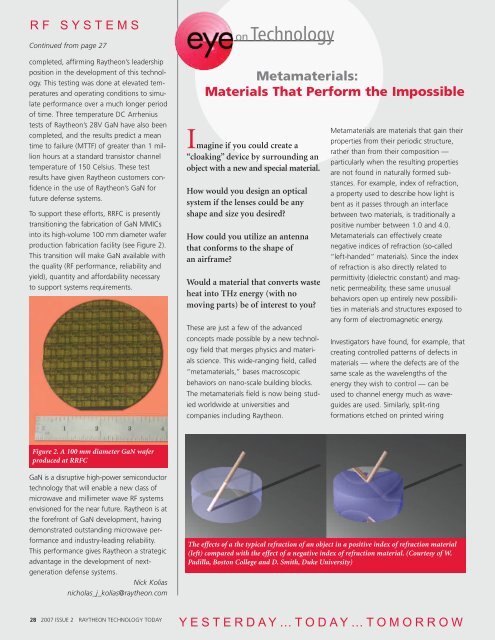

To support these efforts, RRFC is presently<br />

transitioning the fabrication of GaN MMICs<br />

into its high-volume 100 mm diameter wafer<br />

production fabrication facility (see Figure 2).<br />

This transition will make GaN available with<br />

the quality (RF performance, reliability and<br />

yield), quantity and affordability necessary<br />

to support systems requirements.<br />

Figure 2. A 100 mm diameter GaN wafer<br />

produced at RRFC<br />

GaN is a disruptive high-power semiconductor<br />

technology that will enable a new class of<br />

microwave and millimeter wave RF systems<br />

envisioned for the near future. <strong>Raytheon</strong> is at<br />

the forefront of GaN development, having<br />

demonstrated outstanding microwave performance<br />

and industry-leading reliability.<br />

This performance gives <strong>Raytheon</strong> a strategic<br />

advantage in the development of nextgeneration<br />

defense systems.<br />

Nick Kolias<br />

nicholas_j_kolias@raytheon.com<br />

28 <strong>2007</strong> ISSUE 2 RAYTHEON TECHNOLOGY TODAY<br />

onTechnology<br />

Metamaterials:<br />

Materials That Perform the Impossible<br />

Imagine if you could create a<br />

“cloaking” device by surrounding an<br />

object with a new and special material.<br />

How would you design an optical<br />

system if the lenses could be any<br />

shape and size you desired?<br />

How could you utilize an antenna<br />

that conforms to the shape of<br />

an airframe?<br />

Would a material that converts waste<br />

heat into THz energy (with no<br />

moving parts) be of interest to you?<br />

These are just a few of the advanced<br />

concepts made possible by a new technology<br />

field that merges physics and materials<br />

science. This wide-ranging field, called<br />

“metamaterials,” bases macroscopic<br />

behaviors on nano-scale building blocks.<br />

The metamaterials field is now being studied<br />

worldwide at universities and<br />

companies including <strong>Raytheon</strong>.<br />

Metamaterials are materials that gain their<br />

properties from their periodic structure,<br />

rather than from their composition —<br />

particularly when the resulting properties<br />

are not found in naturally formed substances.<br />

For example, index of refraction,<br />

a property used to describe how light is<br />

bent as it passes through an interface<br />

between two materials, is traditionally a<br />

positive number between 1.0 and 4.0.<br />

Metamaterials can effectively create<br />

negative indices of refraction (so-called<br />

“left-handed” materials). Since the index<br />

of refraction is also directly related to<br />

permittivity (dielectric constant) and magnetic<br />

permeability, these same unusual<br />

behaviors open up entirely new possibilities<br />

in materials and structures exposed to<br />

any form of electromagnetic energy.<br />

Investigators have found, for example, that<br />

creating controlled patterns of defects in<br />

materials — where the defects are of the<br />

same scale as the wavelengths of the<br />

energy they wish to control — can be<br />

used to channel energy much as waveguides<br />

are used. Similarly, split-ring<br />

formations etched on printed wiring<br />

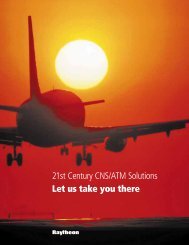

The effects of a the typical refraction of an object in a positive index of refraction material<br />

(left) compared with the effect of a negative index of refraction material. (Courtesy of W.<br />

Padilla, Boston College and D. Smith, Duke University)<br />

Y E S T E R D A Y … T O D A Y … T O M O R R O W