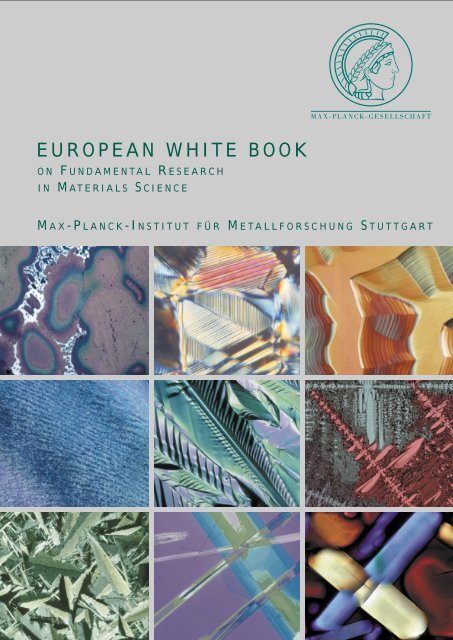

EUROPEAN WHITE BOOK

EUROPEAN WHITE BOOK

EUROPEAN WHITE BOOK

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>EUROPEAN</strong> <strong>WHITE</strong> <strong>BOOK</strong>ON F UNDAMENTAL R ESEARCHIN M ATERIALS S CIENCEM AX-PLANCK-INSTITUT FÜR M ETALLFORSCHUNG S TUTTGART

CONTENTS | PREFACE | EXECUTIVE SUMMARY | INTRODUCTION 41. MATERIALS: SCIENCE AND ENGINEERING 182. MATERIALS: SCIENCE AND APPLICATION 683. INNOVATION IN MATERIALS SCIENCE BYNEW INTERDISCIPLINARY APPROACHES 1144. MATERIALS THEORY AND MODELLING 1265. MATERIALS PHENOMENA 1506. MATERIALS SYNTHESIS AND PROCESSING 1947. ADVANCED ANALYSIS OF MATERIALS 2348. MATERIALS SCIENCE IN EUROPE 2689. MATERIALS SCIENCE AND BASIC RESEARCH IN EUROPE:CONCLUSIONS AND RECOMMENDATIONS 288APPENDICES I TO V 310

MAX-PLANCK-INSTITUT FÜR METALLFORSCHUNG STUTTGART44810161921263237485155576367<strong>EUROPEAN</strong> <strong>WHITE</strong> <strong>BOOK</strong>ON FUNDAMENTAL RESEARCH IN MATERIALS SCIENCEContentsPrefaceG. Wegner, Vice President, Max-Planck-Gesellschaft, München, GermanyExecutive SummaryM. Rühle, H. Dosch, E. Mittemeijer, M.H. Van de Voorde, Max-Planck-Institut für Metallforschung, Stuttgart, GermanyIntroductionM. Rühle, Max-Planck-Institut für Metallforschung, Stuttgart, Germany1. MATERIALS: SCIENCE AND ENGINEERINGIntroduction1.1. Metals and Composites: Basis for Growth, Safety, and EcologyD. Raabe, Max-Planck-Institut für Eisenforschung GmbH, Düsseldorf, Germany1.2. Advanced Ceramic Materials: Basic Research ViewpointF. Aldinger, Max-Planck-Institut für Metallforschung, Stuttgart, GermanyJ.F. Baumard, ENSCI, Limoges, France1.3. Advanced Ceramic Materials: Summary of Possible ApplicationsG. Fantozzi, D. Rouby, J. Chevalier, P. Reynaud, GEMPPM, INSA de LYON, Lyon, France1.4. Inorganic MaterialsJ. Etourneau, I.C.M.C.B., Université de Bourdeaux, Pessac, France1.5. Soft Materials and Polymers: The Rise and Decline of Polymer Science & Technology in EuropeP. Lemstra, Faculteit Scheikundige Technologie, Technische Universiteit Eindhoven, The Netherlands1.6. Soft Materials and Polymers: Strategies for Future Areas of Basic Materials ScienceG. Wegner, Max-Planck-Institut für Polymerforschung, Mainz, Germany1.7. Carbon MaterialsR. Schlögl, Fritz-Haber-Institut der Max-Planck-Gesellschaft, Berlin, GermanyP. Scharff, Institut für Physik, Technische Universität Ilmenau, Thüringen, Germany1.8. Electronic and Photonic MaterialsA.Trampert and K.H. Ploog, Paul-Drude-Institut für Festkörperelektronik, Berlin, Germany1.9. Nanotechnology and Semiconducting MaterialsM. Lannoo, ISEM, Maison des Technologies, Toulon, FranceConclusions6970727678822. MATERIALS: SCIENCE AND APPLICATIONIntroduction2.1. Biomaterials: EvolutionN. Nakabayashi and Y. Iwasaki, Tokyo Medical and Dental University, Kanda, Tokyo, Japan2.2. Biomaterials: Research and DevelopmentW. Bonfield, Department of Materials Science & Metallurgy, University of Cambridge, Cambridge, United Kingdom2.3. Biomaterials: Medical ViewpointL. Sedel, Hôpital Lariboisière, Université Paris, Paris, France2.4. Biomimetic Materials and Transport SystemsR. Lipowsky, Max-Planck-Institut für Kolloid- und Grenzflächenforschung, Golm bei Potsdam, Germany2.5. Materials Science in CatalysisF. Schüth, Max-Planck-Institut für Kohlenforschung, Mülheim an der Ruhr, GermanyR. Schlögl, Fritz-Haber-Institut der Max-Planck-Gesellschaft, Berlin, Germany

8892971001042.6. Optical Properties of Materials: “Harnessing” Light through Novel MaterialsP. Chavel, Laboratoire Charles Fabry de l’Institut d’Optique, Université Paris-Sud, Paris, France2.7. Magnetic MaterialsH. Kronmüller, Max-Planck-Institut für Metallforschung, Stuttgart, GermanyJ.M.D. Coey, Department of Physics, Trinity College, Dublin, Ireland2.8. Superconducting MaterialsR. Flükiger, Département Physique de la Matière Condensée, Université Genève, Genève, Switzerland2.9. Materials for FusionH. Bolt, Max-Planck-Institut für Plasmaphysik, Garching bei München, Germany2.10. Materials for TransportationC.R. and W.E. Owens, UniStates Technology Corporation, Medford, Massachusetts, United States1091122.11. Materials Science in SpaceP. R. Sahm, Institut für Giesserei , RWTH Aachen, GermanyG. Zimmermann, ACCESS e.V., Aachen, GermanyConclusionsCONTENTS1151171171181191211221231241241243. MATERIALS – INNOVATION IN MATERIALS SCIENCE BYNEW INTERDISCIPLINARY APPROACHESY. Bréchet, ENSEEG/INP-Grenoble, Saint Martin d’Heres, FranceW. Pompe, Institut für Werkstoffwissenschaften, Technische Universität Dresden, Dresden, GermanyM. Van Rossum, Advanced Semiconductor Processing Division, IMEC, Louvain, BelgiumIntroduction3.1. Present State of Materials Science3.2. Multidisciplinarity in Materials Science3.3. Obvious Needs for New Ideas3.4. Important Topics in Scaling of Materials3.5. Learning from “Mother Nature”3.6. Option for a New Interdisciplinary Approach3.7. Molecular Bioengineering – a New Challenge for Materials Scientists3.8. Expectations for the Near Future3.9. Actions that have to be UndertakenConclusions51271291341381441484. MATERIALS THEORY AND MODELLINGIntroduction4.1. Predictive Modelling of MaterialsA.M. Stoneham, Centre for Materials Research, University College London, London, United Kingdom4.2. From Basic Principles to Computer Aided DesignK. Kremer, Max-Planck-Institut für Polymerforschung, Mainz, Germany4.3. Theory, Simulation and Design of Advanced Ceramics and CompositesC. A. J. Fisher, Japan Fine Ceramics Centre, Nagoya, Japan4.4. Modelling Strategies for Nano- and BiomaterialsH. Gao, Max-Planck-Institut für Metallforschung, Stuttgart, GermanyConclusions1501535. MATERIALS PHENOMENAIntroduction5.1. Thermochemistry of MaterialsF. Aldinger, Max-Planck-Institut für Metallforschung, Stuttgart, GermanyJ. Ågren, Materials Science & Engineering, Royal Institute of Technology, Stockholm, SwedenR. Ferro, Dipartimento di Chimica, Università di Genova, Genova, ItalyG. Effenberg, MSI, Materials Science International Services GmbH, Stuttgart, Germany

MAX-PLANCK-INSTITUT FÜR METALLFORSCHUNG STUTTGART1581611661761801831875.2. Phase TransformationsE. Mittemeijer, F. Sommer, Max-Planck-Institut für Metallforschung, Stuttgart, Germany5.3. Interface ScienceR. C. Pond, Department of Materials Science & Engineering, University of Liverpool, Liverpool, United Kingdom5.4. NanomaterialsG. J. Davies, Faculty of Engineering, University of Birmingham, Birmingham, United KingdomO. Saxl, The Institute of Nanotechnology, Stirling, Scotland, United Kingdom5.5. Small-Scale Materials and StructuresE. Arzt, P. Gumbsch, Max-Planck-Institut für Metallforschung, Stuttgart, Germany5.6. Colloid Physics and ChemistryM. Antonietti, H. Möhwald, Max-Planck-Institut für Kolloid- u. Grenzflächenforschung, Golm b. Potsdam, Germany5.7. Mechanical Properties of Metals and CompositesP. Van Houtte, Faculty of Applied Sciences, Catholic University of Louvain, Louvain, Belgium5.8. Electronic Structure and CorrelationJ. Kirschner, U. Hillebrecht, Max-Planck-Institut für Mikrostrukturphysik, Halle/Saale, GermanyM. von Löhneysen, Physikalisches Institut, Universität Karlsruhe, Karlsruhe, Germany6192Conclusions1951962012042072102132162192232282326. MATERIALS SYNTHESIS AND PROCESSINGIntroduction6.1. Thin Film ScienceT. Wagner, Max-Planck-Institut für Metallforschung, Stuttgart, Germany6.2. Synthesis and Processing of Inorganic MaterialsJ. Etourneau, I.C.M.C.B., Université de Bordeaux, Pessac, FranceA. Fuertes, Instituto de Ciencia de Materiales, CSIC, Bellaterra-Barcelona, SpainM. Jansen, Max-Planck-Institut für Festkörperforschung, Stuttgart, Germany6.3. Synthesis/Processing of Ceramics and Composite MaterialsT. Chartier, ENSCI, Limoges, France6.4. Synthesis of Polymeric MaterialsP. Lutz, Institut Charles Sadron, Strasbourg, France6.5. Metal-Matrix Composites: Challenges and OpportunitiesA. Mortensen, Swiss Federal Institute of Technology, Lausanne, SwitzerlandT. W. Clyne, Materials Science and Metallurgy Department, University of Cambridge, Cambridge, United Kingdom6.6. Ceramic Matrix CompositesR. Naslain, Laboratoire des Composites Thermo-Structuraux, Université de Bordeaux, Pessac, France6.7. Polymeric Composite MaterialsM. Giordano, S. Iannace, L. Nicolais, Ingegneria die Materialie, Università ”Federico II”, Naples, Italy6.8. Electronic SystemsP. S. Peercy, University of Wisconsin, Madison, Wisconsin, United States6.9. Photonic SystemsP. S. Peercy, University of Wisconsin, Madison, Wisconsin, United States6.10. EcomaterialsK. Yagi, S. Halada, National Institute for Materials Science, Tsukuba, Ibaraki, JapanConclusions

7. ADVANCED ANALYSIS OF MATERIALS235238243Introduction7.1. X-Rays (Synchrotron Radiation)J. Schneider, DESY-HASYLAB, Hamburg, GermanyG. Kaindl, Institut für Experimentalphysik, Freie Universität Berlin, Berlin, GermanyC. Kunz, European Synchrotron Radiation Facility, Grenoble, FranceH. Dosch, Max-Planck-Institut für Metallforschung, Stuttgart, GermanyD. Louër, Laboratoire de Chimie du Solide, Université de Rennes, Rennes, FranceE. Mittemeijer, Max-Planck-Institut für Metallforschung, Stuttgart, Germany7.2. NeutronsD. Richter, Institut für Festkörperforschung, Forschungszentrum Jülich GmbH, Jülich, GermanyK.N. Clausen, Risø National Laboratories, Roskilde, DenmarkH. Dosch, Max-Planck-Institut für Metallforschung, Stuttgart, Germany2472532577.3. High-Resolution MicroscopyM. Rühle, Max-Planck-Institut für Metallforschung, Stuttgart, GermanyK. Urban, Institut für Festkörperforschung, Forschungszentrum Jülich GmbH, Jülich, Germany7.4. Surface Science and Scanning Probe MicroscopyD.A. Bonnell, University of Pennsylvania, Philadelphia, Pennsylvania, United StatesM. Rühle, Max-Planck-Institut für Metallforschung, Stuttgart, Germany7.5. Three-Dimensional Atom ProbeG.D.W. Smith, Department of Materials, Oxford University, United KingdomM. Rühle, Max-Planck-Institut für Metallforschung, Stuttgart, GermanyCONTENTS72592632667.6. Laser SpectroscopyTh. Elsässer, Max-Born-Institut für Nichtlineare Optik und Spektroskopie, Berlin, Germany7.7. NMR SpectroscopyH.W. Spiess, Max-Planck-Institut für Polymerforschung, Mainz, GermanyConclusions2692702722742762782832842842858. MATERIALS SCIENCE IN EUROPEH. Dosch, M.H. Van de Voorde, Max-Planck-Institut für Metallforschung, Stuttgart, Germany8.1. The Importance of Materials8.2. The Role of Basic Materials Science8.3. Social Acceptance of Basic Research8.4. The Interdisciplinarity Challenge8.5. New Schemes for Education, Research Careers and Researcher Mobility8.6. European Centres and Facilities for Materials Science8.7. New Strategies for European Research/Projects and Project Management8.8. Relations between Academia and Industry8.9. International CollaborationAnnex 1 A European Network of Excellence in CatalysisR. Schlögl, Fritz-Haber-Institut der Max-Planck-Gesellschaft, Berlin, Germany9. MATERIALS SCIENCE AND BASIC RESEARCH IN EUROPE:CONCLUSIONS AND RECOMMENDATIONS289291296306307309H. Dosch, M.H. Van de Voorde, Max-Planck-Institut für Metallforschung, Stuttgart, GermanyIntroduction9.1. Materials Phenomena and Techniques9.2. Materials Systems9.3. Materials Interdisciplinarity9.4. New Research Strategies and Infrastructures in Europe9.5. Closing Remarks

MAX-PLANCK-INSTITUT FÜR METALLFORSCHUNG STUTTGARTP REFACE8Because we live in a knowledge-based andinformation-driven society, Europeans arefaced with the challenge of globalization.This affects European industry, economy,and academia on many levels. However, the productionof new knowledge and know-how is no longer the privilegeof only a few nations. We see a world-wide competitionto establish and promote the very best centres ofexcellence in fields where basic insights and the creationof new knowledge produce emerging technologies. In anattempt to gain global leadership, major companies seekto develop close collaborations with these centres acrosspolitical borders. Unfortunately, in the process they almostcompletely neglect old and established ties to their respectivenational academic research systems.Academic research institutions of the individual Europeanmember states have significantly contributed to thepresent success of advanced technologies and the healthycompetitive atmosphere of European Union (EU) industries.However, these institutions and individual centres,which are traditionally supported by national resources,are too small to maintain leadership in the light of the stiffcompetition from North America, East Asia, and otheremerging parts of the world. In the spirit of Europeancooperation it is therefore absolutely necessary to enhancethe creativity and efficiency of the output of research bycombining the efforts of the very best research centres ofthe EU member states, particularly in fields where basicresearch is expected to create or enhance new opportunitiesfor EU industries. By doing this, we will secure thequality of life in these member states.To promote industrial growth, a vibrant economy, andsocial welfare, Europe must be among the world’s leadersin all fields of materials science and engineering research.That goal is certainly achievable. Innovations in materialsscience abound in nearly all arenas of modern Europeansociety, including environment, energy, agriculture,health, information and communication, infrastructureand construction, and transportation.The future promises equally dramatic advances, makingmaterials science a unique and exciting area of great scientificresearch, with far-reaching industrial, economic, andsocietal impact. We will see “intelligent” materials thatwill enable diverse technologies to respond dynamicallyto changes in the environment. New materials will be synthesizedatom by atom. Indeed, the number of possiblecombinations of atomic assemblies to achieve new structuresand properties is seemingly endless, and thismechanistic understanding will provide powerful toolsfor materials and process development. Quite simply,basic research is the most important research investmenta country can make.The exploitation of these possibilities requires thattalented researchers work in multidisciplinary teams thatbring together scientists in materials science, physics,chemistry, biology, mathematics, informatics, and engineering.Capital-intensive, large-scale research instrumentationwill be required to characterize new materialsfrom their smallest constituents at all scales of assemblyto sophisticated equipment for synthesis, processing, andanalysis. Computational research and engineering will

PREFACE9increasingly make use of supercomputers and computernetworks. Research in materials science and engineeringis capital intensive and its success will depend on internationalcollaboration.In Europe, the knowledge and expertise in basic materialsscience is scattered among various research institutions.Thus, the crucial synergistic effect between universitiesand research institutes of various countries is partlylost and the European materials science potential hasnot been fully realized. A new European policy is neededfor long-term basic materials research. In this respect,the intentions of the European Commission to promotethe basic science research landscape in Europe in thenext 6th Framework Programme (2002 – 2006) are veryrefreshing and beneficial to Europe’s future economy andsocial welfare.The field of materials science has great challenges andis of the utmost importance for Europe; therefore, actionis urgent and necessary. It is within this context that theMax Planck Society, Germany’s primary basic researchorganization, has as many as seven different institutesworking in materials science and appropriates 13 percentof its total budget for materials science, almost as muchas its spends on astronomy and even more than it spendson physics. This demonstrates the importance of materialsscience within the context of the different disciplines.It also reveals the high expectations of the scientificcommunity and of the supporting political forces for aconstant stream of innovation coming from the researchon materials.In this light, the Max Planck Society, together with a largenumber of leading materials scientists in Europe and incollaboration with the European Commission’s ResearchArea, has taken the initiative to prepare the present EuropeanMaterials White Book. It is an assessment of basicresearch in materials science worldwide, highlightingfuture directions and pinpointing research priorities forEurope. Examples of the societal impact of the field aregiven, and topics such as materials education, researchcareers, and the role of the civic scientist are discussed.It is our firm conviction that the European researchcentres, if they join forces, are ready to gain world-wideleadership to the benefit of all of Europe.Gerhard WegnerVice-President of the Max Planck SocietyDirector, Max-Planck-Institut für Polymerforschung MainzProfessor, University of Mainz

MAX-PLANCK-INSTITUT FÜR METALLFORSCHUNG STUTTGARTE XECUTIVE SUMMARYManfred Rühle | Helmut Dosch | Eric J. Mittemeijer | Marcel H. Van de VoordeMax-Planck-Institut für Metallforschung, Stuttgart10IIn the year 2000, the Max-Planck-Institut fürMetallforschung in Stuttgart, in conjunction withother materials-related institutes of the MaxPlanck Society, and institutes and universities fromall over Europe, decided to prepare a White Book on thetopic of “Strategies for Future Areas of Materials Scienceand Basic Research in Europe.” The aims of the studieswere:1. To assess the state of the art and pinpoint future challenges,needs, and research priorities,2. To highlight the fundamental scientific opportunitiesin this field,3. To consider the impact of materials science on society,and vice versa,4. To find the best ways of attracting more students tothe field and ensure high-quality education,5. To provide guidelines for science policy makers and tooffer a basis for fundamental materials science programmesin Europe.Preparation of this White Book has involved extensive consultationwith leading materials scientists, primarily withinEurope (most notably from the CNRS in France and theMPG in Germany), but also from the United States andJapan. Discussions were also undertaken with industrialresearch directors and relevant policy makers.Materials science can be defined roughly as “the study ofsubstances from which something else is made or can bemade; the synthesis, properties, and applications of thesesubstances.” This definition covers both natural andsynthetic, traditional and advanced materials. For the purposesof this book, however, the discussion is confined tothose materials that form the basis of modern, futuristichigh technology. These advanced materials include steelsand other metallic alloys; superalloys; polymers; carbonmaterials; optical, electronic, and magnetic materials;superconductors; technical ceramics; composites; andbiomaterials. All of these, and others, are discussed in thisbook in terms of:1. Synthesis and processing to arrange the atoms andlarger-scale components of a system into the desiredconfiguration,2. Composition and microstructure to understand theroles they play in determining the behaviour of materials,3. Phenomena and properties to reveal underlying mechanisms,4. Performance to assess suitability for a given application,5. Materials design and lifetime prediction by theoreticaland computational methods.

The Importance of Materials for Modern TechnologyMaterials science plays a pivotal role in determining andimproving economic performance and the quality of life,particularly in the following areas:Living Environment: Because of pressing environmentalconcerns more efficient use of material and energy resourcesis urgently required. Materials science is helping todevelop new energy generation technologies, more energyefficientdevices, and easily recyclable, less toxic materials.Health: Overcoming disease and providing worldwide medicalcare are high priorities. Materials science, in conjunctionwith biotechnology, can meet this challenge by, e.g.,developing artificial bones and organ implants, safe drugdelivery systems, water filtration systems, etc.Communication: The increasing interconnectedness of ourworld requires faster and more reliable means of communication.The information and associated computerrevolutions closely depend on advances made by scientistsworking on new electronic, optical, and magnetic materials.Consumer Goods: Consumers have come to expect globalproducts/services that are delivered rapidly at reasonableprices. Materials science can improve not only the productsbut also the way they are handled (e.g., packaging),resulting in faster production and delivery times and higherquality goods.Transport: Whether for business, holidays, or space exploration,materials science is needed to provide durable,high-performance materials that make travelling faster,safer, and more comfortable. Examples are the developmentof light-weight aluminium bodies for automobiles,brake systems for high-speed trains, quieter aircrafts, andinsulation tiles for re-entry spacecrafts.EXECUTIVE SUMMARY11Challenges for Basic Research in Materials ScienceSeveral challenges face materials science at the beginningof the 21 st Century. The first is to convince industry,the public, and politicians of the importance of materialsscience in driving modern technological development. Asthere is often a considerable time lag between a scientificdiscovery and its useful application, people can forget thelink that connects fundamental research and future prosperity.Without continued investment in the science base,however, the discoveries of today-and the highly trainedexperts necessary to develop and exploit them-will not beavailable for the innovative products of tomorrow.In the field of materials science, the barriers that divideacademia, government institutions, and industry must bereduced if not completely eliminated. Only in this waywill it be possible to turn fundamental discoveries intopractical applications for the benefit of Europe. Fosteringlinks between researchers, theoreticians, industrial scientists,and managers through collaborative schemes andjoint research institutes is an obvious solution, but manyimportant issues can arise. For example, how can we betterprotect intellectual property rights, and who gets todictate the research agenda? It is also important that professionaladvice on such areas as how to attract investmentfor joint ventures and how to set up spin-off companiesto exploit the results of fundamental research bemade available to public sector scientists.Future Directions and Research PrioritiesGreater emphasis needs to be placed on the fundamentalunderstanding of materials rather than on applied scienceand product development. Naturally, application of materialsis the ultimate goal, but this needs to be built on afirm theoretical basis so that improvements can be mademore efficiently and reliably. Particular attention shouldbe given to understanding a material’s behaviour from theatomic/nano-level via microstructure to macrostructurelevels using advanced analytical techniques and computermodelling. This strategy applies to both the improvementof conventional “bulk” materials, such as steel, andto new functional materials for increasingly smaller,“smarter” devices. As shown in this report, Europe has thecapabilities to provide that fundamental understanding.Materials by DesignIn the past, the search for new and improved materialswas characterized mostly by the use of empirical, trialand-errormethods. This picture of materials science has

MAX-PLANCK-INSTITUT FÜR METALLFORSCHUNG STUTTGART12been changing as the knowledge and understanding offundamental processes governing a material’s propertiesand performance (namely, composition, structure, history,and environment) have increased. In a number of cases,it is now possible to predict a material’s properties beforeit has even been manufactured thus greatly reducing thetime spent on testing and development.The objective of modern materials science is to tailor amaterial (starting with its chemical composition, constituentphases, and microstructure) in order to obtain adesired set of properties suitable for a given application.In the short term, the traditional “empirical” methods fordeveloping new materials will be complemented to a greaterdegree by theoretical predictions. In some areas, computersimulation is already used by industry to weed outcostly or improbable synthesis routes. Greater Europeancollaboration is required to develop computational tool formaterials and processing development and for propertyevaluation in a “virtual” environment.NanomaterialsThe ability to control, manipulate, and design materialson the nanometre scale (10 -9 m) will be one of the majortechnology drivers of the 21 st Century. Many research programmes,both in academia and industry, have sprung uparound the world over the last few years in an intense effortto harness the potential of these materials for generatingnew functionalities, minimizing waste and pollution,and optimizing properties and performance. Nanomaterialsare being developed from almost every type ofmaterial-including polymers, metals, ceramics, composites,and biomaterials. While not confined to any particularmaterials class or system, nanomaterials, along withthe closely associated fields of smart materials and biomimeticmaterials, are united by the use of a “materials bydesign” philosophy in their creation. Some of the manyassorted applications that are likely to be seen in the futureinclude ultraprecise drug-delivery systems, nanobotsfor micromanufacturing, nanoelectronics, ultraselectivemolecular sieves, and nanocomposites for aircraft andother high-performance vehicles.Smart MaterialsOne area of research that will revolutionize our conceptof synthetic materials, as well as how we interact with oursurroundings, are “smart” (or “intelligent”) materials. Unlikenormal, inert materials, smart materials are designedto respond to external stimuli, adapting to their environmentin order to boost performance, extend their usefullifetimes, save energy, or simply adjust conditions to bemore comfortable for human beings. Materials will alsobe developed that are self-replicating, self-repairing, orself-destroying as required, thus reducing waste and increasingefficiency. Smart materials are being developedby combining regular materials from different classes(metals, ceramics, polymers, biomaterials) in complex architectures(e.g., fracture-sensing composites and artificialmuscles). Combined with technologies for manufacturingand controlling structures on the atomic scale(nanomaterials) and mimicking biological systems (biomimetics),the possibilities for newer and better materialsseem almost endless.Biomimetic MaterialsThe rapidly emerging field of biomimetic materials willform one of the most important technologies of the 21 stCentury. Biomimetic materials seek to replicate or mimicbiological processes and materials, both inorganic and organic(e.g., synthetic spider silk, DNA chips, and nanocrystalgrowth within virus cages). Better understandingof how living organisms produce minerals and compositeswill open up new areas of research and applications. Materialswill be able to be fabricated much more preciselyand efficiently, resulting in new functionalities and increasedperformance (e.g., self-repairing, ultrahard, andultralight composites for aircraft). To develop these materials,we will need new chemical strategies that combineself-assembly with the ability to form hierarchically structuredmaterials.Synthesis and ProcessingThe goal of future synthesis and processing techniques isto allow scientists to construct tailor-made materials fromcomplex arrangements of atoms and molecules with thesame precision and control as currently used for manufacturingsemiconductors. Promising synthesis techniquesdescribed in this report include chemical processingfrom simple precursor units, soft solution processing,rapid prototyping of ceramic and metallic components usingink-jet technology, microwave sintering, gas-phasemethods such as chemical and physical vapour deposition(CVD-PVD) for forming thin films, composite infiltration,and many more.Computational Materials ScienceComputer modelling, using supercomputers, heavy-dutyworkstations, and personal computers, will be an indispensabletool for basic and applied materials science inthe future. It is already an important tool in many areas ofscience and engineering, including drug design, climateprediction, aeronautics, and even personnel training!Considerable progress has been made over the last 20years in the simulation of properties and the processing ofmetals, polymers, and ceramics having increasing complexity.Computational strategies are emerging that pro-

vide physical and chemical descriptions of materials overlarger length and time scales. One of the “hot topics” incomputational materials science today is multiscalemodelling, which aims to cover several length and timescales with one consistent simulation framework.Advanced Analytical TechniquesMaterials scientists will require new and more powerfulanalytical techniques so that they can continue the discoveryof new phenomena and develop improved materialsfor the future. Techniques such as high-resolutiontransmission electron microscopy, scanning probe microscopy,X-ray and neutron diffraction, and various kinds ofspectroscopy allow us to examine materials on the atomiclevel. These techniques need to be developed, improved,and extended further by integrating them with morepowerful computers for rapid visualization of data andcomparison with computer models. These techniqueshave an particular importance in the area of materialssynthesis, where they can also be used for manipulatingand controlling materials on the atomic and nano levels,as in atomic force microscopy.EXECUTIVE SUMMARYMaterials Science, Society, and Research Infrastructure in Europe13The development of new materials and their applicationswill eventually affect everyone, not just those in industry,business, or the academic sphere. At this time, when science,technology and society are all rapidly changing, wemust not only consider how materials science affects societybut also the ways in which society affects the developmentof materials science.Social Acceptance of Materials ScienceThere is a need for an improved public understanding ofall forms of science, particularly of a low-profile disciplinesuch as materials science. The materials science communitymust therefore be more effective in communicatingto the public the manifold benefits it brings. Society investsin research not only for the sake of obtaining newknowledge but also to improve human life. Therefore, thepublic has a right to know what scientists do and howbasic science research and achievements affect society.Basic science is viewed sceptically by an increasing numberof young people, partly because scientists have failedto convey the relevance and motivation of their research tothe nonscientific public.Strategies for increasing the public’s understanding ofscience include events and programmes designed to exposemore high school students to the wonders of science.These can include consultations between materials scientistsand high school teachers and authorities on howto incorporate introductory materials science into schoolcurricula; summer internships in industrial laboratoriesfor high school students; and “sabbaticals” for scienceteachers so that they can take science refresher courses atuniversities. Other venues for improving materialsscience’s public profile can include TV shows on popularscience, research institute/university “open-house” events,and scientific newspaper articles and magazines targetedat the general public that are inspiring and up to date.Political Support of ScienceEuropean governments need to be made aware of theimportance of long-term, sustained support for materialsscience in order to ensure future prosperity and growth fortheir citizens. Although individual scientific ingenuity andcreativity are important, they are no longer sufficient forthe groundbreaking research that leads to new discoveries.Large investments in basic research are needed, whichrequires politicians of vision and leadership.Other ways that European governments can bring aboutchange in the relationship between the overall populationand the scientific community is by (a) creating a favourableclimate for investment in basic research, e.g., throughtax incentives; (b) opening dialogues between scientistsand citizens about scientific issues and the directions Europeantechnology should take; and (c) preparing forwardthinking,long-term science policies that give researchersthe freedom to pursue curiosity-driven research, with supportfor turning new discoveries into practical applications.Finally, to ensure that long-term strategies and researchprograms are founded on sound science, experts in materialsscience should also be included in joint EuropeanResearch Councils and their recommendations disseminatedto industry, academia, and the general public.Basic Research and IndustryBoth industry and academia are under pressure to focustheir efforts on market-related aspects of product/processdevelopment at the expense of an understanding of thefundamental science. Many European companies haveeliminated corporate or central research laboratories to

MAX-PLANCK-INSTITUT FÜR METALLFORSCHUNG STUTTGART14align their R&D efforts more closely with immediate businessneeds. This is a dangerous policy for the future. Basicresearch is the most important investment that a companycan make, both for its own future and for the future of thesociety in which it operates. Although “blue skies” researchcan be costly in the short term, most breakthroughs, althoughunpredictable, usually result from such research.This report therefore strongly urges all materials-relatedEuropean industries to increase their investment and commitmentto basic research and create flexible researchagendas for making the most of new discoveries andresearch findings.Pursuing a research agenda in isolation, however, can bean expensive and time-consuming process for an individualcompany. Companies and academia alike would benefitfrom improved infrastructure and networks for performingcollaborative basic research. Even large pharmaceutical,chemical, and semiconductor companies that havesubstantial “in-house” research programmes could benefitfrom European-wide networks because of the extra resourcesand manpower at their disposal. Materials-relatedindustries are therefore encouraged to establish and takepart in cooperative research schemes, particularly the newEuropean Materials Centres described below.Materials Science and Education in EuropeEurope needs to do a number of things to ensure that thereare enough highly trained scientists and talented researchersin the field of materials science.• A better public perception of materials science and itsimportance would encourage more young people tochoose a career in this field. The wide range of careeropportunities in materials science needs to be betterpublicized in schools and universities. The top Europeanuniversities should create materials science departmentsthat can attract the brightest students, and thatare competitive with the best departments and institutionsin the world.• Despite the current shortage of students studying materialsscience and choosing careers in this field, the currentstandards of education and training across Europeare generally high. This level must be maintained or,preferably, improved. Students should be exposed to thelatest technological advances and how they are appliedin different fields. At the same time, career educationmust be promoted to inform students about the range ofopportunities and career paths available in this materialsscience.• Highly trained scientists and talented researchers areneeded at all levels of materials research, from industryto academia. Better incentives are needed to ensure thatEuropean researchers continue to work in Europe ratherthan moving abroad, and obstacles to non-Europeanresearchers working in Europe need to be removed. Agrowing number of materials science graduates are turningto careers in other fields. Therefore, steps should betaken to ensure that none leave because of poor careeropportunities or lack of financial rewards. The numberof women studying materials science also needs to beincreased, and greater support provided for career progression.• The ideal balance between basic and applied researchneeds to be found to ensure Europe’s long-term prosperity.The establishment of dedicated European Centresof Competence in Materials Science and Technologythat will undertake fundamental research on behalfof industry, but are also connected to universities, is oneway to make the most of Europe’s scientific potential.– Long-term fundamental research should be pursuedat European Centres for Materials Science, and alsoencouraged at universities, with researchers benefitingin terms of ideas and training from contact withindustry.– Short-term research programs with industrial relevancecan be carried out at the European Centres forMaterials Technology, with input from university andindustrial researchers in a collaborative framework.– Long-term industrial research (to meet particular strategicneeds) should be undertaken within the partnercompany, with the short-term research centre projectsserving as feasibility studies.• Modern materials science is an increasingly interdisciplinaryactivity in which physicists, chemists, biologists,mathematicians, computer scientists, and engineers canall contribute their expertise to a wide range of scientificand technical problems. The growing fields of nanotechnology,biomaterials, biomimetic materials, and smartmaterials will not prosper without intensive crossoverand interaction between disciplines. Fresh ideas, newinsights, and innovations will undoubtedly result fromgreater multidisciplinary interaction. To reap the rewardsof an interdisciplinary approach, universities andresearch institutes need to encourage more flexiblemovement between disciplines by (a) breaking down rigidadministrative structures and (b) setting up multidisciplinarygroups or centres. National governments, fundingagencies, and the EC should also encourage interdisciplinaryactivities by:

– Sponsoring regular workshops, conferences, and summerschools that focus on multidisciplinary areas inmaterials science– Supporting the establishment of cross-disciplinaryresearch programmes– Encouraging agreements between funding agenciesfor the establishment and coordination of multidisciplinarymaterials research, e.g., bio- and medicalmaterials– Granting fellowships and other financial support toscientists moving from one field to anotherMajor Research FacilitiesEquipments – necessary for many important characterizationmethods – are becoming increasingly sophisticatedand are often too expensive for single medium-sizedcompanies or university departments to afford. Therefore,a strong component of the EC’s basic research supportshould be equipping and supporting large multiuserfacilities at specific locations. In the case of materialsscience, these facilities should include the latest highenergyelectron microscopes and synchrotron and neutronradiation sources (e.g., to examine crystal structures andchemical bonding), high-pressure anvils, and supercomputers.They will also serve as a place of contact betweenexperimentalists and theoreticians, and researchers fromdifferent disciplines. In addition, these state-of-theartfacilities will attract the world’s leading scientists,helping Europe to maintain the highest levels of scientificexcellence.European Centres for Materials Science and TechnologyEuropean Centres of Competence in Materials Scienceand Technology need to be established to foster cross-fertilizationof ideas and state-of-the-art science. They shouldinclude a basic research programme that gives graduateand postdoctoral students the opportunity to performworld-class experiments. The centres should also organizeworkshops, short courses, summer schools, industrialvisits, educational programmes, etc., for training scientistsand engineers. These could be newly established “brickand-mortar” centres, “virtual” (i.e., networked) centres, orextensions of current European materials research institutes.The best of them could be designated “MaterialsCentres of Excellence,” with extra funding and higherwages earmarked for these institutes so as to attract thebest and brightest from around the world. This strategywill help motivate European researchers to return toEurope after stints of working abroad.European Research NetworksMaterials science has advanced to the point where it isoften impractical (or indeed impossible!) to assemble inone place all of the intellectual resources and specialityequipment needed for a large-scale project. “Virtual”centres, or networks for materials science will be formedof research laboratories from academia, industry, andmajor facilities. These centres will be linked by highspeedInternet connections and will act as hubs for interdisciplinaryresearch. This will be the most efficient use ofthe research infrastructure and facilities that are spreadthroughout different Member States.EXECUTIVE SUMMARY15General RecommendationsThis study has identified four major themes that can serveas a guideline in discussing the advancement of materialsscience research in Europe:1. The importance of materials science to the prosperityof future Europeans, and indeed, humankind2. The need for better theoretical understanding of materialsand their behaviour, and the fundamental researchneeded to obtain this3. The highly interdisciplinary nature of materials science,and the excitement and personal rewards that a careerin this field can bring4. The need for continued, long-term investment, particularlybasic research, by national governments, industry,and the European CommissionThe relevance of materials science to modern society needsto be emphasized and promoted beyond the researchcommunity and industry to governments and the generalpublic. Forward-thinking and sustainable initiatives formaterials science research need to be launched that willattract the world’s best scientists and ensure that morefundamental discoveries come our way during the nextcentury. With the cooperation of government, industry,academia, and the general public, European materialsscience research can remain at the forefront of developments.We hope that this report will aid the discussionof how this can best be achieved.

MAX-PLANCK-INSTITUT FÜR METALLFORSCHUNG STUTTGARTI NTRODUCTIONM. Rühle | Max-Planck-Institut für Metallforschung, Stuttgart16Humankind’s existence has always depended on theavailability of materials. Indeed, historians use thedominant materials of an ancient era to classify it:they speak of the Stone Age, the Bronze Age, the IronAge. This reliance on materials has continued to the presentday, not only for our physical existence – clothing, buildings,transport, and the innumerable other inventions that havemarked human progress – but also for our cultural and intellectuallives as well-literature, art, music. In fact, withoutmaterials the human endeavour would hardly be conceivable.The latter half of the 20 st Century was characterized by profoundimprovements in our knowledge and ability to createnew materials to a degree that could only be dreamed of ahundred years ago. These advanced materials underpin allmodern technologies, from silicon chips to jet engines to medicalimaging. Because of this increased use of and reliance onnew materials, society needs to refocus its emphasis on materialsdevelopment, something that it has often neglected inthe past. This requires a re-evaluation of the role of materialsscience in society in order to guarantee the availability of newtools with which to solve some of the most pressing problemsthe world faces today, such as environmental pollution, adwindling supply of resources, overpopulation, and diseaseepidemics.The growing public awareness of these issues coincides withthe intention of the European Commission (EC) to reshapethe fundamental research landscape in Europe. This hasresulted in closer links between the EC and the Max-Planck-Institutes involved in materials science and inspired theidea of compiling this White Book on “Fundamental Researchin Materials Science.”Work on the project began with a discussion meeting betweenJune 13 and 15, 2000 at Ludwigsburg, near Stuttgart, Germany,in line with the preparation of the new EC 6 th FrameworkProgramme (2002 – 2006). About 75 leading scientists fromEurope and the U.S., including experts in the disciplines ofmaterials, mathematics, physics, chemistry, biology, informationtechnology, and engineering, met for two days of brainstormingabout the many different aspects of materialsscience. (The programme is provided in Appendix I and thelist of participants in Appendix II).Topics were selected and reviewed. For each topic, acknowledgedexperts introduced the state of the art and presentedtheir visions for future evolutionary developments andrevolutionary breakthroughs. This was followed by opendiscussions with scientists in the audience.After the workshop, teams were formed and team coordinatorsappointed. Each coordinator and team provided awritten summary of their discussions and ideas. Emphasiswas placed on the directions and opportunities for futurematerials research, with reference to the social and economicimplications where relevant. This input formed the basisof this White Book.The initial conclusions, recommendations, and futureresearch opportunities resulting from this exercise werediscussed further at a second workshop on March 15/16, 2001in Degerloch, again near Stuttgart. (The programme is providedin Appendix III and the list of participants in AppendixIV). Attendance at this meeting was limited to the coordinators,policy makers, representatives of the EC Director-General for Research, heads of national laboratories, andindustrialists.Throughout this period, close contact was maintained withthe EC Research Directorate for Materials to coordinate ourefforts to resulting in new research initiatives.

The format of the White Book follows the format of thissecond meeting. That is, a wide variety of different classes ofmaterials and techniques are examined from as many viewpointsas possible. Contributions from many differentauthors, all respected and acknowledged experts in theirfields, are grouped under the following chapter titles: (1) Materials:Science and Engineering; (2) Materials: Science andApplications; (3) Interdiscipinarity in Materials Science; (4)Materials Modelling and Materials Theory; (5) MaterialsPhenomena; (6) Materials Synthesis and Processing; and (7)Advanced Analytical Techniques. Individual scientists orteams of scientists wrote the individual chapters of each section.The author(s) bear(s) full responsibility for the contentof their chapter. (A list of authors is provided in Appendix V).A few topics were discussed and analyzed by differentscientists from different points of view. This has led to a slightoverlap of a few topics.It should be emphasized that the White Book does not claimto cover all areas of materials science in detail. The chosensubjects reflect the view of the individual scientists present.Nevertheless, we believe that we have covered the main topicsrelevant for the broader development of materials science.The White Book sheds light on recent advances in fundamentalresearch in each of these materials-related fields. It highlightsthe great importance for new synthesis and characterizationmethods, the search for new phenomena and materials,and the growing use of computer models and theoreticalunderstanding in all areas of materials science. One of themajor theme, which came through clearly and consistentlyfrom both, the meetings and the articles contained in thisbook, is that the future of materials science lies in the crossoverand exchange of ideas between disciplines. Consequently,a special chapter (Chapter 3) has been devoted to the interdisciplinarynature of materials science and how best tofoster it. This interdisciplinary aspect must also includeengineering. Because fundamental research in materialsscience eventually results in a product that serves society,materials – both traditional and advanced – must be “engineered”at all length scales. Engineering at the smallest lengthscale results in “nanomaterials” which open up new researchhorizons; not only for tailoring complex materials withspecific and superior properties, but also for exploring newphenomena that arise when matter is confined to withinmolecular-sized structures.An expansion of interdisciplinary research would be to considermaterials science, including fundamental research, as aholistic concept ranging from processing to recycling ofmaterials – each step emphasizing also ecological aspects.The holistic approach of materials science is essential for thefuture welfare of society.Chapter 8 examines the social aspects of science, includingnew schemes for materials education, careers for researchscientists, and inter-European and international mobility ofresearchers. In addition, a new strategy for basic materialsscience research in Europe is presented, with suggestions onhow to organize European research efforts to the best effect.The overall conclusions, recommendations, and directionsfor future research are summarized in the final chapter (Chapter9), which highlights the importance of basic materialsresearch to economic growth and prosperity. This chapter alsoprovides insights into the research needs of various materialsclasses and gives directions for future research opportunitiesand activities in the materials science area.The book as a whole is oriented towards fundamental aspectsof materials research, but visions of the future and otheropinions from industrial research authorities were also takeninto consideration. An important example of this is the rolethat basic materials research will play in future Europeantransportation systems. Materials science also has an importantpart to play in alleviating many of the environmentalproblems that we now face, not least of all by developing newenergy-efficient devices using fast ionic conductors andimproved catalysts.The audience for this book, therefore, is large. It is addressedto all materials scientists and scientists from materials-relateddisciplines in Europe, as well as national and European policymakers. Because of the necessity to focus on materials development,this book is also of important to industry, especiallysmall and medium-sized enterprises. As well as providing anup-to-date account of the latest technology and research topics,it also provides ideas for future innovations, devices, andapplications of materials. If these can be developed by Europeanindustries, then Europe’s economic prospects, and consequentlyits citizens’ welfare, will be much the better for it.This book serves as a call to European politicians to upgradetheir investment in basic materials science at least to a levelcomparable with that in other industrialized countries,notably the U.S. and Japan, so that European industry canremain competitive well into the future, and we can pass on aculturally, scientifically, and economically flourishing Europeto future generations.The editors of the White Book thank all the authors, helpers,workshop participants, and colleagues from all participatingMax-Planck-Institutes, and The Max Planck Society, for theenormous effort they have put in to making the publication ofthis book possible. The support by Dr. Stephan Krämer, MPIfür Metallforschung Stuttgart, during the editing and printingof the White Book is greatly acknowledged.We trust that this White Book will result in the reinvigorationof materials science in Europe. We especially hope it will openthe eyes of the public, opinion makers, and politicians to thewonders of materials science, the benefits it brings, and itsrole as one of the main pillars of economic progress and socialwell-being in Europe and, indeed, the world as a whole.INTRODUCTION17

CHAPTER 11. MATERIALS: SCIENCEAND ENGINEERING1819Materials science is an interdisciplinary researcharea which covers the physics, chemistry and engineeringof all classes of materials. Traditionally, thesematerials are divided into metals and metallic alloys,ceramics, semiconductors and other inorganic materials,and polymers and organic materials. Recently, the scienceof materials has received increased attention because ofthe discovery of new classes of materials and their applicationin new technologies.▲The traditional classification of materials into differentclasses or types is still helpful since specific engineeringapplications still rely on components made from materialsfrom one or other of these groups. In this chapter it will beshown that metals and metallic alloys (including composites)still constitute the majority of structural and functionalmaterials used within the EU, as well as worldwide.Use of this group of materials has an enormous technologicaland ecological impact on society, and one of the challengesof materials science is to come up with metals withimproved properties via cheaper processing routes. This isespecially true for the automotive industry where synthesisand processing controls the microstructure, properties,and performance of metallic materials. It is now well appreciatedthat for this industry-which consumes enormousamounts of metals-to be sustainable, automobile designmust encompass the complete lifecycle of the materialsused, from processing to recycling.Microstructure of polytype SiAlON (transmission optical micrographobtained with polarized illumination, U. Täffner, MPI für MetallforschungStuttgart).IntroductionThe distinction between ceramics and other non-metallicinorganic materials is often difficult to define. In this chaptertwo aspects of these materials are described, namelyfundamental research and real-world applications. The futureof non-metallic materials appears to lie in developmentand exploitation of specific functional properties. Asa group, ceramic materials have perhaps the largest rangeof functions of all known materials, and can be used for adiversity of applications. It is very important to understandthe fundamental processes which lead to specific properties.In simple terms, ceramics are compounds or mixturesof compounds of metallic or metalloid elements with nonmetalelements.The properties of a particular material depend not only onthe chemical nature of its atoms, but also on their arrangementand distribution in its microstructure (grains, pores,etc). Materials with specific thermal, mechanical, nuclear,electrical, magnetic and optical properties can be fabricated.Due to the staggering variety of these materials andtheir possible combinations, there is still a huge amount ofresearch that needs to be done. So far only a fraction of theinorganic materials that could possibly be put to use havebeen studied, and there is little doubt that many new compoundswith unusual or superior properties are still to befound.Inorganic solid state chemistry and physics investigate thebasic principles and provide the necessary background forresearch into the correlation between microstructure andproperties of inorganic compounds. Insights can beengained simply by comparing phenomena of different ma-

MAX-PLANCK-INSTITUT FÜR METALLFORSCHUNG STUTTGART20terials with each other, but more rigorous understandingbased on quantum theory is also necessary for today’sadvanced materials.Polymers find increasing number of applications everyyear. Recently, however, research into “traditional” polymershas declined. At present the polymer manufacturingindustry in Europe is undergoing major restructuring,which has led to severe cutbacks in companies’ Research& Development (R&D). To fill this gap, universities shouldincrease the amount of fundamental research they do intopolymeric materials.All life-forms are based on soft organic materials; polymerscience can therefore also be related to our understandingof biological materials, particularly carbon-based materials.Ceramics, on the other hand, are similar to hard biologicalmaterials such as teeth and bone, so that connectionsbetween these two fields will continue to grow aswell. We can expect many more functionally useful materialsto become available in the future by manipulating thechemistry and processing techniques of all these materials,and combining them in new ways.It is difficult to imagine modern society functioning todaywithout electronics. Electronic, optical, and photonic materialsplay essential roles in information technology, computing,and systems control, as well as electronic consumergoods. There is a great deal of commercial pressure todevelop new materials for use in these areas. Fundamentalresearch into electronic, photonic and optical materialsis therefore essential for the continued improvement andminiaturization of electronic and photonic devices.The following eleven sections summarise the state of theart for the different classes of materials. Expected evolutionaryand revolutionary developments are sketched ineach section.Carbon materials have received a lot of attention recentlythrough specific modifications such as graphite sheets(rolled up to form nanotubes or buckyballs) and syntheticdiamond. The basic principles of inorganic carbon chemistryare understood. These specific forms of carbon areexpected to be useful for a variety of applications in differentbranches of engineering. Hence it is very importantthat links between the science of carbon and itsapplications be strengthened.

1.1. Metals and Composites: Basis for Growth, Safety, and EcologyD. Raabe | Max-Planck-Institut für Eisenforschung GmbH, 40074 Düsseldorf, GermanyContributors:Y. Bréchet (LTPCM, BP75, Domaine Universitaire deGrenoble, Saint Martin d’Heres, France), G. Gottstein (Institutfür Metallkunde und Metallphysik, RWTH Aachen,Aachen, Germany), J. De Hosson (Department AppliedPhysics, University of Groningen, Groningen, The Netherlands),P. Van Houtte (Department MTM, CatholicUniversity Louvain, Louvain, Belgium), V. Vitek (Departmentof Materials Science and Engineering, University ofPennsylvania, Philadelphia, U.S.).1.1.2. State of the Art and Expected TrendsThe state of the art in the field of metals and compositesresearch is characterized by a mature level of property optimizationand characterization particularly as far as bulkmechanical aspects of conventional structural metallic materialsare concerned. Basic principles behind bulk materialskinetics and thermodynamics in such alloys are understoodto an extent that they can be used for the further gradualoptimization of existing alloy concepts with respect tostructural and/or functional properties. Recent Europeanprogrammes have focussed on improving and tailoring existingmaterial concepts for matching technological andcommercial boundary conditions and on designing newmaterials concepts beyond conventional R&D lines.This research concept of the past decade has for manyaspects matured to a level where future activities, whenMATERIALS: SCIENCE AND ENGINEERING211.1.1. The Place of Metals in the World of MaterialsMetallic alloys and composites represent the dominantgroup of structural and functional materials world wideand within the EU. This applies for their technological impacton society as well as for the scientific challenges associatedwith further discoveries and developments in thisfield. Fundamental and long-term oriented research onmetals and composites leads to the development of welltailoredtechnological solutions which serve society withrespect to sustainable progress, ecological benefits, advancedsafety demands, and economic success. Prominentchallenges along these lines lie in understanding anddeveloping the fundamentals of lightweight structural materialsand design solutions, self-organising microstructures,failure-tolerant materials systems, smart materials,and materials for ground and aerospace transportation(Fig. 1.1 and 1.2).Fig. 1.1. Space vehicles which are at the cutting edge of high technologyare built of structural elements of steels, aluminium, magnesiumand beryllium alloys and metal-matrix composites.This report gives an overview of the most important futureresearch topics in the field of metals and composites researchas collected and discussed within a group of about100 leading experts from the EU, Asia, and the U.S. Itgives corresponding recommendations for future basicresearch initiatives on metallic alloys and composites inthe 6 th EC Framework Programme.Fig. 1.2. Modern automotive technology relies on safety equipmentmade of advanced steels, aluminium, and magnesium alloys.

MAX-PLANCK-INSTITUT FÜR METALLFORSCHUNG STUTTGART22designed and pursued along the same lines as before, willlead to a more and more asymptotic research progress. Futurelong term research programmes must, therefore, formulateconcepts to achieve distinct progress steps leadingEC projects beyond existing research plateaus. This approachwould maintain and strengthen the position of metalsand composite research as a key science and technologyproviding progress-critical input to other key areas ofscience and high technology. It should thus be the aim offuture research in this field that coming technology applicationsare being pushed forward by materials rather thenvice versa.Some key rules can be formulated to unleash unused potentialof metallic and composite materials through a newEuropean framework research initiative with the aim ofentailing fundamental progress steps pushing this disciplinebeyond existing R&D asymptotes.• First, EC projects should make extensive use of novel experimentaland theoretical tools as well as advanced combinationsof them. Although further improvements and applicationsof well developed “workhorse” methods are essentialto provide serious and systematic data for novelmaterials concepts, it is less likely that they play a bottleneckrole in future metals research such as the use of novelmethods which will allow new observations, which havenot been made so far (some of the new research tools willbe specified below).processingmicrostructuredesign• Second, EC projects should address fundamental longtermproblems of existing and cutting-edge structural andfunctional metallic materials concepts which are the basisof our economy but are not covered by applied or industryresearch. In this context it is important to note that industrypushes materials developments only to a level of immediatecommercial output and leaves behind numerous unansweredquestions which often affect ecological, economic,performance, and safety aspects. Such conceptsdeserve in part more attention from the fundamental sidein order to avoid long-term misconceptions and exploit anddevelopment better the potential of existing materials.• Third, EC projects should create materials concepts farbeyond conventional approaches, focussing particularly onso far less exploited combinations of different materialclasses, property-structure integrations, and property profiles.In this context it is important that new materials developmentshould be accompanied from the beginning byfundamental research since material development is nowadaysan integrated and interdisciplinary task.• Fourth, future research initiatives should give very highpriority to projects with highly interdisciplinary characterclosely integrating concepts and approaches from areassuch as materials physics, materials engineering, informationtechnology, materials chemistry, mathematics, and/orbiology.1.1.3. Outline and Principles of Future Research StrategyThe basic research strategy required in this field can beclassified into two major disciplines. The first one comprisesexperiments on model systems. The second one comprisesmodelling and computer simulation. As far as metalsand composites are concerned the latter branch particularlyconcentrates on macro- and mesoscale simulationissues.synthesismetals for growth,ecology, and safetypropertiesExperiments on model systems should map essential ingredientsof composition, synthesis, processing, and microstructuredesign which are not well understood but havekey functions in novel material design as well as advancedconventional materials concepts (Fig. 1.3). The followingkey points might characterize projects in this field:performanceFig. 1.3. Essential elements of advanced metals and composites research.• First, projects should make use of novel experimentaltools and/or advanced combinations of experimental toolsexploiting observation methods that have not yet maturedto their full potential. Examples (see section 1.1.4) arenano-mechanical property characterization in conjunctionwith nanoscopic analytical and orientation characterization;3D atom probe methods; high-resolution analyticalmicroscopy in conjunction with automated high-resolutionorientation imaging microscopy; 3D synchrotron X-ray microscopy; field ion beam microscopy in conjunctionwith high-resolution orientation imaging microscopy in

FEG (FEG = field emission gun) scanning electronmicroscopy; advanced neutron scattering methods; in situexperimentation combining sample observation with heatingor mechanical loading. Consideration must also beplaced on fast and appropriate analysis tools which arecapable of extracting and visualizing relevant informationfrom the ever increasing experimental data sets.• Second, projects should address fundamental long-termproblems of existing structural and functional metallic materialsconcepts by use of model experiments which are thebasis of our economy but are not covered by applied or industryresearch. Examples are integrated model design solutionsexploiting materials as well as constructional aspects;metal-metal interfaces and grain boundary triplepointsin the form of well-defined model bi- and tricrystals;metal-metal joints; advanced structural-functional as wellas smart compounds.• Third, projects should create experimental model systemsheading beyond conventional approaches, focussing particularlyon so far less investigated combinations of differentmaterial classes, microstructures, and property profiles.Examples are entangled, cellular and porous metallic microstructures;nanoscale metal-polymer compounds; ultrathin layered metal-ceramic-polymer structures; nanostructuredfunctional-structural composites; woven metallicsystems; nanoscale integration of metals, polymers, andceramics; self organising metal-polymer interfaces; compositefoams; and metal-semiconductor-polymer sheetcompounds.Modelling and computer simulation projects should aimat a fundamental understanding and a prediction of theperformance of novel and advanced conventional structuraland functional materials. The recognition of these basicneeds from the theoretical side, along with the ever increasingcomputing power, has established computer modellingapproaches as one of the major areas in materialsresearch. In this approach one formulates model descriptionsbased on fundamental principles and investigatestheir properties and behaviour by numerical simulations.Modelling and computer simulation will play a key role inunderstanding, tailoring, and predicting materials synthesis,processing, microstructures, and properties. Whilemodelling can produce realistic results for very complexsituations, underlying theories, based on results of modelling,must be built as history-dependent and multi-scaleconcepts, integrating electronic and atomic level as wellas continuum scale information whenever relevant(Fig. 1.4). These allow generalization and deep physicalunderstanding of phenomena studied. Modelling and simulationtools have in recent years matured to a state whereavailable software is increasingly well designed and maintainedand built on robust theoretical and mathematicalgrounds.MATERIALS: SCIENCE AND ENGINEERING23• Fourth, design of model systems should be particularlypursued in projects with highly interdisciplinary characterclosely integrating concepts and approaches from materialsphysics, materials engineering, materials chemistry,mathematics, information technology, and/or biology. Examplesare the application of nanoscale materials mechanicstests to large sets of material samples or graded samplesusing variational alloy chemistry methods in conjunctionwith nano-indentation; the design and investigationof metal-polymer interfaces with high-resolution analyticalexperimental tools as projects between metal physics,physical chemistry, and process engineering; determinationof elastic and plastic response of ultra thin layeredstructures under thermal, electromagnetic, mechanicalloadings, or environmental loadings as projects betweenmetal physics, physical chemistry; process engineering;design and investigation of self organization effects in metal-polymerand metal-ceramic interfaces as projectsbetween ceramics, metal physics, physical chemistry, andbiology; and closer cooperation between experts from theoryand experimentation.Fig. 1.4. Important hierarchical scales of computer simulation methodsin the field of metals and composites research. Future developmentsmust integrate macroscopic finite element predictions, mesoscalemethods, and atomic scale simulations for the design and optimizationof new advanced products.Distinct progress steps pushing this field of computersimulation forward can only be expected when the abovementioned key points are considered. This means that

MAX-PLANCK-INSTITUT FÜR METALLFORSCHUNG STUTTGART24• First, projects should make use of and better integratenovel tools from theory, mathematics, and information technology.Examples are better exploitation of parallel algorithmsand parallel computing power; application of distributedcomputing based on high speed network connections;development of robust and fast parallel non-linearvariational methods for tackling large quantities of coupleddifferential equations; critical reliability investigationsof numerical methods and existing codes; standardizationand sharing of computer codes and resources; closerintegration of electronic ground state and atomic scalecalculations into continuum concepts; improvement ofphysically motivated strain gradient and crystal plasticitycontinuum theory; better integration of and comparisonwith experimental data in case of non ab initio methods;development of fast though robust simulation algorithmsfor the electronic, atomic, and continuum scale; and directcoupling of electronic and atomic dynamics simulationsbeyond the Born-Oppenheimer approximation. Furthermore,particularly large scale simulation efforts requirecloser integration of materials and constructional/design issues. For instance, aspects such as the overall partstiffness results from ingredients of both areas. Such projectsshould introduce design-oriented database-relatedapproaches exploiting artificial intelligence methods. Anotherimportant point of integration are joint simulationsof functional – constructional devices. Also, one shoulddraw more attention to novel information treatment methodssuch as the neural net and fuzzy logic approaches.• Second, simulations should aim at structure- and propertypredictions of model systems pertaining to existingstructural and functional metallic materials. Focus shouldbe placed on the mesoscopic and macroscopic scale.Examples are anisotropic continuum scale CPFE-basedsimulations (CPFE = crystal plasticity finite element methods)of elastic-plastic co-deformation of metallic systemsas well as corresponding simulations considering metalpolymerand metal-ceramic compounds; micromechanicspredictions of polycrystalline matter under mechanicalloads; micromechanics predictions of woven and foamcomposites; joint microstructure simulations integratingcasting, thermomechanical and cold forming issues; andGL-based simulations (GL = Ginzburg – Landau – typephase field methods) of structure- and concentration-dependenttopological mesoscale aspects.• Third, simulations should aim at designing and predictingstructure- and properties of novel material concepts atthe electronic-, atomic-, meso-, and macroscale. Examplesare LDF-type electronic scale predictions (LDF = localdensity functional theory) of the influence of foreignatoms on metal-metal interfaces; MD-based simulation(MD = molecular dynamics) of interfaces and crack tipsunder loads; CPFE-based continuum scale simulations ofbehaviour under elastic-plastic loads; GL-based simulationsof metal-polymer, metal-semiconductor, and metalceramiccompounds; mesoscale joint GL- and CPFEbasedpredictions of self organization kinetics at metalpolymerinterfaces; micromechanics predictions for wovenand foam composites; atomic scale process design simulationsfor micro- and nanoscale compound tailoring usinghyperdynamics concepts.• Fourth, simulation projects should be particularly pursuedin projects with highly interdisciplinary characterclosely integrating concepts and approaches from materialsphysics, materials engineering, materials chemistry,mathematics, information technology, and/or biology. Examplesare the integration of electronic ground state simulationinto continuum models as projects between physicsand materials science; integration of polymer mechanicsand metal mechanics into predictions of layered structuresas projects between materials mechanics and physicalchemistry; development of faster simulation methods andalgorithms as projects between mathematics, informationtechnology, metal physics, and chemistry; the developmentof parallel and distributed methods as projectsbetween mathematics, information technology, metalphysics, and chemistry; and closer cooperation betweenexperts from theory and experimentation.1.1.4. Details of Future Research Programme(a) IntroductionBased on the concept explained in Sect. 1.1.2 this partgives a more detailed outline of recommendations forfuture research topics in the fields of metallic alloys andcomposites. The organization of topics in this chapterfollows in the first place the key subjects as agreed at theLudwigsburg symposium but gives suggestions with relationto the above introduced organization of projects intomodel system experimentation and computer simulation.The key areas of future fundamental research in the fieldof metallic alloys and composites as agreed at the Ludwigsburgsymposium are:• Interface science and microstructure design• Thermodynamics and kinetics• Synthesis and processing• Mechanical and functional properties(b) Interface science and microstructure designLaws of interface motion and energy often follow strongdependencies on state variables. Metal and composite

interfaces typically have bottleneck function in materialsproperties and design. It is likely that substantial new fundamentalinsights and outstanding progress in performancecan be expected particularly from metallic alloysand composites with a high density of homophase and heterophaseinterfaces. Such concepts can be realized in theform of bulk systems with intricate 3D interface percolation,layered systems, and bamboo-type structures.The key focus in this area is a better understanding of nucleationevents and the role of the mechanisms of interfaceformation as well as interface motion. Materials aregetting increasingly dominated by interfaces. This includesmetal / ceramic, metal / metal, metal / polymer etc.interfaces. Investigating such phenomena requires to focuson the electronic and atomic aspects as well as onmacroscopic aspects.Topics in this context with fundamental importance include:(c) Thermodynamics and kineticsThermodynamics and kinetics data are essential for tailoringand predicting novel materials. Particularly in interfacedominated systems thermodynamics and kinetics arenot well understood though they have key function in novelmaterials design. Topics in this context with fundamentalimportance include:1. thermodynamic and kinetic data of multi-componentsystems and interface-intensive systems2. transformations under elasto-plastic and electromagneticloads, effects of point and line defects oninterface transformations3. transformation in confined, low-dimensional, layered,and small scale structures4. development, standardization, and intercalibration inthe field of experimental materials thermodynamics5. Non isothermal and reversal problems in heat treatment6. microstructures arising from competing kineticsMATERIALS: SCIENCE AND ENGINEERING251. self-organising and self-repairing surfaces andinterfaces2. generation, structure, and properties of interfaces withfractal dimension3. nano- and microtribology4. interface and surface systems under thermal, elastoplastic,electromagnetic, environmental and coupledloadings5. surface- and strain-driven continuous anddiscontinuous subgrain coarsening6. elastic-plastic and functional interaction acrossheterophase and homophase interfaces7. nucleation phenomena8. mechanics at interfaces9. interfaces and surfaces turbine blade alloys undercomplex loadings10. functional/structural optimization of interfaces11. interface phenomena in woven and foamed metals andcomposites including corrosion12. role of interfaces in smart materials, particularly innanoscale filter, electronic, and catalytic matter13. interface mobility and effects of other lattice defects,triple junction effects14. recrystallization and grain growth phenomena15. orientation and misorientation evolution at thenano- and microscale16. grain cluster-mechanics17. micromechanics of interfaces and surfaces18. precipitation phenomena under complex loadings,in constrained and layered systems, and in multicomponentsystems19. interface design and manipulation(d) Synthesis and processingMicrostructure design will play a critical role in the synthesisof novel multi-layered and small scale structured materials.Key points to be addressed are the fundamentals of:1. self-organization and self-assembly of microstructureswith desired properties2. in situ processing of functional-structural materials3. layered and graded structures4. super strong metals composites, matter close to thelimits of theoretical strength5. ordering effects of magnetic particles and domains6. metallic foams7. casting defects8. microstructures inheritance in materials processing9. nanoscale particles: processing, self organization,quantum dots10. fabrication of bulk and thin film nanostructuredmetals11. microstructure percolation effects12. intermetallics and oxides: combination of highstrength, ductility, and creep/fatigue resistance,internal oxidation13. in situ nanostructuring through deformation,metallurgical methods, deposition, and diffusion14. in situ decomposition15. field assisted annealing16. high temperature alloys and compounds: turbinematerials, aerospace composites, alloys for hot andaggressive environment17. joining processes