ALDEC Decanter - Alfa Laval

ALDEC Decanter - Alfa Laval

ALDEC Decanter - Alfa Laval

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

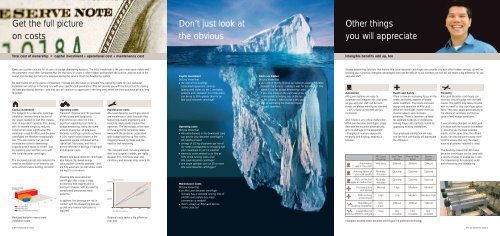

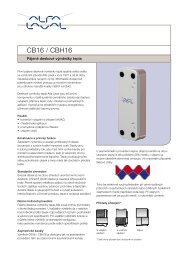

256806_Technology Conversion 10/4/05 12:47 PM Side 4Get the full pictureon costsDon’t just look atthe obviousOther thingsyou will appreciateTotal cost of ownership = capital investment + operational cost + maintenance costIntangible benefits add up, tooCosts are a prime concern for all users of sludge dewatering systems. The initial investment is the part most easily visible andthe parameter most often compared. But the real story on costs is often hidden well beneath the surface, and the bulk of theoverall cost burden normally only emerges during the service life of the dewatering system.So don't settle for a first-glance comparison. Instead, ask <strong>Alfa</strong> <strong>Laval</strong> to calculate how operating costs for your particularinstallation will add up in the long run, with your specific cost parameters. This will provide you with the full picture for makingthe best purchasing decision - one that you will continue to appreciate in the long term, when the initial purchase price is longforgotten.Capital investmentThe footprint for a decanter centrifugeinstallation involves only a fraction ofthe space needed for belt filter installationsof equivalent capacity. This, alongwith its extreme simplicity, reducesconstruction costs significantly. Theinstallation costs for <strong>Alfa</strong> <strong>Laval</strong> decantercentrifuges are therefore exceptionallylow. This also means that you canincrease your plant's dewateringcapacity even if space is limited - justby replacing your belt filter units with<strong>Alfa</strong> <strong>Laval</strong> decanter centrifuges.The enclosed process also reduces theneed for ventilation or air-cleaning systemsand eliminates building corrosion.Reduced footprint means lowerinstallation costsOperating costsTransport, disposal and the purchaseof flocculants and coagulants(FeCl3/lime) are often the mostsignificant operating cost items insludge dewatering. Using the sameamount of polymer, an <strong>Alfa</strong> <strong>Laval</strong>decanter centrifuge normally achieves4-10% higher solids content in thedewatered sludge compared with atypical belt filter press, and this isdirectly reflected in savings in transportand disposal costs.Modern <strong>Alfa</strong> <strong>Laval</strong> decanter centrifugesalso feature the lowest energyconsumption currently available - andare fully automatic so that labour costsare kept to a minimum.Cleaning <strong>Alfa</strong> <strong>Laval</strong> decantercentrifuges after a stop is easy,economical and requires only aminimum of water, with no need forcomplicated pressurized washsystems.In addition, the bearings are not incontact with the dewatering process,so that only minimal lubrication isrequired.Maintenance costs<strong>Alfa</strong> <strong>Laval</strong> decanter centrifuges ensurelow maintenance costs because theyfeature top-quality engineering andmaterials, and provide trouble-freeoperation. The technology at the heartof these systems completely doesaway with the problems associatedwith sludge blocking up filter cloths,clogging caused by fibres and theneed for belt tensioning.The materials used, including stainlesssteel and tungsten carbide, are highlydurable. This minimizes wear andcorrosion, and ensures long service life.750,000500,000250,000Disposal costs make a big differenceover timeCapital InvestmentDid you know that● the cost of the buildings,associated equipment, services(pressurised water, air, etc.), ventilationsystems and installation for a filter presscan be up to 50% greater than for an<strong>Alfa</strong> <strong>Laval</strong> decanter centrifuge?Operating costsDid you know that● 4% extra dryness in the dewatered cakecan pay for your decanter centrifuge in18 months or less?● savings of 1/2 kg of polymer per ton ofdry solids corresponds to recouping halfyour investment in just 12 months?● electricity costs amount to as little as10% of the running costs of an<strong>Alfa</strong> <strong>Laval</strong> decanter centrifuge?● one single operator can run 10 or more<strong>Alfa</strong> <strong>Laval</strong> decanter centrifuges?Maintenance CostsDid you know that● an <strong>Alfa</strong> <strong>Laval</strong> decanter centrifugenormally has a standard running time of24,000 hours before any majorintervention is needed?● there's always an <strong>Alfa</strong> <strong>Laval</strong> servicecentre close by?Costs are hiddenDid you know that● as a rule of thumb, 9/10 of an iceberg's volume is hiddenbeneath the surface – lurking in wait for the unwary? Thesame is true for sludge dewatering costs.If you only focus on the purchase price, itcorresponds to looking only at the tipof the iceberg – which is not a very goodway of estimating the financial impacton your operation.Sludge dewatering solutions that feature <strong>Alfa</strong> <strong>Laval</strong> decanter centrifuges also provide you with other hidden savings, as well asbringing you numerous intangible advantages that may be difficult to put numbers on, but will still make a big difference for youand your staff.Automation<strong>Alfa</strong> <strong>Laval</strong> systems are easy toautomate and integrate into your plant,so you and your staff can be surethings are always working as intended- 24/7, virtually unmanned yet fullymonitored.And if there is any critical malfunction,<strong>Alfa</strong> <strong>Laval</strong> decanter centrifuges simplydeal with the situation automatically,with no damage to the equipment- stopping all auxiliary equipment,emptying and flushing, awaiting asolution.Automationwithin the plantAutoregulation ofprocess qualityAuto protectionagainst malfunctionProcess odorsand spraysSafe workingenvironmentRetrofitting inexisting installationCapabilities fortreating different sludges<strong>Alfa</strong> <strong>Laval</strong><strong>Decanter</strong>Very easyNormallyincludedNormallyincludedMinimalHighVeryEasyTotalHealth and SafetyThere is now an increasing focus on thehealth and safety aspects of wastewatertreatment. The totally encloseddesign and operation of <strong>Alfa</strong> <strong>Laval</strong>decanter centrifuges means there areminimal odours and corrosionproblems. There is therefore no needfor separate buildings or enclosures,making these units perfectly suited forupgrading existing installations.Your employee satisfaction will leap,and the local community will appreciatethe difference.Belt FilterPressDifficultOptionalOptionalHighLowDifficultNotpossibleFrame FilterPressDifficultOptionalOptionalMediumMediumDifficultNotpossibleIntangible benefits make decanter centrifuges the preferred technologyScrewPressDifficultOptionalOptionalMinimalMedium-highDifficultNotpossibleFlexibility<strong>Alfa</strong> <strong>Laval</strong> decanter centrifuges cantreat any kind of sludge with the bestresults. The switch only takes minutes,with no need to stop centrifuge operations.They also adjust automatically tothe effects of variations and fluctuationsin feed sludge conditions.If your process changes, an <strong>Alfa</strong> <strong>Laval</strong>unit deals with the situation immediately,ensuring you the best possibleresults. At the same time, the effluentquality can also be continuously monitoredto ensure that only the exactamount of polymer required is used.This flexibility means that <strong>Alfa</strong> <strong>Laval</strong>decanter centrifuges can be used witha variety of types of sludge (as in contractdewatering, for example) or forboth thickening and dewatering.2 The full picture on costs The full picture on costs 5