Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

souvenir bullet originally had to weigh within %& of a<br />

grain to be acceptable. And the diameter is held to a tolerance<br />

of 2/lO,OOOths of an inch, about one-twentieth the<br />

diameter of a human hair."<br />

The work which brought Sierra bullets to their present<br />

high standards was long and difficult. When Snow and<br />

Harbour first got together and started to consider making<br />

better bullets for target shooting, they found that more<br />

accurate die presses to punch out the jackets and form the<br />

slugs were needed. Secondly, they wanted to improve<br />

bullet design. When another shooter-machinist, Jim Spivey,<br />

added his know-how, the three began to work toward their<br />

goal in earnest. Instead of treating it as a simple coppel<br />

cased pellet hurled through the air, they realized that a'<<br />

bullet was a tremendously complicated center of many '<br />

I<br />

different forces, some acting to throw it to the target, and -,<br />

others trying to divert it.<br />

Experiments with the die presses showed that none wer? j<br />

exactly right for their rigid requirements ofaccuracy. The , ,<br />

partners then adapted the 30-ton BKss press with diq,'.<br />

plungers and other improvements of their own design.<br />

Those die sets are the heart of each riant machine in the<br />

.a<br />

modern Sierra factory. They turn out streams of beautiful<br />

jacketed bullets as fast as corn coming from the sheller.<br />

Only the best tungsten carbide and other tool steels is<br />

used for the dies. One of the partners~and sometimes<br />

two-is always at his lathe and grinding machine shaping<br />

new sets for replacing those worn out on the machines, or<br />

working up a new bullet design. In final shaping of these<br />

beautif~ll~-~olished, precision mechanisms, ordinary micrometer<br />

readings in thousandths are too crude-the<br />

reads out to ten-thousandths for routine work.<br />

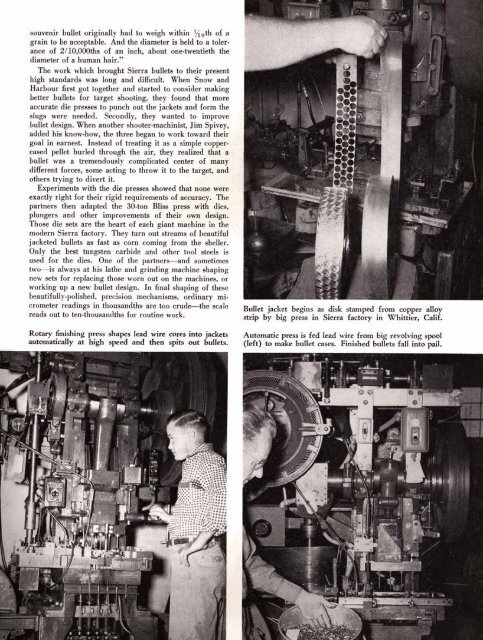

scale Bullet jacket begins as disk stamped from copper alloy<br />

strip by big press in Sierra factory in Whittier, Calif.<br />

Rotary finishing press shapes lead wire cores into jackets<br />

automatically at high speed and then spits out bullets.<br />

Automatic press is fed lead wire from big revolving spool<br />

(left) to make bullet cases. Finished bullets fall into pail.