You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

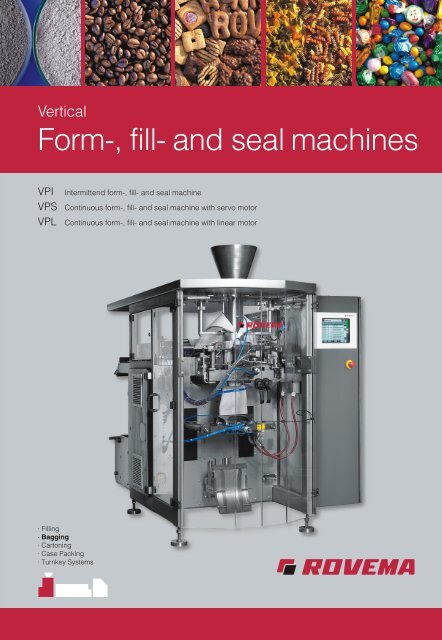

Vertical<br />

Form-, fill- and seal machines<br />

VPI Intermittend form-, fill- and seal machine<br />

VPS Continuous form-, fill- and seal machine with servo motor<br />

VPL Continuous form-, fill- and seal machine with linear motor<br />

· Filling<br />

· Bagging<br />

· Cartoning<br />

· Case Packing<br />

· Turnkey Systems

Vertical<br />

Form-, fill- and seal machines<br />

VPS<br />

Continuous form-, fill- and seal machine with servo motor<br />

The continuous form-, fill- and seal machine VPS with servo<br />

motor convinces with an excellent price-performance ratio.<br />

It is robust and quick and provides safe production<br />

processes. The VPS offers product-oriented handling and<br />

economical packaging of lumped, granulated, powdered<br />

and pasty products.<br />

Versatile and attractive bag styles<br />

The machine can process almost all mono and laminate<br />

packaging materials of different thicknesses to enable the<br />

production of a variety of bag styles.<br />

Auxilliary devices are available to increase the machines<br />

capabilities in order to produce pack styles like side<br />

gusseted, block bottom, Stabilo- Seal, Flexcan or Ropack<br />

bags. Re seal or easy openign features for the bags can be<br />

included.<br />

Highlights of the VPS series<br />

- Very economical due to its very good<br />

price-performance ratio<br />

- Sense&Seal function to avoid product inclusion in cross<br />

seal and to protect jaws and cut of knife. For increased<br />

efficiency and reduced mainenance<br />

- Flexible because of a wide product range and a<br />

variety of bag shapes<br />

- Continuous and intermittent operating modes<br />

- Free configurable and precisely controlled sealing force,<br />

jaw apperture and vertical stroke for long sealing times<br />

within the cycle<br />

- Available with pneumatic or motoric driven gusseting tools<br />

Simple and safe operation<br />

Vertical form fill and seal machine VPS is easy and safe to<br />

use with the <strong>ROVEMA</strong> –P@ckControl software. The<br />

machines control system is based on Siemens PS’s<br />

(optionally Rockwell). The control system is able to operate<br />

with drive components (motors, drives) supplied by many<br />

different manufacturers. The settings for all the possible<br />

sealing path curves, especially for 2-axis machines, are<br />

very complex. The <strong>ROVEMA</strong> P@ckControl software<br />

automatically calculates and adjusts these curves<br />

mathematically and exactly on the basis of the entered<br />

sealing parameters (sealing time, cooling time, bag length<br />

and number of machine cycles). The resulting ease of use<br />

is unique. Maximum and minimum parameter values for<br />

each input field prevent bad entries.<br />

Performance of the VPS<br />

VPS 260<br />

Nominal output (B/min.) bis 150<br />

Sealing force (N) 6000<br />

Size range (mm) 60-260 (320*)<br />

*Gusset fold<br />

Performance specifications as a function of product and packing material

VPL<br />

Continuous form-, fill- and seal machine with linear motor<br />

Continuous form-, fill- and seal machine VPL with linear motor<br />

convinces with the precise drive technology provided by the<br />

linear motor and is focused on the requirements of the food<br />

industry.<br />

Equipped with a full sealing process controller, the VPL series<br />

has almost unlimited applications.<br />

The number of cycles, size ranges, bag lengths, sealing<br />

pressure, sealing time, sealing path, cooling time - all are<br />

variable and programmable. This means: greatest flexibility<br />

and maximum productivity.<br />

Since the drive does not require oil-filled gearboxes, the<br />

machine is environmentally friendly with low maintenance<br />

requirements and low wear.<br />

Flexible, powerful and reliable quality<br />

Long sealing times from the optimized utilization of the<br />

sealing path and a sealing pressure up to 8000 N ensure that<br />

perfect seal quality can be achieved from the shortest to the<br />

longest bags. This also means that difficult films can be<br />

processed properly at high production rates.<br />

The VPL series is equipped with the sense&seal function<br />

that employs electronic product scanning to detect product<br />

particles in the seal. In this case, the sealing process is<br />

interrupted by quickly withdrawing the sealing jaws and not<br />

activating the cut off knive. The machine produces a double<br />

bag that is discharged and automatically restarts the<br />

packaging process. This reduces downtime to a minimum.<br />

The machine also includes the newly patented sealing<br />

process Premiumseal that optimizes the sealing pressure<br />

profile to save time and money. Conditions for maximum<br />

efficiency and <strong>repro</strong>ducibility are provided by individual<br />

adjustments of all the sealing parameters. In each case, the<br />

effect of various packaging material properties or processrelated<br />

features are taken into account, which means that the<br />

best possible packing quality is guaranteed.<br />

Highlights of the VPL series<br />

- Extremely low on maintenance and wear and tear due to<br />

precision gearless linear motor drive technology.<br />

- Powerful, compact, flexible and responsive<br />

- Versatile based on the large size range<br />

- Sense&Seal function to avoid product inclusions in cross<br />

seals and protect sealing jaws and cut off knife for reduced<br />

mainanance cost and increased efficiency<br />

- Premiumseal brings the sealing process to perfection. It is<br />

the key for the best possible seal quality and preserves the<br />

wrapping materials propperties such as barrier layers<br />

Simple and safe operation<br />

The machines control system consists of a Siemens PC<br />

(alternatively a Rockwell PC) with the intelligent <strong>ROVEMA</strong>-<br />

P@ckControl software. This controller is perfectly suited to<br />

control the gearless direct drive linear motors and enables<br />

precise backlash-free, movements at very high outputs.<br />

The modern SERCOSIII bus technology permanently<br />

guarantees the constant monitoring of simultaneous<br />

movements during the packaging process. This ensures<br />

optimized and <strong>repro</strong>ducible quality for the final packaging<br />

products. As a matter of course, the VPL will also accept all<br />

necessary parameters for the packaging process by simply<br />

entering them on the display while bad entries are prevented<br />

by dynamic limiting values.<br />

The modem or Ethernet connection can be used to perform<br />

remote diagnostics of the machine condition at any time.<br />

Operational data are available via appropriate interfaces for<br />

further processing.

REPRO<br />

Performance of the VPL<br />

VPL 180<br />

Nominal output (B/min.) bis 200<br />

Sealing force (N) 5000<br />

Size range (mm) 50-180 (220*)<br />

VPL 260<br />

*Gusset fold<br />

Performance specifications as a function of product and packing material<br />

Nominal output (B/min.) bis 180<br />

Sealing force (N) 6000<br />

Size range (mm) 60-260 (320*)<br />

VPL 400<br />

Nominal output (B/min.) bis 150<br />

Sealing force (N) 8000<br />

Size range (mm) 80-400

Für VPI jede Aufgabe die<br />

Intermittend form-, fill- and seal machine<br />

richtige Lösung.<br />

The all-round talent VPI has nearly no limits for its use! No<br />

matter whether frozen food, cereals or short cut pasta – the<br />

machine ensures at the same time a product safe handling<br />

and economical packaging of coarse, granulated, pasty or<br />

liquid products.<br />

Modular and flexible<br />

The VPI’s modular construction ensures that you are well<br />

prepared for future packaging requirements, trends in pack<br />

designs, or new packaging materials.<br />

The wide variety of formats, along with the ability to process<br />

all kinds of mono or laminated film material and a<br />

comprehensive range of accessories allow the production<br />

of a wide range of bag shapes and sizes.<br />

Highlights of the VPI series<br />

- The wide size range and suit to application add on<br />

modules enable the machine to pack and produce<br />

large variety of produts and bag styles<br />

- Vacuum draw down belts for packaging material<br />

transport for the safe handling of a wide range of<br />

materials<br />

- Sense&Seal function to avoid product inclusion in cross<br />

seal and to protect jaws and cut of knife. For increased<br />

efficiency and reduced mainenance<br />

- Wear-free servo motor based main drive for the<br />

cross-sealing station<br />

- Sealing time, sealing force and jaw apperture of the cross<br />

sealing station can be free configured and stored in<br />

machines control system<br />

Simple and safe operation<br />

Vertical form fill and seal machine VPI is easy and safe to<br />

use with the <strong>ROVEMA</strong> –P@ckControl software. The control<br />

system is PC based and may be equipped with Siemens or<br />

Rockwell hardware. Simple operation via the touch panel<br />

eases modification of even the most complex settings.<br />

Three levels of password-protected access rights support<br />

appropriate hierarchies, dynamically calculated maximum<br />

and minimum parameter values prevent bad entries.<br />

Performance of the VPI<br />

VPI 180<br />

Nominal output (B/min.) bis 140<br />

Sealing force (N) 5000<br />

Size range (mm) 50-180 (220*)<br />

VPI 260<br />

Nominal output (B/min.) bis 120<br />

Sealing force (N) 5000<br />

Size range (mm) 60-260 (320*)<br />

VPI 400<br />

Nominal output (B/min.) bis 100<br />

Sealing force (N) 8000<br />

Size range (mm) 80-400 (410*)<br />

*Gusset fold<br />

Performance specifications as a function of product and packing material

Germany<br />

<strong>ROVEMA</strong> GmbH<br />

35463 Fernwald<br />

Tel.: + (0) 641 409 0<br />

Mail: info@rovema.de<br />

Netherlands<br />

<strong>ROVEMA</strong> Benelux bv<br />

4902 TT Oosterhout<br />

Tel.: + 31 162 576 464<br />

Mail: sales@rovema.nl<br />

Sales partners and<br />

service centers worldwide<br />

Passion for packaging.<br />

United Kingdom<br />

<strong>ROVEMA</strong> Packaging Machines Ltd<br />

Gatehouse Close, Aylesbury<br />

Tel.: +44 12 96 642 060<br />

Mail: sales@rovema.co.uk<br />

Poland<br />

<strong>ROVEMA</strong> GmbH Sp.z o.o.<br />

02-606 Warszawa<br />

Tel: +48 22 844 77 48<br />

Mail: postmaster@rovema.atomnet.pl<br />

Italy<br />

<strong>ROVEMA</strong> Italia s.r.l.<br />

20026 Novate Milanese (MI)<br />

Tel.: 39 02 48 011 785<br />

Mail: info@rovema-italia.it<br />

Spain<br />

<strong>ROVEMA</strong> Spanien S.L.<br />

08208 Sabadell – Barcelona<br />

Tel: +34 937 154 603<br />

Mail: rovema@rovema.es