Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

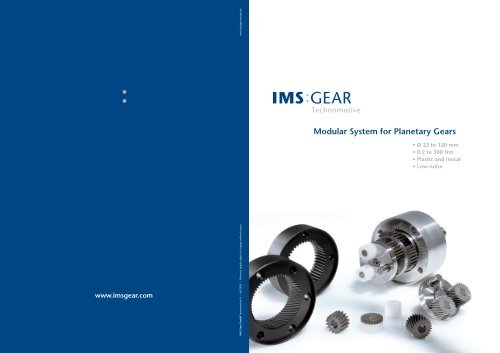

Our planetary gearbox catalogueand what you’ll find in itThis catalogueand its limitsOur modular system offers almost 10,000combination options. This immensevariety allows us to present only a selectednumber of gear units in this catalogue.If the unit you are loooking for is not listed,please contact us. We’d be pleased to help.Page24681013151719212325272931333537Basic InformationThinking aheadOur vast expertiseOur planetary gear unitsOur modular system for planetary gearboxesYour ultimate planetary gearboxOur type seriesmetal (PM), plastic (PK) and low-noise (LN)ø 22mm PK 0.2 – 0.7 Nmø 22mm PM 0.6 – 1.0 Nmø 32mm PK 0.4 – 2.0 Nmø 32mm PM/LN 0.8 – 4.5 Nmø 42 mm PK 0.8 – 4.0 Nmø 42mm PM/LN 3.0 – 15.0 Nmø 52mm PK 2.0 – 10.0 Nmø 52mm PM/LN 4.0 – 25.0 Nmø 62mm PM/LN 8.0 – 50.0 Nmø 72mm PM/LN 14.0 – 84.0 Nmø 81mm PM/LN 20.0 – 120.0 Nmø 105 mm PM/LN 35.0 – 195.0 Nmø 120 mm PM 50.0 – 300.0 Nm41.21212.1Gear reductions (fold-out page)Motor pinions (fold-out page)Specifications for motor attachment (fold-out page)394041Additional informationBearing-mounted input shaftATEX-requirementsConversion table“If you understand geometryyou will understand everything in this world.”Galileo Galilei41.1Addresses and telephone numbersLocations (fold-out page)1

Clemens Rosenstiel andNorbert WillmannDirectors IMS Gear GmbHThinking aheadIMS Gear keeps the world on the moveIMS Gear have been specialists in metalgearing, tooling and toothed-wheelengineering since 1863. In 1983, we addedplastic materials to our product range.The entire value-added and responsibilitychain from the development stage to finalassembly is handled by us in-house. Wehave adapted the concept of “all under oneroof” and taken it to its logical conclusion.The IMS Gear Technomotive Divisionsupplies you with planetary gears inmodular design in plastic, plastic-metalcomposites or in all-metal versions forthe most varied of uses and for a widerange of applications.Our claim for consistent improvement ofcustomer satisfaction goes back to ouraim of a sustained and positive businessdevelopment which, in turn, is based onour vision of the future and our long-termcorporate strategy.Our expertise and experiences in the globalautomotive business in terms of productquality and technology leadership are ourdefining requirements in terms of speed,adaptability, reliability and efficiency.23

Our vast expertiseand what it means for youSoftware development fortooth profile enhancementPrototype and small batch productionProcess planningEquipment designand constructionLogisticsand delivery capabilityDesignGear cutting toolingTest laboratoriesMould toolmanufactureSeries productionAssembly1 2 3 4 5 6 78 9 10111 Software development for toothprofile enhancementWe use our own software to improve toothprofiles beyond DIN standards. This meansthat our gears have less backlash, are moreresistant to wear and tear with optimumperformance in terms of strength.They aresmoother and quieter running, and areless sensitive to tolerances.2 DesignThe in-house design department ofIMS Gear Technomotive is consistentlyengaged in the development of theentire modular system. That's not all!Our team of experts is on standby forcomprehensive and rapid adaptationsto match your specific requirementsand specifications.3 Gear cutting toolingWe at IMS make our own tools for cuttingthe metal gears. This gives you anenormous advantage in lead time, andall the steps from theory to practice arehandled by a single supplier.4 Prototypeand small batch productionIMS Gear Technomotive will supply youwith custom-made sample gear unitsright through to small batches withina couple of days. We achieve this degreeof flexibility with our comprehensiveproduction capability and ourindependence from subcontractorsand outside suppliers.5 Test laboratoriesIn addition to the quality assuranceaccompanying Series production, IMSGear Technomotive continually carriesout stress, wear and tear and life tests.Accompanying every development,our design department together withthe Automotive division uses the noiselaboratory and the climate testinglaboratory of our Technology Centrein Donaueschingen.6 Process planningThis is where IMS Gear Technomotivebenefits from the immense wealth ofexperience of the Automotive divisionwith its large batch production runs.The entire production process fromdevelopment through to packaging isplanned and optimised down to thelast detail. The Technomotive standardtoothed components are also largevolume products. In-house processplanning results in reliable productionat minimum cost, low reject rates andultimate quality.7 Mould tool manufactureThe in-house production of plasticinjection moulding tools allows us torealise and implement our own designs.It also provides measureable proof ofour production capability anddocumentation.8 Equipment design and constructionSince we design and build our ownassembly and test equipment, productiontooling, and parts feeding systems for ourmachines and their peripherals, we arecapable of responding quickly andefficiently to complex production orcustomer specific requirements.9 Series productionIMS Gear Technomotive makes virtuallyall its Planetary Gearbox componentsin-house. As both metal and plasticcomponent production is in-house,we can produce quickly and withultimate cost-efficiency.10 AssemblyManual assembly for a single unitis integrated in micro-batch production.We produce each series on dedicatedassembly lines with large volumecapacity; and we assemble customeror application specific gear solutionsin high unit quantities on automatedassembly units.11 Logistics and delivery capabilityWe permanently hold stocks of allstandard toothed parts for our modularplanetary gearboxes. Many interfacingparts such as motor pinions, flanges oroutput shafts are in stock as semi-finishedproducts.4 5

Our planetary gear unitsand what you should know about them897106Planetary gearsMode of functionPlanetary gearboxes (<strong>PLG</strong>s) operate as theirname implies: the motor-driven sun wheelis in the middle, transmitting its movementto three circumferential planet gears whichform one stage. They are arranged on thebearing pins of a planet carrier. The lastplanet carrier in each sequence is rigidlylinked to the output shaft and so ensuresthe power transmission to the output shaft.The planet gears run in an internallytoothed outer ring gear.PropertiesInput and output are co-axial. The shaftsturn in the same direction. <strong>PLG</strong>s are suitablefor clockwise and anti-clockwise rotation, foralternating, continuous and cyclic operation,and they excel due to their high degreeof efficiency. Unlike other gear types, theircompact design provides ultimate powerdensity and excellent torque transfer in thesmallest space.Their resistance to shock loads is high dueto load distribution over several components(the three planetary wheels) and the supportof the annular gear.1Exploded drawing PM 72234551 Motor pinion input side2 Motor flange3 Metal planet gears, Stage 14 Planet carrier, Stage 15 Outer ring gear6 Metal planet gears and planet carrier, Stage 27 Metal planet gears, Stage 38 Output flange9 Ball bearing10 Output shaftLow-noise variant1 Motor pinion input side, helical toothing3 Plastic planet gears, helical toothing3PM 72 LN5 Outer ring gear, helical toothing1Connecting flangesThis is where the flexibility of the <strong>PLG</strong>manufacturer really shows. IMS planetarygear units can be fitted to any (!) motor,with individual solutions possible onboth the input side and the output side.Contact us with your specificrequirements.DeliveryIMS Gear Technomotive can supply yourgearbox with the motor of your choice,fully assembled and inspected, orindividually with separate motor pinionfor remote assembly. We can also assistyou with motor selection.EfficiencyThe inter-gear efficiency takes only thegear-making process into account,whereas the gearbox efficiency relatesto the losses in the entire gearboxassembly. In this brochure we alwaysspecify the gearbox efficiency which isnecessarily lower than the inter-gearefficiency. Since there are no standardisedmeasuring methods, care is requiredwhen comparing the efficiencyspecified by different manufacturers.Gear backlashGear backlash depends on a largenumber of factors: type of load, numberof stages, bearing, design or materialcombination. When comparing differentmanufacturers, please note that thereare also no standardised measurementmethods. The values specified in thiscatalogue were measured with no loadand with blocked input drive.Heat treatmentThe structural transformation duringheat treatment of the metal componentshas positive effects on strength and wearperformance of the gear units. IMS has itsown heat treatment shop. Since we alsohave the entire metal machining activityin-house, we are capable of selectingfrom a wide choice of heat treatable alloysteels.Load on output shaftDifferent manufacturers use differentmethods of measurement makingcomparison difficult. Comparisons mustbe made with caution. The details in theIMS catalogue are based on the followingconditions: rotational motor speed3,000 rpm, lowest reduction ratio foreach stage, simultaneous axial and radialload, radial load in the centre of thedriven shaft. Send us your specificationand parameters, we'll be pleased tocalculate the maximum axial and radialloads for your application. By modifyingaspects of the basic design, we can alsotolerate higher loads. Give us a call.Low-noise gearsOptimum noise performance makesmore stringent demands on true runningand axial eccentricity of the motorbearing plate, flange and shaft. Thehelical toothing causes axial forces toact on the motor shaft, with the effectthat adequate dimensioning of the motorshaft bearing must be ensured. Tocounter the grease-pumping effect ofthe helical toothing, radial shaft sealinggaskets or sealed motor bearings arerecommended.LubricationOur <strong>PLG</strong>s are grease-packed and thereforemaintenance free throughout their life.Depending on the application, weselect the best possible lubricant from asmany as ten different options.Mounting positionThe grease lubrication and the differentsealing modes allow the IMS planetarygears to be installed in any position.Operating temperatureThe operating temperature rangedepends on material selection andchoice of lubricant. The temperaturerange of our all-metal versions withstandard lubrication is between –30and +140 °C, that of the plastic PKseries is between –15 and +65 °C.Operational dynamicsOptimum operating dynamics areachieved through low moments ofinertia, freedom of rotation and lowwear and tear. Wherever appropriate,IMS Gear Technomotive uses plasticinstead of metal for the planet gearsand arranges these at balanced 120°angles. This results in low moments ofinertia. If required, we achieve theultimate ease of movement by fittinghigh-grade needle bearings or byselecting favourable friction valuesbetween metal and plastic. Wear isreduced by using a special gear toothprofile with tip relief and by usingplastic wheels. Thus the selected IMSmaterial mix guarantees excellentoperational dynamics.Output torqueWhen selecting a planetary gear, theoutput torque or moment is one of themost important variables. The reductionratio lowers the relatively high rotationalmotor speed to a lower output speed,increasing the output torque in inverseproportion. Please refer to page 10 tocalculate the output.Overload torqueThe permitted overload torque (shockload) is defined as a short-term increasein output torque, e.g. during the start-upof a motor. In plastic <strong>PLG</strong>s, the peaktorque equals the overload torque.In plastic-metal combinations or inall-metal versions, the overload torquecan be as much as 1.5 times the peakload.Reduction ratiosIf the number of teeth of the sun wheeland the planetary wheels is changed,different reduction ratios are possiblewithin one and the same stage. IMS GearTechnomotive combines these reductionratios in as many as four stages and soachieves as many as 68 (!) non-integerreduction ratios. An enormous varietyof different combinations can beimplemented.Sealing modesThe protection classes are defined inaccordance with DIN 40500 Part 9.We are also capable of supplying outputseals which will allow you to implementhigher protection classes.Service lifeDepending on ambient andenvironmental conditions and on theoperational specification of the drivingsystem, the useful service life of a <strong>PLG</strong>is between 200 and 10,000 hours. Thewide variety of potential applicationsprohibits generally applicable values forthe useful service life.67

Our modular system for planetary gearboxesand its almost 10,000 optional variantsEven using standard gearing components,our modular system offers an immensevariety of options. Also, pinion variants,flanges, outputs, bearings, lubricants andseals provide a wide range of optionsfor virtually every combination. Since westock all common parts, we are capableof delivering, even small quantities at shortnotice. For clarity, we have listed onlythe metal (P) or plastic (PK) <strong>PLG</strong>series in this catalogue, but we willsend you any reasonable material mixon request. Give us a call. We are hereto advise you.Motor pinions… virtuallyunlimited optionsMotor flange… to date, almost1,300 optionsPlanetary gearsPK/PM… to date, 1,270standard gearvariantsPlanetary gearsLow-noise111 21 21 2 31 2 31 2 3 41 2 3 4……Standard StandardAdaptationOur planetary gears are designed for connecting anycurrent type of motor, using three different modes:with adaptable motor pinion in various designs, orusing our option involving bearing-mounted inputshafts. With appropriate quantities and after consultationswith the motor manufacturer, the motorNine different diameters with as many as four gearstages and a wide variety of reduction ratios rangingfrom 3.7:1 to 2,075.9:1 are available in plastic, metalor material mix versions with output torques rangingfrom 0.2 to 300 Nm. Although this results in animmense variety of options, we describe as standardThe new low-noise modules for the first stage featurea well-attuned combination of module, number ofteeth, helical angle, gearing width and choice ofmaterial, guaranteeing ultimate smooth running andhigh torque stability. With the new tandem planetarygears (patent applied for), even high peak loads areshaft can also be intermeshed directly. With anadapted motor mounting plate, the motor can thenbe connected to the annular wheel without anyadditional motor flange, allowing shorter and morecost-effective gearing assemblies.Flanges are available in plastic, die cast zinc oraluminium, as basic, standard or special flange,adapted individually depending on requirements.For diameters below 42 mm and with PK 52, themotor is connected to the gear via a special flange.For larger quantities you can also obtain toolspecificspecial flanges, e.g. made of plastic ordie cast zinc. Type series P 52 to P 120 are alsoavailable with standard DIN 42948 flanges. Inthis case we recommend designing motor andflange according to DIN 42955-R.gearboxes which can be manufactured from anyof our standard components and their variants.safely transfered. The external dimensions andreductions, identical to those of the straight-toothedgears and differing only in microns, allow easyreplacement in most cases.Output flange… to date, over1,300 optionsOutput… virtuallyunlimitedadaptationoptions……AdaptationThe output flange includes the bearing. Sinteredmetal bearings or ball bearings can be selected tomatch the operating requirements. Gearboxes withtwo RS seals in the ball bearing of the output shaftare protection class IP 53, whereas with two Z coverdisks they are protection class IP 42. Sintered metalThe output shaft is linked to the last planet carrierand can be designed in any customer specific layoutdepending on the machine to be driven.versions are protection class IP 00. Higher protectionclasses can be implemented by applying specificseals.8 9

Your ultimate planetary gearboxand how to select iti = Reduction ration M = Motor speedn AB = Output speedT N = Nominal output torqueT M = Motor torqueη = Gear efficiencyT AB = Output torqueC B = Operating factorThe T AB output torque is the mostimportant variable when selecting themost suitable <strong>PLG</strong>. Use the equationcompendium below to calculate thisvariable. The next important factor isthe gear diameter.Once you have calculated the maximumoutput torque T AB , you can refer to theThe reduction ratio i is used to reduce therelatively high motor speed n Mto a loweroutput speed n AB.With:i = n M/ n ABYour desired nominal output torque T Nistherefore calculated as follows:T N= T M• i • ηTo determine the reduction ratio i andthe gear efficiency η, please refer to theappropriate type series in this catalogue.Determining the operating factor C BDirection Load (shocks) Daily operating timeof rotation 3h 8h 24hconstant none C B= 1.0 C B= 1.1 C B= 1.3medium C B= 1.2 C B= 1.3 C B= 1.5strong C B= 1.4 C B= 1.5 C B= 1.8alternating none C B= 1.3 C B= 1.4 C B= 1.6medium C B= 1.6 C B= 1.7 C B= 1.9strong C B= 1.9 C B= 2.0 C B= 2.2The maximum output torque T ABis calculated as follows:T AB= T N• C Bdiagram on the right to read the <strong>PLG</strong>type series with the appropriate diameter.In most cases and depending on thenumber of gearing stages, a T AB valuecan be implemented with several <strong>PLG</strong>type series. Any questions? Give us a call.We are there to help you.When calculating the actual outputtorque T AB, the calculated nominaloutput torque T Nand the operatingfactor C Bshould also be taken intoaccount. C Bis merely a factor whichaddresses the different workingconditions of a <strong>PLG</strong> and which is theresult of your subjective appraisal. It istherefore only meant as a guide value.We include the following factors in therough estimation of the operating factorC B: direction of rotation, load (shocks)and daily operating time.Refer to the table below to calculatethe approximate operating factor C B.All details in the catalogue referto C B= 1.0Therefore: T AB= T NType seriesPK 22PM 22PK 32PM 32PM 32 LNPK 42PM 42PM 42 LNPK 52PM 52PM 52 LNPM 62PM 62 LNPM 72PM 72 LNStagesPM81 / PM81LN1234PM 105PM 105 LNPM 120123412341234123412341234123412341234123412340.20.40.60.70.40.60.70.750.81.01.02.02.0Once you have calculated the maximum output torqueusing the equation compendium on the left, you canthen refer to the diagram on the top and see whichIMS planetary gear matches. The figures in the type0.82.02.02.253.04.04.04.04.54.55.07.58.0permissible output torque T AB /Nm150.02150.034300.0300.00 15 10 25 50 150 30010.010.012.014.015.015.020.025.025.025.035.042.050.050.060.084.084.0105.0120.0120.0195.0195.0series description denote the gear diameter. Each IMStype series is available with four stages, which meansthat several diameters are often available for one andthe same output torque.T AB/ Nm1011

Please open up!Alternative motor pinion variantsShort pinionBushing + pinionCup-type pinionClamp-type pinionGeared shaftAttachment options• pinning• cross thread• keyway• pressfit• bonding• clamping12

Specifications for motor attachmentIntermediate flangeMotorMotorshaftCylindrial shaft end (Z)DIN 42946Basic flangeThrust ring thickness fMotor pinionDesign variant:Bushing + pinionBore out cross hole Ø qfor tension pin DIN 1481bkchao max.mp max.nTension pinDIN 1481(drilling off with motor shaft)Thread d -4x90°(Shown offset by 45°)ielgPM32 PK32 PM42 PK42 PM52 PK52 PM62 PM72 PM81 PM105 PM120PM32LN PM42LN PM52LN PM62LN PM72LN PM81LN PM105LNPinion Flangea 32 32 42 42 52 52 62 72 81 105 120b 14 H8 14 H8 20 H7 20 H7 30 H7 30 H8 40 H7 40 H7 40 H7 50 H7 60 H7c 28.1 – 0,15 28.1 – 0.15 33.3 33.3 42.5 42.5 51 59 69.5 86 100d M2 M2 M4 M4 M4 M4 M5 M6 M6 M10 M10e 11 11 10.4 10 10.4 10 15.4 20 18.5 20 20f 0.2 0.2 0.2 0.2 0.3 0.3 0.3 0.5 0.3 0.5 0.5g 6.1 – 0.4 6.1 – 0.4 8 + 0.3 8 + 0.3 8 + 0.3 8 + 0.3 10,4 – 0.3 12.1 – 0.3+ 0.1513,5 – 0.25 18.3 – 0.3+ 0.219,4 – 0.3h – – 39 – 0.02 – 49 – 0.02 – 59 – 0.025 69 – 0.025 78 – 0.025 100 – 0.025 115 k7i – – 2.5 – 3 – 3.0 3.5 3.5 3.5 3.3k 22.1 – 0.02* 22.1 – 0.02 24.2 – 0.2 24.7 – 0.03 32,8 – 0.2 33.34 – 0.03 39 – 0.2 42.5 – 0.2 51.8 – 0.2 63.8 – 0.2 76 ± 0.1l 1.8 + 0.1 1.8 + 0.1 2 + 0.1 2.5 + 0.1 2 + 0.1 2.5 + 0.1 2 + 0.1 2 + 0.1 2 +0.1 2 + 0.1 6.1 ± 0.05m 10 10 11–12 11 15 15 18 – 20 20 24 30 35.6n 16 16 27.5 27.5 34 34 38 41.4 48.5 60 70o 3 3 7 7 10 10 12 14 18 21 26p 6 6 11 11 16 16 18 19 21 26 28q – – 2 2 3 3 3 3 3 5 5* k in PM32LN is = 21,1 – 0.0212 X .1

PK 42PK 42Parameter 1-stage 2-stage 3-stage 4-stagePerm. output torque (Appl. factor C B =1.0) 0.8 Nm 2.0 Nm 4.0 Nm 4.0 NmGearbox efficiency, approx. 0.80 0.75 0.70 0.65Max. backlash in ° DEG 1.70° 1.75° 1.80° 1.85°Recommended initial speed 3,000 rpm 3,000 rpm 3,000 rpm 3,000 rpmOperating temperature -15 °C to +65 °C -15 °C to +65 °C -15 °C to +65 °C -15 °C to +65 °COutput side with sintered metal bearingMax. load, radial 15 N 30 N 45 N 45 NMax. load, axial 5 N 10 N 30 N 30 NMax. perm.fitting pressure 150 N 150 N 150 N 150 NGearbox length p 48.9 ± 0.5mm 61.9 ± 0.5mm 74.9 ± 0.5mm 87.9 ± 0.5mmØ x Total length 42.0 x 73.9 mm 42.0 x 86.9 mm 42.0 x 99.9 mm 42.0 x 112.9 mmWeight 200 g 300 g 400 g 500 gOutput side with ball bearing (2RS)Max. load, radial 160 N 230 N 300 N 300 NMax. load, axial 50 N 80 N 110 N 110 NMax. perm.fitting pressure 320 N 320 N 320 N 320 NGearbox length p 48.9 ± 0.5mm 61.9± 0.5mm 74.9 ± 0.5mm 87.9 ± 0.5mmØ x Total length 42.0 x 73.9 mm 42.0 x 86.9 mm 42.0 x 99.9 mm 42.0 x 112.9 mmWeight 400 g 500 g 600 g 700 g· Gear reductions see last page (fold-out page)· Specifications for motor attachment see page 12.1 (fold-out page)Ø42Ø36p 252.8Key, keyway DIN 6885 – A3x3x16Ctrg. DIN 332 – D M3Ordering codes01 Basic flange06 Special flange07 Bearing flange of plastic, sintered bearing on output shaft08 Bearing flange of plastic, ball bearing on output shaft09 Bearing-mounted input shaft (see page 39)10 Bearing flange of plastic, direct bearingBasic designØ H7Ø 322320Ø2.5 – 0.11017.1Ø33.3depth 330° 30°M4x10max. 9Refer to the above table for the values of p.M4Ø33Ø 8 g6Ø 25 h10Order exampleYou wish to order a plastic planetary gear with a diameter of 42 mm of type series PK 42with the reduction ratio 46:1, special flange on motor side, bearing flange of plastic,sintered bearing on output side.Feel free to contact us – we are happy to help youPK 42. 46. 06 / 07Planetary gear, plasticType seriesReduction ratio roundedFlange, motor side (see ordering codes)Flange, output side (see ordering codes)The details given herein are recommended values. Minor variances due to reduction ratios or non-standard testing or measuring methodsetc. may occur. Please refer to pages 6 to 11 and 39 of this catalogue for basic or additional information, or contact us directly. Technicaldetails subject to change without notice.2021

PM 42 | PM 42 LNPM 42 | PM 42 LNParameter 1-stage 2-stage 3-stage 4-stageNEMA flange 1731M3Ø 3.210.5Shown offsetØ42Ø 22 h8Ø22H731Perm. output torque (Appl. factor C B =1.0) 3.0 Nm 7.5 Nm 15.0 Nm 15.0 NmGearbox efficiency, approx. 0.80 0.75 0.70 0.65Max. backlash in ° DEG 0.90° (LN: 1.30°) 1) 0.95° 1.00° 1.05°Recommended initial speed 3,000 rpm 3,000 rpm 3,000 rpm 3,000 rpmOperating temperature -30 °C to +140 °C -30 °C to +140 °C -30 °C to +140 °C -30 °C to +140 °C3142.130.5220.6qRefer to the table on the right for the values of q.3142.1Output side with ball bearing (2RS)Max. load, radial 160 N 230 N 300 N 360 NMax. load, axial 50 N 80 N 110 N 140 NMax. perm. fitting pressure 320 N 320 N 320 N 320 NGearbox length p 49.1 ± 0.5mm 62.2 ± 0.5m 75.3 ± 0.5mm 88.4 ± 0.5mmGearbox length q 72.6 ± 0.5mm 85.7 ± 0.5mm 98.8 ± 0.5mm 111.9 ± 0.5mmØxTotal length(p+lengthfrombearingflange) 42.0 x 74.1 mm 42.0 x 87.2 mm 42 x 100,3 mm 42.0 x 113.4 mmWeight (for gearbox length p) 400 g 500 g 600 g 700 g1) For plastic PL wheels only! Impact of 1st stage for 2-4 stage versions is negligible. · Gear reductions see last page (fold-out page)· Specifications for motor attachment see page 12.1 (fold-out page)Ø42Ø36p2.825Key, keyway DIN 6885 – A3x3x16Ctrg. DIN 332 – D M3Ø32238g6Ø20H7depth 3Basic design30°30°M4Ø 25 h9M3x10M4x10max. 97.9 27.5Ø33.3Refer to the above table for the values of p.Ordering codes01 Basic flange06 Special flange09 Bearing-mounted input shaft (see page 39)17 NEMA flangeOrder exampleYou wish to order a metal planetary gear with a diameter of 42 mm of type series PM 42with the reduction ratio 46:1, special flange on motor side, basic flange on output side.Feel free to contact us – we are happy to help youPM 42 LN. 46. 06 / 01Planetary gear, metalType seriesLow-noise designReduction ratio roundedFlange, motor side (see ordering codes)Flange, output side (see ordering codes)The details given herein are recommended values. Minor variances due to reduction ratios or non-standard testing or measuring methodsetc. may occur. Please refer to pages 6 to 11 and 39 of this catalogue for basic or additional information, or contact us directly. Technicaldetails subject to change without notice.2223

PK 52PK 52Parameter 1-stage 2-stage 3-stage 4-stagePerm. output torque (Appl. factor C B =1.0) 2.0 Nm 5.0 Nm 10.0 Nm 10.0 NmGearbox efficiency, approx. 0.75 0.70 0.65 0.60Max. backlash in ° DEG 1.10° 1.15° 1.20° 1.25°Recommended initial speed 3,000 rpm 3,000 rpm 3,000 rpm 3,000 rpmOperating temperature -15 °C to +65 °C -15 °C to +65 °C -15 °C to +65 °C -15 °C to +65 °COutput side with ball bearing (2RS)Max. load, radial 200 N 320 N 450 N 500 NMax. load, axial 60 N 100 N 150 N 200 NMax. perm. fitting pressure 500 N 500 N 500 N 500 NGearbox length p 55.1 ± 0.5mm 69.2 ± 0.5mm 83.3 ± 0.5mm 97.4 ± 0.5mmØ x Total length 52.0 x 80.1 mm 52.0 x 94.2 mm 52.0 x 108.3 mm 52.0 x 122.4 mmWeight 400 g 500 g 600 g 700 g· Gear reductions see last page (fold-out page)· Specifications for motor attachment see page 12.1 (fold-out page)Key, keyway DIN 6885 – A 4x4x16Ø52p4.225Ctrg. DIN 332 – D M4Ø40Ø4732.5Ø30H8depth 3Basic designØ 32 h8M4Ø 12 h7M5x10max. 810 22.3Ø42.5Refer to the above table for the values of p.Ordering codes01 Basic flange06 Special flange09 Bearing-mounted input shaft (see page 39)Order exampleYou wish to order a plastic planetary gear, with a diameter of 52 mm of type series PK 52with the reduction ratio 25:1, bearing-mounted input shaft on motor side, basic flange onoutput side.Feel free to contact us – we are happy to help youPK 52. 25. 09 / 01Planetary gear, plasticType seriesReduction ratio roundedFlange, motor side (see ordering codes)Flange, output side (see ordering codes)The details given herein are recommended values. Minor variances due to reduction ratios or non-standard testing or measuring methodsetc. may occur. Please refer to pages 6 to 11 and 39 of this catalogue for basic or additional information, or contact us directly. Technicaldetails subject to change without notice.2425

PM 52 | PM 52 LNPM 52 | PM 52 LNParameter 1-stage 2-stage 3-stage 4-stageStandard flangeb 23sc3b3w3Perm. output torque (Appl. factor C B =1.0) 4.0 Nm 12.0 Nm 25.0 Nm 25.0 NmGearbox efficiency, approx. 0.80 0.75 0.70 0.65Max. backlash in ° DEG 0.70° (LN: 1,10°) 1) 0.75° 0.80° 0.85°Recommended initial speed 3,000 rpm 3,000 rpm 3,000 rpm 3,000 rpmOperating temperature -30 °C to +140 °C -30 °C to +140 °C -30 °C to +140 °C -30 °C to +140 °Cs2e2a2n3u3ShownoffsetRefer to the table on the right for the values of k.kf2c2Dim.of motor mount./flange 1) a 3 b 3 w 3 c 3 e 3 n 3 u 3 s 3C 80 2) 80 50 H7 38 H7 10.2 65 3 5.5 5.5C 105 2) 105 70 H7 10.2 85 3 6.5Dimensions of gear unit output/flange a 2 b 2 c 2 e 2 f 2 s 2C 80 80 50 j7 9 65 2.5 M5C 90 90 60 j7 9 75 2.5 5.5C 105 105 70 j7 9 85 2.5 6.5C 120 120 80 j7 9 100 3.0 6.5e3a3Output side with ball bearing (2RS)Max. load, radial 200 N 320 N 450 N 500 NMax. load, axial 60 N 100 N 150 N 200 NMax. perm. fitting pressure 500 N 500 N 500 N 500 NGearbox length p 55.3 ± 0.5mm 69.5 ± 0.5mm 83.7 ± 0.5mm 97.9 ± 0.5mmGearbox length k (motorsize 56) 82.0 ± 0.5mm 96.2 ± 0.5mm 110.4 ± 0.5mm 124.6 ± 0.5mmGearbox length q 76.6 ± 0.6mm 90.8 ± 0.6mm 105.0 ± 0.6mm 119.2 ± 0.6mmØxTotal length(p+lengthfrombearingflange) 52.0 x 80.3 mm 52.0 x 94.5 mm 52.0 x 108.7 mm 52.0 x 122.9 mmWeight (for gearbox length p) 0.7 kg 0.9 kg 1.1 kg 1.3 kg1) For plastic PL wheels only! Impact of 1st stage for 2-4 stage versions is negligible. · Gear reductions see last page (fold-out page)· Specifications for motor attachment see page 12.1 (fold-out page)Ø52p4.225Key, keyway DIN 6885 – A4x4x16Ctrg. DIN 332 – D M41) standard motors2) motor size 56 (B14, B3/B14)Basic designØ510Shown offsetØ38.1H7Ø4032.5Ø30H8depth 3NEMA flange 2347.14M5Ø52Ø38.1 h847.1456.430.31.56qRefer to the table on the right for the values of q.47.1456.447.14M5x10M4max. 87.4 33Ø 12 h7Ø 32 h8Ø 42.5Refer to the above table for the values of p.Ordering codes01 Basic flange02 C 8003 C 9004 C 10505 C 12006 Special flange09 Bearing-mounted input shaft (see page 39)23 NEMA flangeOrder exampleYou wish to order a metal planetary gear with a diameter of 52 mm of type series PM 52with the reduction ratio 46:1, special flange on motor side, basic flange on output side.Feel free to contact us – we are happy to help youPM 52 LN. 46. 06 / 01Planetary gear, metalType seriesLow-noise designReduction ratio roundedFlange, motor side (see ordering codes)Flange, output side (see ordering codes)The details given herein are recommended values. Minor variances due to reduction ratios or non-standard testing or measuring methodsetc. may occur. Please refer to pages 6 to 11 and 39 of this catalogue for basic or additional information, or contact us directly. Technicaldetails subject to change without notice.2627

PM 62 | PM 62 LNPM 62 | PM 62 LNParameter 1-stage 2-stage 3-stage 4-stageb 22Standard flange3sc3 b3Perm. output torque (Appl. factor C B =1.0) 8 Nm 25 Nm 50 Nm 50 NmGearbox efficiency, approx. 0.80 0.75 0.70 0.65Max. backlash in ° DEG 0.65° (LN: 0,95°) 1) 0.70° 0.75° 0.80°Recommended initial speed 3,000 rpm 3,000 rpm 3,000 rpm 3,000 rpmOperating temperature -30 °C to +140 °C -30 °C to +140 °C -30 °C to +140 °C -30 °C to +140 °Cs2ea2n3ShownoffsetRefer to the table on the right for the values of k.kf2c2Dim.of motor mount./flange 1) a 3 b 3 c 3 e 3 n 3 s 3C 80 2) 80 50 H7 7 65 3.0 5.5C 105 2) 105 70 H7 7 85 3.0 6.5C 90 3) 90 60 H7 7 75 3.0 5.5C 120 3) 120 80 H7 7 100 3.5 6.5e3a3Output side with ball bearing (2RS)Max. load, radial 240 N 360 N 520 N 640 NMax. load, axial 70 N 100 N 150 N 200 NMax. perm. fitting pressure 1,000 N 1,000 N 1,000 N 1,000 NGearbox length p 58.2 ± 0.5mm 75.1 ± 0.5mm 92.0 ± 0.5mm 108.9 ± 0.5mmGearbox length k (motorsize 56 and 63) 82.3 ± 0.6mm 99.2 ± 0.6mm 116.1 ± 0.6mm 133.0 ± 0.6mmØxTotal length(p+lengthfrombearingflange) 62.0 x 97.2 mm 62.0 x 114.1 mm 62.0 x 131.0 mm 62.0 x 147.9 mmWeight (for gearbox length p) 0.8 kg 1.2 kg 1.6 kg 2.0 kg1) For plastic PL wheels only! Impact of 1st stage for 2-4 stage versions is negligible. · Gear reductions see last page (fold-out page)· Specifications for motor attachment see page 12.1 (fold-out page)Dimensions of gear unit output/flange a 2 b 2 c 2 e 2 f 2 s 2C 80 80 50 j7 9 65 2.5 M5C 90 90 60 j7 9 75 2.5 5.5C 105 105 70 j7 9 85 2.5 6.5C 120 120 80 j7 9 100 3.0 6.5Ø62p939Key, keyway DIN 6885 – A5x5x18Ctrg. DIN 332 – D M51) standard motors2) motor size 56 (B14, B3/B14)3) motor size 63 (B14, B3/B14)Ø5255.5Ø40H7depth 3Basic designM5Ø 14 h7Ø 40 j7M5x10max. 1012.430.0Ø51Refer to the above table for the values of p.Ordering codes01 Basic flange02 C 8003 C 9004 C 10505 C 12006 Special flange09 Bearing-mounted input shaft (see page 39)Order exampleYou wish to order a metal planetary gear with a diameter of 62 mm of type series PM 62with the reduction ratio 46:1, flange C 80 on motor side, flange C 105 on output side.Feel free to contact us – we are happy to help youPM 62. 46. 02 / 04Planetary gear, metalType seriesReduction ratio roundedFlange, motor side (see ordering codes)Flange, output side (see ordering codes)The details given herein are recommended values. Minor variances due to reduction ratios or non-standard testing or measuring methodsetc. may occur. Please refer to pages 6 to 11 and 39 of this catalogue for basic or additional information, or contact us directly. Technicaldetails subject to change without notice.2829

PM 72 | PM 72 LNPM 72 | PM 72 LNParameter 1-stage 2-stage 3-stage 4-stageStandard flangeb 2s 3c 3b 3Perm. output torque (Appl. factor C B =1.0) 14 Nm 42 Nm 84 Nm 84 NmGearbox efficiency, approx. 0.80 0.75 0.70 0.65Max. backlash in ° DEG 0.60° (LN: 0.90°) 1) 0.65° 0.70° 0.75°Recommended initial speed 3,000 rpm 3,000 rpm 3,000 rpm 3,000 rpmOperating temperature -30 °C to +140 °C -30 °C to +140 °C -30 °C to +140 °C -30 °C to +140 °Cn 3Shownoffset f 2e3e 2c 2a 2 kRefer to the table on the right for the values of k.Dim.of motor mount./flange a 3 b 3 c 3 e 3 n 3 s 3C 80 80 50 H7 9 65 3.0 5.5C 90 90 60 H7 9 75 3.0 5.5C 105 105 70 H7 9 85 3.0 6.5C 120 120 80 H7 9 100 3.5 6.5Output side with ball bearing (2RS)Max. load, radial 320 N 480 N 760 N 1,000 NMax. load, axial 70 N 100 N 160 N 220 NMax. perm.fitting pressure 1,300 N 1,300 N 1,300 N 1,300 NGearbox length p 73.4 ± 0.5mm 93.0 ± 0.5mm 112.6 ± 0.5mm 132.2 ± 0.5mmGearbox length k (motorsize 56 and 63) 94.6 ± 0.6mm 114.2 ± 0.6mm 133.8 ± 0.6mm 154.4 ± 0.6mmØxTotal length(p+lengthfrombearingflange) 72.0 x 122.4 mm 72.0 x 142.0 mm 72.0 x 161.6 mm 72.0 x 181.2 mmWeight (for gearbox length p) 1.4 kg 1.9 kg 2.4 kg 2.9 kg1) For plastic PL wheels only! Impact of 1st stage for 2-4 stage versions is negligible. · Gear reductions see last page (fold-out page)· Specifications for motor attachment see page 12.1 (fold-out page))Dimensions of gear unit output/flange a 2 b 2 c 2 e 2 f 2 s 2C 80 80 50 j7 9 65 2.5 M5C 90 90 60 j7 9 75 2.5 M5C 105 105 70 j7 9 85 2.5 6.5C 120 120 80 j7 9 100 3.0 6.5Ø72Ø60p949Key, keyway DIN 6885 – A5x5x30Ctrg. DIN 332 – D M555Ø 16 h7Ø 40 H7depth 3Basic designM6Ø 45 j7M5x10max. 1216.536.6Ø59Refer to the above table for the values of p.Ordering codes01 Basic flange02 C 8003 C 9004 C 10505 C 12006 Special flange09 Bearing-mounted input shaft (see page 39)Order exampleYou wish to order a metal planetary gear with a diameter of 72 mm of type series PM 72with the reduction ratio 46:1, flange C 80 on motor side, flange C 105 on output side.Feel free to contact us – we are happy to help youPM 72 LN. 46. 02 / 04Planetary gear, metalType seriesLow-noise designReduction ratio roundedFlange, motor side (see ordering codes)Flange, output side (see ordering codes)The details given herein are recommended values. Minor variances due to reduction ratios or non-standard testing or measuring methodsetc. may occur. Please refer to pages 6 to 11 and 39 of this catalogue for basic or additional information, or contact us directly. Technicaldetails subject to change without notice.3031

PM 81 | PM 81 LNPM 81 | PM 81 LNParameter 1-stage 2-stage 3-stage 4-stageStandard flangeb 23sc3b3Perm. output torque (Appl. factor C B =1.0) 20 Nm 60 Nm 120 Nm 120 NmGearbox efficiency, approx. 0.80 0.75 0.70 0.65Max. backlash in ° DEG 0.50° (LN: 0.85°) 1) 0.55° 0.60° 0.65°Recommended initial speed 3,000 rpm 3,000 rpm 3,000 rpm 3,000 rpmOperating temperature -30 °C to +140 °C -30 °C to +140 °C -30 °C to +140 °C -30 °C to +140 °Cs2e2a2nShownoffset3f2c2Refer to the table on the right for the values of k.kDim.of motor mount./flange 1) a 3 b 3 c 3 e 3 n 3 s 3C 80 2) 81 50 H7 9 65 3.0 5.5C 90 3) 90 60 H7 9 75 3.0 5.5C 105 2) 105 70 H7 9 85 3.0 6.5C 120 3) 120 80 H7 9 100 3.5 6.5e3a3Output side with ball bearing (2RS)Max. load, radial 400 N 600 N 1,000 N 1,300 NMax. load, axial 80 N 120 N 200 N 280 NMax. perm. fitting pressure 1,500 N 1,500 N 1,500 N 1,500 NGearbox length p 77.9 ± 0.5mm 99.6 ± 0.5mm 121.3 ± 0.5mm 143.0 ± 0.5mmGearbox length k (motorsize 56 and 63) 104.1 ± 0.6mm 125.8 ± 0.6mm 147.5 ± 0.6mm 169.2 ± 0.6mmGearbox length q 112.4 ± 0.5mm 134.1 ± 0.5mm 155.8 ± 0.5mm 177.5 ± 0.5mmØxTotal length(p+lengthfrombearingflange) 81.0 x 126.9 mm 81.0 x 148.6 mm 81.0 x 170.3 mm 81.0 x 192.0 mmWeight (for gearbox length p) 1.8 kg 2.5 kg 3.2 kg 3.9 kg1) For plastic PL wheels only! Impact of 1st stage for 2-4 stage versions is negligible. · Gear reductions see last page (fold-out page)· Specifications for motor attachment see page 12.1 (fold-out page)Dimensions of gear unit output/flange a 2 b 2 c 2 e 2 f 2 s 2C 90 90 60 j7 9 75 2.5 M5C 105 105 70 j7 9 85 2.5 M6C 120 120 80 j7 9 100 3.0 6.5pØ81 949Key, keyway DIN 6885 – A6x6x28Ctrg. DIN 332 – D M61) standard motors2) motor size 56 (B14, B3/B14)3) motor size 63 (B14, B3/B14)Basic design69.58Ø5.5M510Shown offsetØ8173NEMA flange 34Ø h8Ø73H769.58Ø65M656Ø 19 h7Ø 50 j7Ø 40 H7depth 369.58865021069.5886M6x12max. 1218 31Ø 69.5qRefer to the table on the right for the values of q.Refer to the above table for the values of p.Ordering codes01 Basic flange02 C 8003 C 9004 C 10505 C 12006 Special flange09 Bearing-mounted input shaft (see page 39)34 NEMA flangeOrder exampleYou wish to order a metal planetary gear with a diameter of 81 mm of type series PM 81with the reduction ratio 46:1, special flange on motor side, basic flange on output side.Feel free to contact us – we are happy to help youPM 81 LN. 46. 06 / 01Planetary gear, metalType seriesLow-noise designReduction ratio roundedFlange, motor side (see ordering codes)Flange, output side (see ordering codes)The details given herein are recommended values. Minor variances due to reduction ratios or non-standard testing or measuring methodsetc. may occur. Please refer to pages 6 to 11 and 39 of this catalogue for basic or additional information, or contact us directly. Technicaldetails subject to change without notice.3233

PM 105 | PM 105 LNPM 105 | PM 105 LNParameter 1-stage 2-stage 3-stage 4-stageStandard flangeb 2s 3c 3b 3Perm. output torque (Appl. factor C B =1.0) 35 Nm 105 Nm 195 Nm 195 NmGearbox efficiency, approx. 0.80 0.75 0.70 0.65Max. backlash in ° DEG 0.55° (LN: 0.90°) 1) 0.60° 0.65° 0.70°Recommended initial speed 3,000 rpm 3,000 rpm 3,000 rpm 3,000 rpmOperating temperature -30 °C to +140 °C -30 °C to +140 °C -30 °C to +140 °C -30 °C to +140 °CShowns 2 n offset3f 2 e3e 2c 2a 3a 2kRefer to the table on the right for the values of k.Dim.of motor mount./flange 1) a 3 b 3 c 3 e 3 n 3 s 3C 105 105 70 H7 15 85 3.0 6.5C 120 120 80 H7 15 100 3.5 6.5C 140 140 95 H7 15 115 3.5 8.5C 160 160 110 H7 15 130 4.0 8.5Output side with ball bearing (2RS)Max. load, radial 600 N 900 N 1,500 N 1,750 NMax. load, axial 120 N 180 N 300 N 400 NMax. perm. fitting pressure 2,000 N 2,000 N 2,000 N 2,000 NGearbox length p 92.9 ± 0.5mm 124.0 ± 0.5mm 155.1 ± 0.5mm 186.2 ± 0.5mmGearbox length k (motorsize 71) 129.2 ± 0.6mm 160.3 ± 0.6mm 191.4 ± 0.6mm 222.5 ± 0.6mmGearbox length k (motorsize 80) 139.2 ± 0.6mm 170.3 ± 0.6mm 201.4 ± 0.6mm 232.5 ± 0.6mmGearbox length q 132.6 ± 0.5mm 163.7 ± 0.5mm 194.8 ± 0.5mm 225.9 ± 0.5mmØxTotal length(p+lengthfrombearingflange) 105.0 x 151.9 mm 105.0 x 183.0 mm 105.0 x 214.1 mm 105.0 x 245.2 mmWeight (for gearbox length p) 4.4 kg 6.0 kg 7.6 kg 9.2 kg1) For plastic PL wheels only! Impact of 1st stage for 2-4 stage versions is negligible. · Gear reductions see last page (fold-out page)· Specifications for motor attachment see page 12.1 (fold-out page)Dimensions of gear unit output/flange a 2 b 2 c 2 e 2 f 2 s 2C 120 120 80 j7 12 100 3.0 M6C 140 140 95 j7 12 115 3.5 M8C 160 160 110 j7 12 130 3.5 M8Ø105Ø85p59595Key, keyway DIN 6885 – A8x7x40Ctrg. DIN 332 – D M10Ø 50 H7depth 3.5Ø7.1Shown offsetØ 55.54 H7NEMA flange 4288.8888.88106.7M645.9Ø 105q212.7Ø 55.54 h888.88106.788.88Basic designM8x16M10max. 1916.544.6Ø 25 h7Ø70 j7Ø86Refer to the table on the right for the values of q.Refer to the above table for the values of p.Ordering codes01 Basic flange02 C 10503 C 12004 C 14005 C 16006 Special flange09 Bearing-mounted input shaft (see page 39)42 NEMA flangeOrder exampleYou wish to order a metal planetary gear with a diameter of 105 mm of type series PM 105with the reduction ratio 46:1, special flange on motor side, basic flange on output side.Feel free to contact us – we are happy to help youPM 105 LN. 46. 06 / 01Planetary gear, metalType seriesLow-noise designReduction ratio roundedFlange, motor side (see ordering codes)Flange, output side (see ordering codes)The details given herein are recommended values. Minor variances due to reduction ratios or non-standard testing or measuring methodsetc. may occur. Please refer to pages 6 to 11 and 39 of this catalogue for basic or additional information, or contact us directly. Technicaldetails subject to change without notice.3435

PM 120PM 120Parameter 1-stage 2-stage 3-stage 4-stageStandard flangeb 23sc 3 b3Perm. output torque (Appl. factor C B =1.0) 50 Nm 150 Nm 300 Nm 300 NmGearbox efficiency, approx. 0.80 0.75 0.70 0.65Max. backlash in ° DEG 1.00° 1.50° 2.00° 2.50°Recommended initial speed 3,000 rpm 3,000 rpm 3,000 rpm 3,000 rpmOperating temperature -30 °C to +140 °C -30 °C to +140 °C -30 °C to +140 °C -30 °C to +140 °Cs2e2a2n3ShownoffsetRefer to the table on the right for the values of k.kf2c2Dim.of motor mount./flange 1) a 3 b 3 c 3 e 3 n 3 s 3C 105 2) 120 70 H7 15 85 3.0 6.5C 140 2) 140 95 H7 15 115 3.5 8.5C 120 3) 120 80 H7 15 100 3.5 6.4C 160 3) 160 110 H7 15 130 4.0 8.5e 3a3Output side with ball bearing (2RS)Max. load, radial 600 N 900 N 1,500 N 1,750 NMax. load, axial 120 N 180 N 300 N 400 NMax. perm. fitting pressure 2,500 N 2,500 N 2,500 N 2,500 NGearbox length p 106.4 ± 0.5mm 140.6 ± 0.5mm 174.8 ± 0.5mm 209.0 ± 0.5mmGearbox length k (motorsize 71) 148.9 ± 0.6mm 183.1 ± 0.6mm 217.3 ± 0.6mm 251.5 ± 0.6mmGearbox length k (motorsize 80) 158.9 ± 0.6mm 193.1 ± 0.6mm 227.3 ± 0.6mm 261.5 ± 0.6mmØxTotal length(p+lengthfrombearingflange) 120.0 x 179.4 mm 120.0 x 213.6 mm 120.0 x 247.8 mm 210.0 x 282.0 mmWeight (for gearbox length p) 5.6 kg 8.0 kg 10.4 kg 12.8 kg· Gear reductions see last page (fold-out page)· Specifications for motor attachment see page 12.1 (fold-out page)Dimensions of gear unit output/flange a 2 b 2 c 2 e 2 f 2 s 2C 140 140 95 j7 15 115 3.0 M8C 160 160 110 j7 15 130 3.5 M8Ø 120p1573Key, keyway DIN 6885 – A 10x8x50Ctrg. DIN 332 – D M12Ø 10054Ø 60 H7depth 3.5Basic designM10Ø 32 k6Ø 80 j7M10x22max. 211) standard motors2) motor size 71 (B14, B3/B14)3) motor size 80 (B14, B3/B14)3716.7 55Ø100Refer to the above table for the values of p.Ordering codes01 Basic flange02 C 10503 C 12004 C 14005 C 16006 Special flange09 Bearing-mounted input shaft (see page 39)Order exampleYou wish to order a metal planetary gear with a diameter of 120 mm of type series PM 120with the reduction ratio 46:1, flange C 120 on motor side, flange C 140 on output side.Feel free to contact us – we are happy to help youPM 120. 46. 03 / 04Planetary gear, metalType seriesReduction ratio roundedFlange, motor side (see ordering codes)Flange, output side (see ordering codes)The details given herein are recommended values. Minor variances due to reduction ratios or non-standard testing or measuring methodsetc. may occur. Please refer to pages 6 to 11 and 39 of this catalogue for basic or additional information, or contact us directly. Technicaldetails subject to change without notice.36X

Option bearing-mounted input shaftPK22PK32, PM32, LNPK32PK42, PM42, LNPK52, PM52, LNPM62, LNPM72, LNPM81, LNPM105, LNPM120Shaft load based on shaft centre and n 1 = 3,000 rpmradialaxialFitting pressure10N3Nmax. 150N25N10Nmax. 120N25N10Nmax. 120N70N40Nmax. 320N110 N50Nmax. 500N120N60Nmax. 1,000N160N80Nmax. 1,300N200N100Nmax. 1,500N240N125Nmax. 1,800N300N150Nmax. 2,500NDimensionsStageskabcdefhlmopzBearings1 2 3 427 35 44 52221914 h84 h7M2 x 43 x 120°104,514,52Area 3,5 x 8Sintered bearing1 2 3 438 47 57 66322620 h86 h7M3 x 44 x 90°16,63,42032,5A2 x 2 x 12Ball bearing1 2 3 441 51 60 70322620 h86 h7M3 x 44 x 90°16,63,42032,5A2 x 2 x 12Sintered bearing1 2 3 461 74 87 100423625 h96 h7M4 x 10 a)4 x 90° a)22,22,82523A2 x 2 x 16Ball bearing1 2 3 471 85 99 113524032 h810 h7M5 x 104 x 90°2052532A3 x 3 x 16M3 x 9Ball bearing1 2 3 469 86 103 120625240 j712 h7M5 x 104 x 90°3093955A4 x 4 x 20M4 x 10Ball bearing1 2 3 483 102 122 142726045 j714 h7M5 x 104 x 90°3093955,5A5 x 5 x 22M5 x 12,5Ball bearing1 2 3 490 112 134 155816550 j716 h7M6 x 124 x 90°4094955A5 x 5 x 30M5 x 12,5Ball bearing1 2 3 4106 137 169 2001058570 j719 h7M8 x 164 x 90°4094956A6 x 6 x 28M6 x 16Ball bearing1 2 3 4132 166 200 23412010080 j728 h7M10 x 224 x 90°58157354A10 x 8 x 50M10 x 22Ball bearinga) Position =ˆ M4 output sideP5 DIN 6885, Page 1 l kZ5 DIN 332, Type DfhomeabcdInput SideOutput sideOrdering codes09 Bearing-mounted input shaftOrder exampleYou wish to order a metal planetary gear with a diameter of 120 mm of type series PM 120with the reduction ratio 46:1, bearing-mounted input shaft, flange C 140 on output side.Feel free to contact us – we are happy to help youPM 120. 46. 09 / 04Planetary gear, metalType seriesReduction ratio roundedbearing-mounted input shaft (see ordering codes)Flange, output side (see ordering codes)The details given herein are recommended values. Minor variances due to reduction ratios or non-standard testing or measuring methodsetc. may occur. Please refer to pages 6 to 11 and 39 of this catalogue for basic or additional information, or contact us directly. Technicaldetails subject to change without notice.3839

PM type series in ATEX designDesigned for use in potentially explosiveatmospheres, the planetary gear range PM 32to PM 120 is also available in explosion-protecteddesign in compliance with ATEX 100a.The explosion-protected planetary gears complywith Directive 94/9/EG for explosion protectionin non-electric operational equipment for devicegroup II, category 2 in gas atmospheres.For more detailed information on our ATEXplanetary gears, please contact us. We’d bepleased to help.Conversion tableFeel free to contact us – we are happy to help youTorqueFrom ➔ toozin / 141.61 Nmlbft / 0.738 NmNm * 141.61 ozinNm * 0.738 lbftForceFrom ➔ tooz / 3.60 Nlbf / 0.225 NN * 3.60 ozN * 0.225 lbfLengthFrom ➔ toin * 2.54 cmft * 30.48 cmcm / 2.54 incm / 30.48 ftMassFrom ➔ tooz * 28.35 glbs * 453.5 gg / 28.35 ozg / 453.5 lbs40 41

Please open up!Our international sites and locationsand how to contact us3 hFrankfurtFranceStrasbourgBaselSchwarzwaldStuttgartFreiburg DonaueschingenGenèveEisenbach MünchenBodenseeZürichSchweizNashvilleNew YorkBaselWashington, D. C. MemphisGainesvilleAtlantaVirginiaBeachJacksonvilleIMS Gear GmbHHeinrich-Hertz-Straße 1678166 Donaueschingenphone +49(0)771.8507-0fax +49(0)771.8507-444www.imsgear.comIMS Gear GmbHTechnomotive DivisionHauptstraße 5279871 Eisenbachphone +49(0)771.8507-282fax +49(0)771.8507-220e-mail technomotive@imsgear.comU.S.A.IMS Gear Inc.1234 Palmour DriveSuite BGainesville, GA 30501phone +1770.8409600fax +1770.840804441 .1

Gear reductions1-stage 2-stage 3-stage 4-stagePK PM LN PK PM LN PK PM LN PK PM LN PK PM LN PK PM LN PK PM LN PK PM LNØ22* • • – – – – Ø22* • • – – – – Ø22* • • – – – – Ø22* • • – – – –Ø32 • • • – – – Ø32 • • • – – – Ø32 • • • – – – Ø32 • • • – – –Ø42 • • – – – • Ø42 • • – – – • Ø42 • • – – – • Ø42 • • – – – •Ø52 • • – – – • Ø52 • • – – – • Ø52 • • – – – • Ø52 • • – – – •Ø62 – • – – – • Ø62 – • – – – • Ø62 – • – – – • Ø62 – • – – – •Ø72 – • – – – • Ø72 – • – – – • Ø72 – • – – – • Ø72 – • – – – •Ø81 – • – – – • Ø81 – • – – – • Ø81 – • – – – • Ø81 – • – – – •Ø105 – • – – – • Ø105 – • – – – • Ø105 – • – – – • Ø105 – • – – – •Ø120* – • – – – – Ø120* – • – – – Ø120* – • – – – – Ø120* – • – – – –* not all reduction ratios available ex stockReduction ratios i rounded4:1 (3.70) 4:1 (3.65) 14:1 (13.73) 14:1 (13.53) 51:1 (50.89) 50:1 (50.16) 189:1 (188.61) 186:1 (185.88)4:1 (4.28) 5:1 (4.59) 16:1 (15.88) 16:1 (15.65) 59:1 (58.85) 58:1 (58.01) 218:1 (218.12) 215:1 (214.96)5:1 (5.18) 5:1 (5.36) 18:1 (18.36) 17:1 (17.01) 68:1 (68.06) 67:1 (67.08) 252:1 (252.24) 249:1 (248.59)7:1 (6.75) 7:1 (6.55) 19:1 (19.20) 19:1 (18.92) 71:1 (71.16) 70:1 (70.13) 264:1 (263.72) 260:1 (259.91)9:1 (8.63) 22:1 (22.20) 23:1 (22.96) 79:1 (78.71) 81:1 (81.11) 292:1 (291.71) 287:1 (287.49)25:1 (25.01) 25:1 (24.65) 93:1 (92.70) 91:1 (91.36) 305:1 (304.99) 301:1 (300.57)27:1 (26.85) 28:1 (27.76) 95:1 (95.17) 98:1 (98.07) 337:1 (337.35) 339:1 (338.56)29:1 (28.93) 28:1 (28.05) 100:1 (99.5) 101:1 (101.89) 344:1 (343.54) 348:1 (347.60)35:1 (34.97) 34:1 (33.92) 107:1 (107.20) 106:1 (105.65) 353:1 (352.71) 361:1 (361.17)46:1 (45.56) 45:1 (44.69) 115:1 (115.07) 115:1 (114.77) 369:1 (368.76) 365:1 (364.66)58:1 (58.22) 124:1 (123.97) 123:1 (123.20) 397:1 (397.29) 392:1 (391.53)130:1 (129.62) 128:1 (127.74) 408:1 (407.89) 420:1 (420.28)139:1 (139.13) 137:1 (136.99) 426:1 (426.46) 425:1 (425.34)150:1 (149.90) 145:1 (145.36) 459:1 (459.45) 457:1 (456.56)169:1 (168.84) 166:1 (166.40) 480:1 (480.36) 473:1 (473.40)181:1 (181.24) 176:1 (175.75) 493:1 (493.18) 492:1 (491.89)195:1 (195.26) 192:1 (191.54) 516:1 (515.62) 515:1 (515.24)236:1 (236.09) 232:1 (231.59) 531:1 (531.34) 533:1 (533.08)308:1 (307.54) 302:1 (301.68) 556:1 (555.52) 547:1 (547.47)393:1 (392.98) 596:1 (596.30) 595:1 (594,73)626:1 (625.73) 623:1 (622.97)642:1 (642.42) 638:1 (638.40)672:1 (671.67) 679:1 (678.94)721:1 (720.98) 713:1 (713.15)724:1 (723.63) 745:1 (745.38)777:1 (776.76) 775:1 (774.72)837:1 (836.86) 832:1 (831.60)875:1 (874.94) 862:1 (862.27)939:1 (939.18) 925:1 (924.65)1012:1 (1011.84) 1046:1 (1046.08)1140:1 (1139.73) 1123:1 (1123.21)1223:1 (1223.41) 1200:1 (1200.07)1318:1 (1318.05) 1293:1 (1292.91)1594:1 (1593.65) 1563:1 (1563.24)2076:1 (2075.94) 2036:1 (2036.33)2653:1 (2652.59)Notes on selecting the reduction ratiosThe details given herein are recommended values. Minor variances due to reduction ratios are non-standard testing or measuring methodsetc. may occur. Please refer to pages 6 to 11 and 39 of this catalogue for basic or additional information, or contact us directly. Technicaldetails subject to change without notice.41 .2