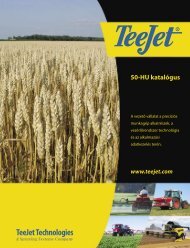

LEGACY 6000 - TeeJet

LEGACY 6000 - TeeJet

LEGACY 6000 - TeeJet

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

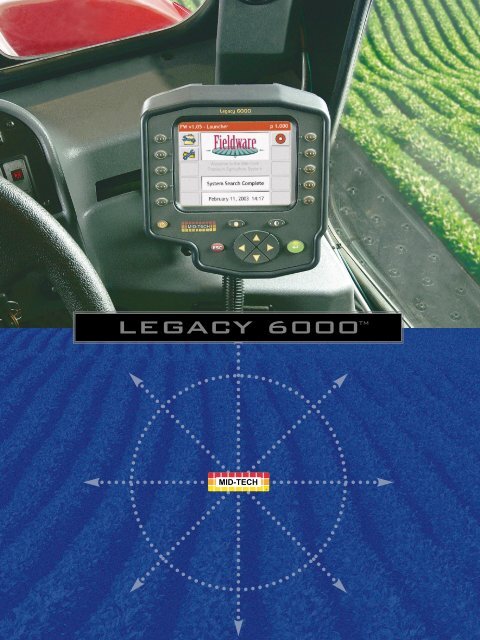

<strong>LEGACY</strong> <strong>6000</strong>tmMID-TECH

<strong>LEGACY</strong> <strong>6000</strong>elegantly simpleElegantly simplethe legacy <strong>6000</strong> wraps up your most challenging field processesrecords them and puts them easily under your control, with onlyone console in the cab.liquid productapplicationgpsprecisionlightbar guidanceanhydrousproductapplicationgranularproductapplicationprintablereportson-screenfield mappingautomatic steeringassistance

MID-TECHimagine having one systemImagine having a single control system with thecapability of managing all of your application tasksfrom the simplest to the most demanding. From variablerate seeding with fertilizing to multiple productapplication of dry and/or liquid products at the sametime, the Mid-Tech Legacy <strong>6000</strong> system does it all.■ fixed-rate or variable-rateapplication—liquid, dry oranhydrous products■ complete field mapping with hazardmarking■ manual lightbar guidance withon-screen map display■ interface with automatic steeringsystems■ optional office software usesapplication data to create detailedjob reportsThe tasks can be done individually or all togetherwith a single console using Mid-Tech’s new Legacy<strong>6000</strong> system. It’s built of modular components combinedto make a custom fit in each installation. Thisflexibility opens a wider range of options than everbefore. It also means this system is uniquely capableof supporting future growth quickly, easily andwithout duplicating your investment.There are four modules in all. The console in thecab is one of these modules and the one with whichpeople are most familiar. The other modules manageproduct control, the switches in the system like thosethat regulate boom sections on a sprayer or seed binsin an air seeder, and other network functions. Allmodules are linked together with a single, heavydutycommunications and power cable, or bus.When we say flexible, we mean it. An applicationrequiring multiple product control would simplyuse a Product Control Module for each channel. TheSwitch Sense Module likewise monitors up to 20 boomsections. If there were 30 boom sections to manage, anadditional Switch Sense Module connected to thenetwork would instantly expand the system.Adding a module is easy. It’s about the size of apaperback book and can be mounted anywhere onthe chassis. It plugs into the network and is instantlyrecognized. Software wizards guide you through theset-up process. Servicing the system in the field is justas simple, with built-in diagnostic tools to make thejob easy.What makes this system so flexible and robust? It is aCAN bus system, a Controller Area Network, connectedby a high-speed cable or bus, which allows a vastamount of information to be shared across the system.This self-managing system constantly monitors its ownoperational status, and reports any inconsistencies tothe operator before they become a problem. It’s anentirely new way of looking at product control andhow to manage it.

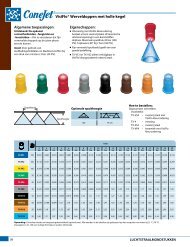

a feature-rich system with the simplicityof icon-guided, push button controlthe 10 soft keyson the left andright of thedisplay associatewith the onscreenmenusclear visualicons guide youthrough themenu selectionprocesspower—on andoff switchseparate contrastand brightnesskeys make screenadjustments easyescape—takes youback one levelarrow keys navigateyou through the menu:left/right, up/down onestep at a timeenter—acceptsthe highlightedfeature andsaves yoursettings tobegin theprogrameasy softwareset-up wizardsreal-timeon-screen mapsat the end of the dayprint reports

gpsantennacan bus systemPSMSSMPCMPCM1 2 3 4 5 6lightbar legacy <strong>6000</strong> power switch product productspeed sense control controlmodule module module modulethe legacy <strong>6000</strong> console is the front-end of the powerful can bussystem. behind the scenes, other modules connect to various mechanismsto provide the functionality and control your system demands.these examples show the legacy <strong>6000</strong> system optimized three ways.seed and fertilizeat varying rates123456Navigate in straight, curvedand circular swaths using alightbarMap and record field operationsin real time and stayinformed of job progressPSM—Connects to vehiclepower and distributes it tothe control system; informsthe control system ofvehicle speedSSM—Monitors the on/offstatus of each segment ofthe seed and fertilizerapplicationsPCM 1—Vary the rate ofseed across the field basedon a prescription mapPCM 2—Apply fertilizer atfixed or variable rates, andindependently of seedingratesdual hopper applicationof two products123456Navigate in straight, curvedand circular swaths using alightbarMap and record field operationsin real time and stayinformed of job progressPSM—Connects to vehiclepower and distributes it tothe control system; informsthe control system ofvehicle speedSSM—Monitors the on/offstatus of each bin’s masterapplication switchPCM 1—Monitor and controlapplication rate ofproduct one (fixed or variablerate); monitor spinnerspeed for display on theconsolePCM 2—Monitor and controlapplication rate ofproduct two, fixed or variableratemultiple product directchemical injection12345678Navigate in straight, curvedand circular swaths using alightbarMap and record field operationsin real time and stayinformed of job progressPSM—Connects to vehiclepower and distributes it tothe control system; informsthe control system ofvehicle speedSSM—Monitors the on/offstatus of each boom sectionswitchPCM 1—Controls the applicationrate of the main carrierPCM 2—Controls the applicationrate for chemicalinjection pump 1; monitorschemical 1 flow sensorPCM 3—Controls the applicationrate for chemicalinjection pump 2; monitorschemical 2 flow sensorPCM 4—Controls the applicationrate for chemicalinjection pump 3; monitorschemical 3 flow sensorexploit the capabilities of thelegacy <strong>6000</strong> with automatic steeringthe legacy <strong>6000</strong> system can link with an automatic steering system to take precisecontrol of vehicle position. the operator manages the automatic steeringsystem with the legacy <strong>6000</strong> — another benefit of a single, in-cab console. automaticsteering drives a vehicle with tremendous, repeatable accuracy in bothstraight and curved patterns. the ability to operate in fog or dust, day or nightwith high levels of accuracy means a better return on capital investment forequipment, a better application job, and a more attentive, alert operator.

<strong>LEGACY</strong> <strong>6000</strong>technical specifications<strong>LEGACY</strong> <strong>6000</strong> CONSOLEDimensions8.0" W x 7.7" H x 4.5" D (203 x 196 x 114 mm)Weight2.3 lbs. (1.0 kg)EnclosureEngineering thermoplastic ABS/PC alloy with highimpact and chemical resistance properties.Sealedin compliance with IP65 and ANSI/ASAE EP455ConnectorsSealed, 31 pin DeutschEnvironmental Storage -4°F to 158°F (–20°C to +70°C)Operating 32°F to 122°F (0°C to +50°C)Humidity 5-95% (non-condensing)Display Full color, sunlight readable, transflective 5.7"(145 mm) diagonal LCDKeypadBacklit elastomeric tactile keypad, 10 softkeys fordirect program navigation, four directional keys,enter, escape, brightness and contrast.Microprocessor 32-bit Intel ® StrongArm, SA 1110 with SA 1111companion chip, 206 MHz.Memory32 MB DRAM32 MB FlashOperating System Microsoft ® Windows ® CE 3.0DrivesPCMCIA type II, single slotInput/Output CAN*, Bosch 2.0BSerial RS 232 (2)USB (1)Bi-directional digital interfaceAlarmAudible alarmMountingStainless steel U-shaped bale bracket or RAM mount availableOtherReal-time clock with battery back-upMODULE SPECIFICATIONSDimensions4.7"W x 2.3"H x 6.0"D (120 x 60 x 150mm)WeightMaterial1.9 lbs. (0.9 kg)Powder-coated cast aluminumInput/Output CAN, Bosch 2.0BPower Requirement9 to 16 volts DC supplied to the Power SpeedModule provides power to the entire network.(Legacy <strong>6000</strong> console can operate as a standalonecomputer requiring 9-16 volts power.)RECEIVER REQUIREMENTS (GPS INPUT OPTIONAL)Sub-meter DGPS Compatible with differentially-corrected, GPS(DGPS) receivers outputting NMEA 0183 GGAsentence at 2 Hz or greaterRTKCompatible with RTK GPS receivers outputtingNMEA 0183 GGA sentenceLIGHTBAR GUIDANCE (OPTIONAL)LightbarCompatible with Swath XL CAN lightbarWARRANTYLegacy <strong>6000</strong> is backed by Mid-Tech’s full 21/2 year product warranty. Ourdedicated customer support staff assures you of continued service andon-site training makes your staff more effective and efficient.*Controller Area Network (CAN) is the intellectual property of RobertBosch GmbH.<strong>LEGACY</strong> <strong>6000</strong> MODULESPower Speed Module This is the primary arbitrator for the bus and thegateway for parallel CAN bus networks. PSMaccepts a speed sensor and has an RS 232 port.Switch Sense Module Senses the status of switches aboard the vehicle;controls up to 20 switches per module.Additional SSMs expand capability.ModuleProduct Control Controls product delivery system by connectingto the actuator and sensor. Outputs can be bioruni-directional. One PCM is needed for eachproduct to be metered.Copyright © 2003, Midwest Technologies IL, LLC. Printed in the USA. Part number 98-01066 Rev.0MID-TECHMidwest Technologies IL, LLC • 2864 Old Rochester Rd. • Springfield, IL 62703Phone 217.753.8424 • Fax 217.753.8426 • Customer Service 800.643.8324 • www.mid-tech.com