Effective Hazard Recognition and Control - SAIF Corporation

Effective Hazard Recognition and Control - SAIF Corporation

Effective Hazard Recognition and Control - SAIF Corporation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Effective</strong><strong>Hazard</strong> <strong>Recognition</strong><strong>and</strong> <strong>Control</strong>S927 5.12

<strong>SAIF</strong> <strong>Corporation</strong> is a not-for-profit, state-chartered workers’compensation company. We make workers’ compensation insuranceaffordable <strong>and</strong> available to the employers of Oregon.And we strengthen the Oregon economy by helping to keepworkers’ compensation insurance costs low while keeping theworkplace safe.We are dedicated to the safety of Oregonians <strong>and</strong> strive tomake Oregon the safest place to work.To find more information <strong>and</strong> materials on preventing slips,trips, <strong>and</strong> falls visit:www.saif.com > I am An Employer > SafetyWriter: Tim McDonald, CSPEditors/Reviewers: Kevin Pfau, MBA, CPCUPhilip Scott, CIH, CSPJim Nusser, MS-EHS

Table of contentsTable of ContentsIntroduction ........................................................................................................ 3Safety committee inspection requirements ...................................................... 6Inspection procedures ....................................................................................... 7<strong>Control</strong>ling hazards.......................................................................................... 12Recognizing hazards......................................................................................... 14Work surface <strong>and</strong> walkway hazards................................................................. 15Machinery hazards............................................................................................ 19Electrical hazards............................................................................................. 29Chemical hazards............................................................................................. 33Environmental hazards..................................................................................... 37Ergonomic hazards........................................................................................... 45Unsafe work practices...................................................................................... 53Resources......................................................................................................... 56

Safety committeeinspection requirementsFor a more detailedexplanation, go to:http://www.cbs.state.or.us/osha/pdf/rules/division_1/437-001-0765.pdfA well-run safety committee can have a powerful impact on the safety of anorganization. OAR 437-001-0765 establishes guidelines <strong>and</strong> requirementsfor the formation <strong>and</strong> operation of safety committees in Oregon. Onekey requirement is that safety committees conduct hazard identificationinspections at least on a quarterly basis. The following are a summary of themain requirements pertaining to inspections:TrainingEach person conducting safety <strong>and</strong> health inspections must be trained. Thetraining should include your company’s inspection procedures, hazards inthe workplace <strong>and</strong> methods to correct hazards. It is also important thatidentifying <strong>and</strong> addressing unsafe work practices be a part of the inspectiontraining.Inspection proceduresProcedures need to be established to effectively conduct workplaceinspections. This includes assigning areas to be inspected, documentation,<strong>and</strong> actions to be taken following the inspection. Additionally, someone shouldbe accountable to ensure follow up <strong>and</strong> correction of hazards.Quarterly inspectionsSafety committee inspections need to be conducted on at least a quarterlybasis <strong>and</strong> cover the entire facility each time. This can be accomplished byinspecting the entire facility with the inspection team or by splitting up theinspection team, with each group inspecting a different part of the facility. Forlarger <strong>and</strong> more complex facilities, an alternative method is to inspect onethirdof the property each month.Reviewing inspection reportsA part of establishing inspection procedures is to determine who will bereviewing the inspection reports <strong>and</strong> how recommendations will be submittedto management. Management needs to be involved in the inspection processso that recommendations can be approved <strong>and</strong> to make sure correctiveactions are taken.System for reporting hazardsIn addition to the above inspection requirements, a system needs to beestablished that allows employees an opportunity to report hazards <strong>and</strong>submit safety- <strong>and</strong> health-related suggestions. The classic example is asafety suggestion box. Other examples include creating an email addressspecifically for making suggestions, suggestion competitions, directcommunications, <strong>and</strong> more.6 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Inspection proceduresA variety of methods are employed when conducting inspections; some are veryinformal, while others are quite elaborate <strong>and</strong> methodical. The following modelis somewhere in between in that it combines simplicity with accountability <strong>and</strong>follow up to ensure hazards are corrected in a timely manner.Assign inspection team areasDistribute hazard reportsto responsible partiesConduct inspectionsRecord hazardson inspection formsGive forms tosafety committee chairFileCommunicate actions takento safety committee chairReview results at nextsafety committee meetingYES<strong>Hazard</strong>scorrected?NOBack to responsible partiesfor clarification <strong>and</strong> discussionAssign inspection team areasIndividual inspection team members are assigned to specific areas within thefacility. In a small operation, the entire inspection team may visit all areasof the facility. Larger operations may need to parcel out areas for smallerinspection teams.Conduct inspectionsBecause the entire facility needs to be inspected at least quarterly, planningshould focus on accomplishing this in a timely manner. A good strategy is toconduct inspections at different times of the day, throughout the year, so thatdifferent operating conditions <strong>and</strong> schedules can be observed. In productionareas, an effective method is to begin where raw materials arrive <strong>and</strong> followthe flow through machining, assembly, finishing, <strong>and</strong> shipping. At eachprocess, identify activities <strong>and</strong> conditions where an injury is likely. If any itemsare of a critical nature or present an imminent danger, these critical itemsshould be immediately reported to the person responsible for taking action.<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 7

Inspection proceduresAddressing unsafe work practicesWhen an unsafe work practice is observed during a hazard inspection, itis important that it be treated as any other hazard. The observed actionshould be recorded on the inspection form <strong>and</strong> dealt with through the safetycommittee. Typically, only the unsafe act <strong>and</strong> location are recorded. Theemployee’s identity is omitted, but the person responsible for that area isinformed of the unsafe work practice so that changes can be made. Changesmay include training the group <strong>and</strong> reinforcing the safe work practice ormaking a physical change so the unsafe act is less likely.It may be beneficial to have the responsible supervisor accompany theinspection team so that observed unsafe acts can be addressed immediately.Companies with strong safety cultures may have policies that permit, <strong>and</strong>even encourage, workers to openly discuss unsafe work practices when theyare observed. Formalized programs often referred to as “tough caring” or“I’ve got your back” empower employees by establishing mutual agreementsto look out for one another. Each party promises to accept correctivecomments as a show of concern for their safety. This philosophy applies evenwhen the offender is a supervisor.I’ve got your backIf you see me doing something unsafe,approaching an unsafe condition,or slipping into automatic behavior,would you please let me know?I agree to do the same for you.I will accept your intervention as an actof caring about my health <strong>and</strong> safety.I agree to intervene for the same reason.I will take your informationwith trust <strong>and</strong> respect,so we can mutually benefit.8 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

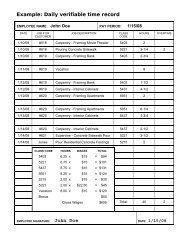

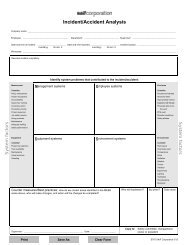

Inspection proceduresRecord hazards on inspection formsMany companies use their own inspection forms as part of the inspectionprocess. This tends to be superior to using a generic downloaded form. Thereare certainly hazards common to most operations, but each business also hasits own unique hazards. The best forms combine common <strong>and</strong> job-specifichazards to guide inspection teams.Inspection checklists are popular for conducting inspections because theyprovide guidance in what to look for. This is particularly useful when theinspection team members are inexperienced <strong>and</strong> unfamiliar with the hazardsin the workplace. However, a drawback to checklists is that they often getchecked off without much other information. Checklists also frequently omita section for unsafe work practices <strong>and</strong> are rarely customized for a specificwork area.The example form pictured below is provided full-size in the forms section. Itcombines common <strong>and</strong> area-specific hazards, with broad checklist categoriesas prompts for the inspection team. Ample space is provided to elaborate orexplain hazards observed.<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 9

Inspection proceduresSend completed forms to committee chairOnce the inspection is complete <strong>and</strong> the inspection form filled out, it shouldbe given to the safety committee chair or the company’s safety coordinator.Distribute hazard report to responsible partiesWhen the safety committee chair or safety coordinator receives inspectionreports, they should be reviewed <strong>and</strong> items recorded for future discussion.The forms or other communication device should be used to inform theresponsible parties of any hazards needing action. A reasonable amount oftime should be determined for a response.If not addressed on the inspection form itself, the specific items should beprioritized, particularly if there are any critical items needing attention.Communicate actions taken to safety committeeResponsible parties should communicate back to the safety committee chairor safety coordinator the status of the items noted. If the item has been takencare of, the date of correction should be noted.Review results at next safety committee meetingAt the very next safety committee meeting, the results of the inspections <strong>and</strong>the status of items noted should be discussed. Individual inspection formscan be used or, if appropriate, a compiled list of hazards can be reviewed.It is important that safety committee members be kept informed of hazardstatus so they can see the results of their efforts.<strong>Hazard</strong>s correctedCorrected hazards should be noted in the safety committee minutes <strong>and</strong>removed from the list for future review.<strong>Hazard</strong>s not corrected<strong>Hazard</strong>s that have not been corrected need to remain on the safety committeelist until resolved or management finds an alternative way to make sure thehazard will not result in injury.Sometimes a hazard cannot be completely eliminated, but alternativemethods may be employed to make the situation less hazardous or tootherwise safeguard workers. Low priority items need no further action aslong as a responsible party agrees to make needed corrections.10 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Inspection proceduresDetermining priorityNew inspection teams sometimes have a tendency to create long laundry lists oftrivial items with little or no safety consequence. Keeping the inspection focusedon the things that can truly lead to accidents will give the effort more credibilitywith management. In order for identified hazards to be given due considerationby management <strong>and</strong> other responsible parties, they must be prioritized.ProbabilityUnlikely Probable ImminentmediumprioritymediumpriorityLOWpriorityHIGHprioritymediumprioritymediumpriorityHIGHpriorityHIGHprioritymediumpriorityIn this illustration, theprobability of injury <strong>and</strong> severityof injury are on the X-Y axis.Low-priority items are unlikelyto result in an injury <strong>and</strong> suchinjuries will tend to be minor. Incontrast, high-priority items arelikely to result in injuries, with amore severe outcome.Minor Moderate SeriousSeverityFor example, a glass jar of peanut butter sitting near the edge of a shelf couldget knocked off <strong>and</strong> could result in an injury. However, the probability of thisoccurring is low <strong>and</strong> the resulting injury, if any, would most likely be a minor cut.Therefore, these conditions would result in a Low Priority being assigned to it.In another example, a worker repairing a leaking pipe in a 6 foot trench withvertical sides <strong>and</strong> s<strong>and</strong>y soil has a high probability that an accident will occurby the sides collapsing. The most likely outcome would be a serious or fatalinjury. As such, this would be a high priority item.When the probability of an injury is “Imminent” <strong>and</strong> the likely severity is“Serious”, a special condition, known as an “Imminent Danger” is present.Swift action is required because of the urgency of the situation. This shouldrequire the temporary suspension of the specific operation until the conditionis mitigated.<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 11

<strong>Control</strong>ling hazardsOnce hazards have been identified, finding a means to effectively eliminateor control them is crucial. The best hazard identification program can be ahuge waste of time if the hazards remain or are ineffectively dealt with. Inaddition, unresolved hazards can adversely impact the attitudes of the safetycommittee <strong>and</strong> the company as a whole.<strong>Hazard</strong> eliminationThe best way to deal with a hazard is to eliminate it. This can be done bydiscontinuing a process, automating a process, or providing a tool or devicethat removes the employee from the hazard zone.<strong>Hazard</strong> reductionIf you can’t completely eliminate a hazard, make a change that reducesthe hazard to an acceptable level. If a chemical is involved, finding a lesshazardous, but equally effective chemical is desirable.Less effective More effectiveThe hierarchyof hazard control<strong>Hazard</strong> elimination<strong>Hazard</strong> reductionEngineering controlAdministrative controlPersonal protective equipmentEngineering controlProviding an engineering control isolates,ventilates, contains, or otherwise controlsthe hazard through some physical means.Placing a guard on a hazardous movingpart is an example. The hazard remains,but the workers are protected from thepoint of operation. The reason this is lesseffective than hazard elimination or hazardcontrol is because it is possible to remove anengineering control or shut off the means ofcontrol, thus exposing employees.Administrative controlsAdministrative controls are best used incombination with a more effective meansof control. Administrative controls includeprocedures <strong>and</strong> training to avoid or reduceexposure to the hazard.Personal protective equipment (PPE)PPE provides a barrier between theworker <strong>and</strong> the hazard. It never eliminatesthe hazard, but will provide a degree ofprotection should the worker come incontact with the hazard, whether it bephysical or chemical in nature.12 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

<strong>Control</strong>ling hazards<strong>Hazard</strong> control examplesLess effective More effective<strong>Hazard</strong>elimination<strong>Hazard</strong>reductionEngineeringcontrolAdministrationcontrolPersonal protectiveequipmentReplace the machine with a quieter one thatdoes the same thing.Adjust the machine or install a muffling deviceto reduce noise level.Install a sound-reduction curtain around themachine.Limit amount of time near machine.Wear earplugs while in vicinity.Example:Noisyprocessing machineLess effective More effective<strong>Hazard</strong>elimination<strong>Hazard</strong>reductionEngineeringcontrolAdministrationcontrolPersonal protectiveequipmentUse a non hazardous replacement or eliminateneed to clean parts.Substitute a less hazardous chemical for thecaustic one.Enclose process in a glove hood.Use personal protective equipment <strong>and</strong>implement job rotation schedule.Wear protective gloves <strong>and</strong> face shield whileh<strong>and</strong>ling parts.Example:Caustic chemicalfor parts cleaningLess effective More effective<strong>Hazard</strong>elimination<strong>Hazard</strong>reductionEngineeringcontrolAdministrationcontrolPersonal protectiveequipmentInstall a mechanized system for productselection <strong>and</strong> transport.Order materials in smaller sizes <strong>and</strong> lift largeritems with devices.Provide h<strong>and</strong> trucks <strong>and</strong> hoists to h<strong>and</strong>leheavier items.Establish safe lifting limits <strong>and</strong> procedures.Conduct training.Wear protective gloves <strong>and</strong> slip-resistantfootwear.Example:Frequent <strong>and</strong>heavy lifting<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 13

Recognizing hazardsThe best tools for identifying hazards are experience <strong>and</strong> knowledge of yourindustry. In addition, underst<strong>and</strong>ing your company’s prior accident history cangive you a great perspective for what can <strong>and</strong> has gone wrong. Your accidenthistory should be reviewed <strong>and</strong> analyzed by the safety committee regularly.Other excellent sources for identifying hazards in your workplace include:• Oregon OSHA www.orosha.org for links to rules, publications <strong>and</strong> topicalresources. A number of specialized inspection checklists are available.• <strong>SAIF</strong> <strong>Corporation</strong> www.saif.com for links to various safety topics.Also, a safety consultant can provide guidance <strong>and</strong> assist you in hazardidentification at your location.• Local fire department.• Industry associations <strong>and</strong> publications.The remainder of this guide provides numerous examples of hazardstypical in many work environments. These provide visual cues <strong>and</strong>written descriptions of the types of things to observe for while conductinginspections. For the sake of order <strong>and</strong> brevity, the hazards have beenorganized into seven categories.• Work surface <strong>and</strong> walkway hazards• Machinery hazards• Electrical hazards• Chemical hazards• Environmental hazards• Ergonomic hazards• Unsafe work practicesAlthough this guide should provide hazard inspection teams a fairlycomprehensive list of hazards typical in the workplace, it does not attemptto address each <strong>and</strong> every hazard which might be anticipated. These hazardshowever, are common in most workplaces.14 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Work surface <strong>and</strong>walkway hazardsKey concerns• Obstructions• Clutter• Slippery surfaces• Damage• Falls from elevations<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 15

Work surface <strong>and</strong>walkway hazardsObstructions <strong>and</strong> clutterFloors may be cluttered with furniture, electrical cords, <strong>and</strong> materials thatpose a trip hazard.How is the overall housekeeping? A disorganized or dirty area may bereflective of an underlying poor safety attitude. Inspecting authorities tend tobe more thorough when the first impression is one of poor housekeeping.Inadequate housekeeping practices produce fire <strong>and</strong> trip hazards. Frequent <strong>and</strong>regularly scheduled cleanups should be part of the company’s safety culture.22” minimum22” minimumOAR 437-02-0022(3)16 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Work surface <strong>and</strong>walkway hazardsSlippery surfacesWalking surfaces can be very hazardous if they are slippery. Floors become“skating rinks” when liquid spills are not swiftly cleaned up. Outsidewalkways <strong>and</strong> parking lots are hazardous when rain, snow or ice is present.Walk-in coolers <strong>and</strong> freezers present special hazards because ice can formon the floor.Damaged surfacesBroken flooring, damaged steps, potholes <strong>and</strong> other damaged surfaces canresult in trips <strong>and</strong> falls, as well as twisted ankles <strong>and</strong> even fractures. Inaddition, be watchful for damaged ladders <strong>and</strong> the condition of stairs.<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 17

Work surface <strong>and</strong>walkway hazards22 CFR 1910.23(e)ElevationsSt<strong>and</strong>ard railings are required for any open-sided floor or platform that isfour or more feet above the adjacent floor surface; or any open-sided floor orplatform when it is above an adjacent hazard.6' maximum42"Toeboard if workers below3 feetOAR 437-002-0026When placing a ladder, makesure that its base is one foot outfor every four feet in height.The ladder rails should alsoextend at least three feet abovethe edge of the roof.12Top securedin placeIf the ladder is to be usedthroughout a work shift, it shouldalso be secured in place.34118 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Machinery hazardsKey concerns• Guarding for:• Point of operation• In-running nip points• Rotating motion• Flying chips <strong>and</strong> sparks• Lockout/tagout<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 19

Machinery hazardsGeneral requirement for machine guardingCFR 1910.212(a)(1)One or more methods of machine guarding shall be provided to protect theoperator <strong>and</strong> other employees in the machine area from hazards such asthose created by:• Point of operation• In-going nip points• Rotating parts• Flying chips• SparksPoint of operationThis is the point at whichcutting, shaping, orforming is accomplished.20 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Machinery hazardsIn-running nip pointsThis hazard occurswhen rotating partson machinery comeclose together or areintermeshed.Rotating motionRotating motion takesthe form of shafts, shaftends, collars, couplings,flywheels <strong>and</strong> spindles,whether fast or slow.Flying chips<strong>and</strong> sparksFlying chips <strong>and</strong> sparksare generated frommaterial shaping (forexample, drilling, milling,<strong>and</strong> grinding) <strong>and</strong> weldingprocesses.<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 21

Machinery hazardsIf you can reach it or it can reach you,you need to safeguard it.Safeguarding methodsGuards• Fixed• Interlocked• Adjustable• Self-adjustingDevices• Presence sensing• Pullback• Restraint• Safety controls (tripwire cable, two-h<strong>and</strong> control, etc.)• GatesLocation <strong>and</strong> distanceFeeding <strong>and</strong> ejection methods• Automatic or semi-automatic feed <strong>and</strong> ejection• RobotsMiscellaneous Aids• Awareness barriers• Protective shields• H<strong>and</strong>-feeding tools• Sawstop ®22 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Machinery hazardsGuardsMechanical guards provide a physical barrier to prevent contact with the pointof operation.In general, adjustable <strong>and</strong> fixed guards should be positioned just above thematerial being processed, so that a finger cannot pass between the material<strong>and</strong> point of operation.Adjustable guards need to be continually monitored to ensure h<strong>and</strong> <strong>and</strong> fingerprotection because material sizes can vary, thus increasing the gap betweenguard <strong>and</strong> material.Fixed guardsAdjustable guardSelf-adjusting guardInterlocked guardsare usually installedon moveable barriersthat, when opened, willshut down power to themachine being protected.BarrierInterlock device<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 23

Machinery hazardsCFR 1910.215(b)(9)CFR 1910.215(a)(4)Tongue guardTool restBench grindersOne of the more commonmachine hazards cited byOSHA is the adjustment ofa bench grinder’s tool rest<strong>and</strong> tongue guard. The gapbetween each of these <strong>and</strong>the grinding wheel shouldnever exceed 1/8” <strong>and</strong> 1/4”respectively.Guarding devicesGuarding devices do not provide a physical barrier, but protect the workerthrough other methods.Two-h<strong>and</strong> controls require the worker to depress two buttons simultaneouslyto engage the machine. This is effective as long as the devices remain in goodrepair <strong>and</strong> a worker does not bypass the safety feature.Two-h<strong>and</strong> controlPresence sensing device24 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Machinery hazardsPresence sensing devices use an infrared beam to shut the machine offwhenever something blocks the light. Another type of presence sensingdevice is a pressure-sensitive mat placed on the floor in a danger area.Pullback devices are an older technology that physically pull the h<strong>and</strong>s out ofthe way when the machine engages.Interlocked gatePullback deviceOther guarding methodsNumerous other guarding methods have been developed to prevent or reducethe possibility of injury when working around points of operation.Points of operation more than seven feet above the floor are considered safe<strong>and</strong> do not need to be guarded.Keeping a point of operation behind a closed <strong>and</strong> locked door enclosureeffectively prevents most people from accessing it.HeightSawStop® is a specially designed table saw witha built-in safety device that detects when a fingeror other body part makes contact with the blade.Within milliseconds, the blade drops below the tablesurface <strong>and</strong> imbeds in a braking material, completelystopping the blade. This greatly reduces or eliminatesan injury from the saw blade.> 7 feet<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 25

Machinery hazardsAwareness barriers work like the warning track on a baseball field. Theydon’t really prevent injury, but let you know when you are close.Robotics or other automation methods are effective at preventing workersfrom being exposed to points of operation. However, any task using roboticsneeds to be carefully evaluated to ensure barriers or other devices protectworkers against robot swing <strong>and</strong> movements.RoboticsAwareness barrierCFR 1910.242(b)When pressurized air greater than 30 psi is used for cleaning purposes, thenozzle needs a pressure relief device that limits pressure to 30 psi if the flowis dead-ended.26 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Machinery hazardsDetermining the adequacy of fixed guardsWhen a guard has been installed to protect workers from the point ofoperation, the most important consideration is whether or not a worker canreach the point of operation, <strong>and</strong> consequently be injured.OSHA has published guidelines for allowable guard opening sizes. This isbased upon distance from the point of operation. The further from thepoint of operation, the larger the opening can be.CFR 1910.217(c)(2)(i)Point of operationGuard opening requirementsDistance of openingfrom point of operationAs an example, if a guard is 7 inches from the point of operation, themaximum allowable guard opening is 7 /8” wide.A guard opening gauge can be purchased or madeto help assess the safety of a guard’s openings.It is commonly referred to as a “gotcha stick,”<strong>and</strong> its stair step design allows you to determineif a guard’s gaps are too wide. As long as the tipcannot touch the point of operation, the guard’sopenings are narrow enough.A template to assist you in making your own guardopening gauge can be found at the end of thisguide. The photo to the right illustrates the use ofsuch a device.maximum widthof opening1/2" to 1 1 /2" 1/4"1 1 /2" to 2 1 /2" 3/8"2 1 /2" to 3 1 /2" 1/2"3 1 /2" to 5 1 /2" 5/8"5 1 /2" to 6 1 /2" 3/4"6 1 /2" to 7 1 /2" 7/8"7 1 /2" to 12 1 /2" 1 1 /4"12 1 /2" to 15 1 /2" 1 1 /2"15 1 /2" to 17 1 /2" 1 7 /8"17 1 /2" to 31 1 /2" 2 1 /8"Over 31 1 /2" 6"<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 27

Machinery hazardsLockout/tagoutWhen conducting a hazardassessment, it is importantto be on the lookout forrepair tasks where workersmay be exposed to variousenergy sources.If someone is performingmaintenance or repairs<strong>and</strong> a form of energy ispresent or storedit must be isolated ordissipated.Energy sourcesElectricity is the most common energy source associated with locking outa piece of equipment. Workers need to be protected against the accidentalenergizing of a circuit when repairs are being made.Stored hydraulic, pneumatic, <strong>and</strong> steam pressure can also pose significantrisks. Generally, such sources need to be dissipated or blocked off so movingparts are not activated.Suspended items (gravity) need to be blocked up while doing work.Spring tension needs to be blocked or released, <strong>and</strong> piped chemicals need tobe blocked off or drained.ElectricityPiped chemicalsSpring tensionSteam pressurePneumatic pressureGravityHydraulic pressure28 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Electrical hazardsKey concerns• Clear access toelectric panels• Labeling of electriccircuits• Condition <strong>and</strong> use ofextension cords• Grounding of cords<strong>and</strong> devices<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 29

Electrical hazardsBlocked electrical panelsElectrical panels need to have direct access <strong>and</strong> at least 36 inches of clearspace in front of them.Electrical panel labelingEach circuit needs to be clearlylabeled. In an emergency, thequick location of specific circuitsis essential.Any open slots need to becovered with “blanks” to preventinadvertent contactwith electricity.30 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Electrical hazardsPower cordsExtension cords can be found in almost every work environment. Damagedcords can be dangerous as they can cause fires <strong>and</strong> serious injury.Extension cords should be used for temporary tasks then put away afterwards.They should never be used in place of permanently wired electrical cable, norshould they be run where they are subject to damage. An additional outlet shouldbe installed if an extension cord is being used on an ongoing basis.Grounding prongs are sometimes broken off, accidentally or on purpose. Thisremoves an important safety feature <strong>and</strong> can result in electrocution.Power strips are sometimes “daisy chained” together. This increases the loadon power strips <strong>and</strong> the circuit, which overheat the circuit, resulting in fire<strong>and</strong>/or injury.Make sure electrical cords are neatly arranged <strong>and</strong> do not pose a trip hazard.Use a cord cover when a trip hazard is present.Cords should be free of damage <strong>and</strong> splicesNever used for permanent power sourceCord worked lose from plugPower strip daisychainGrounding prong missingTrip hazardNot fully pluggedinto receptacleCord coverTestingAn inexpensive <strong>and</strong>simple electrical circuittester can be used to testcords <strong>and</strong> circuits. It cantest for the presence of aground, reversed polarity,short circuits, <strong>and</strong> other conditions. Some have tripbuttons to test ground fault circuit interrupters (GFCIs).<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 31

32 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Chemical hazardsKey concerns• Material safety datasheets• Container labeling• Storage of chemicals<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 33

Chemical hazards29 CFR 1910-1200Material safety data sheets<strong>Hazard</strong> Communication St<strong>and</strong>ard establishesthat MSDSs need to be available for all hazardoussubstances in the workplace.Material safety data sheets provide detailedinformation about a chemical’s hazardousproperties, h<strong>and</strong>ling methods, PPE required,storage methods, <strong>and</strong> disposal.The data sheets should be organized so thatinformation on specific substances can be easily<strong>and</strong> quickly located. A well-written table ofcontents can effectively serve this purpose.It is desirable to have one master MSDS book,in a central location <strong>and</strong> smaller books in areascontaining MSDSs pertaining to those areas.Container labelingContainers of hazardous chemicals need to have labels. Secondary containersalso need labels if the material will remain in the container beyond one shift.The label needs to include:• Product identification• <strong>Hazard</strong> warning that communicates specific health <strong>and</strong> physical hazardsVarious labeling systems exist. Some are peel-off labels you customize <strong>and</strong>print, or fill out by h<strong>and</strong>. Others are pre-printed by the manufacturer.34 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Chemical hazardsStorage of chemicalsChemicals should be stored neatlyat all times. Steps should betaken to make sure the materialsdo not leak. This is typicallyaccomplished by providingchemical-resistant trays orcontainment pallets.Excellentstorage methodsMake sure incompatible materialsare not stored together. Forexample, oxidizers (OXY) shouldnot be stored with combustiblematerials, since oxygen isreleased with heat <strong>and</strong> cangreatly increase a fire’s intensity.In a confined area, an explosioncan occur.Poorstorage methodsDrum storageWhen dispensing flammable liquids, the fluidmotion can cause a static charge to build up.A spark can then ignite flammable vapors inthe area.ClampTransferpumpClampCFR 1910.106(e)(6)HoseTherefore, drums containing flammable liquidsneed to be electrically grounded to preventthe buildup of static electricity. Also, cable <strong>and</strong>clips should be used to bond the drum with asecondary container during dispensing.GroundingwireBondingwireClampSAFETYCANTo groundFlammable liquid storageFlammable liquids stored in an area should be kept in an approved cabinetany time the total quantity exceeds 25 gallons.CFR 1910.106(d)(3)Approved cabinets may contain up to 60 gallons of class I flammables <strong>and</strong>/orclass II combustibles, or up to 120 gallons of class III combustibles.Class I flammable: Flashpoint below 100 degrees FClass II combustibles: Flashpoint at or above 100 degrees F, but below140 degrees FClass III combustibles: Flashpoint above 140 degrees FA maximum of three approved cabinets may be kept in an area.<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 35

Chemical hazardsOAR 437-002-0293Gas cylinder storageBecause gas cylinders are under extremely high pressure, damage to theirvalve can cause them to be propelled, like a rocket, causing serious propertydamage <strong>and</strong> injury.Consequently, gas cylinders need to be secured against falling <strong>and</strong> damage.Securely strapping or chaining them to a structural member is an effectiveway to protect them from falling over. Caging them is even better. Protectivecaps need to be in place when the cylinders are not in use.UnsafeBetterEven betterCFR 1910.253(b)(4)(iii)Cylinder separationFlammable gasses cannot be stored with or near oxygen cylinders. Theymust be separated by at least 20 feet or stored on opposite sides of a noncombustiblebarrier at least five feet tall.Flammable gas<strong>and</strong> combustibles20 foot minimumor non-combustiblebarrier at least five feet highOxygen36 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Environmental hazardsKey concerns• Routes of exposure• Types of contaminants• Noise <strong>and</strong> othercontaminants• Environmentalcontrols<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 37

Environmental hazardsRoutes of exposureRoutes of exposure are the ways a hazardous substance may enter the body.High noise levelsthrough earsInhalation of airbornecontaminants throughnose <strong>and</strong> mouthAbsorption ofcontaminants throughskin, sweat gl<strong>and</strong>s,<strong>and</strong> eyes.Ingestion ofcontaminants on food,fingers, <strong>and</strong> cigarettesthrough mouthSkin contactAirborne contaminantsVaporsVapors form above a liquid as a result of evaporation. The term “vapor” comesfrom evaporation.These are typically present above open containers with flammables or heatedliquids (such as dipping processes).Liquid spills also form vapors, <strong>and</strong> they are present when wiping downsurfaces with a chemical.FumesFumes are produced when metals are heated. This is most common duringwelding <strong>and</strong> cutting, soldering, <strong>and</strong> heat treating.The nature of welding is such that workers often have to get in close to seewhat they are doing. Consequently, the welding plume is often right in theirbreathing zone. <strong>Effective</strong> local exhaust ventilation is important.38 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Environmental hazardsGasesGases are typically stored in pressurized cylinders such as welding gasses(acetylene, O2), liquid nitrogen, carbon dioxide, <strong>and</strong> chlorine gas.MistsMists are produced when a liquid, under pressure, is atomized.Common mist-producing activities include spray finishing, pesticideapplication, <strong>and</strong> airbrush work.Also, a hydraulic line can produce a mist if the line is ruptured.SmokeSmoke is produced when “ordinary” combustibles are burned.Common sources include cigars <strong>and</strong> cigarettes, structural fires, incinerators,<strong>and</strong> burn piles.DustDust is created whenever dried particulates are disturbed. Most of the time,dust is an irritant rather than a health hazard.Common dust-producing activities include sweeping, blowing down surfaces,construction, <strong>and</strong> various manufacturing processes.<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 39

Environmental hazardsIngestionContaminants can be ingested intentionally, but in an occupational setting,this most commonly is done unknowingly.Transfer of contaminants to food can occur if they are kept in proximityto each other. Food should not be opened, exposed, or consumed incontaminated areas.Not washing h<strong>and</strong>s thoroughly can result in contamination from h<strong>and</strong>ling foodor placing fingers in the mouth.Smoking can also permit contaminants to be ingested or breathed.AbsorptionContaminants can also be absorbed through the eyes, sweat gl<strong>and</strong>s,skin, <strong>and</strong> hair.Wearing the correct personal protective equipment is essential to preventthis kind of contaminant exposure.Eyes Sweat gl<strong>and</strong>s Skin Hair40 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Environmental hazardsSkin contactCaustic chemicals <strong>and</strong> acids can seriously damage the skin if a spill occurs.Properly selected gloves <strong>and</strong> safe chemical-h<strong>and</strong>ling procedures areessential to prevent such injuries.OAR 437-002-0161(5)In general, the longer the skin contact, the worse the damage.Sometimes a minor spill on clothing or inside a glove can be veryserious, as it can remain in contact with the skin for an extended periodof time.Eyewash stations <strong>and</strong>/or showers are necessary whencaustic chemicals are in use <strong>and</strong> should be located lessthan ten seconds walking distance from the anticipatedhazard. Eye wash stations should be capable of a waterflow of at least .4 GPM for 15 minutes. Safety showersshould be capable of 20 PGM for 15 minutes. Bothshould be kept clean <strong>and</strong> tested weekly.NoiseWhenever high noise levels are encountered, hearing protection should be worn.If the average noise level for an eight hour shift is at or above 85 decibels, afull hearing conservation program is required.ExamplesQuiet country strollLibraryTypical office30 dB40 dB60 dBVacuum cleaner running 70 dBTypical factory80 dBMilling machine85 dB70 dB90 dBMotorcycle at 25 ft90 dBPower mower95 dBHelicopter taking off100 dBSteel mill, auto horn110 dBThunderclap, chain saw120 dBMilitary jet taking off130 dB103 dB110 dB<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 41

Environmental hazardsOther environmental hazardsA number of other environmental hazards may present themselves,depending on the kind of activities your business engages in.Some examples:Hot or coldenvironmentsGlareBiological materialsRadioactive energyEnvironmental controlsSubstitutionSubstitution is an excellent way to reduce or eliminate an environmentalhazard. When you use a less hazardous substance to perform a given task,the task becomes inherently safer.42 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Environmental hazardsVentilationAirborne contaminants should be kept away from the work area as much aspossible. When a contaminant is present, it needs to be diluted or, better yet,removed from the breathing zone.Ventilation can be as simple as opening a door or window in order to allowa fresh air exchange. Specific hazards require more controlled ventilationsuch as local exhaust, where a hood or exhaust duct will draw away airbornecontaminants. Sometimes, ventilation may take the form of a spray finishingbooth or room.Local exhaust ventilationGeneral ventilationPersonal protective equipmentPersonal protective equipment (PPE) can be an effective means ofprotective workers against hazards, especially when used in conjunctionwith other control measures such as hazard reduction or engineeringcontrols. Its effectiveness is greatly impacted by inconsistent use of <strong>and</strong>poor maintenance of PPE.CFR 1910.132(d)CFR 1910.132(d), also known as the PPE st<strong>and</strong>ard, requires that a hazardassessment be conducted to determine which tasks require the use ofPPE. This assessment needs to documentthe type <strong>and</strong> usage of PPE to be worn.Affected employees are to receive trainingin the care <strong>and</strong> use of the required PPE <strong>and</strong>employers are required to enforce its use.<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 43

44 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Ergonomic hazardsKey concerns• Soft tissue injuries(acute <strong>and</strong> cumulative)• Force• Frequency• Posture<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 45

Ergonomic hazardsSoft tissue injuriesMuscles are used to perform work. The more frequently a particular set ofmuscles is used, the more fatigue results. When you rest, these muscles arerestored.Similarly, a container with water dripping in the top will soon overflow unlessa valve is opened to drain off the water. However if the water flows too swiftlyor the valve is not opened enough, the container can soon overflow.Your body, in a similar fashion, needs rest following work. If the task is tooforceful, repetitive, involves poor postures or goes too long without a break,fatigue can turn into a soft tissue injury.Soft tissue injuries typically take the form of sprains <strong>and</strong> strains. Theyare injuries resulting from acute overexertion, inflammation or long termrepetitive motions. Soft tissues include joints, muscles, ligaments, <strong>and</strong>tendons.Examples of acute sprains<strong>and</strong> strains include:• Back strain from lifting• Twisted ankle or knee• Jammed finger/thumb• Any overexertion injuryfrom a single eventExamples of repetitive conditions,otherwise known as cumulativetrauma, include:• Carpal tunnel syndrome• Bursitis• Tendonitis• Tenosynovitis• Trigger finger• Any inflammation fromrepetitive motionRisk FactorsThe elements of force, frequency, <strong>and</strong> posture each play a role in the cause<strong>and</strong> prevention of soft tissue injuries.Be aware of these specific aspects of tasks in your inspection areas in orderto spot situations where an employee may be in danger of developing adisabling condition.Typically, this begins as discomfort, then develops into pain, <strong>and</strong> then finallybecomes an injury.46 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Ergonomic hazardsForceForces include the weight of an object being lifted, the amount of exertion topush or pull an object, <strong>and</strong> contact pressure against a h<strong>and</strong> or other body partwhen exerting a force.In seeking solutions, try to limit loads to 35 pounds. This can sometimes bedone by ordering supplies in smaller sizes. When this cannot be done, teamlifting is a good solution. However, the best solution is using a mechanicalh<strong>and</strong>ling aid.An alternative solution to a heavy lifting situation is to change the processso the load is too heavy to lift manually, <strong>and</strong> then use mechanical liftingequipment to do the job.FrequencyFatigue or injury may result when excessive joint or muscle flexion occurswithout rest, regardless of forces applied.To reduce frequency, consider cross training employees so that they can dovarious tasks. By varying the muscle groups used, the forces are spread out,which reduces fatigue. Scheduled job rotations throughout the day are a moreformal means of reducing the effects of repetitive motion.Any time you can automate a task, you will greatly reduce the potential forrepetitive motion injuries. This can also save labor <strong>and</strong> other costs.PostureWhen work is done in an awkward posture, the forces exerted are oftengreater on muscles <strong>and</strong> joints being used. Consequently, injuries are morelikely. A simple example is lifting an object near your body with your elbows inclose to your sides. Compare that with lifting the object with your arms awayfrom your body. With the arms extended, the force required to lift is increased<strong>and</strong> is transferred to your lower back.Whenever possible, work should be done with neutral postures to reduce thepossibility of soft tissue injuries.Neutral postures include:• Work performed close to the body• Back in a natural s-curve (not stooping over)• Head facing forward <strong>and</strong> level• Shoulders relaxed• Wrists straight <strong>and</strong> thumbs higher than little fingers<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 47

Ergonomic hazardsCommon ergonomic hazardsHere are some common situations where injuries from force, frequency <strong>and</strong>posture are likely.Bending over at the waistBent wristsElbows out <strong>and</strong> away from the bodyUpper body twisting48 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Ergonomic hazardsOver reaching with upper body extendedOver reaching with arms suspendedContact pressure on arm <strong>and</strong> thighsContact pressure on h<strong>and</strong>Pinch gripPinch grip<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 49

Ergonomic hazardsErgonomic solutionsHere are several examples of common ways to reduce or eliminateergonomic hazards.Install spring-loaded bottomsin bins or carts. This will allowthe contents height to be raisedas items are removed. Thisreduces the amount of bendingover needed to reach items inthe bottom.Angle the work so that itcan be h<strong>and</strong>led at a morecomfortable height <strong>and</strong> toreduce awkward postures.Use load-leveling devicesbeneath pallets so thatmaterials can be h<strong>and</strong>led inthe knee-to-shoulder zone.If the device is equipped witha turntable, use this featureto reduce the need to walkaround the pallet. Neverreach over the pallet to stackor unstack.50 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Ergonomic hazardsRetract keyboard legsRetract keyboard legs as they tendto cause you to bend your wristsupward. Keyboarding with a bentwrist can lead to a soft tissueinjury due to repetitive motion.Position the keyboard so that your wristsremain straightAdjust the keyboard <strong>and</strong> chairheight so that your wristsremain straight when yourfingers are on home row.Suspend the toolStrategically storeitems on shelvesto minimizeoverreaching. Keepheavier <strong>and</strong> morefrequently useditems in the “kneeto shoulder” range.Arrange workstations sothe majority of work isperformed close in, withelbows near the sides.Frequent side tasks shouldbe within the “normal reachradius” <strong>and</strong> infrequent sidetasks within the “extendedreach radius”.<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 51

52 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Unsafe work practicesKey concerns• Horseplay• Improper tool use• Unsafe lifting• Bypassing safety devices• Not using PPE<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 53

Unsafe work practicesThe risk taking cycleThe risk taking cycle typically begins with an unsafe act that does not resultin an injury. The absence of an injury is essentially a positive consequencefor the risk taker, who may actually feel rewarded. These add up to positivereinforcement for taking the risk, which encourages even more risk taking.Unsafe actReinforces unsafework practiceNo injuryRewardPositiveconsequencesIt is estimated that more than 80 percent of all workplace accidentsare the direct result of an unsafe act. Therefore, it is important thatinspection teams observe work behaviors while conducting inspections.The way behavior observations are done is dependent upon managementpolicies <strong>and</strong> the company’s safety culture. Some companies have aformal behavior observation program where areas <strong>and</strong>/or individuals areobserved for safety practices, with input given on the spot. Without sucha program, it may be best to passively observe <strong>and</strong> note any unsafe workpractices, but not the names of the individuals observed. Management,now aware of specific unsafe work practices, can conduct training orimplement other corrective measures.The following examples were shared by <strong>SAIF</strong> safety management consultantswhen asked to describe the worst hazard they had ever seen. Note the unsafebehaviors associated with the causes of these accidents.“In line with some of the other forklift ‘worsts,’ I saw the maintenance manager at one of myaccounts st<strong>and</strong>ing on the mast of a forklift. He was at least 20 feet above the ground.”“My worst hazard was an individual powerwashing a concrete floor while st<strong>and</strong>ing in a pool ofwater that had extension cords snaking through it to the work lights he was using to illuminatethe area.”54 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Unsafe work practices“I visited an employer that was manufacturing largesteel plates to armor military vehicles that were beingshipped to the Middle East. These plates were movedusing large overhead cranes, <strong>and</strong> I would estimatethe plates weighed several hundred, if not thous<strong>and</strong>s,of pounds. As the crane was moving the plates, wewitnessed workers st<strong>and</strong>ing under the plates as theywere in motion. The consultant suggested to the safetycontact who was with us that perhaps it was not a goodidea to have workers st<strong>and</strong>ing directly under the platesas they were suspended from the crane <strong>and</strong> in motion.”“I was doing a safety ride-along observation with anemployee when he suddenly drove through a gapin a highway divider barrier <strong>and</strong> proceeded to drivetowards on coming traffic. He then made a suddenleft turn into the company parking lot. He told me notto worry, he used this shortcut ‘all the time.’ I stillremember his name. ““At an auto repair shop, I saw a mechanicworking under a car that was sitting on a woodenchock placed in the center to support the weightof the vehicle.”“This would probably be mine. It was at a nurserywith underground piping that had burst. WhenI arrived, the worker was in this vertical trenchtrying to repair the pipe. The trench was aboutsix feet deep, <strong>and</strong> some of the sides had alreadybegun to collapse.”“I once saw a small chemical productsmanufacturer dispensing methanol from anungrounded, unsecured spherical fiberglass tank(a 1,000 gallon tank intended for undergrounduse) using a swimming pool pump plugged intoan extension cord <strong>and</strong> plumbed with PVC. Thetank was held upright by resting on a truck tire.”Common unsafe work practicesUnsafe acts may be committed intentionally or accidentally. Anytime oneis observed, it is likely that dozens of other unsafe acts went unnoticed. Itis not only important to note unsafe work practices, but to determine whythey occurred. Often, it is a practice that has become accepted because ofpoor job design, lack of appropriate equipment or inadequate training.HorseplayImproper or no ladder use Improper tool use No seat beltUnsafe liftingGuard removedBypassing safety deviceNot wearing personalprotective equipment<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 55

ResourcesMany resources are available to provide additional information <strong>and</strong> tools tostrengthen your safety inspection program.The safety section in the employer guide on saif.com has resources on avariety of industry-specific topics. Each topic has a list of related publications,videos, trainings, <strong>and</strong> websites.www.saif.com/safetyOregon OSHA has several materials specifically for inspection activities.General inspection information:www.cbs.state.or.us/osha/subjects/inspection.htmlSpecific inspection checklists:www.cbs.state.or.us/osha/st<strong>and</strong>ards/checklists.htmlWorksafe BC is an excellent Canadian safety resource with many usefulmaterials including safety posters, inspection checklists, video clips, <strong>and</strong>hazard spotting activities.www2.worksafebc.com/Safety/Home.aspCROET (Center for Research on Occupational Environmental Toxicology) is aresearch body of Oregon Health Sciences University. Useful data related tochemical hazards can be found here.www.ohsu.edu/xd/research/centers-institutes/croet/56 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 57

58 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>

Example of correspondencewith responsible party for hazard corrections(Company name)Safety committee reportDate:To:Re: Safety inspectionDuring the safety committee inspection on your area on the above date, thefollowing hazards or unsafe behaviors were observed. Please review <strong>and</strong>respond, noting actions or intended actions, <strong>and</strong> return by (date).Yours in safety(Name of safety committee chair or safety coordinator)Item:Actions:Date completed:Item:Actions:Date completed:Item:Actions:Date completed:<strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong> 59

1.5".25"2.5".375"3.5".5"”Gotcha stick” templateTransfer the above template to wood,plastic, metal, or other durable material.To test if a guard’s openings arenarrow enough, insert the narrow tipof the gotcha stick between the widestopenings.As long as the tip does not reach thepoint of operation, the guard openingsare narrow enough..625"5.5"Note: Because some printers will renderthis image differently, make sure youdouble check the template’s dimensionsfor accuracy.6.5".75"7.5".875"1.25"60 <strong>Effective</strong> <strong>Hazard</strong> <strong>Recognition</strong> <strong>and</strong> <strong>Control</strong>