26.7 mm - Schempp-Hirth

26.7 mm - Schempp-Hirth

26.7 mm - Schempp-Hirth

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

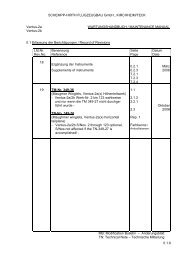

SCHEMPP-HIRTH<br />

Flugzeugbau GmbH.<br />

Kirchheim/Teck<br />

Sailplane variant Standard Cirrus B:<br />

APPENDIX to<br />

Technical Note No.<br />

278 - 38<br />

WORKING INSTRUCTIONS<br />

Page: 01<br />

No. of pages: 06<br />

This sailplane variant is equipped with the connection for the 16 m wing tip extension.<br />

Therefore the winglet for 15 m wingspan needs only to be adjusted:<br />

1. a) Slip the winglet on the spar tube. Trim the surmounting wing shell for an equal gap to<br />

the inner wing.<br />

b) If the wing bolts does not fit to the winglet bearing increase the bore diameter.<br />

Then apply resin with cotton flocks on the grease protected bolts and mount the<br />

winglet again.<br />

2. Copy the bore in the spar tube for the securing bolt to the winglet. First drill a hole with<br />

a diameter of 7 <strong>mm</strong>, then insert spar tube (III) for verification of the proper position and<br />

finally enlarge the hole to a diameter of 8 <strong>mm</strong>.<br />

3. After the mounting of the winglet with the securing bolt check the play of the winglet. If<br />

required add washers on the winglet bolts.<br />

/ 2

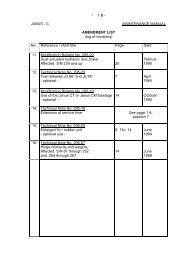

SCHEMPP-HIRTH<br />

Flugzeugbau GmbH.<br />

Kirchheim/Teck<br />

APPENDIX to<br />

Technical Note No.<br />

278 - 38<br />

Sailplane variants<br />

Standard Cirrus, Standard Cirrus G, Standard Cirrus CS 11-75L<br />

Page: 02<br />

No. of pages: 06<br />

These sailplane variants feature no connection for a 16 m wing tip extension. Therefore the<br />

connections for the winglets must be retrofitted.<br />

1. Mark wing tip cut-off line according the sketch shown on page 03.<br />

Then cut off the wing tip.<br />

2. a) Mount wing rib (I) with suspension bolts on the spar tube (III) and mount winglet.<br />

b) Fit wing rib (I) see page 06 to wing structure until the winglet matches the wing<br />

contour.<br />

c) If required remove and chamfer the foam.<br />

3. a) Position the wing with winglet with the aid of template “A” (dimensions see page 04<br />

and the photo on page 05). Fit the winglet with rib in the wing that the toe angle of<br />

the winglet matches the template “A” respective refer to drawing on page 06.<br />

b) Adjust the angle of the trailing edges of the wing and winglet with the aid of the<br />

template “B” see also photo on page 05.<br />

c) Damaged GFRP-cloth of the inner sandwich shell should be replaced by a 92125<br />

diagonal.<br />

d) After curing of the inner sandwich laminate check again the position of the winglet<br />

with the aid of the templates “A” and “B”.<br />

4. Bond end rib (I) to wing structure using thickened resin with winglet held in proper<br />

position by the templates “A” and “B”.<br />

5. After curing and tri<strong>mm</strong>ing bond the wing suspension bolts in the wing rib (I).<br />

6. Fit end rib (II) to wing tip cut off previously.<br />

Thereafter insert spar tube (III) into GFRP tube on end rib (I), slide end rib (II) onto<br />

spar tube (III).<br />

Finally bond wing tip to end rib (II) (using thickened resin) - make sure that tip matches<br />

the wing contour.<br />

7. Drill hole (IV) (which takes up the locking pin in the winglet) through the wing structure<br />

(first drill a hole with a diameter of 7 <strong>mm</strong>, then insert spar tube (III) for verification of the<br />

proper position and finally enlarge the hole to a diameter of 8 <strong>mm</strong>).<br />

8. Insert spar tube (III) into winglet and let the locking pin engage.<br />

9. Bond spar tube (III) with winglet (securing bolt engaged) with resin and cotton flocks in<br />

wing rib (I).<br />

10. Copy the bore in the spar tube for the securing bolt to the wing tip. Drill first with 7 <strong>mm</strong>,<br />

check the position of the hole then enlarge the hole to a diameter of 8 <strong>mm</strong>.<br />

10. Do the paint work (if necessary).<br />

/ 3

SCHEMPP-HIRTH<br />

Flugzeugbau GmbH.<br />

Kirchheim/Teck<br />

cut-off line perpendicular<br />

to upper surface of wing<br />

94.13°<br />

APPENDIX to<br />

Technical Note No.<br />

278 - 38<br />

90°<br />

90°<br />

reference line<br />

200 <strong>mm</strong><br />

[7.87 in.]<br />

<strong>26.7</strong> <strong>mm</strong><br />

[1.05 in.]<br />

outwards from<br />

90° reference line<br />

cutting edge<br />

wing tip<br />

200 <strong>mm</strong><br />

[7.87 in.]<br />

Page: 03<br />

No. of pages: 06<br />

/ 4

SCHEMPP-HIRTH<br />

Flugzeugbau GmbH.<br />

Kirchheim/Teck<br />

50 <strong>mm</strong><br />

[1.97 in.]<br />

winglet toe angle stop<br />

100 <strong>mm</strong><br />

[3.94 in.]<br />

400 <strong>mm</strong><br />

[15.75 in.]<br />

Template "B"<br />

(trailing edge)<br />

winglet toe angle stop<br />

WINGLET-MOUNTING TEMPLATES<br />

APPENDIX to<br />

Technical Note No.<br />

278 - 38<br />

86°<br />

Template "A"<br />

wing leading edge stop<br />

Template "B" (trailing edge)<br />

420 <strong>mm</strong><br />

[16.54 in.]<br />

566<br />

[22.28 in.]<br />

93°<br />

450 <strong>mm</strong><br />

[17.72. in.]<br />

450 <strong>mm</strong><br />

[17.72 in.]<br />

Page: 04<br />

No. of pages: 06<br />

120 <strong>mm</strong><br />

[4.72 in.] 379.5 <strong>mm</strong><br />

[14.94 in.]<br />

winglet toe angle stop<br />

Template "A" (port wing)<br />

(bottom side for starboard wing)<br />

86°<br />

200 <strong>mm</strong><br />

[7.87 in.]<br />

406 <strong>mm</strong><br />

[15.98 in.]<br />

wing leading edge stop<br />

900 <strong>mm</strong><br />

[35.43 in.]<br />

/ 5

SCHEMPP-HIRTH<br />

Flugzeugbau GmbH.<br />

Kirchheim/Teck<br />

Template "B"<br />

(trailing edge)<br />

APPENDIX to<br />

Technical Note No.<br />

278 - 38<br />

winglet toe angle stop<br />

Template "A"<br />

Page: 05<br />

No. of pages: 06<br />

wing leading edge stop<br />

/ 6

SCHEMPP-HIRTH<br />

Flugzeugbau GmbH.<br />

Kirchheim/Teck<br />

Outboard wing with removable standard wing tip Outboard wing with removable winglet<br />

toe angle - wing leading edge/<br />

tangent line to lower surface of winglet profile<br />

86°<br />

IV<br />

65<br />

III<br />

A B<br />

IV<br />

I<br />

APPENDIX to<br />

Technical Note No.<br />

278 - 38<br />

II<br />

65 <strong>mm</strong><br />

[2.56 in.]<br />

V<br />

Ø8 <strong>mm</strong><br />

[Ø0.31 in.]<br />

spar tube locking pin<br />

Page: 06<br />

No. of pages: 06<br />

SECTION A-B