Chapter 1 Gas Power Cycle

Chapter 1 Gas Power Cycle

Chapter 1 Gas Power Cycle

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

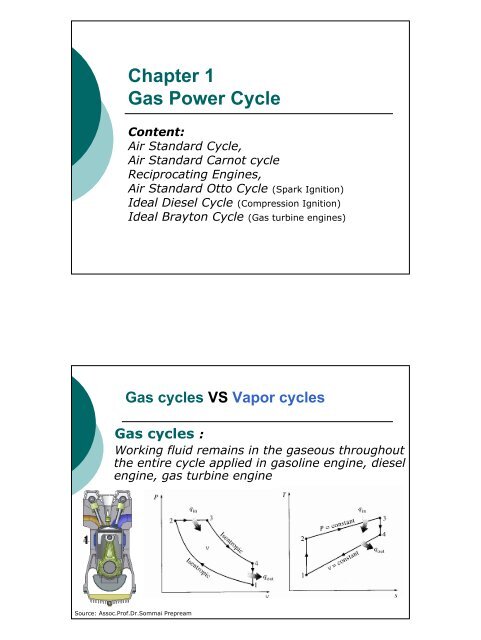

<strong>Chapter</strong> 1<br />

<strong>Gas</strong> <strong>Power</strong> <strong>Cycle</strong><br />

Content:<br />

Air Standard <strong>Cycle</strong>,<br />

Air Standard Carnot cycle<br />

Reciprocating Engines,<br />

Air Standard Otto <strong>Cycle</strong> (Spark Ignition)<br />

Ideal Diesel <strong>Cycle</strong> (Compression Ignition)<br />

Ideal Brayton <strong>Cycle</strong> (<strong>Gas</strong> turbine engines)<br />

<strong>Gas</strong> cycles VS Vapor cycles<br />

<strong>Gas</strong> cycles :<br />

Working fluid remains in the gaseous throughout<br />

the entire cycle applied in gasoline engine, diesel<br />

engine, gas turbine engine<br />

Source: Assoc.Prof.Dr.Sommai Prepream

<strong>Gas</strong> cycles VS Vapor cycles (cont’d)<br />

Vapor cycles :<br />

Working fluid exists in the vapor phase during<br />

on part of the cycle and in the liquid phase<br />

during another part such as in steam power<br />

plant cycle and refrigeration cycles<br />

The Carnot <strong>Cycle</strong> and Its Value in Engineering<br />

Heat<br />

Engine<br />

Source, T H<br />

Sink, T L<br />

Q H<br />

Q L<br />

W net<br />

The 4 processes of the carnot cycle: (Heat Engine)<br />

� Reversible Isothermal heat transfer from high temp.<br />

reservoir.<br />

� Reversible adiabatic expansion.<br />

� Reversible Isothermal heat transfer to low temp. reservoir<br />

� Reversible adiabatic compression

Example 8.1 Show that the thermal efficiency of a Carnot<br />

cycle operating between the temperature limits of T L AND<br />

T H is solely a function of these two temperatures.<br />

Solution<br />

from<br />

Wnet<br />

QL<br />

ηth<br />

= = 1−<br />

QH<br />

QH<br />

TH 1<br />

2⎛<br />

δQ<br />

⎞<br />

and S2<br />

− S1<br />

= ∫ ⎜ ⎟<br />

1 ⎝ T ⎠rev<br />

for rev. Isothermal process, T = const.<br />

TL 4<br />

1 2<br />

1Q2<br />

then S2<br />

− S1<br />

= Q<br />

T ∫ δ =<br />

1 rev T<br />

or<br />

1Q2<br />

= T ( S2<br />

− S1)<br />

Therefore,<br />

QH<br />

= TH<br />

( S2<br />

− S1),<br />

and QL<br />

= TL<br />

( S3<br />

− S4<br />

)<br />

But S1<br />

= S4,<br />

and S2<br />

= S3<br />

QL<br />

TL<br />

( S3<br />

− S4<br />

) TL<br />

ηth<br />

= 1−<br />

= 1−<br />

= 1−<br />

Q T ( S − S ) T<br />

H<br />

H<br />

Actual <strong>Gas</strong> <strong>Cycle</strong><br />

2<br />

1<br />

H<br />

T<br />

Q H<br />

Q L<br />

s 1 =s 4 s2 =s 3<br />

� Open <strong>Cycle</strong> (intake, discharge)<br />

� Working fluid is not a pure<br />

substance<br />

� Heat input by COMBUSTION of<br />

a fuel<br />

� Involve friction<br />

Source: Assoc.Prof.Dr.Sommai Prepream<br />

Exhaust<br />

gas<br />

2<br />

3<br />

s<br />

Fuel + air<br />

mixture

Intake<br />

valve<br />

Bore<br />

Air-Standard Assumption<br />

� The working fluid is air which continuously<br />

circulated in a close loop and behave as an<br />

ideal gas<br />

� All the processes are internally reversible<br />

� The combustion process is replaced by a<br />

heated-addition process from the external<br />

source<br />

� The exhaust process is replaced by a heat<br />

rejection process which restores the<br />

working fluid to its initial state<br />

Over View on Reciprocating Engines<br />

Exhaust<br />

valve<br />

Stroke<br />

TDC<br />

BDC<br />

Top Dead Center (TDC) : Position of the piston<br />

when it forms the smallest volume in diameter<br />

Bottom Dead Center (BDC) : Position of the<br />

piston when it forms the largest volume in diameter<br />

Stroke : Length of piston travel<br />

Bore : Diameter of the cylinder<br />

Clearance Volume (Vc ) : minimum volume<br />

formed in the cylinder when the piston is at TDC<br />

Displacement Volume (Vd ) :Swept Volume (Vmax-Vmin )<br />

Source: Assoc.Prof.Dr.Sommai Prepream<br />

Compression Ratio (r v ) = (V max /V min ) = (V BDC /V TDC )<br />

Mean Effective Pressure (MEP) : Fictious pressure that acted on the<br />

piston during the entire power stoke<br />

Net Work during the actual cycle (Wnet ):<br />

Wnet = (MEP) x (Piston Area) x (Stroke) = (MEP) x (Displacement Volume)

P<br />

Mean Effective Pressure, MEP Concept<br />

Actual Processes<br />

v min<br />

W net<br />

Equivalent<br />

v max<br />

TDC BDC<br />

Source: Assoc.Prof.Dr.Sommai Prepream<br />

Four Stroke Engine<br />

v<br />

P<br />

MEP<br />

Equivalent by MEP<br />

v min<br />

W net<br />

v max<br />

Wnet = (MEP) x (Displacement Volume)<br />

= (MEP) x (Vmax-Vmin )<br />

Intake Compression <strong>Power</strong> Exhaust<br />

1. Intake Stroke piston moves from TDC to BDC,<br />

drawing in fresh air-fuel mixture.<br />

2. Compression Stroke piston moves from BDC to<br />

TDC, compress air-fuel mixture.<br />

3. <strong>Power</strong> Stroke piston at TDC, spark plug ignite<br />

the air-fuel mixture. the combustion occur<br />

very fast that, in theory, the piston still at<br />

TDC. After that the piston is pushed to BDC.<br />

4. Exhaust Stroke piston moves from BDC to TDC,<br />

pushes the combustion gases out.<br />

v

Two Stroke Engine <strong>Power</strong><br />

Compression<br />

Intake &<br />

Exhaust<br />

1. Compression Stroke piston moves from<br />

BDC to TDC, compress air-fuel<br />

mixture.<br />

2. <strong>Power</strong> Stroke piston at TDC, spark plug<br />

ignite the air-fuel mixture. After the<br />

piston is pushed to BDC. Meanwhile,<br />

about half way, combustion gases are<br />

discharged and fresh air-fuel mixture<br />

is drawing in .<br />

Actual and Ideal cycles in spark-ignition engine<br />

Actual four-stoke spark-ignition<br />

engine<br />

Ideal Otto<br />

cycle<br />

Under the Air-Standard Assumption

P<br />

Air Standard Otto <strong>Cycle</strong><br />

Ideal Otto cycle consists of four internally reversible processes:<br />

Process 1-2 Isentropic Compression<br />

Process 2-3 v = constant, heat added<br />

Process 3-4 Isentropic expansion<br />

Process 4-1 v = constant, heat rejection<br />

3<br />

2<br />

v 2 =v 3<br />

Pv k = c<br />

Pv k = c<br />

w in<br />

w out<br />

1<br />

v 1 =v 4<br />

TDC BDC<br />

Source: Assoc.Prof.Dr.Sommai Prepream<br />

4<br />

v<br />

T<br />

1<br />

2<br />

v = const.<br />

v = const.<br />

q in<br />

q out<br />

s 1 =s 2 s3 =s 4<br />

There are only 2-stroke of all 4-processes,<br />

Analysis of Air Standard Otto <strong>Cycle</strong><br />

Constant volumeheat<br />

transfer<br />

1<br />

st<br />

v = const.<br />

⇒ w = 0<br />

Idealgas:<br />

and<br />

IsentropicProcessof<br />

Idealgases<br />

and<br />

law : closedsystem<br />

2<br />

2<br />

2<br />

q<br />

in<br />

3<br />

out<br />

k<br />

3<br />

= u − u + w<br />

3<br />

=<br />

2<br />

4<br />

3<br />

3<br />

1<br />

= P<br />

3<br />

k<br />

1v1<br />

2<br />

2<br />

q = u − u<br />

Pv<br />

q<br />

Pv<br />

RT, du<br />

= q = C (T −T<br />

)<br />

k<br />

v<br />

v<br />

3<br />

= P<br />

2<br />

=<br />

q = q = C (T −T<br />

)<br />

1<br />

3<br />

k<br />

2v2<br />

C dT<br />

P ⎛ 2 v ⎞ ⎛ 1 V ⎞ 1<br />

= ⎜<br />

⎟ = ⎜<br />

⎟<br />

P1<br />

⎝ v2<br />

⎠ ⎝V2<br />

⎠<br />

( k−1)<br />

/ k<br />

T ⎛ ⎞ ⎛ ⎞<br />

2 P2<br />

v1<br />

= ⎜<br />

⎟ = ⎜<br />

⎟<br />

T1<br />

⎝ P1<br />

⎠ ⎝ v2<br />

⎠<br />

2<br />

4<br />

= constant<br />

k<br />

v<br />

k −1<br />

P<br />

T<br />

3<br />

2<br />

v 2 =v 3<br />

1<br />

Pv k = c<br />

2<br />

s 1 =s 2<br />

3<br />

4<br />

Pv k = c<br />

v = const.<br />

v =<br />

const.<br />

w in<br />

q in<br />

q out<br />

s<br />

w out<br />

4<br />

1<br />

v 1 =v 4<br />

3<br />

4<br />

s3 =s 4<br />

v<br />

s

Analysis of Air Standard Otto <strong>Cycle</strong> (cont’d)<br />

Thermal efficiency<br />

w<br />

η th =<br />

q<br />

w<br />

1<br />

2<br />

3<br />

C<br />

= c,<br />

k =<br />

C<br />

P2v<br />

2 − P1v<br />

1<br />

1w<br />

2 =<br />

1−<br />

k<br />

R(<br />

T2<br />

− T1<br />

)<br />

1w<br />

2 =<br />

1−<br />

k<br />

qL<br />

4 q<br />

or,<br />

η th = 1−<br />

= 1−<br />

q q<br />

Mean Effective Pressure<br />

w<br />

net<br />

w =<br />

Pv<br />

k<br />

net<br />

= w + w<br />

∫<br />

net<br />

in<br />

Pdv<br />

= MEP ( v − v )<br />

4<br />

H<br />

1<br />

p<br />

v<br />

2<br />

2<br />

1<br />

3<br />

P<br />

T<br />

3<br />

2<br />

v 2 =v 3<br />

1<br />

Pv k = c<br />

2<br />

s 1 =s 2<br />

Pv k = c<br />

v = const.<br />

v =<br />

const.<br />

Spark-ignition Engine<br />

1. The higher r v the higher thermal eff.<br />

2. The higher r v cause Self-Ignition � engine knock<br />

3. Higher Octane Number of fuel used retard the self-ignition<br />

4. Typical r v of gasoline engine ~ 9.0 – 10.0<br />

5. Thermal efficiency of actual spark ignition engine ~ 25-30%<br />

v<br />

w in<br />

q in<br />

q out<br />

w out<br />

4<br />

1<br />

v 1 =v 4<br />

3<br />

4<br />

s3 =s 4<br />

v<br />

v<br />

s

Example 8.2 An ideal Otto cycle has a compression ratio of 8. At the<br />

begining of the compression process, the air is at 100 kPa and 17 o C,<br />

and 800 kJ/kg of heat is transfered to air during the heat addition<br />

proceed. Accounting for the variation of specific heats of air with<br />

temperature, determine, (a) the maximum temperature and pressure<br />

which occur during the cycle, (b) the net work out put, (c) the thermal<br />

efficiency, and (d) the mean effective pressure of the cycle<br />

Given:<br />

rv = 8.0<br />

P1 = 100 kPa and<br />

T1 =17oC qH = 800 kJ/kg<br />

variation of specific<br />

heats<br />

Determine:<br />

a) T max<br />

b) w net<br />

c) η th<br />

d) MEP<br />

P<br />

3<br />

2<br />

v 2 =v 3<br />

Pv k = c<br />

Pv k = c<br />

4<br />

1<br />

v 1 =v 4<br />

v<br />

T<br />

1<br />

2<br />

s 1 =s 2<br />

v = const.<br />

v = const.<br />

(a) T max = T 3 :find state 2 and then 3 using Ideal gas eqn.<br />

and Table A-17<br />

Table A-17 ; T 1 = 290 K � u 1 = 206.91 kJ/kg, and v r = 676.1<br />

w in<br />

1-2 Isentropic proc. v r2/v r1 = v 2/v 1 , v 2/v 1 =1/r v = 1/8,<br />

� v r2 = v r1/r v = 676.1/8.0 = 84.51<br />

Table A-17 : at v r2 = 84.51 � T 2 = 652.4 K and u 2 = 475.11 kJ/kg,<br />

P 2v 2 /T 2 = P 1v 1/T 1 ,<br />

P 2 = P 1(v 1/v 2 )(T 2/T 1 ) = (100 kPa)(8.0)(652.4/290) = 1799.7 kPa<br />

2-3 Constant volume heat added,<br />

1 st law q 23 = w 23 + u 3 –u 2 ; w 23 = 0<br />

q 23 = u 3 –u 2 ; 800 kJ/kg = u 3 – 475.11<br />

� u 3 =1275.11 kJ/kg � table A-17: T 3 = 1575.1 K and v r3 = 6.108<br />

P 3v 3/T 3 = P 2v 2 /T 2 ,<br />

P 3 = P 2(v 2/v 3 )(T 3/T 2 ) = (1799.7 kPa)(1/8.0)(1575.1/652.4) = 543.4 kPa<br />

T max =T 3 = 1575.1 K answer<br />

w out<br />

q in<br />

q out<br />

3<br />

4<br />

s3 =s 4<br />

s

(b) w net = q H –q L , similar to q 23 ; -q L =q 41 = u 1 –u 4<br />

3-4 Isentropic proc.<br />

v r4/v r3 = v 4/v 3 , v 4/v 3 =r v = 8, � v r4 = v r3r v = 6.108*8.0 = 48.864<br />

Table A-17 : at v r4 = 48.864 � T 2 = 795.6 K and u 4 =588.74 kJ/kg,<br />

4-1 Constant volume heat rejected,<br />

1 st law q 41 = w 41 + u 1 –u 4 ; w 41 = 0<br />

q 41 = u 1 –u 4 = 206.91 - 588.74 = -381.83 kJ/kg<br />

q L = -q 41 = 381.83 kJ/kg<br />

w net = q H –q L = 800 – 381.83 = 418.17 kJ/kg answer<br />

(c) η th = w net /q H = 418.83/800 = 0.523 or 52.3 % answer<br />

(d) MEP = w net /(v 1-v 2 ) ; P 1v 1 = RT 1<br />

� v 1 = 0.832 m 3 /kg , v 2 =v 1/8,<br />

MEP = 574.4 kPa answer<br />

Spark-ignition Engine<br />

Diesel cycles: the ideal cycle for<br />

compression-ignition engine<br />

Ideal diesel cycle consists of four internally reversible processes:<br />

Process 1-2 Isentropic Compression<br />

Process 2-3 P = constant, heat added<br />

Process 3-4 Isentropic expansion<br />

Process 4-1 v = constant, heat rejection<br />

P<br />

2<br />

q in<br />

v 2 =v 3<br />

3<br />

Pv k = c<br />

Pv k = c<br />

4<br />

1<br />

v 1 =v 4<br />

q out<br />

v<br />

T<br />

1<br />

2<br />

P = const.<br />

v = const.<br />

q in<br />

q out<br />

s 1 =s 2 s3 =s 4<br />

4<br />

3<br />

s

1st law : closed system<br />

Ideal gas:<br />

and<br />

Analysis of Ideal Diesel <strong>Cycle</strong><br />

Constant pressure heat transfer<br />

2<br />

P = const.<br />

⇒ w = P ( v − v )<br />

and<br />

2<br />

2<br />

4 1<br />

3<br />

3<br />

3<br />

2<br />

= − q = C ( T −T<br />

)<br />

Isentropic Process of Ideal gases<br />

3<br />

1<br />

4<br />

3<br />

2<br />

3<br />

1<br />

k<br />

1v1<br />

4<br />

3<br />

Pv = RT, dh = C dT<br />

q = q = C (T −T<br />

)<br />

in<br />

2<br />

2<br />

q = u − u = −C<br />

( T −T<br />

)<br />

q<br />

q = u − u + w<br />

out<br />

k<br />

Pv = P<br />

k<br />

p<br />

3<br />

v<br />

= P<br />

2<br />

2<br />

4<br />

2<br />

k<br />

2v2<br />

P ⎛ 2 v ⎞ ⎛ 1 V ⎞ 1<br />

= ⎜<br />

⎟ = ⎜<br />

⎟<br />

P1<br />

⎝ v2<br />

⎠ ⎝V2<br />

⎠<br />

( k −1)<br />

/ k<br />

T ⎛ ⎞ ⎛ ⎞<br />

2 P2<br />

v1<br />

= ⎜<br />

⎟ = ⎜<br />

⎟<br />

T1<br />

⎝ P1<br />

⎠ ⎝ v2<br />

⎠<br />

3<br />

q = u − u + P ( v − v ) = h − h<br />

v<br />

2<br />

3<br />

4<br />

1<br />

= constant<br />

k<br />

p<br />

k −1<br />

2<br />

1<br />

3<br />

2<br />

P<br />

T<br />

2<br />

q in<br />

v 2 =v 3<br />

2<br />

1<br />

s 1 =s 2<br />

3<br />

Pv k = c<br />

P = const.<br />

Pv k = c<br />

q in<br />

v = const.<br />

Analysis of Ideal Diesel <strong>Cycle</strong><br />

Cut off ratio (r c ) is the ratio of the cylinder<br />

volume after and before the combustion process<br />

Thermal<br />

w<br />

η th =<br />

q<br />

from<br />

at<br />

net<br />

H<br />

r c<br />

efficiency<br />

q<br />

= 1 −<br />

q<br />

V3<br />

v3<br />

= =<br />

V v<br />

T1<br />

( T4<br />

/ T1<br />

− 1)<br />

= 1 −<br />

kT ( T / T − 1)<br />

2<br />

definition<br />

processes<br />

3<br />

out<br />

in<br />

of<br />

2<br />

2<br />

1 − 2 and 3 − 4<br />

2<br />

T4<br />

− T1<br />

= 1 −<br />

k ( T − T )<br />

r<br />

c<br />

and<br />

k<br />

1 ⎡ r ⎤<br />

c − 1<br />

η th = 1 − k −1<br />

⎢ ⎥<br />

r ⎣ k ( rc<br />

− 1)<br />

⎦<br />

3<br />

2<br />

isentropic<br />

P<br />

T<br />

2<br />

q in<br />

v 2 =v 3<br />

2<br />

3<br />

Pv k = c<br />

1<br />

s 1 =s 2<br />

Pv k = c<br />

P = const.<br />

q in<br />

v = const.<br />

q out<br />

4<br />

1<br />

v 1 =v 4<br />

q out<br />

4<br />

1<br />

v 1 =v 4<br />

4<br />

3<br />

s3 =s 4<br />

q out<br />

v<br />

4<br />

3<br />

s3 =s 4<br />

q out<br />

v<br />

s<br />

s

Compression Ignition Engine<br />

1. The thermal efficiency of Diesel cycle always higher than Otto cycle<br />

( η th , diesel > ηth,<br />

otto ).<br />

2. The diesel engines operated at the higher rv and burn the fuel more<br />

completely.<br />

3. Typical rv of diesel engine ~ 12.0 – 23.0<br />

4. In a gasoline engine, it’s air intake is carefully restricted and controlled by<br />

the carburetor for a 15:1 air to fuel ratio. However, in the diesel engine,<br />

the air intake is unrestricted.<br />

5. Thermal efficiency of actual diesel engine ~ 35-40%.<br />

Compressor<br />

Typical<br />

compression<br />

ratios for<br />

diesel<br />

engines<br />

Brayton <strong>Cycle</strong>: The Ideal <strong>Cycle</strong> for<br />

<strong>Gas</strong>-turbine Engines<br />

Combustion Chamber<br />

Turbine<br />

An open-cycle gas turbine engine<br />

Win<br />

v<br />

qin<br />

Heat Exchanger<br />

Compressor Turbine<br />

Heat Exchanger<br />

qout<br />

Wout<br />

An closed-cycle gas turbine engine

Ideal Brayton <strong>Cycle</strong><br />

Brayton <strong>Cycle</strong> consists of four internally reversible processes:<br />

Process 1-2 Isentropic Compression (in a compressor)<br />

Process 2-3 P = constant, heat added<br />

Process 3-4 Isentropic expansion (in a turbine)<br />

Process 4-1 P = constant, heat rejection<br />

qin<br />

T<br />

W Wout<br />

s<br />

in<br />

= const.<br />

22<br />

4<br />

2<br />

3<br />

2<br />

4<br />

3<br />

qout<br />

P = const. at process 2 -3<br />

and 4 -1<br />

and P = P and P = P<br />

1<br />

qin<br />

P = const.<br />

P = const.<br />

qout<br />

3<br />

s 1 =s 2 s3 =s 4<br />

Analysis of Ideal Brayton <strong>Cycle</strong><br />

The energy balance for a steady - flow process for Brayton cycle<br />

and<br />

( q − q ) + ( w − w ) = h<br />

in<br />

q = q = h − h = C (T −T<br />

)<br />

q<br />

in<br />

out<br />

out<br />

1<br />

3<br />

4<br />

2<br />

= q = h − h = C (T −T<br />

)<br />

1<br />

Isentropic Process of Ideal gases at process1<br />

- 2 and 3-<br />

4<br />

net<br />

H<br />

k<br />

Pv = P<br />

in<br />

out<br />

p<br />

p<br />

exit<br />

3<br />

− h<br />

4<br />

inlet<br />

2<br />

1<br />

4 1<br />

k k<br />

1v1<br />

= P2v<br />

2 = constant<br />

1<br />

qout<br />

( k −1) / k<br />

⎞ 2<br />

( k −1)<br />

/ k<br />

⎛ P ⎞ 3 T3<br />

s 1 =s 2<br />

s3 s3 =s 4 s<br />

and<br />

T ⎛ 2 P<br />

=<br />

T ⎜<br />

1 P ⎟<br />

⎝ 1 ⎠<br />

= ⎜<br />

P ⎟<br />

⎝ 4 ⎠<br />

=<br />

T4<br />

Thermal efficiency<br />

w<br />

η th =<br />

q<br />

qout<br />

= 1 −<br />

q<br />

T4<br />

− T1<br />

T1<br />

( T4<br />

/ T1<br />

− 1)<br />

= 1 −<br />

= 1 −<br />

k ( T − T ) kT ( T / T − 1)<br />

Pressure<br />

P2<br />

ratio ( rp<br />

) = ; Then<br />

P1<br />

η th = 1 −<br />

r<br />

1<br />

in<br />

from isentropic at processes 1 − 2 and 3 − 4 and<br />

k −1/<br />

k<br />

p<br />

3<br />

2<br />

2<br />

3<br />

2<br />

s<br />

T<br />

P<br />

2<br />

2<br />

qin<br />

qin<br />

P = const.<br />

P = const.<br />

qin<br />

3<br />

s = const.<br />

qout<br />

3<br />

1 4<br />

qout<br />

4<br />

v

<strong>Gas</strong> Turbine Engine<br />

1. The thermal efficiency of an ideal Brayton cycle depends on the<br />

pressure ratio and k.<br />

2. In commom designs, the pressure ratio should be in range of 11-16,<br />

however, it can work in the range at r p= 5 – 20.<br />

3. At the fixed turbine inlet temp. (T 3), the net work output increase with<br />

the pressure ratio, reaches a maximum, and then starts to decrease.<br />

4. <strong>Cycle</strong> efficiency can be improved through increasing the tutbine inlet<br />

temp., increasing the efficiency of turbomachinery components,<br />

modification of the basic cycle.