730 Articulated Truck

730 Articulated Truck

730 Articulated Truck

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

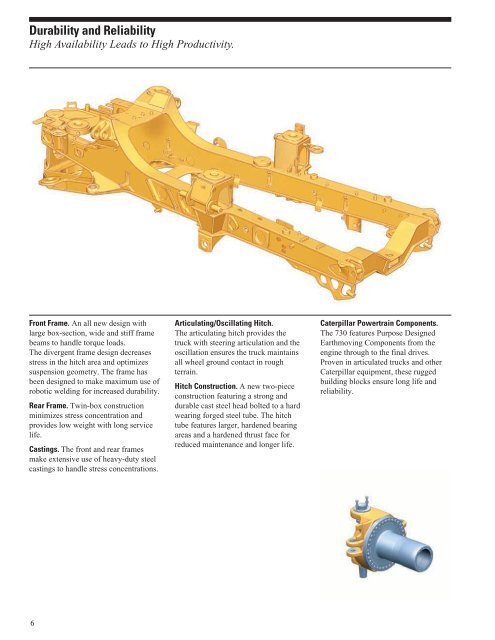

Durability and ReliabilityHigh Availability Leads to High Productivity.Front Frame. An all new design withlarge box-section, wide and stiff framebeams to handle torque loads.The divergent frame design decreasesstress in the hitch area and optimizessuspension geometry. The frame hasbeen designed to make maximum use ofrobotic welding for increased durability.Rear Frame. Twin-box constructionminimizes stress concentration andprovides low weight with long servicelife.Castings. The front and rear framesmake extensive use of heavy-duty steelcastings to handle stress concentrations.Articulating/Oscillating Hitch.The articulating hitch provides thetruck with steering articulation and theoscillation ensures the truck maintainsall wheel ground contact in roughterrain.Hitch Construction. A new two-piececonstruction featuring a strong anddurable cast steel head bolted to a hardwearing forged steel tube. The hitchtube features larger, hardened bearingareas and a hardened thrust face forreduced maintenance and longer life.Caterpillar Powertrain Components.The <strong>730</strong> features Purpose DesignedEarthmoving Components from theengine through to the final drives.Proven in articulated trucks and otherCaterpillar equipment, these ruggedbuilding blocks ensure long life andreliability.6