Atlas axles - Classic Ford

Atlas axles - Classic Ford

Atlas axles - Classic Ford

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

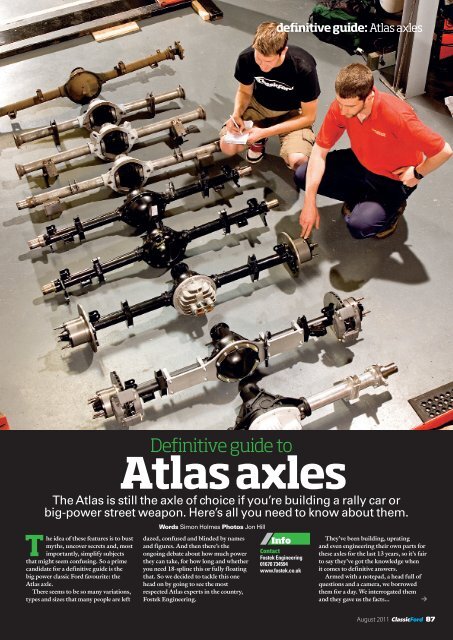

cftechHow much powercan <strong>axles</strong> take?What’s the weakest part of the <strong>Atlas</strong> axle? Why do CWP ratiosmatter? Why is grip the most important factor? And,how to buy an axle secondhand...The most important factor hereis grip, as the more you have,the more likely you are to breaksomething. Generally speaking thoughif you were to start with a totallystandard Capri axle in good workingorder and drive with moderate care,then they are usually fine until aboutthe 300 bhp for a fast road car. Afterthat, it depends largely on how muchyou abuse the car and if it’s being usedfor drag racing or rallying — if so,the shafts will start snapping.However, with the right upratedcomponents fitted they’ve beenproved reliable on 500 bhp YB-poweredfast road, track and strip cars. Thereare a couple of points worth knowingabout though...CWPThe crown wheel andpinion ratio can bechanged to givedifferent accelerationcharacteristics.What CWP ratios are available?3.09:1These are thehighest ratiosavailable andcame in mostV6- enginedCapris. They arevery common,but generallyuseless, as theyare deemed too‘lazy’ for the road.3.22:1This was a ratiofound in some Mk13-litre Capris andis very rare. Butsadly, again, prettyuseless in mostroad cars as theyare too high.ShaftsThese are the weakest points of the<strong>Atlas</strong>. If you’re using standard shafts,source some from a low mileage car— ones that have been marked toindicate what side they come from,as shafts twist marginally over timeand tend to set into position, like acorkscrew. They are at their strongestonce set, as they become ‘workhardened’, which means if they everswap sides for whatever reason thenthey’re more likely to break.CWPOut the box these are very strong andrarely break. However, the lower theratio, the weaker the pinions becomeas the amount of extra teeth thatphysically have to fit to decrease theratio makes them smaller and thereforeweaker. It’s also worth noting that theoriginal <strong>Ford</strong> items are stronger thanreproduced items and as a resultcommand more money.3.44:1Ideal for big poweror big torqueYB-engined carsthat won’t find theslightly high ratioa problem.Originally cameon 2-litre PintopoweredCapris.3.75:1The most desirableof all the ratios fora fast road car, asit offers the bestcompromise andis ideal for theaverage YBenginedcar. Thesewere fitted to the1600cc PintopoweredCapris.Buyingsecondhand:what to look forIdeally get one with as low mileage as possible and ingood working order, although it’s hard to tell from theoutside, so here are some pointers. If the oil inside the diffis clean and full to capacity it’s generally a good sign; theback plates tend to corrode, leak oil and then they run lowon lubrication, which causes excess wear to the internals.It’s best to spend extra time and money looking for theright size and ratio for your application, rather than buyingany old axle that comes along and having to spend moneyadapting it. Expect to pay around £150 for a 52-inch <strong>Atlas</strong>without an LSD and £500-plus for the rare Capri Specialaxle which had a plated ZF LSD in it. A narrow 50-inch<strong>Atlas</strong> from a Mk1 Capri will normally go for around £300as it’s more desirable for the wide arch cars and rally boys.4.1:1This is a rare <strong>Ford</strong>Motorsport itemand wasn’t fittedto any road car asstandard. It’s idealfor an NA-poweredcar and they havesince beenreproduced asan aftermarketitem by variouscompanies.4.6:1Common on P100pick-ups and someTransits, there’sa steady demandfor these from therally boys whoregularly use them,as they are too lowfor the road.5.1:1These were therare standard-fitTransit items forspecial vehicles,such asAmbulances oreven ice creamvans. There’s ahigh demand fromthe rally boys.They’re availableas reproductionitems.How toimprove themDifferentials, casings and shafts... what you need to know.DifferentialThe first thing to do, if youhaven’t already, is fit an LSD, asthe standard open diff isn’t idealfor putting down any kind ofdecent power. For a road car,Fostek suggests using a QuaifeATB as it’s easy to maintain andkind to halfshafts. But they doadvise it’s considered to bestrictly a road-going diff andnot suited to track or for harshdriving (which includesburnouts and doughnuts). Ifthat’s more up your street, or thecar will be spending time at thetrack or the strip, then a plateddiff is better suited to yourneeds. They are motorsportorientated items and althoughthey lock both wheels fortraction in a harsher way, theycan be adjusted through rampangles and preloads, to suit aless aggressive road goingapplication. Fostek prefer to usethe Gripper diffs, which costaround £900, as ZF items. Theywere very popular but are nolonger available new. Be awarethat the P100 came with an opendiff in a heavy duty casing whichlooks like an LSD to theuntrained eye, so be carefulwhen buying secondhand.ShaftsAll standard shafts are onepiece16 spline and quite smallin diameter, which makes themthe weakest link, so the firstthing is to upgrade to largertwo-piece 18 spline shafts. To fitlarger shafts the casing doesn’tneed to be modified, but theside gears that connect them tothe diff will need to be changedor machined to suit. Normally,Plated DiffsDesigned with motorsport in mind,these are ideal for big power cars.Open DiffsStandard in most <strong>axles</strong>, theseare the first thing to replace.an LSD will be fitted already atthis stage and the side gearsneeded to fit 18 spline shaftscost about £150 for the pair. Forthe shafts themselves there arequite a few different brandsavailable, but Fostek have hadgood results from using twopiece shafts from Phil andMick Squires at Rally andCompetition Equipment (01782523664) which are about £125each. These are known as Group1 shafts but are in the fact thesame diameter and spline countas what would be used for aGroup 4 axle. The matchingouter flanges, to make them atwo piece shaft, are £70 eachand the new bearings to go withthem are £40 each. New wheelstuds will also be needed foraround £20 a set. The shaftscome in the most common sizesto cater for baby, narrow andfull-width <strong>axles</strong> off the shelfand for more bespoke orcustom applications suchas the slightly shorter47.5-inch Fostek prefer touse in un-arched Escortscan also be supplied. Thequality is outstandingand will cope withmost high powerapplications. ButFostek do sell aneven heavierduty, gundrilled,rolled-spline versionthat come with an unbreakableguarantee for £1200 a pair,and can be done to anylength required.CasingFor the average fast road car nomore needs to be done, or canbe done, to increase thestrength of the axle internals interms of power than a good LSDand a set of uprated shafts.However, as soon as you start touse a car in harsh conditions,rough terrain on a rally stage orthe extreme cornering forces ofa track, thicker tubes and extrabracing is needed to stop anyflex or twisting of the tubes outof the pig’s head.Fostek have just had somebrand new castings done for thepig’s head in high grade, highstrength iron, which are evenbetter than the original <strong>Ford</strong>item. They are the first companyto successfully do this and willonly be supplying them withtheir own <strong>axles</strong>, so will not besold separately. Alloy ones arein the pipeline too, which offera big weightsaving.definitive guide: <strong>Atlas</strong> <strong>axles</strong><strong>Atlas</strong> prosand consAdvantagesOver something like an English,they use a bigger CWP, biggertubes, bigger bearings, have astronger casing, use bigger wheelbearings and there’s lots of potentialto improve them to nearindestructible levels. Alsosometimes an English axle isn’twide enough to fit a wide arch carand finally, now everything hasbeen re-produced a brand newaxle can be built up from scratch.DisadvantagesWeight is the main one and thesignificant one; they weigh a fairbit more than an English axle.There’s some work and expenseneeded to fit one, as there’s noreadily available off the shelf itemfor most cars as it has to bemodified. Due to their bigger size,a diff tunnel may be needed if thecar is running extra low. Also, incomparison to the rear loadingEnglish axle, the front loading <strong>Atlas</strong>is harder and more time-consumingto work on, which comes into effectif you want to change ratios often.How reliableare they?Once the correctly uprated partshave been fitted to suit the intendeduse, they are very strong, reliable<strong>axles</strong>. This depends if they havebeen built correctly in the first place,as it’s important to check what’sknown as the backlash clearance toensure it’s within its tight tolerance.If it hasn’t been done correctly it willcreate excess heat, noise and wear.It needs to be carefully adjusted,using shims, to make sure there’sgood contact between the teeth andsimilarly the pinion needs to have agood mesh with the crown wheel.This ensures the longevity of thecomponents and through this kindof clinical preparation Fostek haveseen <strong>axles</strong> cope with over 5000race miles between rebuilds.90 August 2011August 2011 91

cftechmyths1<strong>Atlas</strong> <strong>axles</strong>won’t takebig power? False.With the right partsfitted they havebeen proven onbig power and biggrip cars.2Group 4floating <strong>axles</strong>are stronger?False. Thedifferencesare only on thehub arrangementand not the pig’shead internals.3<strong>Ford</strong> nevermade a Baby<strong>Atlas</strong> for the Escort?False. They arevery, very rare,but they werefitted to someEuropean cars.4An LSD isstronger thanan open diff? False.They are as strongas each other.5 A standardaxle can copewith 350 bhp? True.This has beenknown withgentle road drivingand, importantly,lower grip levels.What is a fully floatingGroup 4 axle?This is something you hearbeing banded about a lotwithin rally circles and itrelates to the strength of the hubarrangement, rather than thepower it can cope with. The heavyduty upgrades to the hubs allowfor sustained shocks and harsh useover rough ground such asrallying. The centre pig’s headsection, including the CWP, diff andshafts, is virtually the same as anyother Group 1 or fast road uprateditem, but the tubes are thicker andheavily braced. They also use astub axle arrangement andbearing carrier, so the hub itself isdesigned to spread the load ontothe tubes and axle. On a normalaxle the shafts and bearings haveto transfer the torque of the engineas well, taking the wheel load, butthis way its role is reduced to justtransmitting power. This is done byanchoring the hub, using twotapered roller bearings, whichstops wheel movement no matterwhat the wheel encounters. It alsomeans that even under very hardcornering the wheels will alwayspoint in the same direction, whichis ideal for track or circuit basedcars too. As it’s a fair amount ofwork to machine the necessaryend parts, and different shafts areneeded, it’s not something that canbe done as a kit or as an afterthought once the axle’s been built.Only the outer hubs and shafts are different.FullyfloatingThis is somethingwe hear being useda lot, but it onlyrelates to the hubarrangement, togive extra strength.On the left is a Group 4, next to a normal axle.About Fostek engineeeringRun by father and son duo John and TomFoster, the company started out around13 years ago when they were buildingthemselves a rally car. When it came to theaxle they found no one could supply themwith one. Taking the initiative, they read a fewbooks and had a go at doing it themselves,with good results. They were soon doinganother for a friend’s car and word spread. Inthe early days they had to machine and adaptstandard parts, as very little was readilyavailable. But they now make their own parts,redesigning items along the way to be bothstronger and lighter. Over time they’ve learntwhat works and what doesn’t and now turnout hundreds of <strong>axles</strong> a year for customers allover the world for road and competition use.They quickly established a reputation as beingthe leading force and experts in <strong>Atlas</strong> <strong>axles</strong>and their latest development of newly castpig’s heads means they can now supplya complete brand new axle from scratch.So if you’ve got a big power engine and needan axle, Fostek are the ones.Fostek is a familyrun businesswhich catersfor everything<strong>Atlas</strong> related.92 August 2011