Omnicompact Stacking Door - Stöbich Brandschutz

Omnicompact Stacking Door - Stöbich Brandschutz

Omnicompact Stacking Door - Stöbich Brandschutz

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Airport Munich, Germany<br />

… here you find refferences<br />

Marktkauf, branch Goslar, Germany<br />

BMW, Munich, Germany<br />

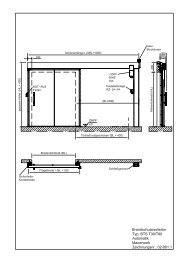

Low lintel design<br />

Standard design<br />

Clear width (=LB) ≤4500: total width = LB + 604<br />

Clear width (=LB) > 4500: total width = LB + 708<br />

Gravigen drive unit 400V/AC<br />

750/1500 W<br />

(Standard motor on right side, above 1.100 kg<br />

door weight - 2nd drive unit)<br />

Headquarters<br />

<strong>Stöbich</strong> <strong>Brandschutz</strong> GmbH<br />

Pracherstieg 6<br />

38644 Goslar, Germany<br />

Phone +49-(0)5321-5708-0<br />

Fax +49-(0)5321-5708-991<br />

Branch South<br />

<strong>Stöbich</strong> <strong>Brandschutz</strong> GmbH<br />

Gewerbehof 8<br />

73441 Bopfingen, Germany<br />

Phone +49-(0)7362-9614-0<br />

Fax +49-(0)7362-9614-50<br />

Clear height<br />

Clear height<br />

Glazing<br />

Branch East<br />

<strong>Stöbich</strong> <strong>Brandschutz</strong> GmbH<br />

Geltestraße 12<br />

06188 Landsberg OT Queis, Germany<br />

Phone +49-(0)34602-552-0<br />

Fax +49-(0)34602-552-50<br />

Branch West<br />

<strong>Stöbich</strong> <strong>Brandschutz</strong> GmbH<br />

Max-Planck-Straße 13<br />

59423 Unna, Germany<br />

Phone +49-(0)2307-98689-0<br />

Fax +49-(0)2307-98689-50<br />

*1: depends on LH<br />

(clear width)<br />

Armoured gas concrete<br />

Solidity class G4.4<br />

Wall thickness min. 200mm<br />

Gas concrete<br />

Stone solidity class 4<br />

Wall thickness min. 240 mm<br />

Concrete DIN 1053<br />

Solidity class B15<br />

Wall thickness min. 140mm<br />

Brickwork DIN 1053-1<br />

Minimum solidity class 12<br />

Wall thickness min. 240mm<br />

Required wall types<br />

according to approval<br />

Z-6.3-1674<br />

Drive unit:<br />

• Rotary current-Gravigen-drive system 400V/750 W/1500 W with hold-open<br />

device 24V DC.<br />

Differing dimensions<br />

on request<br />

Construction standard dimensions T30 T90<br />

• width (mm): 1000-9000 1000-4500<br />

• height (mm): 2000-6000 2000-4500<br />

Elements:<br />

International sales partners respectively subsidiaries<br />

· Australia<br />

· Austria<br />

· Belgium<br />

· Bosnia and<br />

Herzegovina<br />

· Bahrain<br />

· Bulgaria<br />

· Brazil<br />

· Canada<br />

· China<br />

· Croatia<br />

· Cyprus<br />

· Czech<br />

· Denmark<br />

· Estonia<br />

· Finland<br />

· France<br />

· Great Britain<br />

· Greece<br />

· Hong Kong<br />

· Hungary<br />

· Iceland<br />

· Ireland<br />

· Israel<br />

· Italy<br />

· Latvia<br />

· Liechtenstein<br />

· Lithuania<br />

· Luxembourg<br />

· Macedonia<br />

· Mexico<br />

· Netherlands<br />

· New Zealand<br />

· Norway<br />

· Poland<br />

· Portugal<br />

· Qatar<br />

· Romania<br />

· Russia<br />

· Serbia and<br />

Montenegro<br />

· Saudi Arabia<br />

· Singapore<br />

· Slovakia<br />

· Slovenia<br />

· Spain<br />

· Sweden<br />

· Switzerland<br />

· Turkey<br />

· Ukraine<br />

· USA<br />

Function:<br />

• The closing in daily use and in case of fire is speed-controlled and current<br />

less via stored energy.<br />

• The re-opening is done motor-driven.<br />

• The door blade is stacked in the lintel area.<br />

• Double walled design made of galvanized steel sheet (optional powdercoated,<br />

nitrited or stainless steel) foamed with mineral hard foam SOLIPOR<br />

Side guides:<br />

• Galvanized design (coated or in stainless steel on request)<br />

• Lateral overlapping 230 mm<br />

*Lateral overlapping 295 mm; clear width ≥ 5000mm<br />

More Infos<br />

(CD or Internet)<br />

· United Arab Emirates 09/2010-02-M-1000-EN<br />

<strong>Omnicompact</strong><br />

<strong>Stacking</strong> <strong>Door</strong><br />

Smoke barriers<br />

Smoke protection closures<br />

Textile fire protection closures<br />

Conveyor system closures<br />

Tube closures<br />

Fire protection stacking doors<br />

Fire protection high-speed doors<br />

Control units<br />

Fire protection hoods<br />

Fire protection-insulation doors for ships and buildings<br />

Fire protection doors - panel walls/hygiene

Wall problem<br />

Are there any limitations on the shear wall?<br />

Space problem<br />

Are there any limitations in the room?<br />

E.g. roadways, crane rails or installations?<br />

Visual demand<br />

Constructional measures<br />

Safe utilisation<br />

Load to the ceiling<br />

Your problems, your questions… we have the innovative answers!<br />

Are you very exigent concerning the design?<br />

Invisibly integrated, colour-design or stainless steel design?<br />

Conditions around the opening<br />

Is there a risk that the door does not close securely<br />

because of dirt in the closing area? Can the traffic of e.g.<br />

fork lifters cause damage to the door or to the frame?<br />

Are constructional measures necessary, as for example wall fore-parts, wall<br />

bracings, additional reinforcements?<br />

What are your demands concerning safety and cycles? How are the<br />

guidelines according to EN 12605 and EN 12634 implemented into<br />

practice - e.g. hindrances in the closing area, failure of the drive system,<br />

etc.? Is a frequent operation (cycles) a criteria for you application?<br />

Can you induce additional loads to the ceiling?<br />

Minor demand for space<br />

The <strong>Omnicompact</strong> system has minimal demands for space in the<br />

lintel area and laterally at the opening.<br />

Minimal construction depth<br />

There are multiple choices for the installation by space-saving assembly on only one side of<br />

the wall. The stacking design leads to very small space requirements. With one only partition<br />

level we achieve minimal operational demands on the room. The side guides have a small<br />

construction depth, as all partition elements run on one common line.<br />

Product aesthetics<br />

The <strong>Omnicompact</strong> system offers a design of the surface in terms of colour or<br />

stainless steel, invisibly integrated in false ceilings, installation of the side<br />

guides into the niche<br />

Insensible construction<br />

Modest construction situation<br />

No load to the ceiling<br />

Primary door components are available in stainless steel or with<br />

anticorrosive coating. Due to the vertical closing direction the door is<br />

insensible against dirt in the closing area. <strong>Door</strong> blade and side guides<br />

are beyond the hazard zones. Single elements can be exchanged in<br />

case of damage<br />

Plane wall is sufficient.<br />

Wall fore parts / wall bracings are not required.<br />

A fire-protected steel beam as lintel is sufficient.<br />

DIN EN 12604 and DIN EN 12453<br />

Closing edge surveillance, crash backup and jamming protection<br />

by a joint covering guarantee optimal safety during the closing<br />

process. Frequent operation is no problem due to the design of<br />

the elements.<br />

Due to the construction of the <strong>Omnicompact</strong>, no induced forces have to be<br />

lead into the ceiling.<br />

<strong>Omnicompact</strong> – Innovative fire protection stacking doors since 1997<br />

Optional: Glass cutout<br />

in the element<br />

Crash back up<br />

creates optimal safety<br />

in case of faults on the<br />

bearing chains and on the<br />

drive system.<br />

Gravigen-drive<br />

with integrated holdopen<br />

device and speed<br />

control, as an option with<br />

an additional local, network<br />

independent energy supply for<br />

emergency opening.<br />

Finger jamming<br />

protection, which means that<br />

there are no gaps between<br />

the element joints during the<br />

closing process<br />

Details on the <strong>Stöbich</strong> control units can be<br />

found in the separate brochure.<br />

Robust door blade<br />

elements in sheet steel<br />

design, foamed with<br />

hard foam SOLIPOR<br />

for optimal insulation<br />

characteristics<br />

Optional: Flanged,<br />

manual emergency<br />

opening and an<br />

additional mechanic<br />

hold open device.<br />

Automatic<br />

surveillance of the<br />

closing edge<br />

Certified according<br />

to