Cheese Industry Packaging Information - R.E.Morrison Equipment Inc.

Cheese Industry Packaging Information - R.E.Morrison Equipment Inc.

Cheese Industry Packaging Information - R.E.Morrison Equipment Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

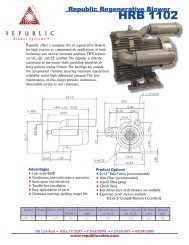

<strong>Cheese</strong> <strong>Industry</strong>Clean and dry Hepa quality air can be used toproduction accelerate speed, the and evaporation a portable design of brine allowing wash the onsystem cheese, to be making moved between it possible different to cut lines and based package oncheese wheels without leaving them sitting inproduction.storage to dry. Most hard cheese is vacuumWhen metal or plastic trays or totes are used theypackaged for freshness and the package ishave to be cleaned and dried between uses. In smallshrunk tight using hot water. If the packageto remains medium production wet it can’t facilities be accurately often production inkjet codedstops without while using workers expensive wash and dry inks, trays and to enable the weighcontinued scale becomes production. contaminated The air knife system with dries water fallingthe from totes the and package. trays immediately Consequently, after the automated the scalemust be dried and re-calibrated frequently towash, eliminating the need for larger tray inventoriesshow true dry package weight. Also, labelsand the expensive real estate required for ambient airare more difficult to apply on a wet package.evaporation drying.This is where the ADAMARK system excels.Installing The Becker a line 7.5 of or German 10 Hp engineered ADAMARK and air knifemanufactured drying system vacuum at the pumps exit are of ideal the for hot degassing waterpastes shrink and tunnel spreadable will cheese. solve all Without of these air bubbles, waterthe related product problems. reaches accurate If an fill existing volume and 4-foot weight longconveyor is not available, the ADAMARKwithout the risk of air born bacteria within the product.self-contained conveyorized blower systemOil free or oil lubricated Becker pumps are worldis available. The system comes as a completerenowned as the vacuum source on wrapping anddrop-in addition with installed top andcarton bottom erecting air knives, equipment. a variable speed drive beltto In highly match automated any production factories, robotic speed, pick and and a portableplace design systems allowing use quiet, the oil system free, and to compact be moved Beckerpumps between as the different vacuum source. lines based Many available on production. vacuhoistWhen vacuum metal assisted or plastic lifting equipment trays or totes use Becker are usedoil they free rotary have vane to be or cleaned regenerative and vacuum dried pumps between asthe uses. source. In Not small vacuum to medium pumps production are created equal. facilitiesoften production stops while workers washand dry trays to enable continued production.It is The the ADAMARK internal manufacturing air knife tolerances system that dries providea vacuum the totes pump and with trays a good immediately volume to Hp after ratio. the Asautomated wash, eliminating the need foran example at full designed vacuum a 5 Hp Beckerlarger tray inventories and the expensive realregenerative vacuum pump will often out perform aestate required for ambient air evaporationcompetitive 7.5 Hp model.drying.In Canada both large and small cheese producersuse The our Becker products. line of German Canadian engineered cheese products andmanufactured vacuum pumps are ideal forfind loyal customers because of their outstandingdegassing pastes and spreadable cheese.quality and taste. However, a customer’s decisionWithout air bubbles, the product reachesto try a new brand is driven almost entirely by theaccurate fill volume and weight without thepackaging. risk of air For born a competitive bacteria edge, within the package the product.has Oil to free be clean or oil and lubricated clear of watermarks, Becker with pumps nonwrinkledare world labels renown and legible as date the codes. vacuum That’s source why onR.E. wrapping <strong>Morrison</strong> and products carton are used erecting every equipment.day byCanada’s In highly top automated producers large factories, and small; robotic we dry pickproducts and place remarkably systems well. use quiet, oil free, andcompact Becker pumps as the vacuum source.Many available vacu-hoist vacuum assistedlifting equipment use Becker oil free rotaryvane or regenerative vacuum pumps as thesource. Not all vacuum pumps are createdequal. It is the internal manufacturingtolerances that provide a vacuum pump witha good volume to Hp ratio. As an exampleat full designed vacuum a 5 Hp Beckerregenerative vacuum pump will often outperform a competitive 7.5 Hp model.In Canada both large and small cheeseproducers use our ADAMARK and Beckerproducts. Canadian cheese products findloyal customers because of their outstandingquality and taste. However, a customer’sdecision to try a new brand is driven almostentirely by the packaging. For a competitiveedge, the package has to be clean and clearof watermarks, with non-wrinkled labels andlegible date codes. That’s why R.E. <strong>Morrison</strong>products are used every day by Canada’s topproducers large and small; we dry productsremarkably well.1.800.668.8736 3615 Laird Road, Mississauga, ON, Canada www.remequip.com2