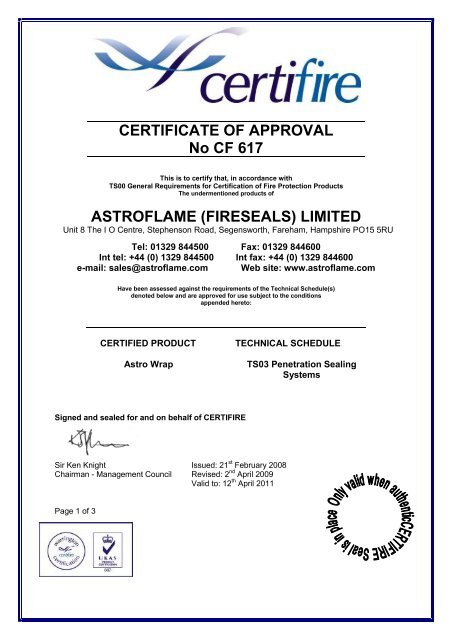

CERTIFICATE OF APPROVAL No CF 617 ASTROFLAME ... - Safelincs

CERTIFICATE OF APPROVAL No CF 617 ASTROFLAME ... - Safelincs

CERTIFICATE OF APPROVAL No CF 617 ASTROFLAME ... - Safelincs

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Astro Wrap<strong>CERTIFICATE</strong> <strong>No</strong> <strong>CF</strong> <strong>617</strong>ASTR<strong>OF</strong>LAME (FIRESEALS) LTD1. This approval relates to the use of Astro Wrap for the fire protection where services arepenetrating walls. The detailed scope is given in the Approval Matrix included in thisCertificate. This shows the thickness and acceptable services for Astro Wrap required toprovide fire resistance periods in accordance with BS 476: Part 20: 1987 or BS EN 1366-3: 2004 (denoted by * in the tables) of up to 240 minutes for differing services and wallconstructions.2. This certification is designed to demonstrate compliance of the product or systemspecifically with Approved Document B (England and Wales), Section D of the TechnicalStandards (Scotland), Technical Booklet E (N. Ireland). If compliance is required to otherregulatory or guidance documents there may be additional considerations or conflict tobe taken into account.’3. The product is approved on the basis of:i) Initial type testingii) Audit testing at the frequency specified in TS03iii) A design appraisal against TS03iv) Inspection and surveillance of factory production controlv) Production surveillance under ISO 9001:20084. The concrete floors and masonry or concrete walls shall be at least 100 mm thick andhave at least the same fire rating as that required for the penetration seal.5. The services which may be fitted through the seals are PVC, ABS, MDPE and HDPEpipes of various sizes, as detailed within the Approval Matrix included in this Certificate.6. The approval relates to ongoing production. Product and/or its immediate packaging isidentified with the manufacturers’ name, the product name or number, the CERTIFIREname or name and mark, together with the CERTIFIRE certificate number andapplication where appropriate.Further InformationFurther information regarding the details contained in this data sheet may be obtainedfrom Astroflame Fireseals Ltd (Tel: 01329 844500).Further information regarding CERTIFIRE certification and other approved products canbe obtained from CERTIFIRE (Tel:01925 646777).Page 2 of 3 SignedIssued: 21 st February 2008Revised: 2 nd April 2009Valid to: 12 th April 2011

<strong>CERTIFICATE</strong> <strong>No</strong> <strong>CF</strong> <strong>617</strong>ASTR<strong>OF</strong>LAME (FIRESEALS) LTDAstro Wrap - Approval MatrixProduct Name:Coating / DFT:Density:PVC Pipe Size*(up to)63 mm Ø by 3.2 mmwall thickness*Astro WrapN/AN/AWrap size Wall/Floor Thickness Integrity Insulation60 by 3.5 mm150 mm 180 minutes 180 minutes110 mm Ø by 3.2mm wall thickness*60 by 6 mmMDPE Pipe Size*(up to)Wrap size Wall/Floor Thickness Integrity Insulation63 mm Ø by 6.5 mmwall thickness60 by 3.5 mm90 mm Ø by 9 mmwall thickness60 by 6 mm150 mm 240 minutes 240 minutesHDPE Pipe Size*(up to)Wrap size Wall/Floor Thickness Integrity Insulation110 mm Ø by 7 mmwall thickness60 by 6 mm 150 mm 240 minutes 240 minutesABS Pipe Size*(up to)Wrap size Wall/Floor Thickness Integrity Insulation160 mm Ø by 10.5 60 by 6 mm + 60 bymm wall thickness 3.5 mm (Floor only)150 mm 240 minutes 240 minutes* Performance in accordance with BS EN 1366-3: 2004Maximum aperture: 183 mm ØThe walls and floors shall be a minimum of 100 mm thick for periods of up to 60minutes integrity performance and 150 mm thick for periods of up to 240 minutesintegrity.Walls/FloorsThe minimum density for the concrete or brick of the wall is 780kg/m 3 and forwalls made of concrete blocks is 600kg/m 3 .All concrete or masonry walls or floors shall have at least the same fire rating asthat required of the pipe wrap.Concrete/masonry walls and floors:ApplicationTechnique:The Pipewrap is folded around the pipe and secured tightly with adhesive tape.The wrap is the slid along the pipe into the wall or floor aperture and grouted intoposition using Silverseal Mortar or Pyrocoustic sealant.Service Coat-Back : <strong>No</strong>t required U Value: <strong>No</strong>t knownService SupportRequirements:Services should be rigidly supported via steel angles, hangars or channels,not further than 500 mm from the surface of the sealing system on bothfaces.Resistance to Smoke:<strong>No</strong>t evaluated by thisapprovalWeather Capability:Acoustic Rating:<strong>No</strong>t evaluated by thisapprovalMovement Capability:PVC – Polyvinyl ChlorideMDPE – Medium Density PolyethyleneHDPE – High Density Polyethylene ABS – Acrylonitrile Butadiene Styrene<strong>No</strong>t evaluated by thisapproval<strong>No</strong>t evaluated by thisapprovalPage 3 of 3 SignedIssued: 21 st February 2008Revised: 2 nd April 2009Valid to: 12 th April 2011