Superior Solutions - German-Pavilion

Superior Solutions - German-Pavilion

Superior Solutions - German-Pavilion

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

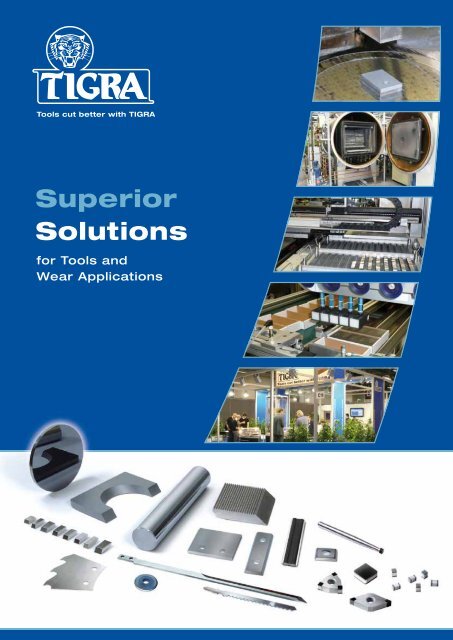

Tools cut better with TIGRA<strong>Superior</strong><strong>Solutions</strong>for Tools andWear Applications

TIGRfor Woodworking ToolsInserts and blanks for woodworkingLargest program worldwide9 carbide grades for each application.Standard and customized.Large stock for all types of inserts.Carbide saw tipsIn excellent qualityComprehensive program with large variety of grades,close tolerances and best brazing features thanks to idealcoating! Pretinned available, too.Special dimensions upon request.Planer knivesHSS / Black Oxide and tungsten carbideSuitable for the systems Tersa, Centrolock, Terminus, Centrostar,Variplan, Sinus and Enshin in tungsten carbide and several HSSgrades. Produced with latest Black Oxide technology.Some systems also available as coils.Thin planer knives in HSS, High Performance Steel,T.C.T. and solid carbide.Take our advantages to your benefit!Beste carbide grades Unique product range Best serviceMore than 20 different carbide grades and TIGRAlloylet you always find the best grade for your application.We are readily available to advise you.To get all cutting materials from one reliable, highquality and inexpensive source saves much timeand gives you security.Dedication to customers´ needs is our philosophy.Our friendly and competent people are trained torespond professionally and quickly to your individualrequest.Tools cut better with TIGRA

A – <strong>Superior</strong> Solutionfor Metal Working ToolsPCD-Polycrystalline DiamondAs blanks and segmentsSpecial adapted grades for long lifetime andconsiderable reduced erosion time.Express delivery service for segments withinthree working days. Special grades availablefor wear applications, Sandwich PCD, laserweldable PCD as well as specially adaptedgrades for aluminium working.PcBNBlanks, segments and semi-finished insertsPcBN blanks and segments in solid and single-sided versions inmany grades, semi-finsihed inserts in solid and sandwich version,over the entire surface or tipped. Available in different work flowversions!PcBN semi-finished milling tools for manufacturing PcBN drills,reamers etc..Carbide inserts for tipping, pre-sintered and pre-ground available.Rods and barsMany dimensions on stockMicrograin rods as sintered and ground, without and with coolanthole(s), straight or with helix.Carbide grades for highly abrasive materials and for high speedcutters (HSC) on stock.Flat and square bars in various dimensions and grades, as standardand due to customer´ s request.Tungsten carbide, HSS, PCD and PcBNSpecial individuality <strong>German</strong> quality standards Automated productionMadein<strong>German</strong>yComplex specialized carbide parts are our expertise.Thanks to individual programming we can producealmost every part according to customers´ drawings.Just ask us!In our carbide manufacturing in Oberndorf am Lech,we produce due to the highest quality, safety and environmentalstandards. Each year several hundredsof tons of carbide are produced.Our high-tech production enables us to offer highestquality at low prices. Our machinery is of the latesttechnological progress.

s ...For Wear and Special ApplicationsWear partsIndividual according to customer‘s drawingGround and unground carbide parts for optimizedwear protection in machines, for recycling andspecial applications in different industrial fieldsas per customer´s drawing. Production batchesfrom 1 to 1 million pieces!Special knives for textile, leather,foil and composite material workingFor long lifetimesCarbide knives in special carbide grades for plotters,single and multilayer cutters for working and cuttingfoils, film, leather, textiles and composite materials.Injection molded partsFor special parts produced in high quantitiesComplex shapes can be produced particularly economicallyand in high precision with latest injectionmolding technology. The near-net-shape productionenables sophisticated geometries and reducesgrinding expenses.- all from one supplier!Low prices Highest quality Quick deliveryA high degree of automation enables great advantagesto our customers, both in price and quality.Continuous improvements in production to customers´benefit is our constant concern.Automatic quality control with latest camera andlaser technology in the production process andautomatic re-adjusting guarantees the best possibleprecision.Our optimized storage allows short delivery times,even for non-standard. Express delivery service fortips for brazing and PCD segments in just 3-5 days,cut special parts within 2-3 weeks!

TIGRA – A family owned company with the tradition of putting your needs firstSince its foundation in 1982 TIGRA has expanded at a rapid pace. We have been recognized with prestigiousEconomic Awards for being the most innovative regional company in Bavaria and obtained certificationto become a training enterprise. We are very proud of this honor we achieved by using the resourcesof being a medium-sized company and our model character that has always been a part of our company.From our inception, TIGRA has specialized in the production and machining of hard materials for the toolindustry as well as in special applied carbide parts.Due to our method of business using our comprehensive knowledge of tungsten carbide productionand machining, innovative self-developments, and the latest technologies in manufacturingtoday, we have captivated the market. TIGRA´s flexible production capabilities and alarge choice of grades in all material groups are well-known standing for high qualityand inexpensive precision parts, which are used in several industrial fields. TIGRA isconsidered as one of the major carbide manufacturers and suppliers of ultra-hardcutting materials concerning optimized manufacturing and assembly of milling,chipping and cutting tools as well as industrial knives for high-precisionprofiling and planing. Small batches of less than 10 parts by mass productionin millions will be produced and delivered in the factory in Oberndorf,<strong>German</strong>y. Continuous improvements in latest pressing, sinteringand grinding techniques with highest level of automation,current quality control by camera and laser up to automaticpackaging and labeling allow the company short productiontimes, individuality and flexibility. Thanks to intensely promotedself-innovations the Bavarian company is now world-leadingin many areas of cutting materials. TIGRA´s well-trained sales teamserves customers in over 70 countries around the world.TIGRAs product range includes cutting inserts and tips for brazed tools forwoodworking, blanks for metal and composite material working cutters, carbideinserts for tipping with ultra-hard cutting materials, carbide wear parts of varioustypes, knives for the foil, textile, leather and composite material working industry andall types of carbide products due to the customer´s specific drawing. Through intensivecollaboration with leading partners, the product range is completed with PCD, PCBN, HighSpeed Steel (HSS) and other materials, which are offered as raw materials, semi-finished andfinished articles.Headquartered in Bavaria, daughter companies inthe USA, Brazil, and China, and reliable internationalpartners the company underlines its constant demandfor expansion and innovation. The two ManagingDirectors Helge Motzer, and son Bernd Motzer,are in complete agreement regarding the furtherdevelopment of their enterprise. The quality, reliability,short delivery time and favorable pricing aresome of the decisive factors keeping us ahead ofour competition. „We will continue to strive to fulfillevery need of our customers worldwide, and toexceed all expectations and find new and improvedmethods, products and services to grow with ourcustomers in the future.“Helge and Bernd Motzer (from right to left)TIGRA´s Managing Directors

TIGRA GmbHGewerbering 2D-86698 Oberndorf am Lech<strong>German</strong>yTel. +49 (0)9090 9680 - 01Fax +49 (0)9090 9680 - 50www.tigra.desales@tigra.dewww.tigra.deTIGRA USA, Inc.1106 8 th ST CT SEHickory, NC 28602USAPhone +1 828-324-8227Fax +1 828-324-8097www.tigra-usa.comsales@tigra-usa.comTIGRA do Brasil Ltda.Rua Isaías Régis de Miranda 1193Vila Hauer81630-050 Curitiba / PRBrasilTel. +55 41 3276 3731Fax +55 41 3377 3075www.tigra.detigra@tigradobrasil.com.brTIGRA China Co. Ltd.1-1-101 Hua Long Mei ShuNo.15 Jian Guo RoadChaoYang DistrictBeijing, 100024P.R. ChinaTel. +86 10 5921 4353Fax +86 10 5921 4352www.tigra-china.comsales@tigra-china.com3-2010