Boost your productivity: - Siemens Industry, Inc.

Boost your productivity: - Siemens Industry, Inc.

Boost your productivity: - Siemens Industry, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

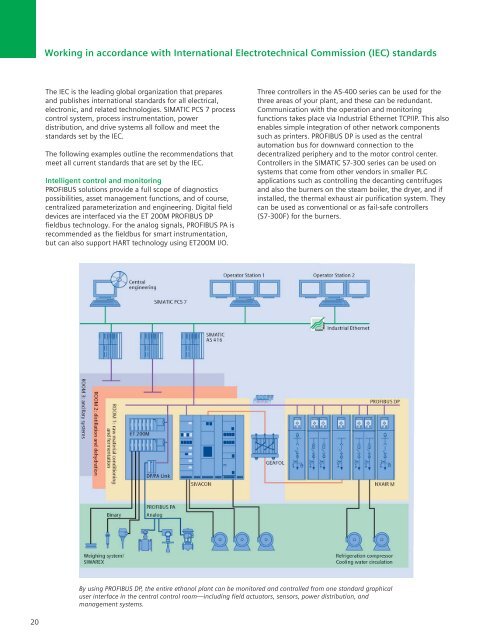

Working in accordance with International Electrotechnical Commission (IEC) standardsThe IEC is the leading global organization that preparesand publishes international standards for all electrical,electronic, and related technologies. SIMATIC PCS 7 processcontrol system, process instrumentation, powerdistribution, and drive systems all follow and meet thestandards set by the IEC.The following examples outline the recommendations thatmeet all current standards that are set by the IEC.Intelligent control and monitoringPROFIBUS solutions provide a full scope of diagnosticspossibilities, asset management functions, and of course,centralized parameterization and engineering. Digital fielddevices are interfaced via the ET 200M PROFIBUS DPfieldbus technology. For the analog signals, PROFIBUS PA isrecommended as the fieldbus for smart instrumentation,but can also support HART technology using ET200M I/O.Three controllers in the AS-400 series can be used for thethree areas of <strong>your</strong> plant, and these can be redundant.Communication with the operation and monitoringfunctions takes place via Industrial Ethernet TCP/IP. This alsoenables simple integration of other network componentssuch as printers. PROFIBUS DP is used as the centralautomation bus for downward connection to thedecentralized periphery and to the motor control center.Controllers in the SIMATIC S7-300 series can be used onsystems that come from other vendors in smaller PLCapplications such as controlling the decanting centrifugesand also the burners on the steam boiler, the dryer, and ifinstalled, the thermal exhaust air purification system. Theycan be used as conventional or as fail-safe controllers(S7-300F) for the burners.By using PROFIBUS DP, the entire ethanol plant can be monitored and controlled from one standard graphicaluser interface in the central control room—including field actuators, sensors, power distribution, andmanagement systems.20