ACCUMAX PLUS DIVIDER - AMF Bakery Systems

ACCUMAX PLUS DIVIDER - AMF Bakery Systems

ACCUMAX PLUS DIVIDER - AMF Bakery Systems

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

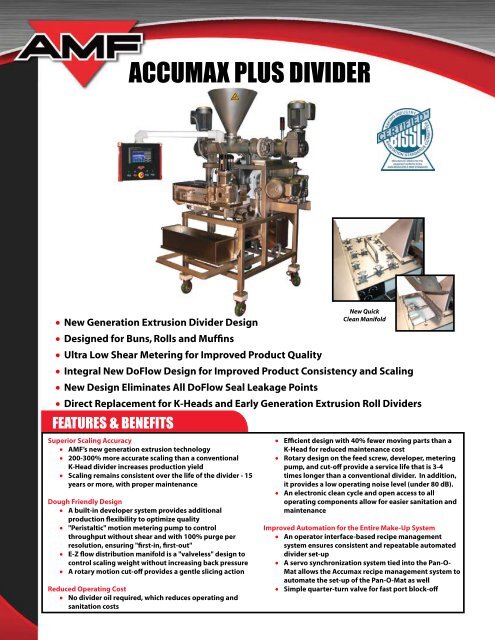

<strong>ACCUMAX</strong> <strong>PLUS</strong> <strong>DIVIDER</strong>• New Generation Extrusion Divider Design• Designed for Buns, Rolls and Muffins• Ultra Low Shear Metering for Improved Product Quality• Integral New DoFlow Design for Improved Product Consistency and Scaling• New Design Eliminates All DoFlow Seal Leakage PointsFEATURES & BENEFITSSuperior Scaling Accuracy• <strong>AMF</strong>’s new generation extrusion technology• 200-300% more accurate scaling than a conventionalK-Head divider increases production yield• Scaling remains consistent over the life of the divider - 15years or more, with proper maintenanceDough Friendly Design• A built-in developer system provides additionalproduction flexibility to optimize quality• " Peristaltic" motion metering pump to controlthroughput without shear and with 100% purge perresolution, ensuring "first-in, first-out"• E-Z flow distribution manifold is a "valveless" design tocontrol scaling weight without increasing back pressure• A rotary motion cut-off provides a gentle slicing actionReduced Operating Cost• No divider oil required, which reduces operating andsanitation costsNew QuickClean Manifold• Direct Replacement for K-Heads and Early Generation Extrusion Roll Dividers• Efficient design with 40% fewer moving parts than aK-Head for reduced maintenance cost• Rotary design on the feed screw, developer, meteringpump, and cut-off provide a service life that is 3-4times longer than a conventional divider. In addition,it provides a low operating noise level (under 80 dB).• An electronic clean cycle and open access to alloperating components allow for easier sanitation andmaintenanceImproved Automation for the Entire Make-Up System• An operator interface-based recipe managementsystem ensures consistent and repeatable automateddivider set-up• A servo synchronization system tied into the Pan-O-Mat allows the Accumax recipe management system toautomate the set-up of the Pan-O-Mat as well• Simple quarter-turn valve for fast port block-off

<strong>ACCUMAX</strong> <strong>PLUS</strong> <strong>DIVIDER</strong>MECHANICAL FEATURES• Stainless steel open frame on casters for easy access duringmaintenance and sanitation• Variable speed auger and paddle are independent of eachother allowing maximum production flexibility for fulldevelopment• Patented quick clean manifold• Patented "Quarter Block" system provides quick and simpleport blocking• Polished stainless steel guards and hopper for easysanitation• Standard 100 lb. (45 kg) stainless steel round hopper forsmooth flow and easy cleaning• Stainless steel feed screw and developer housing fordurability and minimum dough flow resistance• 4” (102 mm) diameter stainless steel auger and developerpaddle• 5 HP auger and developer drives in DoFlow Plus• Feed screw, developer, and metering pump have directcoupled drives, no chains or pulleys• All major drives are severe duty gearmotor drives• Integral stainless steel dough developer• Stainless steel metering pump for precise, linear flowcontrol with ultra low shear peristaltic action• E-Z flow distribution and scaling manifold features internalflow diverters to precisely balance flow without additionalback pressure. Diverters are adjustable by external controlswith location indicators• Individual UHMW cut-off knives slice clearly, withouttearing gluten stands and provide precise doughballplacements at any speed• High speed cut-off for up to 125 cuts/minute• Easy access to all operational areas, no tools required forsanitation• A PLC actuated divider pushback is also supplied that willautomatically push the divider back in case of pressureloss to prevent under scaled product from entering themake-up system. A removable catch pan is provided tocollect the dough pieces for recycling to the divider.• Strong, simple, efficient Venturi-style vacuum generatorensures efficient auger loading and degassing withminimal maintenanceSimple “Leak Free”Developer DriveSystemStainless Steel Feed ScrewRemovable Catch PanBuilt-In Developer andGentle Sine Metering PumpELECTRICAL FEATURESOperator panel includes the following:• Allen Bradley PanelView Plus keypadoperator interface to control:– Developer speed– Feed screw speed– Metering pump speed– Vacuum pressure– Alarm messages– Product codes• Allen Bradley pushbuttons for:– Two-button start– Stop/Emergency stop– MCR resetEZ Flow Manifold with Vane Adjustment Indicators• NEMA 12 remote electrical enclosure(painted steel) including:– Main disconnect switch– Allen Bradley CompactLogix– Allen Bradley inverters– Exair panel cooler• Keyed type safety switches• Closed loop pressure control system withpressure transducer• PLC controlled clean-in-place system forreduced sanitation costAccumax Cut-Off Assembly• Servo drive cut-off knife to synchwith existing proofer and S/M/POperator Interface Panel

<strong>ACCUMAX</strong> <strong>PLUS</strong> <strong>DIVIDER</strong>DIMENSIONAL DRAWINGHeadquarters:Europe Office:Asia Office:FOR MORE INFORMATION PLEASE CALL YOUR ACCOUNT MANAGER OR2115 W. Laburnum Ave. 6 The SidingsRoom 15-2, A-BuildingRichmond, Virginia 23227 Station Road, GuiseleyThunis Dev. BuildingTel: 1-800-225-3771 Leeds LS20 8BX, England No.11 Hui Xin East St.or 1-804-355-7961Tel: 44-1943-875703Chaoyang District1-800-BAKERS-1Fax: 1-804-342-9724 Fax: 44-1943-871806Beijing, China 100029sales@amfbakery.com sales-europe@amfbakery.com Tel: 86-10-64823613Fax: 86-10-64934259 www.amfbakery.com<strong>AMF</strong>’s focus on continuous improvement may resultsales-asia@amfbakery.comin changes to machinery specifications without notice. 04/2010