APPLICATION OF SUGAR BEET MOLASSES IN THE ... - FINS

APPLICATION OF SUGAR BEET MOLASSES IN THE ... - FINS

APPLICATION OF SUGAR BEET MOLASSES IN THE ... - FINS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

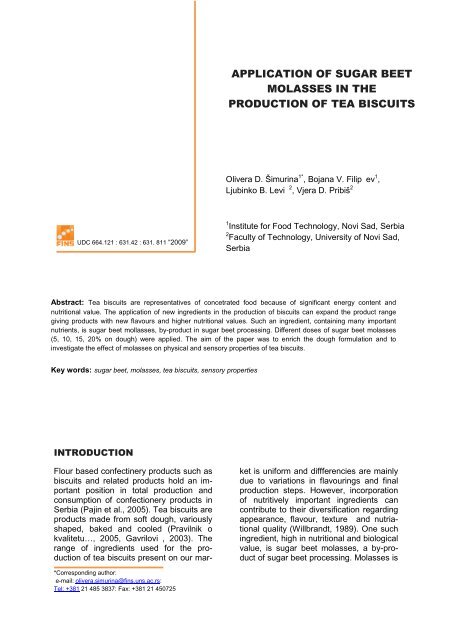

<strong>APPLICATION</strong> <strong>OF</strong> <strong>SUGAR</strong> <strong>BEET</strong><strong>MOLASSES</strong> <strong>IN</strong> <strong>THE</strong>PRODUCTION <strong>OF</strong> TEA BISCUITSOlivera D. Šimurina 1* , Bojana V. Filipč ev 1 ,Ljubinko B. Lević 2 , Vjera D. Pribiš 2UDC 664.121 : 631.42 : 631. 811 “2009”1 Institute for Food Technology, Novi Sad, Serbia2 Faculty of Technology, University of Novi Sad,SerbiaAbstract: Tea biscuits are representatives of concetrated food because of significant energy content andnutritional value. The application of new ingredients in the production of biscuits can expand the product rangegiving products with new flavours and higher nutritional values. Such an ingredient, containing many importantnutrients, is sugar beet mollasses, by-product in sugar beet processing. Different doses of sugar beet molasses(5, 10, 15, 20% on dough) were applied. The aim of the paper was to enrich the dough formulation and toinvestigate the effect of molasses on physical and sensory properties of tea biscuits.Key words: sugar beet, molasses, tea biscuits, sensory properties<strong>IN</strong>TRODUCTIONFlour based confectinery products such asbiscuits and related products hold an importantposition in total production andconsumption of confectionery products inSerbia (Pajin et al., 2005). Tea biscuits areproducts made from soft dough, variouslyshaped, baked and cooled (Pravilnik okvalitetu…, 2005, Gavrilović , 2003). Therange of ingredients used for the productionof tea biscuits present on our marketis uniform and diffferencies are mainlydue to variations in flavourings and finalproduction steps. However, incorporationof nutritively important ingredients cancontribute to their diversification regardingappearance, flavour, texture and nutriationalquality (Willbrandt, 1989). One suchingredient, high in nutritional and biologicalvalue, is sugar beet molasses, a by-productof sugar beet processing. Molasses is*Corresponding author:e-mail: olivera.simurina@fins.uns.ac.rs:Tel: +381 21 485 3837: Fax: +381 21 450725

Šimurina O. et al., Application of sugar beet molasses in the production of tea biscuits,Food Processing, Quality and Safety 4(2008) 201-206a promising ingredient for use in confectioneryproducts having been a naturalsweetener, nutritious (rich in minerals andvitamins) and as such an alternative tohighly refined sugars (Lević et al., 2005).Molasses has high content of solids(approximately 80%), saccharose (51% inaverage), 1% rafinose, 0.25% glucose andfructose, 5% proteins, 6% betain, 1.5%nucleosides, 1.5% purine and pirimidinebases, organic acids and pectins (Šušić etal., 1989). Important constituents of molassesare minerals and vitamins, too.Minerals are nutrients necessary forgrowth and normal physiological functionningof body and are part of many enzymesand hormones (Bíró et al., 1988).They must be supplied by food since thebody cannot synthesize them. In molasses,calcium, potassium and iron are presentin substantial amounts although theircontents vary over wide ranges. It is especiallyimportant to note that minerals inmolasses are dissolved and that potassiumis dominant with a share of 75% (byweight) of total cations (Šušić et al., 1989).Regarding potassium intake, it has beenknown that vegetable sources of potassiumare more advantageous havingmore favourable potassium to sodium ratio,potassium content almost double tothat of sodium (Bíró et al., 1988). Molassesalso contains B group vitaminsanddoes not contain fats and fibres. Inaddition, molasses shows humectancy,antioxidant and water activity loweringproperties which are important to the shelflifeof the products (Hickenbottom, 1996).In this paper, properties of biscuits preparedwith sugar beet molasses added invarious amounts were studied.MATERIALS AND METHODSIngredientsCommercially available whaeat flour type500 (ash content 0.46-0.55g/100 g drymatter) was used. The flour had characteristicsthat complied with special requisitesof biscuit flours (Gavrilović , 1981,Nikolić et al., 1988): low protein (9.5%d.b.) and wet gluten content (20%), qualityclass B 2 by farinogram. Rheological parameterswere also adequate: extensigrapharea 32 cm 2 , resistance 160 B.U., extensibility127 mm, amylograph peak viscosity340 B.U.Sugar beet molasses was procured fromsugar beet factory in Kovač ica, Serbia.Physical and chemical properties of molassesare given in Tab. 1.Table 1.Physicochemical properties of molassesSaccharose content, % 50,50Moisture content, % 17,20Ash content, %/d.b. 13,92Total nitrogen, %/d.b. 2,21Invert sugar content, % 1,45pH 7,20Aw 0,63Colour, I.U. 16830Physicochemical analysesChemical analyses performed on molasseswere in accordance to AOAC methods(2000). pH was determined by potentiometricmethod in aqueous solution(water: molasses ratio equal to 1:1) usingpH meter “ISKRA”, MA 5740. Mineral compositionwas determined by AAS usingspectrometer “Varian”, model “Spectra10”. Water activity was measured at 21 ºCusing apparatus Aw Wert Messer Luff.Flour quality was analyzed according tostandard methods (Pravilnik o metodamafizič kih i hemijskih analiza,1988).Preparation of biscuitsBasic biscuit formulation includes wheatflour, margarine and sugar in ratio100:40:35, respectively. As leaveningagent, baking powder was used at 1%dose (flour basis). Sugar beet molasseswas added at four doses: 5, 10, 15 and20% (flour basis). The amount of sugar inthe formulation was reduced with increasingdoses of molasses: from 35% in con-

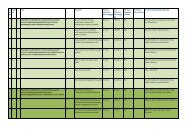

Šimurina O. et al., Application of sugar beet molasses in the production of tea biscuits,Food Processing, Quality and Safety 4(2008) 201-206trol to 13.6% in biscuit made with 20%molasses. The amount of water added variedto obtain cohesive dough suitable forthe production of mold-cut biscuits.Ingredients were mixed in Diosna mixer asper "all-in" method. All ingredients weremixed together in one phase for 15 min.The formed dough was packed in polyethylenebags and left to rest 1 hour at+4 ºC. After resting, dough was sheeted touniform thickness (10 mm) and cut outusing a round cutter.Sensory evaluationSensory evaluation of biscuits was inaccordance to method described by Gavrilovićet al. (1985). Five, randomly chosencookies were taken to measureweight, height and width (diameter).Spread ratio was calculated from the ratioof with and height in relation to thewidth/height ratio of the control. Sensoryevaluation of biscuits included the followingparameters: shape, appearance ofupper surface, appearance of lower surface,fracturability, structure, chewinessand taste. The scores for each parameterranged from 1 to 5. Each parameter wasassigned a different factor of significance:0.3 for shape, 0.5 for upper surface, 0.4for lower surface, 0.4 for fracturability, 0.6for structure, 0.8 for chewiness and 1.0 fortaste. Total score was obtained by summingthe scores for each parameter previouslymultiplied with factor. A panel offive judges was engaged in the cookiescoring.Colour parametersColour of biscuits was measured by a photo-electrictristimulus colorimeter MOMCo-lor 100. Colour parameters were recordedas CIE (dominant wavelength DW (nm),colour purity P(%) and average reflectanceY(%) and CIELab values (lightness-L*; redand green hue-a*, yellow and blue hue-b*)(Robert, 1977).Textural parametersHardness of tea cookies was measured bycutting on a TA.XTplus Texture Analyzer(Stable Micro Systems, England, UK) witha reversible blade, using its knife edge.The analyzer was set to measure force incompression. Each cookie was preciselycentred on the platform and the blade waslowered to deform and break (snap) thebiscuits at a travel distance of 15 mm andtest speed 2.0 mm/s. The trigger force wasset at 25 g. The peak force was measuredand represented the index of cookie hardness.Shear force was determined on WarnerBratzler device (Standardized Warner-Bratzler Shear Force Procedures).Data analysisData were analyzed by ANOVA test usingStat-graphics Plus V 7.1 (Statistical GraphicsCorporation, UK). Mean separationwas accomplished by Tukey’s test.RESULTS AND DISCUSSIONBaking test was performed increasing theamount of molasses in dough (5, 10, 15,20% flour basis) to determine a dosewhich is optimal for the formation of doughsuitable for cut biscuits of appropriate physicaland sensory properties.Table 2.Properties of dough supplemented with various doses of molassesMolasses content,% flour basis05101520Dough consistencyHomogenous, greasy, plastic, optimal consistency for cut teabiscuitsHomogenous, greasy, plastic, optimal consistency for cut teabiscuitsHomogenous, greasy, plastic, medium soft, optimal consistencyfor cut tea biscuitsHomogenous, greasy, plastic, soft, optimal consistency fordeposited and cut tea biscuitsHomogenous, greasy, plastic, maximally soft, optimal consistencyfor deposited and cut tea biscuitsMoisture contentin dough,%19,118,416,816,014,3

Šimurina O. et al., Application of sugar beet molasses in the production of tea biscuits,Food Processing, Quality and Safety 4(2008) 201-206Increasing molasses content affecteddough properties. Dough became softer,more plastic and suitable for handling. Theaddition of molasses changed the colour(data not shown) of dough from yellow inthe control to dark brown in the samplewith 20% molasses. Dough moisture decreasedby 0.7-4.8% as the content of molassesincreased.The addition of molasses increased biscuitdiameter in comparison to the control. Thelowest increase of 6.1% was recorded for20% molasses level and the highest increaseof 8.9% for 10% molasses. Thehighest spread ratio was recorded forhigher molasses doses (15 and 20%).Density of biscuits increased with increasedcontent of molasses which alsoreflected to the biscuit structure (shearforce and hardness in Tab. 3).Table 3.Physical attributes of tea with molassesQuality attributes Molasses content, %0 5 10 15 20Average diameter, cm 6,40±0.11 a 6,83±0.13 ab 6,97±0.11 b 6,95±0.21 b 6,79±0.23 abSpread ratio, % - 21,6±5.21 ab 14,7±3.23 a 28,6±4.84 b 27,3±4.31 bHeight, cm 1,30±0.31 b 1,15±0.52 ab 1,24±0.432 ab 1,10±0.14 a 1,09±0.15 aVolume, cm 3 41,80±1.2 b 42,06±1.1 b 47,36±1.3 a 41,88±1.4 b 39,54±1.1 cDensity, kg/cm 3 x 10 -6 514±3.45 a 537±3.68 ab 564±4.21 b 606±4.53 c 564±3.85 bcShear force, lb 3,60±3.5 a 4,00±4.3 b 3,25±3.6 a 5,85±4.8 bc 8,10±5.2 cHardness, kg 10.65±1.8 ac 12.45±2.4 b 9.82±2.0 a 13.38±3.8 bc 15.4±4.5 cTotal score 15.2Total score 18.3Total score 17.3Total score 18.4Total score 15.1Fig. 1. Sensory properties of biscuits madewith sugar beet molassesSensory profile of biscuits made with theaddition of molasses is presented in Fig. 1.The shape of cookies was slightly deformeddue to manual dough handling butthis fault can be easily overstepped bymachine cutting. The biscuits made withmolasses were intensively coloured (darkbloomy and brown) (data not shown). Darkcolour of biscuits comes from mela-

Šimurina O. et al., Application of sugar beet molasses in the production of tea biscuits,Food Processing, Quality and Safety 4(2008) 201-206noidines and caramelization products ofmolasses. Molasses can be used as aneffective natural colorant in a wide rangeof products. The lower and upper surfacesof the supplemented biscuits were smootheras compared to the control. Theaddition of molasses contributed to theformation of more regular, even and brittlefracture and better mastication. The mostregular structure was observed with thesamples containing 10 and 15% molasses.The addition of molasses in doses 5 to15% positively affected taste and odour(full, aromatic, pleasant, caramel-like, andginger bread-like).Sensory estimations of biscuit colour arein agreement with objective colour measurements.Indicator of yellow colour (b*value) and lightness (L* value) decreasedwith increased molasses concentration indough (Tab. 4). There was distinctive differrencein the colour and lightness betweenupper and lower surfaces of biscuits– the lower surface was darker in all samples.Table 4.Objective colour values for doughs with different molasses contentColourparametera*-0,486,4810,93CIELAB b*L * 30,2226,9522,0069,9252,8245,79CIEDW(nm)Y(%)P(%)Molasses content, % flour basis0 5 10 15 20576,540,6439,0580,520,8927,758715,1213,0-2,1013,0441,21572,512,0013,2-0,5719,5739,59576,511,0117,7Table 5.Sensory and objective colour parameters for tea biscuits cookies supplemented with molassesMolasses content, %0 5 10 15 20ColourSurfaceparameter upper lower upper lower upper lower upper lower upper lowera* 1,75 -4,24 0,64 10,45 4,36 4,44 -0,27 8,48 11,99 5,43L * 79,65 74,30 62,74 57,09 53,57 53,81 51,22 46,68 43,41 40,29CIELAB b* 28,04 33,40 30,53 32,41 27,64 31,54 24,18 27,46 11,32 21,52DTD(nm)CIE Y(%)Č (%)Sensorydescriptiveevaluation579 574,5 578 582,5 580,5 579 576,5 582,5 582,5 58256,08 47,18 31,28 25,02 21,58 21,80 19,46 15,78 13,44 11,4329,3 40,2 41,5 47,1 57,3 48,8 39,0 47,1 23,7 40,2BeigeBeigeLightbrownBloomybrownBloomybrownBloomybrownBloomybrownBloomybrownBloomy,darkbrownBloomy,darkbrownCONCLUSIONSugar beet molasses is an interestingingredient for the production of confectioneryproducts, especially biscuits andrelated products because, above all, itsnutritive value (natural sweetener with highmineral content) and physical characteristics(colour, consistency, humectancy).Sugar beet molasses can be directlyadded to dough for machine cut and depositedbiscuits in dose up to 20% flourbasis contributing to improved colour (chocolate-like)and softer consistency.Biscuits prepared with 10 and 15% molasseshad better physical and sensoryproperties (structure, odour, taste) comparingto the control.ACKNOWLEDGMENTSResults presented here are part of researchwithin framework of Project TR-20112 (coordinator dr Lj. Lević ) financedby the Ministry of Science and TechnologicalDevelopment of the Republic ofSerbia.REFERENCES1. Association of Official Analytical Chemistry(AOAC) (2000). Methods of Analysis of

Šimurina O. et al., Application of sugar beet molasses in the production of tea biscuits,Food Processing, Quality and Safety 4(2008) 201-206Official Analytical Chemists. 17th ed., Washington,DC.2. Bíró, G., Lindner, K. (1988). Tápanyagtáblázat.Medicina Könyvkiadó, Budapest,34-35.3. Gavrilović , M. (1981). Uticaj kvaliteta brašnana tehnološki proces proizvodnjekeksa i njegov kvalitet. Doktorska disertacija,Tehnološki fakultet, Novi Sad.4. Gavrilović , M. (2003). Tehnologija konditorskihproizvoda (drugo izdanje), Tehnološkifakultet, Novi Sad, 536-544.5. Gavrilović , M., Jovanović , O. (1985). Ulogaprobnih peč enja u proceni tehnološkogkvaliteta sirovina za brašneno-konditorskeproizvode. Žito-hleb, 12 (1), 15-22.6. Hickenbottom, J. (1996). Use of molassesin bakery products. AIB Technical Bulletin,18 (6), 1-6.7. Lević , Lj., Filipč ev, B., Šimurina, O., Svrzić ,G., Mastilović , J. (2005). Melasa šeć ernerepe kao dodatak specijalnim vrstamahleba. In Proceedings of the 3 rd InternationalCongress and 5 th Croatian Congressof Cereal Technologists “Flour-Bread'05”, Opatija, Croatia.8. Nikolić , Lj., Joka, A. (1988). Neki aspektiproizvodnje č ajnih peciva. Žito-hleb,15,1-2,33-36.9. Pajin, B., Jovanović , O., Torbica, A., Šarić ,M. (2005). Tehnološki kvalitet brašna domaćih sorti pšenice za proizvodnju brašneno-konditorskihproizvoda. Žito-hleb, 32(6), 199-203 .10. Pravilnik o kvalitetu i drugim zahtevima zafine pekarske proizvode, žita za doruč ak isnek proizvode (2005) “Službeni list SCG”,br. 12/2005.11. Pravilnik o metodama fizič kih i hemijskihanaliza za kontrolu kvaliteta žita, mlinskih ipekarskih proizvoda, testenina i brzo smrznutihtesta (1988). “Službeni list SCG”, br74/1998.12. Robert, A.R. (1977). The CIE 1976 Color-Difference formulae. Color Research Applied,2(7), 25-31.Standardized Warner-BratzlerShear Force Procedures for GenetocEvaluation,http://meat.tamu.edu/shearstand.13. Šušić , S., Sinobad, V. (1989). Istraživanjau cilju unapređ enja industrije šeć era Jugoslavije.Hemijska Industrija Suppl, 43 (1-2),10-21.14. Willbrandt, S. (1989). Geschmackliche undgesundheitliche Aspekte im Zusammenhangmit Gewürzen in Backwaren. Getreide,Mehl und Brot, 43 (10), 309-311.